Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Revista Colombiana de Biotecnología

Print version ISSN 0123-3475

Rev. colomb. biotecnol vol.18 no.2 Bogotá July/Dec. 2016

https://doi.org/10.15446/rev.colomb.biote.v18n2.53853

DOI: http://dx.doi.org/10.15446/rev.colomb.biote.v18n2.53853

ARTÍCULO DE INVESTIGACIÓN

Co-digestión anaerobia de vinaza y gallinaza de jaula: alternativa para el manejo de residuos agrícolas colombianos

Anaerobic co-digestion of vinasse and chicken manure: alternative for Colombian agrowaste management

Marin-Batista José*, Salazar Luis**, Castro Liliana***, Escalante Humberto****

* MSc, Universidad Industrial de Santander, Colombia.

jdmbatista05@gmail.com

** MSc, Universidad Industrial de Santander, Colombia.

luissanantonio2010@hotmail.com

*** PhD, Profesora Escuela de Ingeniería Química, Universidad Industrial de Santander, Colombia

licasmol@uis.edu.co

**** PhD, Profesor Escuela de Ingeniería Química, Universidad Industrial de Santander, Colombia

escala@uis.edu.co

Recibido: marzo 16 de 2016 Aprobado: octubre 19 de 2016

Resumen

La digestión anaerobia es una tecnología atractiva para el manejo de residuos al producir energía en forma de biogás y estabilizar la materia orgánica. En este estudio, se evaluó el proceso de co-digestión de vinaza y gallinaza de jaula como una alternativa de manejo y estabilización de residuos generados por la agroindustria colombiana. Se llevaron a cabo, ensayos de biometanización en relaciones de mezcla vinaza y gallinaza de 1:0, 3:1, 1:3 y 0:1 en base a VS. La relación de 3:1 de vinaza y gallinaza permitió aumentar la producción específica de metano en un 55% respecto a la producción específica ponderada de 0.65 m3 CH4/kg VS. Las mezclas entre los sustratos presentaron un efecto sinérgico positivo. La gallinaza de jaula mejoró la capacidad de amortiguación de la mezcla, disminuyendo el riesgo de acidificación por cambio drástico en el pH durante la digestión de la vinaza. Por otra parte, la vinaza permitió diluir la concentración total de nitrógeno amoniacal evitando la inhibición de amoniaco. Dado el aumento de la producción de metano, el co-tratamiento de vinaza y gallinaza mejora la recuperación de energía y la viabilidad económica de la instalación de la planta de biogás como parte de la cadena de producción de etanol.

Palabras clave: Digestión anaerobia, vinaza, gallinaza de jaula, prueba de potencial de biometanización, efecto sinérgico.

Abstract

Anaerobic digestion is an attractive technology for waste management meanwhile energy is recovering. This study evaluated the feasibility of codigesting vinasse and chicken manure (CM) as management alternative for Colombian agro industries. Biochemical methane potential was tested for different vinasse to CM ratios of 1:0, 3:1, 1:3 and 0:1 on VS basis. Vinasse and CM ratio of 3:1 increased the specific methane production up to 55% regard to the weighted specific methane production of 0.65 m3CH4/kg VS. Mixtures between the substrates had a positive synergistic effect. CM improved buffer capacity diminishing the risk on acidification by drastic pH shift during vinasse digestion. Furthermore, vinasse allowed dilution of total ammonia nitrogen concentration avoiding ammonia inhibition. Since a higher methane production, vinasse and CM co-treatment improves the energy-recovery and economic feasibility of installing biogas plant as part of the ethanol production chain.

Keywords: Anaerobic codigestion, vinasse, chicken manure, biomethane potential test, synergistic effect.

Introduction

The expansion of ethanol distilleries in Colombian sugarcane refineries has increased the production of vinasse, the main waste stream of ethanol distillation process (Dávila-Rincón et al., 2009). Production of vinasse varies from 8 to 15 L per liter of ethanol obtained (Zieminski et al., 2015). Vinasse is characterized by acid pH (4.0–5.0) and high potentially polluting organic matter (76 - 110g COD L-1) in form of soluble sugars (9.5-7.9gL-1) and phenols (0.4–12.4 gL-1) (Moraes et al., 2015). Several treatments such as aerobic conventional methods (trickling filters, lagoon), evaporation–condensation (with and without combustion), ozonation and direct dispersion on soil as a fertilizer have been proven for purification, utilization and disposal of these wastewaters (Jáuregui-Jáuregui et al., 2014; Jimenez et al., 2006). Those methods are high costly and simultaneously generate other pollutants.

In other hands, poultry industries in Colombia produce chicken manure (CM) as main biomass of the sector. With an annual production of 31,592 ton of CM per million of birds, the valley becomes the third poultry region in the nation (Marin-Batista et al., 2015; Escalante et al., 2010). CM present a high content of organic matter, mainly in form of proteins (15.6 %), cellulose (20 %), hemicellulose (23.2 %) and lignin (2.3 g/L) (Li et al., 2013). Composition of CM enable obtaining new products such as compost and meat meal (Huang et al., 2011; Rosales et al., 2007), but those methods are not enough to dispose the CM produced annually.

Anaerobic digestion (AD) is a biotechnological process that enables the stabilization of waste meanwhile the organic matter is converted into methane-rich biogas. During AD more than 90% of the energy available for direct oxidation is transformed in methane and only 10% of the energy is consumed in bacterial growth (Kumar, 2008). AD process offers the possibility of recycling nutrients such as nitrogen and phosphorus contained in the effluent, which is feasible to apply as biofertilizers (Fernandez et al., 2008). Among the process advantages there are the reduction of environmental impact (odors and greenhouse gases emission), low by-products generation, not utilization of chemical compounds, low operational costs and positive energy balance (Ward et al., 2008).

Recently, vinasse and CM have increased its attractiveness as substrate for anaerobic digestion due to their high available and easy degradable organic matter (Moraes et al., 2015; Nui et al., 2013). However, inherent drawbacks during anaerobic mono digestion involve operations with high hydraulic retention time that is economically unfeasible for industrial application (Li et al., 2014). Researches on AD of vinasse reveal drastic pH drop during the startup of the process (Syaichurrozi et al., 2013), pH shifts are correlated with volatile fatty acids (VFA) concentrations and depends on buffering capacity of the system. Moreover, drastic changes on pH affect directly the microbial population growth for methanogens and decreases methane yield (Espinoza-Escalante et al., 2009). In other hands, CM is a high nitrogen content organic waste. The main source of nitrogen on CM is its high content of proteins, which anaerobically degraded into ammonia (Li et al., 2013). Total ammonia nitrogen concentrations (TAN), over 2-4 g/L (Wang et al., 2014), reduce the population of methanogens and generate volatile fatty acids (VFA) accumulation (Nui et al., 2013). Consequently, it is presented a dynamic equilibrium between VFA and TAN known as a pseudo-steady state where the process operates at steady state but with low methane production (Lu et al., 2013).

Anaerobic co digestion (AcoD), the simultaneous AD of two or more substrates, is a feasible option to overcome the drawbacks of mono-digestion as well to improve the plant economic feasibility due to higher methane production (Mata-Alvarez et al., 2014). This variant of AD consists on mixing two or more substrates with complementary characteristics for combined treatment (Astals et al., 2014). AcoD is known as a feasible solution to overcome inhibitions and improve process performance due to better carbon availability, nutrient balance and buffering capacity (Wang et al., 2014). Vinasse and CM are potential candidate for cotreatment. CM provides (i) alkalinity and (ii) macro and micro nutrients (Marin-Batista et al., 2015) fostering pH buffering systems meanwhile vinasse can help to dilute ammonia nitrogen accumulated by CM digestion.

This study aimed to evaluate synergistic effect of chicken manure (high nitrogen content) and vinasse (high carbon content) during anaerobic codigestion. Both substrates proceed from Colombia agro industry and its codigestion will work as energy-recovery and nutrients approach as part of the ethanol production chain.

Material and Methods

Substrates and inoculum

Vinasse utilized in this study was produced following the most widely used steps in Colombian factories (Quintero et al., 2008). Vinasse production consisted on two stages: i) sugarcane molasses fermentation and ii) alcohol separation. For sugarcane molasses fermentation were used molasses obtained from an agricultural inputs establishment. Previous fermentation molasses was diluted until 30°brix (300g of sucrose per liter), percentage (w/v) of soluble solids (Brix) was determined with a portable refractometer for sugar – Brixco (0-80% ATC). Fermentation was carried out on batch mode using 80 L tank at environmental conditions (26±2°C and 0.98 atm). The tank was loaded with the molasses juice until 70% of its total capacity. The yeast used for fermentation stage corresponded to strain of Saccharomyces cerevisiae named S. cerevisiae LPB. pH and additional supplementary nutrients such as magnesium (MgSO4.7H2O) and nitrogen (NH4NO3) were conducted as recommended by Siqueira et al., (2008). Fermentation was ended when CO2 liberation finished (20 days of visual observation) (Siqueira et al., 2008). Alcohol separation was performed on a pilot double-effect evaporator. The pilot operated to 2 Psia and capacity of 80 L. The evaporation process produced a vapor stream condensed and collected from the top. The condensed stream consisted of 30% alcohol (v/v) dissolution. The volumetric alcohol concentration (v/v) was determined with alcohol hydrometer - Bellwether. The remaining liquid in the evaporator corresponded to vinasse used in this study, which was collected and storage (4°C) for further characterization.

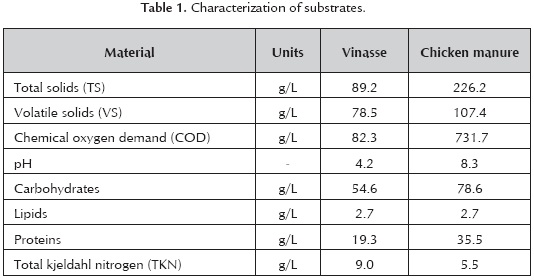

Chicken manure (CM) was collected from a local chicken layer farm located in Lebrija-Santander, Colombia. CM consisted of a mixture among manure, thin feathers and eggshells. Table 1 shows CM and vinasse physicochemical properties. The cattle slurry used as inoculum was collected from slaughterhouse located in Rio Negro –Santander, Colombia. The inoculum had a total solid (TS) concentration of 30.1 g/L, volatile solid (VS) concentration of 20.8 g/L and methanogenic activity of 2 COD CH4/gVSS·day.

Biochemical methane potential test

Biochemical methane potential (BMP) test were carried out in triplicate at 37±2°C following the guidelines described by Angelidaki et al. (2009). Tested mixtures between vinasse and CM were set at 1:0, 1:3, 3:1 and 0:1 on VS basis. The inoculum to substrate ratio, on VS basis, was kept at 2 for all the mixtures. Each reactor had a 60 mL capacity, 12 mL of inoculum and the same initial VS load of the substrate, in order to compare results. Distilled water was added to adjust a working volume of 35 mL for each reactor. Triplicate blank were used to determine the background methane yield of the inoculum. All digesters were manually shaken twice a day for about 1 min. Methane produced during BMP was quantified by the volumetric displacement of an alkaline solution. The volume of methane displaced was normalized and expressed in terms of specific methane production (SMP) m3 CH4/kg VS added (Angelidaki et al., 2009).

Identification of synergistic effects

Synergistic effect was evaluated as an additional SMP obtained during co-digestion over the weighted average of the individual feedstock's SMP (Labatut et al., 2011). Weighted specific methane production (WSMP) was calculated using the equation (1):

Where, YV correspond to SMP for vinasse digested as mono substrate, YCM correspond to SMP for CM digested as mono substrate. α is the volatile solids fraction added of vinasse and β the volatile solids fraction added of chicken manure.

Synergistic effects () were identified as a qualitative parameter for evaluation of the process performance. Synergistic effects were determined using the equation (2):

Where, SMP correspond to experimental SMP achieved for the ratio tested. WSMP correspond to the average of experimental SMP obtained by digestion of both feedstocks as mono- substrate. Finally, if the value of is +1, the mixture presented synergistic effect. Otherwise, if the value of is -1, the mixture presented antagonistic effects.

Analytical techniques

Analyses of total solids (TS), volatile solids (VS), chemical oxygen demand (COD), total Kjeldahl nitrogen (TKN), proteins and lipids were performed according to the Standard Methods for the examination of wastewater (APHA, 2005). Carbohydrates were estimated by subtracting the amount of protein and lipids from volatile solids (Galí et al., 2009). TRS was determined by colorimetric method (Miller, 1959). Total alkalinity (TA) and TVFA were quantified by titration (Anderson et al., 1992). pH values were determined by a pH meter (691, Metrohm) and total ammonia nitrogen according to the standard methods procedures (APHA, 2005).

Statistical analysis

The experimental data was statistically analyzed using one way analysis of variance (ANOVA) by using MINITAB 17 (17.1.0.0). Pairwise comparisons of the means of SMP and TAN were conducted by the Fisher Least Significant Difference (LSD) calculated with 95% confidence.

Results and discussion

Characterization of substrates.

Substrates characterization is presented in table 1. Vinasse tested in this study showed values on COD, pH and TKN similar at industrial sugarcane vinasse (Moraes et al., 2015). Nevertheless, Vinasse prepared in this study correspond a feedstock viable to evaluate a model substrate for sugarcane vinasse anaerobic digestion. Vinasse and CM presented high organic matter contents available for the anaerobic process. Literature reported appropriate pH values for starting-up of AD process on range of 7 to 8 (Li et al., 2013). Vinasse presented an acid pH value of 4.2 and CM a basic pH value of 8.4. Basic pH value in CM must be to its high concentration of ammonia and trace element such as cd, Co, Cr, Cu, Mo, Zn and Ni that raise alkalinity (Bolan et al., 2010). Then, it is expected that vinasse to CM mixing ratios accomplish suitable pH values for the AD process.

Biomethane potential test (BMPt)

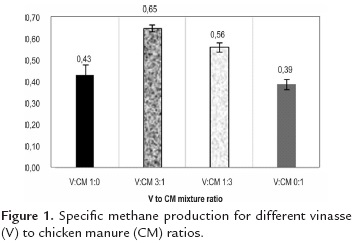

The specific methane production (SMP) for vinasse to CM ratios (1:0, 3:1, 1:3 and 0:1 on VS basis) were determinate in biodegradability test. Figure 1 shows the average value of SMP after withdrawing the methane production from the inoculum blank assays, which was 0.17±0.02 m3 CH4/kg VS. Monodigestion assays were Vinasse to CM ratios of 1:0 and 0:1. The monodigestions accomplished SMPs of 0.43±0.04 m3 CH4/kg VS and 0.39±0.02 m3 CH4/kg VS, values in that range reported at literature (Djalma et al., 2016; Marin-Batista et al., 2015). Then, anaerobic digestion of chicken manure and vinasse by separately works as a strategy for waste management. Anaerobic digestion of both wastes in a single reactor should be a well strategy for the waste management as well as energy recovery. Vinasse to CM ratios of 3:1 and 1:3 represented the codigestion between both feedstocks. Codigestion assays significantly (p=0.00) increased the SMP up to 0.65±0.01 m3 CH4/kg SV and 0.56±0.02 m3 CH4/kg SV for Vinasse to CM ratio of 3:1 y 1:3, values higher than monodigestion assays. Previous studies reported than CM could provide essential nutrients fostering microbial metabolism and therefore methane production (Li et al., 2013). In codigestion assay, methane production increased as well as Vinasse increased in the ratio. Probably, due to high concentration of easily and rapidly biodegradable sugars in vinasse that raise exponentially the conversion efficiency (Yang et al., 2015). Most of organic matter in CM is conformed of proteins and low degradable compose as well as cellulose, hemicellulose and lignin (Li et al., 2013). Then, a high supplementation of CM reduces the biodegradability rate resulting in a slightly lower methane production when methane yield is compared at the 30 days digestion.

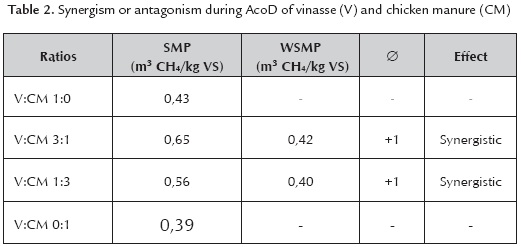

Table 2 presents a comparison of SMP, WSMP and synergistic effects (. WSMP correspond to weighted average of the individual waste's SMP. WSMP represents the expected methane production by mixing vinasse and chicken manure. WSPM was calculated using equation 1. Subtraction between SMP and WSMP indicated an extra methane production obtained during digestion assay. Values of SMP and WSMP increased proportionally as portion of vinasse increases in the mixture. Both SMP and WSMP showed the same tendency confirming the accuracy of BMPt. Vinasse to CM ratio of 3:1 and 1:3 achieved an extra methane production higher up to 55% and 44%, respectively. The extra methane production can be attributed to synergistic effect (Labatut et al., 2011). Currently, there is limited knowledge about how waste composition influences AcoD performance or whether interactions between substrates enhance or attenuate inhibition thresholds, degradation rates, or biogas yields on individual substrates (Astals et al., 2014). It could be explained because of the variety in the substrate composition encourage the growth of microorganisms stimulating the anaerobic degradation process (Pagés-Díaz et al., 2014), since mixtures could have all of the nutrients and trace elements that microorganisms need for their growth. Then, Synergistic effect could be defined as a qualitative parameter to evaluate the feasibility of the co digesting mixture and the SMP could be used as indicator of synergism. In this study, synergistic effects were tested using the equation 2. According to the results (table 2) vinasse to CM ratios of 3:1 and 1:3 presented values of +1. Then all the mixture ratios presented synergistic effects.

Monitoring of response variable during anaerobic codigestion of different Vinasse to CM ratios

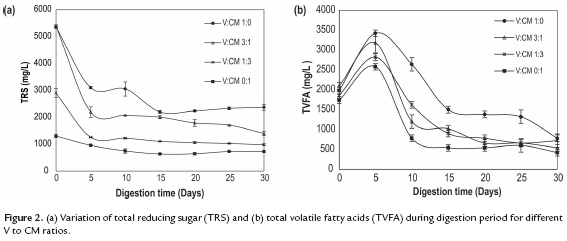

The total reducing sugar (TRS) consumption over time indicates the performance on startup of the process (Castro et al., 2014). TRS profile during co digestion for vinasse to CM ratios of 1:0, 3:1, 1:3 and 0:1 are showed in figure 2a. It is observed that control (V:CM 1:0 and 0:1) showed TRS consumption until the tenth day of digestion, unlike vinasse to CM ratios of 3:1 and 1:3 was until fifth day of digestion. The results for vinasse to CM ratios of 1:0, 3:1, 1:3 and 0:1were 210.8 mg.L-1d-1, 639.9 mg.L-1d-1, 329.5 mg.L-1d-1 and 44.5 mg.L-1.d-1, respectively. Co-digestion samples presented higher sugar consumption than mono-digested samples. Vinasse to CM ratio of 3:1 presented the highest hydrolytic activities, indicating a better affinitive from the ratio to inoculum (Quintero et al., 2012). Nevertheless, co digestion of vinasse and CM improved the TRS consumption rate on both feedstocks.

The dynamic of Total Volatile Fatty Acids (TVFA) are showed in figure 2b, which are one of the most important indicators for measuring anaerobic digestion performance (Abouelenien et al., 2014). Concentrations on TVFA increased during the first days of digestion for all the vinasse to CM ratios. Increment on TVFA concentration could be attributed to activity of acidogens converting TRS released during hydrolytic stage in the startup of the process (figure 2a). In this study, TVFA values were 3420 mg/L, 3180 mg/L, 2820 mg/L and 2580 mg/L for vinasse to CM ratios of 1:0, 3:1, 1:3 and 0:1, respectively. After the fifth day of process, vinasse to CM ratios decreased the concentration on TVFA, denoting consumption of organic matter as result of activity of acetogens capable to transform acetate into methane. Vinasse achieved high concentrations of TVFA due to its easy degradable sugars. However, the present of metabolic components as propionic acid (Djalma et al., 2016) and sulfides (Barrera et al., 2015), which are co factors in enzymatic reactions, could affect the VFA consumption rate.

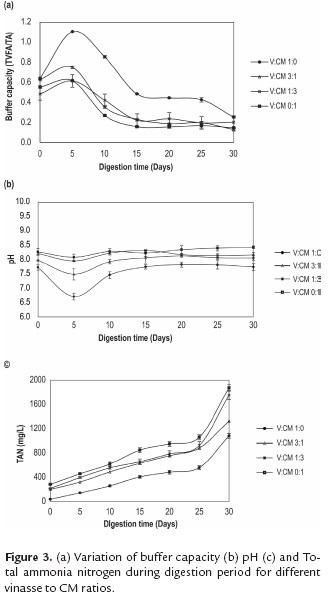

Stability indicators of digestion process for different vinasse to CM ratios

Low specific methane production is generally a consequence of imbalance between the different microbial populations caused by low pH, accumulation of VFAs, and high concentration of free ammonia, which are parameters indicator of process stability (Li et al., 2013). Figure 3 presents the profile of buffer capacity, pH and Total Ammonia Nitrogen (TAN) concentration during digestion period. Anaerobic processes achieve stability on ranges of buffer capacity (TVFA/total alkalinity) values between 0.2-0.8 (Nue et al., 2013). Buffer capacity values higher than 0.8 indicates imbalance between the population of acidogens and methanogens (Raposo et al., 2006). In this study, the buffer capacity for vinasse to CM ratios of 3:1, 1:3 and 0:1 kept on range stated as stability values. On the contrary, monodigestion of vinasse presented instability on buffer capacity achieving values up to 1.10. These results were consistent with variation of pH and TAN (figure 3b and 3c). The concentration of TAN increased significantly (p<0.003) as the amount of CM increased in the mixture. It has been widely reported inhibition for methanogens to final concentration of TAN over the threshold of 3000 mg/L (Wang et al., 2014). Vinasse to CM control ratio of 0:1 reached the highest final TAN concentration of 1875 mg/L, so far to the ammonia inhibition threshold. Total ammonia nitrogen (TAN) concentration could contribute to buffer capacity and help to maintain the pH value (Li et al., 2014). Results indicate that codigestion moderate buffer capacity to alkalinity values up to 5000 mg CaCO3/L, which support ph drops and TVFA accumulation.

Conclusion

Anaerobic codigestion is a feasible technology as a management alternative for vinasse and chicken manure. Chicken manure improved trace element arising buffer capacity of the system and reducing the risk of acidification on vinasse mono digestion. Specific methane production increased significantly (p=0.000) up to 0.65±0.01 m3 CH4/kg SV and 0.56±0.02 m3 CH4/kg SV for vinasse to CM mixing ratios of 3:1 y 1:3. Synergistic effects during codigestion of vinasse and chicken manure augmented the methane production up to 55%. However further studies are required to explain the synergistic effects occur during anaerobic co digestion.

References

Anderson, G.K., & Yang, G. (1992). Determination of bicarbonate and total volatile acid concentration in anaerobic digesters using a simple titration. Water Environment Research, 64, 53-59. [ Links ]

Angelidaki, I., Alves, M., Bolzonella, D., Borzacconi, D., Campos, J.L., Guwy, A.J., Kalyuzhnyi, S., Jenicek, P., & Van Lier, J. B. (2009). Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Science & Technology, 59 (5), 1-8. [ Links ]

APHA, (2005). Standard methods for the examination of water and wastewater. American Public Health Association, Washington, ISBN 978-0-87553-047-5. [ Links ]

Astals, S., Batstone, D.J., Mata-Alvarez, J., & Jensen, P.D. (2014). Identification of synergistic impacts during anaerobic co-digestion of organic wastes. Bioresource Technology,169, 421-427. [ Links ]

Abouelenien, F., Namba, Y., Kosseva, M.R., Nishio, N., & Nakashimada, Y. (2014). Enhancement of methane production from co-digestion of chicken manure with agricultural wastes. Bioresource Technology, 159, 80-87. [ Links ]

Barrera, E.L., Spanjers, H., Solon, K., Amerlinck, A., Nopens, I., & Dewulf, J. (2015). Modeling the anaerobic digestion of canemolasses vinasse: Extension of the Anaerobic Digestion Model No. 1 (ADM1) with sulfate reduction for a very high strength and sulfate rich wastewater. Water research,71, 42- 54. [ Links ]

Bolan, N.S., Szogi, A.A., Chuasavathi, T., Seshadri, B., Rothrock, M.J., & Panneersel, P. (2010). Uses and management of poultry litter. World's Poultry Science Journal,66, 673-698. [ Links ]

Castro, L., Guzmán, C., & Escalante, H. (2014). Aprovechamiento de la biomasa lignocelulósica, Algunas experiencias de investigación en Colombia. Digestión anaerobia de una biomasa lignocelulósica en Colombia: Bagazo de Fique como caso de estudio. Bogotá, Colombia: Utadeo. [ Links ]

Dávila-Rincón, J., Machuca-Martínez, F., & Marriaga-Cabrales, N. (2009). Reducción de demanda química de oxígeno, carbono orgánico total y sólidos totales en vinazas mediante electroflotación/oxidación. Revista Ingeniería e Investigación, 29 (1), 35-38. [ Links ]

Djalma, A., Koyama, M.H., De Araújo, M.M., & Zaiat, M. (2016). Thermophilic anaerobic digestion of raw sugarcane vinasse. Renewable Energy,89, 245- 252. [ Links ]

Escalante, H., Orduz, J., Zapata, H., Cardona, M.C., & Duarte, M. (2010). Atlas del potencial energético de la biomasa residual en Colombia. Unidad de planeación minero energética, Universidad Industrial de Santander, UIS. [ Links ]

Espinoza-Escalante, F., Pelayo-Ortíza, C., Navarro-Corona, J., González-García, Y., Bories, A., & Gutiérrez-Pulido, H. (2009). Anaerobic digestion of the vinasses from the fermentation of Agave tequilana Weber to tequila: The effect of pH, temperature and hydraulic retention time on the production of hydrogen and methane. Biomass and bioenergy, 33, 4-20. [ Links ]

Fernandez, J.M., Plaza, C., Garcia-Gil, J.C., & Polo, A. (2009). Biochemical properties and berley yield in a semi arid mediterranean soil amended with two kinds of sewage sludge. Applied soil ecology, 42, 18-24. [ Links ]

Huang, G., Wang, X., & Han L. (2011). Rapid estimation of nutrients in chicken manure during plant-field composting using physicochemical properties. Bioresource Technology, 102, 1455-1461. [ Links ]

Galí, A., Benabdallah, T., Astals, S., & Mata-Alvarez, J. (2009). Modified version of ADM1 model for agro-waste application. Bioresource Technology, 100, 2783-2790. [ Links ]

Jáuregui-Jáuregui, J.A., Méndez-Acosta, H.O., González-Álvarez, V., Snell-Castro, R., Alcaraz-González, V., & Godon, J.J. (2014). Anaerobic treatment of tequila vinasses under seasonal operating conditions: Start-up, normal operation and restart-up after a long stop and starvation period. Bioresource Technology, 168, 33-40. [ Links ]

Jimenez, A.M., Borjaba, R., Martín, A., & Raposo, F. (2006). Kinetic analysis of the anaerobic digestion of untreated vinasses and vinasses previously treated with Penicillium decumbens. Journal of Environmental Management, 80, 303-310. [ Links ]

Kumar, S. (2008). Anaerobic biotechnology for bioenergy production: Principles and applications. Blackwell Publishing, USA 2008, 299-63. [ Links ]

Labatut, R.A, Angenent, L., & Scott, N.R., (2011). Biochemical methane potential and biodegradability of complex organic substrates. Bioresource Technology, 102, 2255-2264. [ Links ]

Li, Y., Zhang, R., He Y., Zhang, C., Liu, X., Chen, C., & Lui, G. (2014). Anaerobic co-digestion of chicken manure and corn stover in batch and continuously stirred tank reactor (CSTR). Bioresource Technology, 156, 342-347. [ Links ]

Li, Y., Zhang, R., Chen, C., Liu, G., He, Y., & Liu, X. (2013). Biogas production from co-digestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions. Bioresource Technology, 149, 406-412. [ Links ]

Marin-Batista, J., Castro, L., & Escalante, H. (2015). Efecto de la carga orgánica de la gallinaza de jaula en el potencial de biometanización. Revista Colombiana de Biotecnología, 17 (1), 18-23. [ Links ]

Mata-Alvarez, J., Dosta, J., Romero-Güiza, M.S., Fonoll, X., Peces, M., & Astals, S. (2014). A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renewable Sustainable Energy, 36, 412-427. [ Links ]

Miller, G. (1959). Use of DinitrosaIicyIic acid reagent for determination of reducing sugar. Analytical Chemistry, 31 (3), 426-428. [ Links ]

Moraes, B.S., Zaiat, M., & Bonomi, A. (2015). Anaerobic digestion of vinasse from sugarcane ethanol production in Brazil: Challenges and perspectives. Renewable and Sustainable Energy Reviews, 44, 888-903. [ Links ]

Niu, Q., Qiao, W., Qiang, H., Hojo, T., & Li, Y. (2013). Mesophilic methane fermentation of chicken manure at a wide range of ammonia concentration: Stability, inhibition and recovery. Bioresource Technology 137, 358-367. [ Links ]

Pagés-Díaz, J., Pereda-Reyes, I., Taherzadeh, M., Sárvári-Horváth, I., & Lundin, M. (2014). Anaerobic co-digestion of solid slaughterhouse wastes withagro-residues: Synergistic and antagonistic interactions determined in batch digestion assays. Chemical Engineering Journal, 245, 89-98. [ Links ]

Syaichurrozi, I., Budiyono, & Sumardiono, S. (2013). Predicting kinetic model of biogas production and biodegradability organic materials: Biogas production from vinasse at variation of COD/N ratio. Bioresource Technology, 149, 390-397. [ Links ]

Raposo, F., Banks, C.J., Siegert, I., Heaven, S., & Borja, R. (2006). Influence of inoculum to substrate ratio on the biochemical methane potential of maize in batch tests. Process Biochemistry, 41, 1444-1450. [ Links ]

Rosales, L., Bermúdez, J., Moronta, R., & Morales, E. (2007). Gallinaza: Un Residual Avícola como fuente alternativa de nutrientes para producción de biomasa microalgal. Revista Colombiana de Biotecnología, 9 (1), 41-48. [ Links ]

Quintero, M., Castro, L., Ortiz, C., Guzmán, C., & Escalante, H. (2012). Enhancement of starting up anaerobic digestion of lignocellulosic substrate: fique's bagasse as an example. Bioresource Technology, 108, 8-13. [ Links ]

Yang, G., Zhang, P., Zhang, G., Wang, Y., & Yang, A. (2015) Degradation properties of protein and carbohydrate during sludge anaerobic digestion. Bioresource Technology, 192, 126-130. [ Links ]

Wang, M., Li, S.P., Yin, L., Liu, D., Zhang, Y., Li, W., & Zheng, G. (2014). A novel alternate feeding mode for semi-continuous anaerobic co-digestion of food waste with chicken manure. Bioresource Technology,164, 309-314. [ Links ]

Ward, A.J., Hobbs, P.J., Holliman, P.J., & Jones, D.L. (2008). Optimization of the anaerobic digestion of agricultural resources. Bioresource technology, 99, 7928-7940. [ Links ]

Zieminski, K., & Kowalska-Wentel, M. (2015). Effect of enzymatic pretreatment on anaerobic co-digestion of sugar beet pulp silage and vinasse. Bioresource Technology, 180, 274-280. [ Links ]