INTRODUCTION

At the beginning of the 20th century the concept of lactic acid bacteria (LAB) emerged as an independent group. Today this group shows a huge biotechnological potential, and it is present in a large number of fermentative food processes destined for human consumption such as dairy, vegetables, meat and bakery products, as well as in silage for animal food (Lee et al., 2013; J. C. Ramírez et al., 2011). These bacteria not only contribute to the development of the organoleptic, rheological and nutritional characteristics of foods, but also generate unfavorable environments for the development of pathogenic microorganisms such as Bacillus, Pseudomonas, Listeria and Escherichia among others, given their bioconservative capacity to produce antimicrobial substances (Cizeikiene et al., 2013; Topisirovic et al., 2006). In addition to this important role in bio-conservation processes, some strains of lactic acid bacteria belonging to the genus Lactobacillus are beneficial to human and animal health, due to their potential in reducing enteric diseases in humans and farm animals, and the subsequent contamination of food products derived from them (Argyri et al., 2013; Ávila et al., 2010; L Axelsson, 1998). The purpose of this paper is to expose the main research and development trends in the production of lactic acid bacteria for industrial purposes with emphasis on the culture media required for their growth.

Search procedure

This review is, focused on presenting the alternatives of culture media for the production of Lactobacillus in the last 12 years, the study was divided into two parts: A synthetic literature review on the generalities of LAB, and a systematic review on specific media for cultivation of Lactobacillus. With this purpose, the Web of Science databases, consisting of KCL (Korean Journal Database), Russian Science Citation Index, SciElo Citation Index, Springer and ScienceDirect, was used. The following search terms were used: 1) for the Title field: "Lactobacillus" with connector "AND" and in Topic field: "culture media"; 2) published between 2005 and 2016; 3) type of document: articles; 4) language (English, Portuguese and Spanish). Once the records were obtained, filters were used to focus on the ten research areas in which this type of studies are done. In order to reduce the search size, the results were refined by using "Science and Technology" as research domain and even more specific research areas of this type of studies such as: "Food Science and Technology", "Applied Biotechnology and Microbiology", " Microbiology", "Applied Chemistry", and "Chemical Engineering".

Using the Web of Science search engine, the internal analysis of articles obtained in the last twelve years (a reduced sample greater than 500 articles) was performed using the following criteria: 1) The ten most important research areas; 2) the thirteen authors registered as the most important in these research areas; 3) the record of publications in the same period of time; and 4) the ten most important countries in this type of study. From this reduced sample, about 60 articles were selected using the following exclusion criteria: 1) Reports that do not contribute to the objective of this review by not making explicit the culture media for LAB; 2) papers that do not report the type of microorganism, substrate or supplement, type of fermentation, fermentation conditions, and biomass production. The extracted information was compiled in an MS Excel spreadsheet, designed with the search criteria used. In this format, some works published prior to the time period covered by this review were also included given their relevance and pertinence. Moreover, patents reported between 2000 and 2016 on Lactobacilli were consulted through the Google Patent Search using the same search criteria indicated above.

Search results on culture media for lactic acid bacteria

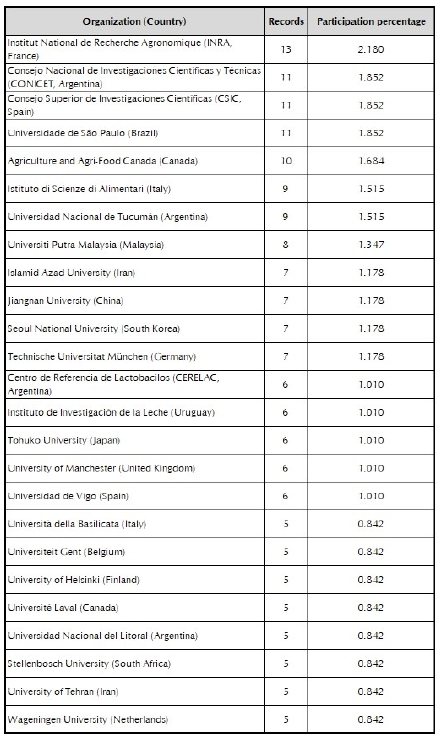

The initial search performed on Lactobacillus culture media, once the search criteria and the respective filters were applied, showed 594 records, which were analyzed for this review. From the records analyzed, 13.1% of the papers are authored by 13 researchers, who lead the studies on Lactobacillus in the last twelve years. These authors belong to research groups from Canada, Italy, South Africa, England, Poland, Japan, Argentina, Belgium, and the United States. Table 1 shows the 25 affiliation organizations of these authors. Taking into account the classification of research areas used by Web of Science, the articles found belong to the following five research areas in descending order: Applied Microbiology and Biotechnology (196), Microbiology (176), Food Science and Technology (163), Molecular Biology and Biochemistry (31), Agriculture (28).

Table 1 Amount of publications of the 25 main organizations to which the research groups working on Lactobacillus belong between 2005-2016.

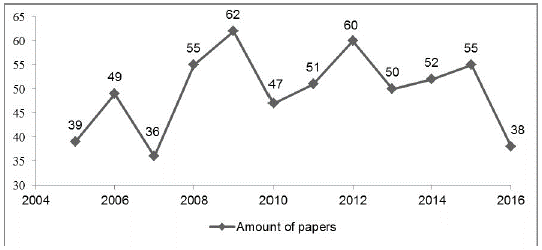

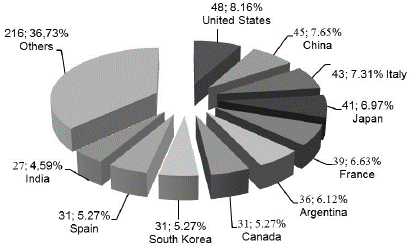

The ten countries with the highest participation in studies on culture media for Lactobacillus in the world in the last twelve years are shown in figure 1. It is noteworthy that only three records corresponding to Colombian researchers appear in Web of Science in the last twelve years, comprising a share of 0.5%. The amount of publications in the last twelve years was also consulted for this search in the selected databases and the results are illustrated in figure 2.

Figure 1 Distribution by country of the institutions to which the authors of articles on culture media for Lacto bacillus belong in the period 2005-2016.

Patent search

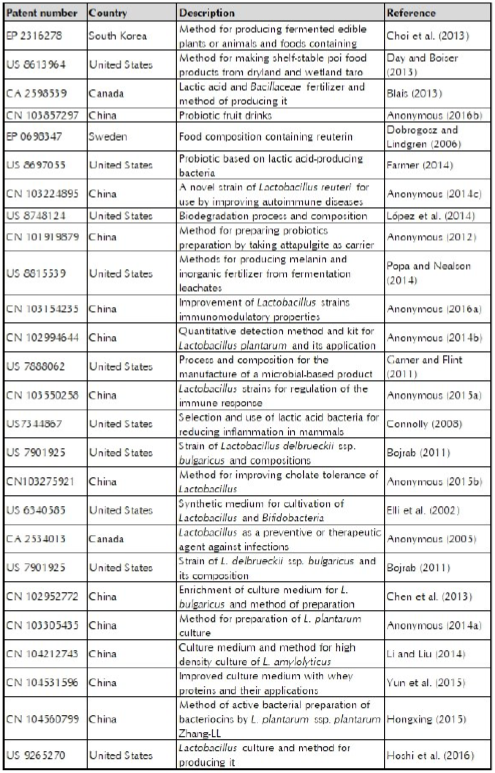

The literature reports an important amount of patents on new Lactobacillus strains, as well as processes for differentiating and quantifying lactic bacteria in some natural products, the composition and enrichment of media for their cultivation, and processes for producing, characterizing and applying products with probiotic properties obtained from Lactobacillus, among others. Table 2 presents the list of patents found in the last decade (from 2005 to August 2016 as a reference period for the analysis) regarding Lactobacillus.

It should be noted that the patents on Lactobacillus granted in the period from 2000 to August 2016, show a great interest in the identification of new strains based on their natural substrates (mainly dairy and meat products), as well as their potential use as preventive or therapeutic agents against pathologies related to the human intestinal tract (Anonymous, 2005, 2016a; Bojrab, 2011; Connolly, 2008; Farmer, 2014). The companies filing patents on this topic aim their resources towards economic methods for production of Lactobacilli cultures at industrial level. Most patent documents refer to the use of whey (Yun et al., 2015), corn starch (Li & Liu, 2014) and even whole milk (Anonymous, 2014a; Chen et al., 2013). In other cases, the inventors resort to the design of synthetic media for the isolation of bioactive molecules, functional metabolites or production of LAB of interest (Elli et al., 2002). For the enrichment of these media, the use of free bases, ribonucleosides, deoxyribonucleosides, casein hydrolysates, hydroxyproline, and glutamic acid was reported. Some patents introduced their inventions for preservatives, which enable the protection of the Lactobacillus culture, both in the subculture and during storage. It should be highlighted that, because of the recognized importance of probiotics, efforts are made to design growth media enriched with constituents such as sulfur amino acids, ovalbumin, bile powder, trehalose, and raffinose.

Features of lactic acid bacteria

Lactic bacteria are chemo-organotrophic microorganisms. Their morphology appears as cocci or bacilli, commonly associated in short chains, are Gram positive, non -sporulated, and aerotolerant. They are negative in the oxidase, catalase and benzidine tests. They lack cyto-chromes and generally do not reduce nitrate to nitrite. These bacteria synthesize lactic acid as the main product of carbohydrate fermentation (Lars Axelsson, 2004; Bovo et al., 2014; Stieglmeier et al., 2009;Vásquez et al., 2009; Waldir et al., 2007).

The LAB exhibit two metabolic pathways for fermentation of monosaccharides: Homolactic fermentation or glycolysis (pathway Embden-Meyerhof-Parnas) and hetereolactic fermentation of the 6-phosphoglucanate (6FG) or pentoses pathway. Consequently, LAB have been classified as obligatory homofermentative, facultative heterofermentative, and obligatory hetereofermentative microorganisms (Lars Axelsson, 2004; Gänzle, 2015), The acidolactic bacteria shows slight proteolytic activity due to the proteases and peptidases attached to the cell wall or released by them, as well as weak lipolytic activity due to the action of intracellular lipases.

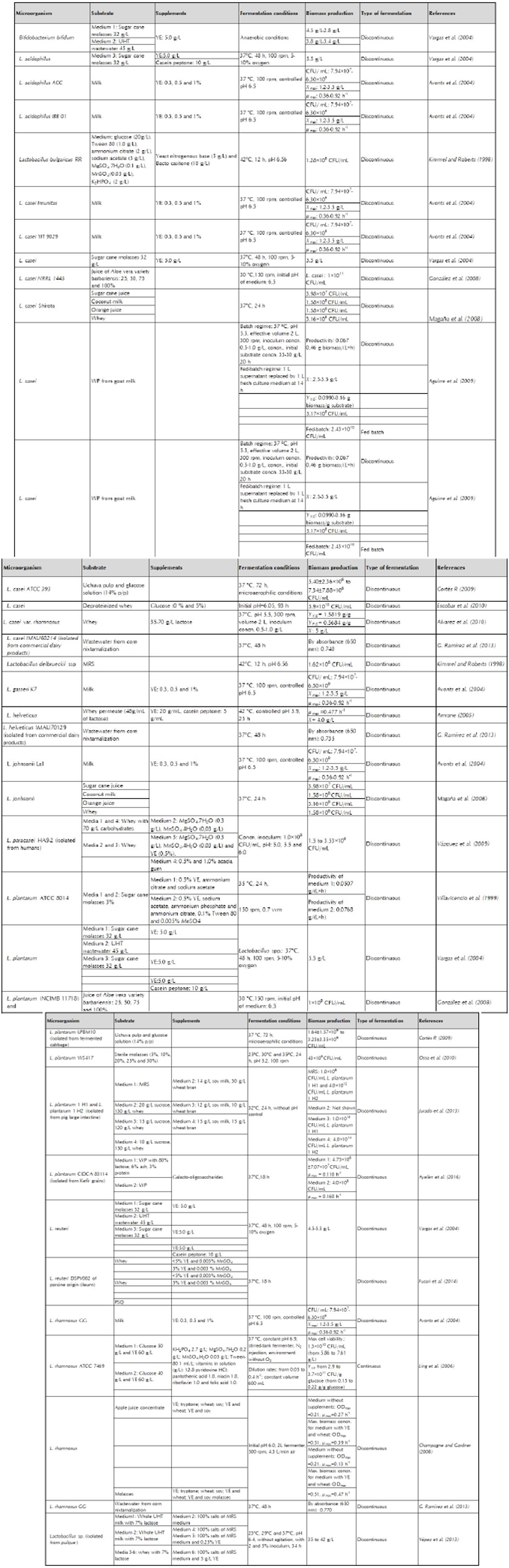

The culture media and main fermentation conditions for production of the main Lactobacillus species used for production of probiotics, starter cultures, and bacteriocins, are shown in table 3 (organized alphabetically by species name followed by the year of publication). Among the most individually studied Lactobacillus or a mixture of them, isolated from natural substrates, the following species should be highlighted for their probiotic and biopreservation activities: L. acidophilus, L. casei, L. delbruecki, L. plantarum, L. helveticus, L. rhamnosus, and Bifidobacterium bifidum.

Culture media for lactic acid bacteria

A culture medium must contain the nutrients and growth factors required by the microorganism and be free of contaminating microorganisms (Garcia et al., 2010). These requirements are characteristic of each species. LAB show complex nutritional requirements such as amino acids, peptides, derivatives of nucleic acids, vitamins, salts, fatty acids or esters of fatty acids, and fermentable carbohydrates (Parra, 2010). These requirements are usually met when the culture medium contains fermentable carbohydrates, peptone meat, and yeast extract. In general, for Lactobacillus it is desirable for the nitrogen to be organic in the form of amino acids or peptides. In this sense, glutamic acid, isoleucine and valine are considered as growth factors and must be present in the culture medium (González et al., 2008). Many species require the presence of manganese, acetate and esters of oleic acid, especially Tween 80 (Berbegal et al., 2015).

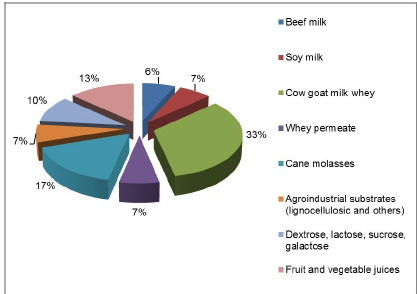

According to table 3 and figure 4, it can be observed that most studies on the production of Lactobacillus biomass still make use of whey and sugar cane molasses as source of carbon and energy. In recent years, the use of fruit juices, as well as of by-products and agro-industrial waste has gained importance for media formulation. The above corroborates the research trend in the search for feedstocks of high availability and lower cost with the purpose of reducing the sale price of the final products derived from the Lactobacilli biomass.

Figure 3 Type of substrate and percentage of use in culture media for Lacto bacillus in the last fifteen years.

In Latin America, different research efforts have been reported aimed at the use of native products for LAB growth given the great availability of biological resources and economies with a high weight of the agriculture and agro-industry in these countries. For example, the growth kinetics of Lactobacilli with probiotic potential in the intestinal tract are being studied in Mexico using the agro-industrial residue derived from the fermentation of agave honey, a pre-Hispanic drink called pulque in that country (Yépez et al., 2013).

In Colombia, the use of wastewater sludge from sugar cane processing as well as the sugar cane molasses has been proposed as feedstocks given the importance of the sugar industries including the industry for production of non-centrifugal sugar or solid brown sugar (called panela in that country) (Ossa et al., 2010). Likewise, the use of lignocellulosic materials for LAB production with pro-biotic functionality by submerged fermentation, such as wheat bran, has been reported (Jurado et al., 2013). Obtained Lactobacillus may be used to produce probiotics, which can colonize the intestine when consumed orally. This would open new possibilities in the diversification of the feedstocks basis for industrial fermentation processes. Other researchers have proposed the use of cereals like barley and malt for the development of lactic acid bacteria with probiotic potential such as L. plantarum NCIMB 8826 and L. acidophilus NCIMB 8821 (Rathore et al., 2012). Complex or enriched liquid media are currently being used supplemented with some components that increase the production costs of lactic cultures. Particularly, as can be seen in this review, the nitrogen sources used such as yeast extract, tryptic casein peptone, and meat extract have a high cost in industrial fermentations. Table 3 shows the most widely used substrates in the last twelve years, supplements added to the media, conditions of fermentation, type of fermentation, and data on production of biomass obtained. Table 3 does not report the average biomass yields since these data are scarcely published in the available literature, being risky to make any comparation about the performance of synthetic media related to those based on agro-industrial waste. Considering the final viable biomass concentration (in CFU/mL), the medium based on whey and sucrose as carbon sources, and soy milk and wheat bran as nitrogen sources employed by Jurado et al. (2013) allowed reaching the highest concentration of L. plantarum. In the case of L. casei, the best medium was almost exclusively based on a by-product (or waste) from the dairy industry (Escobar et al., 2010): the cheese whey (see table 3). These outcomes suggest that the utilization of waste materials for media formulation is an attractive way to enhance the performance of LAB cultivation, enabling, at the same time, the decrease in the feedstock costs during production of probiotic microorganisms and starter cultures. In this sense, the evaluation of lignocellulosic hydrolyzates for LAB fermentation could be a promising research trend in the near future. In general, the range of cell concentrations (in CFU/mL) for main LAB presented in table 3 is as follows: L. acidophilus 7.94X107 - 6.30x109, L. casei 7.94x107 -6.30x10s, L. plantarum 4.0x108 - 4.0x1014 and L. rhamnosus 7.94X107 - 3.7x1011. It should be noted that the papers reviewed for this work reported the data on bio-mass concentrations with different units (CFU/mL, g/L, Optical Density); this difficults the comparison among the different media used in those papers.

Culture conditions for Lactobacillus

The temperature for the cultivation of mesophilic and thermophilic LAB found in this study ranges from 23 to 37°C and 42°C, respectively, with incubation times from 18 to 93 hours and a pH from 5.2 to 6.9. The discontinuous cultivation was the type of fermentation used in almost all the studies reviewed (table 3), which does not allow a more precise evaluation of other alternative regimes that are more efficient like the continuous culture.

The highest production of viable cells (4.0x1014 CFU/ mL) mentioned above, corresponded to a batch system for production of two L. plantarum strains. More research efforts are required at the bench and pilot levels in continuous and discontinuous fermentations in order to assess the efficiency of alternative cultivation regimes for Lactobacillus production.

Applications of LAB

Lactic acid bacteria are increasingly used in the improvement of human and animal health and nutrition (Senz et al., 201 5; Süle et al., 2014). It has been known for several decades that LAB have an inhibitory potential in food against the development of altering microorganisms and pathogens, which is useful for prolonging shelf-life and increasing the hygienic quality of foods (Concha-Meyer et al., 2011; Forney et al., 2004; Siamansouri et al., 2013). Therefore, LAB are widely investigated as natural biological agents because of their antimicrobial potential and as a response to the demand for safe, fresh or minimally processed foods, without preservatives and with a longer shelf-life (Serna & Enriquez, 2013). In general, from the industrial viewpoint, LAB are being applied in the production of antimicrobial substances, sugar polymers, sweeteners, aromatic compounds, vitamins, and are also used as probiotics (Aro & Rojas, 2013; Leroy & De Vuyst, 2004).

The term probiotic was redefined in 2002 by the United Nations Food and Agriculture Organization (FAO) and the World Health Organization (WHO) as a "living microorganism that ingested in the right amounts confers a healthy benefit to the host" (Colombo et al., 2014; Miranda et al., 2013). Fermented dairy products are the most used foods to carry probiotic bacteria. The probiotic strains predominating in these dairy derivatives are L. acidophilus, L. casei, and B. lactis (Geng & Boyer, 2014; Tabasco et al., 2014). These bacteria have been used in recent decades as probiotic supplements in functional food and animal nutrition (Senz et al., 2015). Also, a limited amount of LAB species are used as a starter culture in the meat industry; the main cultures are L. sakei, L. curvatus, L. plantarum, Pediococcus pentosaceus, and P. acidilactic.

CONCLUSIONS

Most papers on Lactobacillus production are focused on the production of lactic acid and, in some cases, on evaluating the growth of Lactobacillus of industrial importance, mainly for human and animal health, and food. Currently, the best production system for LAB corresponds to the submerged fermentation in a batch regime at mesophilic conditions using whole whey or whey permeate supplemented with nitrogenous materials like yeast extract, soy milk or wheat bran.

Research efforts are being made all over the world to improve the production systems, as well as cultivation methods and media for LAB production. In the case of Colombia, research groups and centers have the responsibility of intensifying their efforts to offer highly efficient technological alternatives to the national industry, that allow the production and application of LAB as a growth factor for the food sector. In this regard, among other aspects, it is necessary to increase the international visibility of Colombian scientific production in this area, as it is evident from the results of this review. Thus, national researchers will contribute to supply the demand for high quality scientific knowledge on starter microorganisms for fermented foods such as meat, dairy and vegetables, among others; as well as on the culture media in which they are grown (including the use of agro-industrial wastes as raw materials). Furthermore, research in prebiotic ingredients or additives derived from LAB allowing the increase of the benefits to the consumer must be continued.