1. INTRODUCTION

The ice cream was originated in China, where King Tang (AD 618 -697) of Shang had a method for creating ice-milk mixtures. From China it passed to India, to the Persian cultures and then to Greece and Rome. But it is precisely in Italy of the Middle Age when ice cream rooted in Europe; Marco Polo in the 13th century, upon returning from his journeys to the east, brought several recipes of frozen desserts used in Asia for hundreds of years, which were implemented with some popularity in the Italian courts [1].

The meaning of the term “ice cream” varies from country to country, due to different regulations and traditions, and therefore includes a wide range of ingredients and composition, as well as product texture and manufacturing processes [2].

Ice creams are foods produced by freezing, with or without agitation, a pasteurized mixture composed of a combination of dairy ingredients, which may contain vegetable fats, fruits, eggs and their derivatives, flavorings, sweeteners, and other food additives for subsequent consumption in various forms and sizes [3].

According to [1] ice cream is a whipped product made up of air bubbles, which are limited by layers of a mixture of proteins, sugars, salts, and other dissolved components. It also contains globules of emulsified fat and ice crystals.

As stated by [4] ice cream is a frozen food rich in proteins, fats, carbohydrates, and minerals, which is obtained from the mixture of dairy ingredients, sweeteners, hydrocolloids, stabilizers, emulsifiers, and flavorings. The ingredients involved are few, but the interaction between them is complex because it is an emulsion, froth, and dispersion at the same time. Fat globules, air bubbles, and ice crystals are dispersed in a concentrated sugar solution to form an aerated, frozen, semisolid matrix.

It is a highly complex food system because its structure is formed by the confluence of multiple interdependent events that occur during the transformation from the initial state of stable emulsion to the final state of frozen matrix [4].

It is not only a widely accepted product among the public of all ages and sectors, but it also has a high nutritional value and is a source of energy. Its caloric value depends on the percentage of carbohydrates (lactose, sweeteners, sugars), proteins and lipids. In addition, it provides a large amount of fat-soluble vitamins (A, D, E, K). It is also the most widely consumed frozen dairy dessert worldwide. The global ice cream market was valued at USD $ 68 052.20 million in 2020 and is projected to reach USD $ 122 051.10 million by 2031 [5].

In the years 2019 and 2020, ice cream production in Cuba had values of 21.6 MM gal and 17.2 MM gal, respectively, while in 2021 production fell to 11.7 MM gal [6], mainly due to the effects of Covid-19 pandemic.

According to [7], strawberry ice cream is placed in the fifth place in the top 5 flavors among ice cream makers and scoop shops, while it is placed in fourth place in the top 5 flavors among consumers. In other report [8], strawberry ice cream is the fourth most popular ice cream flavor based on sales, with 3.7 % of the total, in a list lead by vanilla ice cream with 30 %.

Raw material is any compound that can be subjected to a transformation process or special treatment, in order to obtain a final product [9]. In [10] the raw materials used in the preparation of ice cream are specified according to the following classification:

The main ingredients, which are present in significant amounts or portions such as milk, sugar, fat, and water.

Insignificant ingredients, found in small portions, such is the case of emulsifiers, stabilizers, colorings, and flavorings.

Components such as chocolate, cookies, wafers, small amounts of fruit or dried seeds, among others, which are combined with the ice cream to give a better presentation.

Among the main raw materials currently used to produce ice cream are fluid milk and/or skimmed milk powder, fat, sucrose, stabilizer, emulsifier, and air [11].

Fluid milk is the main liquid component of ice cream, which must have a balanced composition of micronutrients, minerals, vitamins, and amino acids. It is worth noting the composition of lactose, which is a disaccharide with low solubility and high sweetening power. Milk proteins help to form the structure of the ice cream, improve its texture and shake, and are essential for the formation of a stable emulsion during the homogenization of the mixture.

Fat influences the flavor of the ice cream, participates in its texture, helps in the stability of the mixture, and improves the air injection process, making the consistency of the ice cream smoother and creamier.

Sucrose is the main ingredient in the ice cream formulation since it provides the characteristic sweet flavor to the ice cream. This component reduces the freezing point of the ice cream, as well as lowers the melting point of the mixture, which is important in the preparation of ice cream in order to avoid dripping when it is being consumed.

The stabilizers or thickeners that are usually used in the manufacture of ice creams are more or less complex polymers of simple carbohydrates. These compounds are intensely embedded in water and form colloidal solutions, and their function is to improve texture, increase firmness and viscosity and reduce the rate of diffusion of water and salts. They also delay the growth of ice and lactose crystals thus improving the stability of the ice creams during storage.

Emulsifiers are substances capable of stabilizing emulsions due to their molecular structure. They must be made up of a lipophilic or hydrophobic part that dissolves well in the non-aqueous phase and another polar or hydrophilic part that dissolves well in water. The hydrophobic part generally consists of a long alkyl chain and the hydrophilic part contains cleavable groups, or also hydroxyl groups. In immiscible systems, for example oil/water, the emulsifiers occupy the limiting surface between both phases, reducing the interfacial tension, thus facilitating a fine distribution of one phase within the other. In ice cream, one of the missions of emulsifiers is to partially destabilize the emulsion, that is, to help a certain coalescence and aggregation of the fat droplets to take place so that they can form the network that will incorporate the air bubbles. In addition, the use of emulsifiers gives the ice creams a dry appearance when they come out of the freezer, simultaneously improving the resistance to melting of the ice cream, being both desirable quality attributes.

Another basic ingredient is air, which must be clean and free of microorganisms. In case of compressed air, it must be free of oil and water, and filtered in a sterile filter. To get the best texture and body, the air bubbles in the ice cream have to be smaller than 100 µm, this also intensifies the aroma. The higher the solids content of the ice cream, the more air is usually added, although ice creams containing fruit and nuts require less air. It is introduced under agitation and is a necessary ingredient because without it the ice cream would be too thick, hard, and cold. The increase in volume of the ice cream made during the cold agitation is known as “overrun.” The increase refers to the volume of the mixture that enters the machine before being agitated.

The ice creams are classified in several ways, being one of the main classifications that referred to its fats content. In this case, the ice creams are classified as [1]:

Cream ice creams: They consist of 7 to 10 % milk fat, 6-8 % non-fat solids, 20-32 % total milk solids, no more than 0.5 % stabilizer, no more than 0.2 % of monoglycerides and diglycerides, 0.1 % of emulsifiers and an incorporation of air no greater than 100 % of the volume of the mixture.

Milk ice creams: Its content is 2.5 % milk fat, 5 % non-fat milk solids, 12 % and 27 % total solids and an incorporation of air no greater than 100 % of the volume of the mixture.

Water ice creams or sorbets: These are frozen products composed by sugar, water, fruit, flavor, color, stabilizer and, sometimes, milk solids, in the form of skimmed milk powder, whole milk powder or condensed milk. Its overrun is from 20 to 40 %.

Yoghurt ice cream: Can contain fruit. Its average composition is 3 to 6 % fat, 11-20 % sugars, 10-12 % non-fat solids, 0.85 % stabilizers and emulsifiers and an average of 70 % water.

Dietetic ice creams: These are ice creams with low caloric content. Its average composition is 14.4 % sugar, 9.6 % syrup or honey, 73 % water and 3 % fruit base. In addition, they can contain fruit pulp in different amounts.

From the manufacturing point of view, the ice cream can be categorized as industrial or artisanal depending on the process technologies used and the production scale applied [2]:

Artisanal: They are composed by milk, milk cream, chocolate, dried and fresh fruits, among other natural raw materials, and no additives or preservatives are required, as the product is manufactured on a daily basis. Commonly, these ice creams are sold in the same places where they are fabricated, and they are marketed in vases and pots of varied sizes, from 150 g to 1 kg.

Industrial: They are produced with milk powder, flavors, emulsifiers, stabilizers, industrial concentrates, essences, and coloring agents. The production facilities employ automated manufacturing processes that allow handling large volumes of product. Marketing depends on the demand estimated by the manufacturing company.

The typical process of industrial elaboration of ice cream has several steps, where each one of them has its own importance and specific purpose in order to obtain a final product (ice cream) with the required hygiene and quality. The main steps of the ice cream industrial production process are as follows [1].

Reception and storage of raw materials: Quality control of the purchased ingredients is carried out, thus avoiding the use of ingredients in bad or contaminated conditions.

Weighing and dosing: Depending on the established formulation, a strict quality control is carried out over the weight of the ingredients; small amounts of some of them can produce inappropriate characteristics or even exceed the legal limits established for the ice cream to be produced.

Ingredients mixing: It is necessary to have an effective mixing system to obtain uniform and homogeneous mixtures, where the mixing order should be taken into account since it contributes to a better result in the final quality of the ice cream.

Pasteurization: In the ice cream industry, a time-temperature combination is used almost exclusively (78-80 ºC, for 20 to 40 seconds), obtaining various effects during this stage, which are: denaturalization of the proteins in the serum and producing faster water absorption, the ingredients are completely dissolved, the emulsifiers act, the stabilizers absorb the liquid part, the fats become liquid and disperse uniformly, and the possible existing microbiological contamination is eliminated.

Homogenization: The purpose of homogenization is to obtain a mix of uniform size before freezing, thus avoiding the crystallization of fats at low temperatures. The result is a greater shake capacity, as it improves the body, melting and storage properties. Likewise, it gives a softer texture and a smoother material. On the other hand, the homogenization pressure depends on several factors such as: composition of the mix, type of fats used and homogenization conditions.

Cooling: The faster the mixture cools, the better the ice cream will result, in terms of taste and less bacterial contamination.

Aging: The aging time is a variable depending on the composition and current legislation, it should not be less than four hours or more than 72 hours, at a temperature greater than 4 ºC but less than 6 ºC. At this stage, the following changes are made fat crystallization and hydration of the stabilizers and dairy solids. The subsequent advantages are obtained because of aging: fine texture, less risk in the formation of ice crystals during storage, best agitation, and reduction the crystallization of fats at low temperatures.

Flavoring and coloration: There are some cases where flavor and color are added together with the rest of the ingredients; the most common ones are that they are added at this stage of the process, to avoid possible alterations of these ingredients when heating the mixture during pasteurization.

Whipping and freezing: The purpose of this step is to transform the liquid mixture into a semi-solid state. During this operation, three parameters of great importance occur for the formation of the ice cream structure, which are: 1) Part of the water freezes, that is, when faster is the freezing the crystals formed will be smaller, which gives a better texture to the final product; 2) Air is added to the mix that serves as a balancer for a very fine globular structure; for which the ice cream gets consistency, sponginess and adequate texture; and 3) There is a partial release of the fats during whipping, which will result in an agglomeration of the fat particles that will stabilize in the incorporated air, thus influencing the formation and stability of the structure of the ice cream.

Incorporation of additional ingredients: This is the moment when it is necessary to add to the ice cream the ingredients that are required to give it a greater quality. Dried fruit chopped fruit and other alternatives are added to the produced ice cream.

Filling and hardening: At this stage, the ice cream goes through the automatic or manual filling lines, giving it the desired final shape (cone, cup, bulk, vase, etc.) and incorporating into the ice cream the layers or ripples that it requires, as well as the convenient decoration. When the ice cream comes out of the filling machine, it has a semi-fluid consistency; it is not hard enough to maintain its shape, depending on the filling equipment used. For this reason, the freezing process is complemented by the hardening process, which consists of lowering the temperature of the ice cream to - 25º C as quickly as possible to avoid the formation of large ice crystals.

There are several authors who have carried out profitability and pre-feasibility studies of ice cream production plants. In this sense, [12] carried out an analysis and evaluation of technical, environmental, and economic aspects at a pre-feasibility level for the production of industrial-type ice cream in Argentina. Also, in [13] a pre-feasibility study and techno-economic evaluation of the industrial production of yogurt ice cream in Argentina were carried out, in order to determine its technical, economic-financial, and environmental viability. Likewise, [14] carried out a pre-feasibility study for the installation of a traditional ice cream production plant “Muyuchy” in Ayacucho, Peru. In [15] an ice cream production process was diagnosed through simulation with Promodel Student software to determine what area represents the bottleneck for the two presentations studied, that is, the returnable containers and Peru transparent containers, thus determining that the area with the biggest problems is the filling one, proposing then the acquisition of an automatic filling machine for each evaluated presentation. On the other hand, [16] determined the feasibility of creating a company to produce canine ice cream and to commercialize ice cream for human consumption in Bogotá, Colombia. Lastly, in [17] a liqueur-based ice cream production plant was designed in Piura, Peru, determining various economic and profitability indicators of the proposed process.

The simulation, from the point of view of chemical engineering, is the solution of the equations of mass and energy balances for chemical processes in steady or dynamic state, as well as the sizing and costing of the main equipment involved in the production process. It entails computation using software models that describe chemical, physical, and biological processes, as well as other technical processes and unit operations. The basic requirements for its application require a deep knowledge of the chemical and physical properties of the pure components and mixtures, the reactions involved, and the mathematical models that, in combination, allow the simulation of a process using computational tools.

The simulation of chemical processes is a tool that has become indispensable for the adequate solution of process problems. In this scope, this tool makes it possible to analyze, design and optimize processes of interest in chemical and environmental engineering. Currently, there are several professional chemical process simulators available such as SuperPro Designer(, ChemCAD(, Aspen HYSYS(, Unisim(, among others.

The SuperPro Designer( is a professional process simulator developed by Intelligen Inc., through which the modeling, techno-economic evaluation and optimization of integrated processes are possible in a wide range of industries such as biotechnology, pharmaceuticals, food, wastewater treatment, water purification and agrochemistry. Concerning the dairy industry, this simulator has been used specifically to develop models of alternative pasteurization methods for fluid milk such as microfiltration and pulsed electric field, in order to use them to calculate energy use, greenhouse gas emissions, water consumption and economic parameters, and compare their results with conventional high-temperature, short-time pasteurization [18]. Also, in [19] the techno-economic evaluation of a goat milk powder production process was carried out with a production capacity of 106 MT/year. Similarly, in [20] the simulation of a skimmed milk production process was carried out with an annual production capacity of 700 tons.

In case of using SuperPro Designer( simulator to simulate industrial ice cream production plants, two studies are reported. The first [21] consisted of simulating a chocolate ice cream production process with an annual production capacity of 961 520 L, while in the second [22] a vanilla ice cream production plant was simulated with an annual capacity of 7 200 metric tons, where 60 % of the production is packaged in 1 kg containers, and the rest is formulated into chocolate covered sticks. However, to the authors’ knowledge, the use of SuperPro Designer( simulator to carry out the techno-economic evaluation of an industrial scale strawberry ice cream production plant has not been reported yet, so it is not known the values of the main profitability and feasibility indicators that a plant of this type could present.

Considering the above, the objective of this study consisted in carrying out an analysis of the technical and economic feasibility of an industrial-scale strawberry ice cream production process using the SuperPro Designer( simulator, and under the current economic conditions of Cuba. The main differences that this simulation study present with respect to the simulation of a chocolate ice cream production plant carried out in [21] are that several raw materials are not consumed on it such as the cream, the skimmed milk powder, and the cocoa powder, while other different raw materials are used instead in the simulation model of this work, such as Red Color 4 and strawberry syrup. Likewise, the annual production capacity of the strawberry ice cream plant is different from the annual production capacity of the chocolate ice cream plant; that is, 1 201 770 L of strawberry ice cream are produced per year in this study, while 961 520 L of chocolate ice cream are produced per year in [21]. Similarly, the cream tank used in [21] is not employed in this study since this raw material is not consumed on it. Also, the unit costs of the shared raw materials of both production processes are different. Finally, the purchase costs of the common equipment used in both simulation studies are not the same.

Comparing the ice cream production process simulated in this study with that simulated in [22], it can be found that the flavors differ (strawberry flavor in this study versus vanilla flavor in [22]) as well as the annual production capacity (1 201 770 L of strawberry ice cream versus 7 200 metric tons of vanilla ice cream) which leads to the use of different types of raw materials (the vanilla ice cream production process simulated in [22] consumes cream, vanilla flavor, glucose syrup, and skim milk powder, which are not consumed in the model simulated in this study), with dissimilar raw materials unit costs and consumption per batch. Finally, the production technology published in [2] significantly differs from that applied in this study, mainly regarding the use of a higher number of tanks, some extra raw materials dosing steps, and a scrapped surface heat exchanger after the air injection procedure.

The novelty of this work consists in that this is the first time that a technology to produce strawberry ice cream at industrial scale is simulated in SuperPro Designer( simulator, to determine its main techno-economic and profitability indicators. The main contribution of the study is that a simulation model was obtained that could be used to test new raw materials and equipment, evaluate different operation parameters in selected equipment, modify or adjust flowrates and operating times, carry out optimization studies to maximize productivity and economic feasibility, among other actions, for a strawberry ice cream production process. The production technology was implemented using data, operational and design parameters of an existent ice cream production plant located in Camagüey city, Cuba, as well as employing information published in several chemical engineering handbooks.

2. MATERIALS AND METHODS

2.1 Description of the industrial-scale strawberry ice cream production process

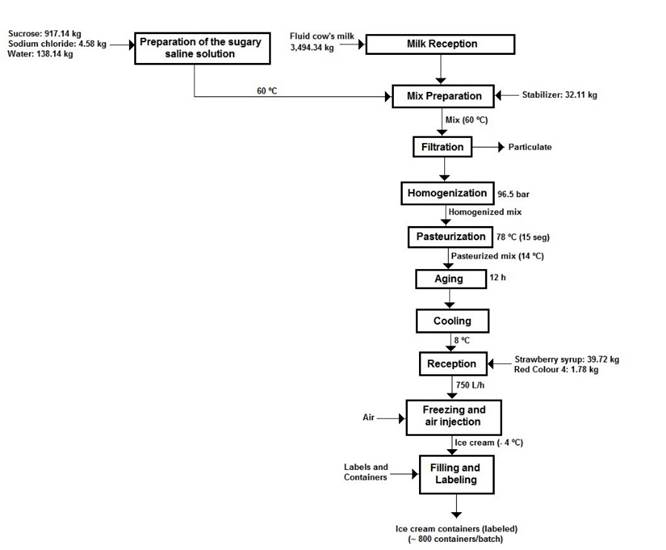

The industrial-scale ice cream production process proposed in this study consists of the following steps: 1) Reception of liquid cow milk; 2) Preparation of the sugary saline solution; 3) Preparing the mix; 4) Filtration; 5) Homogenization; 6) Pasteurization and cooling; 7) Aging; 8) Cooling; 9) Freezing and air injection; and 10) Packaging and labeling. Each of these steps is described below.

1) Reception of liquid cow’s milk: About 3 494.34 L of liquid cow’s milk are pumped to a 4 000 L cylindrical metal tank using a diaphragm pump. Once inside the tank, several quality tests are carried out to this milk to determine the following parameters: acidity, fats percentage, non-fat solids percentage, density, and temperature, with the aim of decide if this milk can be used as a raw material in the production process.

2) Preparation of the sugary saline solution: About 4.58 kg of sodium chloride, 917.14 kg of refined sugar (sucrose), and 138.14 kg of water are added to two 500 L cylindrical metal tanks with mechanical agitation. Once inside the tank, the resulting mixture is heated to 60 ºC by supplying steam at 152 ºC through the jacket of both tanks, and this temperature is maintained for 20 minutes under constant agitation by means of a blade-type stirrer. This favors the correct dilution of both raw materials in the water.

3) Preparation of the mix: Once the fluid milk is approved for utilization in the production process by the quality control department, it is pumped, by means of a centrifugal pump, towards the mixing tank, which is a 5 000 L agitated cylindrical metallic tank. The sugary saline solution is then pumped into this mixing tank once the established heating time has been completed. Then, 32.11 kg of the stabilizer (Brigel L-6108) are added to the mixing tank, and the mixture is heated to 60 ºC through the circulation of steam at 152 ºC inside the jacket of this tank and applying continuous agitation. The resulting mixture is kept at a temperature of 60 ºC for 20 minutes, with the purpose of properly dilute the stabilizer in the liquid mixture.

4) Filtration: Once the agitation time is completed in the mixing tank, the mixture contained on it is pumped by means of a centrifugal pump towards the mesh filters, to remove suspended solids and foreign material that have not been diluted in the mix preparation stage.

5) Homogenization: The preheated and filtered mixture is sent to a homogenizer where the size of all particles is reduced, with special emphasis on the fat globules, which reduce their size to less than 2 µm. This leads to a uniform distribution of the fats in the mixture, thus becoming into a genuine emulsion making the resulting mixture totally homogenous. Homogenization takes place at a pressure of 95.2 atm (1 400 psi).

6) Pasteurization and cooling: The homogenized mixture is pasteurized at a temperature of 78 ºC for 15 seconds, using hot water at 90 ºC as the heat transfer agent. Subsequently, the pasteurized mix is cooled in the same pasteurizer to approximately 14 ºC, using chilled water at 2 ºC. In this case, the pasteurization is carried out with the objective of eliminating pathogenic microorganisms that could decompose the product, while the subsequent cooling is carried out to delay the microbial development, providing greater physical and thermal stability to the pasteurized cold mixture.

7) Aging: The pasteurized and cooled mixture is sent to a 5 000 L cylindrical metallic tank where it ages for 12 hours. During this time, the proteins are hydrated, the correct combination of the stabilizer with the water takes place in order to fulfill its function effectively, as well as to ensure the solidification of the fat globules.

8) Cooling and reception of the cooled mixture: After the aging time, the aged mixture is pumped by means of a centrifugal pump though a plate heat exchanger, where it’s cooled to 8 ºC using chilled water at 2 ºC. The cooled mixture is then sent to a 5 000 L metallic tank equipped with agitation (reception tank), where 1.78 kg of the colorant Red Color 4 and 39.72 kg of strawberry syrup are added, as the prior step to the freezing and air injection procedure.

9) Freezing and air injection: The aged and cooled mix contained in the reception tank is suctioned by a pump installed in the freezer unit at a flow rate of 750 L/h, where it is whipped and frozen with the incorporation of air until it forms a 50 % of the mixture (referred to as 50 % overrun). This stage is where the ice cream is obtained at a temperature of - 4 ºC with a smooth and firm consistency, thus freezing part of the water remaining in the mixture (( 40.0 %).

10) Packaging and labeling: The ice cream formed in the freezer unit is packaged in 10 L capacity containers, and then the filled containers are appropriately labeled with labels that contain information about the batch such as ingredients content, expiry date, among other. About 830 labeled containers of strawberry ice cream are obtained per batch. In Figure 1, the block diagram of the industrial scale strawberry ice cream production process is shown.

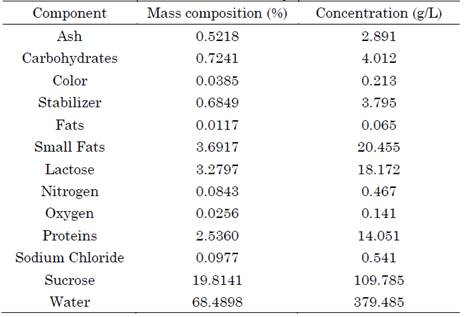

2.2 Chemical composition of liquid cow’s milk and strawberry syrup used in the simulation

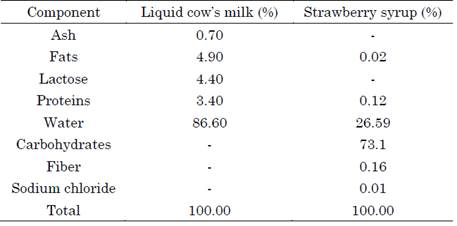

Table 1 shows the percentage chemical composition of liquid cow’s milk [23] and the strawberry syrup [24] used in the simulation.

2.3 Unit cost of raw materials

Table 2 presents the unit costs of all the raw materials consumed in the strawberry ice cream production process, which were taken from a real ice cream production plant currently installed and operating in the city of Camagüey, Cuba. The material requirements to produce one liter of strawberry ice cream are also shown.

Table 2 Unit costs of raw materials used in the industrial scale strawberry ice cream production process, and their requirements per liter of produced ice cream

Source: Created by the authors.

The amounts of raw materials used in the simulation were taken from an existing industrial-scale strawberry ice cream production process that is implemented in a real ice cream production plant located in Camagüey city, Cuba, which presents the same production capacity of containers per batch used in this study (830 labeled containers of strawberry ice cream).

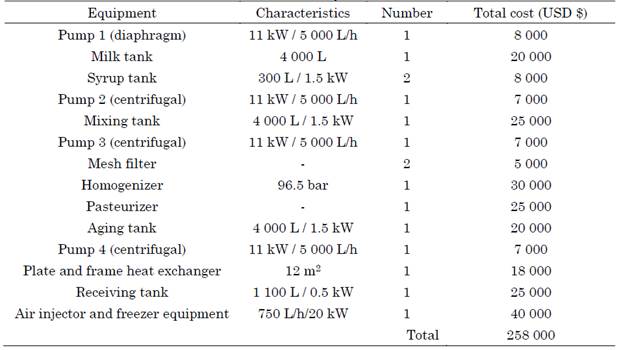

2.4 Equipment cost

Table 3 exhibits the purchase costs of all the process equipment used in the strawberry ice cream production plant [25] -[27], which were updated to the month of January 2023 using the Chemical Engineering magazine’s cost index = 1 015.6 [28]. Type 316 stainless steel was selected as the construction material for all the main equipment involved in the production process.

Table 3 Purchase cost of the main equipment used in the production process

Source: Created by the authors.

To carry out the design of the main equipment of the production process, the indications and recommendations published in [29] -[32] were taken into account, as well as design data and parameters of the equipment installed in a real industrial-scale ice cream production plant, with a production capacity of strawberry ice cream similar to that used in this study (830 labeled containers per batch),which is currently operating in the city of Camagüey, Cuba.

2.5 Simulation of the industrial scale strawberry ice cream production process in SuperPro Designer( simulator

To simulate the industrial scale strawberry ice cream production process in SuperPro Designer( simulator, the following considerations and techno-economic parameters were taken into account, which constitute the inlet data used to formulate the simulation model.

A construction period of 14 months, a startup period of 4 months and a project lifetime of 20 years were considered, as well as an interest rate of 11 % was selected to determine the Net Present Value (NPV) indicator [26].

The plant will produce at 70 % of its production level during the first five years of operation, at 90 % during the next five years (from year 6 to year 10), and at 100 % during the rest of its life (from year 11 to year 20). A product failure rate of 10 % was applied, that is, 10 % of the finished product (ice cream) produced annually in the proposed plant is discarded for not meeting the quality parameters. In this case, the discarded product is used as animal feed for pigs.

An income taxes value of 32 % was taken into account, while the annual expenses for advertising and sales were set in USD $ 2 500. The working capital was estimated to cover expenses for 15 days of labor, raw materials, utilities, and waste treatment. The startup and validation cost were assumed as 10 % of the Direct Fixed Capital [33].

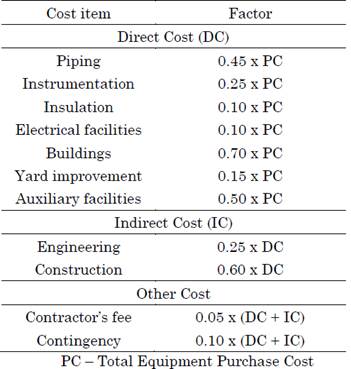

Regarding the estimation of direct fixed capital, the cost factors shown in Table 4 were taken into account for a grass-rooted/green-field type food production plant [27].

The purchase cost of the unlisted equipment was assumed as 0.40 of the total equipment purchase cost. As for the facility-dependent cost, it was determined by selecting the Capital Investment Parameters option, specifically the Maintenance (using equipment-specific multipliers) and Depreciation (using the contribution from each equipment’s undepreciated purchase cost) options.

Research and development (R&D) costs were not taken into account because these will be assumed by a research institute located in Havana city, Cuba, in order to obtain new ice cream formulations and to optimize existing ones from the techno-economic point of view, to transfer then the know-how obtained to the ice cream production plant proposed in this study. In this case, the know-how generated in the research institute is free of charge, since the main objective of this institution is precisely to obtain new ice cream formulations which must be more profitable and feasible from the techno-economic point of view, in order to be supplied to the industrial-scale production plants installed throughout the country to increase its profitability and productivity.

The depreciation of the capital investment was calculated by the straight-line method for a period of 10 years and a salvage value equal to 5 % of the initial cost.

It was also considered that the costs related to quality assurance and control are 15 % of the total cost of labor [33], that the salary of operators and supervisors is USD $ 0.28/h and USD $ 0.35/h, respectively, that the annual process validation expenses amount to USD $ 3 000 [33], while around USD $ 70 000 per year is spent due to the consumption of fuel in the boiler (this cost item is included in the miscellaneous costs of the annual operating costs, as shown in Table 9).

The plant operates 24 hours, where the operators and supervisors work in two shifts of 12 hours each, while 8 operators and two supervisors will be needed for each working shift.

Table 5 shows the utilities consumed in the proposed ice cream production plant, with their unit costs.

Table 5 Utilities consumed in the ice cream production process and their unit costs

Source: Created by the authors.

The unit cost of standard power was considered as USD $ 3.29/kWh, similar to the electricity cost of an industrial scale ice cream production plant located in the city of Camagüey, Cuba, while it was assumed that the plant consumes an additional electricity of 50 kW/h per batch.

Finally, a cycle time slack of 8 hours was considered, and 150 batches will be produced per year, while the nominal production capacity was set at 830 containers/batch. A selling price of USD $ 15.00 for each container of strawberry ice cream (10 L of capacity) was selected.

2.6 Economic profitability indicators

To evaluate the profitability of a project in the chemical industry several indicators are used, were the most important are the NPV, Internal Rate of Return (IRR), Payback Time (PT), unit production cost and Return on Investment (ROI). The NPV is a monetary figure that results from comparing the present value of income with the present value of expenses. In concrete terms, the NPV is the difference between income and expenses in dollars on the same date [34]. Is a profitability measure used to evaluate the viability of an investment or to compare the profitability of a number of different investments. It represents the total value of future net cash flows during the lifetime of a project, discounted to reflect the time value of money at the beginning of a project (i.e., at time zero). If an investment does not have a positive NPV, or if there are other opportunities with a higher NPV, then the investment should not be undertaken.

The IRR is defined as the interest rate that makes the NPV equal to zero, or also, the interest rate that equals the present value of the discounted flows with the investment. An important interpretation of the IRR is that it is the maximum interest rate at which an investor would be willing to borrow money to finance the entire project, paying with the benefits (net cash flows) the entire capital and its interest [34].

The IRR, which is also known as Discounted Cash Rate of Return (DCRR) is calculated based on cash flows before and after income taxes. The cash flow after income taxes corresponds to the net cash flow. The cash flow before income taxes is calculated as the net cash flow plus the income taxes.

The PT is a measure of the time needed for the total capital investment to be exactly balanced by the cumulative net profits. It is calculated by dividing the total capital investment charged to this project by the annual net profit. The shorter the PT, the more attractive the project appears to be.

The unit production cost is the ratio of the annual operating cost to the annual production rate. This is a significant variable of the selling price of the product and the profitability of the process, as well as a comparative basis with similar processes.

The ROI is another profitability measure used to evaluate the viability of an investment or to compare the profitability of a number of different investments. It is calculated by dividing the annual net profit by the total capital investment charged to this project. If an investment does not have a positive ROI, or if there are other opportunities with a higher ROI, then the investment should not be undertaken.

3. RESULTS AND DISCUSSION

The Figure 2 shows the process flowsheet of the strawberry ice cream production process obtained through the simulation in SuperPro Designer®.

Source: Created by the authors.

Figure 2 Process flowsheet of the strawberry ice cream production process obtained in SuperPro Designer(

3.1 Chemical composition of strawberry ice cream obtained in the simulation

Table 6 shows the percentage chemical composition and concentration of the strawberry ice cream obtained through the simulation in SuperPro Designer(.

Table 6 Percentage chemical composition and concentration of the strawberry ice cream obtained through the simulation

Source: Created by the authors.

Considering the results of Table 6, it can be indicated that the fats (small fats) content (3.6917 %) of the ice cream stream obtained by the simulation, is below the range stated by [10], which reports 7-15 % by weight for a typical ice cream and is also below the range reported by [35], while it’s within the range established by [1] which is of 2-14 %. In the case of the water (68.4898 %) and proteins (2.5360 %) content, both are within the range reported by [1] which is of 50-78 % and 1-6 % for water and proteins, respectively, while the water content is within the range reported by [10] which is of 60-72 %, and the proteins content is below the range suggested by this author, which is of 4-5 %. Finally, the simulated proteins content of this study is within the range reported by [35] of 2-3 %.

For lactose, the value determined by the simulator (3.2797 %) is below the range reported by [10], which is of 5-7 %. Also, the content of carbohydrates (0.7241 %) is below the value reported by [1], which is of 13-22 % for this component.

It can be noted from Table 6 that the three main components of the ice cream are water, sucrose, and small fats, comprising around 92 % of the simulated ice cream stream, which is in accordance with the reported by [10].

Considering that the fats (small fats) content is of 3.6917 %, the strawberry ice cream stream obtained by the simulation can be classified as milk ice cream according to the Cuban standards [36], which reports that the minimal fats content must be above 2 % for this type of ice cream.

The authors of this study consider that the simulated strawberry ice cream stream adequately agrees with the majority of the consulted literature for an ice cream of milk type, thus obtaining a healthy and nutritious food for human consumption. The results of this study validate the simulation model obtained in SuperPro Designer( with respect to the composition of the raw materials, the selected unit operations, and the mass balances performed by the simulator.

3.2 Economic evaluation

The performed techno-economic evaluation gives useful results about the simulated ice cream production process, in order to make the decision whether the project is feasible and profitable or not.

Table 7 lists the main techno-economic indicators of the strawberry ice cream production process determined through the simulation in SuperPro Designer(.

Table 7 Main techno-economic indicators of the strawberry ice cream production process

Source: Created by the authors

About USD $ 3.858 million are required to construct and erect the proposed ice cream production plant, while the annual operating cost, which includes costs that are related to the demand for a number of resources (i.e., raw materials, consumables, labor, heating/cooling utilities and power), as well as additional operational costs, reached a value of USD $ 847 000. On the other hand, the annual total revenues, the annual production capacity, and the unit production cost amounted USD $ 1.803 million, 120 177 containers and USD $ 7.04/container, respectively.

The working capital, which represents tied-up funds required to operate the business, and includes the investment in raw materials, consumables, etc., had a value of USD $ 42 000, while the startup cost, which includes pre-opening, one-time expenditures incurred to prepare a new plant for operation, was USD $ 347 000.

The gross profit, which is calculated by subtracting the annual operating cost from the total annual revenues, had a value of USD $ 956 000, while the net profit, which is calculated as the annual gross profit minus the annual income taxes plus the annual depreciation, was USD $ 980 000. The calculated values of both the gross profit and net profit indicators can be considered satisfactory and indicate the feasibility if the project [26].

The gross margin, which is a measure of profit that reflects the percentage of annual revenues that become gross profit, had a value of 53.03 %, and can be considered acceptable [26]. The Return of Investment, a profitability measure for the project that can be used to compare different investment options, had a value of 25.39 %. The payback time, which is another profitability measure that represents the time needed for the total capital investment to be recovered by the cumulative net profits, was 3.94 years, which implies that the plant is capable of recovering the investment expenses with a reasonable period of time, while the IRR, which represents the interest rate for which the NPV of a project is zero, and can be used as a reference rate to compare with interest rates (after risk assessment is included), had a value of USD 24.29 %. Finally, the NPV had a positive value of USD $ 2.860 million, thus indicating that the strawberry ice cream venture is profitable since the projected earnings generated by the ice cream production investment exceeds the anticipated production costs. Considering that the calculated payback time is less than 5 years, the IRR is higher than 20 %, and the NPV obtained has a positive value, the project can be considered economically profitable and an attractive investment [26], [27], [34].

In a previous work carried out by the authors of this study [21], an industrial-scale chocolate ice cream production plant with a production capacity of 808 10-L containers per batch was simulated in SuperPro Designer(, a total capital investment of USD $ 2.173 million, a unit production cost of USD $ 9.07/container, as well as a NPV, IRR and PT of USD $ 1.444 million, 24.45 % and 4.45 years, respectively were obtained. It is worth mentioning that in this study the 10 L container of chocolate ice cream is commercialized at USD $ 14.00.

The authors [22] carried out the techno-economic evaluation in SuperPro Designer( of a vanilla ice cream production plant with a production capacity of 7 200 metric tons of ice cream per year, where the 60 % of the production is packaged in 1 kg containers, and the rest is formulated in chocolate covered sticks. The total capital investment of this project was USD $ 18 442 million, with a unit production cost of USD $ 0.42/container, while a VAN, IRR, and PT value of USD $ 7 860 million, 9.19 % and 6.51 years respectively were obtained. In this study, the 1 kg container of vanilla ice cream is commercialized at USD $ 2.00, while the chocolate covered stick is sold at USD $ 0.30.

Another author [14] carried out a pre-feasibility study to determine the profitability of a Muyuchy traditional ice cream production plant in Ayacucho, Peru, with an annual production capacity of 55.26 MT, obtaining an NPV, IRR and PT value of USD $ 85 640.40, 36.41 % and 3.41 years, respectively. A total investment cost of the project of USD $ 62,848 was also obtained, including pre-operative interest on fixed assets, and working capital, while the sale price reached USD $ 0.234 per 50 g of product (traditional Muyuchy ice cream).

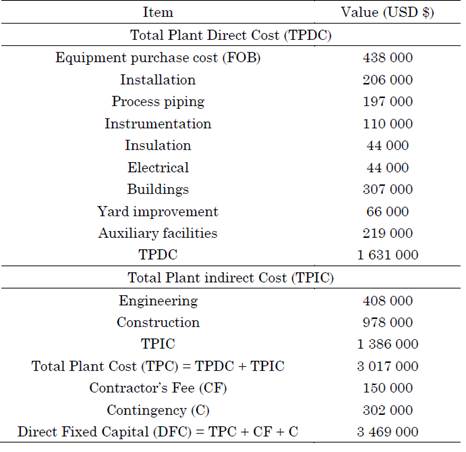

3.3 Direct fixed capital

The Direct Fixed Capital (DFC) refers to the fixed assets of an investment, such as plant and equipment. It is calculated as the sum of direct, indirect, and miscellaneous costs that are associated with a plant’s capital investment. The direct costs include cost elements that are directly related to an investment, such as the cost of equipment, process piping, instrumentation, buildings, facilities, etc. The indirect costs include costs that are indirectly related to an investment, such as the costs of engineering and construction. Additional costs such as the contractor’s fee and contingencies are included in miscellaneous costs. By default, the DFC is estimated using cost correlations to estimate the purchase cost of all major process equipment and cost factors with respect to purchase cost to generate estimates for all other cost elements. Table 8 presents the different items considered in the estimation of direct fixed capital of the project.

The equipment purchase cost, which is the vendor's selling price of major equipment [also known as the free-on-board (FOB) cost], excluding items such as taxes, insurance, delivery and installation, amounted USD $ 438 000, while the installation cost (cost item referred to the in-place construction of equipment at the new plant site and includes the cost of foundations, slabs, supports, and local equipment services), the process piping cost (cost of process fluid piping that connects the equipment, as well as connections to the main utility headers and vents, including valves, piping supports, insulation, and other items associated with equipment piping), and the instrumentation cost (cost item that includes the costs of transmitters and controllers with all required wiring and tubing for installation, field and control room terminal panels, alarms and enunciators, indicating instruments both in the field and in the control room, on-stream analyzers, control computers and local data-processing units, and control room display graphics) were USD $ 206 000, USD $ 197 000 and USD $ 110 000, respectively. Similarly, the insulation cost (which includes the cost of insulation and painting, and can become unusually high in low temperature plants such as an ice cream plant), the electrical cost (referred to the cost of electrical facilities, including battery limits substations and transmission lines, motor switch gear and control centers, emergency power supplies, wiring and conduit, bus bars, and area lighting), and the building cost [includes the cost of process towers, subsidiary concrete slabs, stairways and catwalks (not equipment-specific), control rooms and other battery limits buildings (e.g., change rooms, cafeteria, furnished offices, warehouses, etc.). It also incorporates the costs for non-electric building services as well as for a variety of safety-related items] amounted USD $ 44 000, USD $ 44 000, and USD $ 307 000, respectively. Likewise, the yard improvement cost (referred to the costs of excavation, site grading, roads, fences, railroad spur lines, fire hydrants, parking spaces, and others) and the auxiliary facilities cost (which includes the cost of process-oriented service facilities that are vital to the proper operation of the plant. An example of an auxiliary facility is a steam plant) reached the values of USD $ 66 000 and USD $ 219 000, respectively. Since it is a grass-rooted/green-field plant, the costs for the building, yard improvement, and auxiliary facilities are high [37].

Also, the Engineering cost [cost item that includes the preparation of design books that document the whole process (e.g., the design of equipment, specification sheets for equipment, instruments, auxiliaries, etc., the design of control logic and computer software, the preparation of drawings) and other engineering-related costs] and construction cost (cost item that contains the costs associated with the organization of the total construction effort. They do not include the cost of construction labor) were USD $ 408 000 and USD $ 978 000, respectively.

Finally, the contractor’s fee (which is the contractor's profit and should be added even if a corporation does its own construction, because the construction division is expected to show a profit) and the contingency cost (cost item that attempts to compensate for missing elements, while even advanced-stage estimates will include a contingency to account for unexpected problems during construction, such as strikes, flooding, delays, and unusually high price fluctuations) were USD $ 150 000 and USD $ 302 000, respectively. In conclusion, the direct fixed capital for this project amounted USD $ 3.469 million.

In [21] the direct fixed capital has a value of USD $ 1.737 million, while in [22] the value of this parameter is of USD $ 15.876 million.

It is important to state that the techno-economic evaluation performed in this work is a preliminary study, that is, the present estimate can be classified as class 4 (study estimate), according to the generally accepted classification for capital cost estimations based on that published by the Association for the Advancement of Cost Engineering (AACE International) [38]. Specifically, the equipment is roughly sized, and the approximate cost is determined. The total cost of the equipment is then factored to give the estimated capital cost. Thus, the results obtained from the performed economic analysis provide information to decide whether the project can be continued or not, which is an important step for further systematic and accurate economic evaluations.

3.4 Annual operating costs

The operating cost of a project includes costs that are related to the demand for a number of resources (i.e., raw materials, consumables, labor, heating/cooling utilities and power), as well as additional operational costs. Table 9 breaks down the different cost items involved in the annual operating cost, along with their percentage contribution.

Table 9 Cost items involved in the annual operating cost, and their percentage influence

Source: Created by the authors.

The facility-dependent cost [which accounts for additional costs related to the use of a facility and was estimated in this study based on capital investment parameters (i.e., maintenance and depreciation of the fixed capital)] constitutes the first cost item that contributes the most to the annual operating costs, with USD $ 356 000 (42.03 %). This is due to the significant maintenance and depreciation costs incurred by the production process, which is common for high-value products that are produced in single-product facilities. To reduce the impact of this cost, the food and chemical processing industries tend to use multi-product facilities where a number of products are manufactured in campaigns throughout the year.

The second most significant cost item was the utilities [which is the total cost of heating/cooling utilities (i.e., heat transfer agents) and power utilized in the production process], with USD $ 215 000 (25.44 %). This is because the high demand for electricity, steam, hot water, glycol, and chilled water by the equipment installed in the production process, particularly the pumps, agitated tanks, cooler, air injection equipment and pasteurizer.

The raw materials consumption is the third most significant cost item that affects the annual operating cost, with USD $ 196 000 (23.14 %). This is due to the relatively high consumption of the several raw materials and materials used in the production process, mostly liquid milk (annual cost of USD $ 121 235, see Table 10) and the 10 L containers (USD $ 52 077).

Table 10 Cost items involved in the materials cost, and their percentage influence

Source: Created by the authors.

In [21] the annual operating cost was of USD $ 862 000, while in [22] a value for this parameter of USD $ 24.122 million was obtained. As noted, the resulting annual operating cost of [21] is the same as the value of this parameter obtained in this study. In this case, the raw materials cost of [21] (USD $ 367 000) is about 1.87 times higher than the value of this parameter for this study (USD $ 196 000), which is due to the consumption of more expensive raw materials such as cocoa powder, cream, and skimmed milk powder. Some other cost items that are higher in value in [21], as compared with this study, are the labor-dependent (3 times) and laboratory/QA/QC (1 time), which is due to the higher demand of operators, quality control personnel, supervisors and other workers needed, because the highest amount of equipment involved, as well as the use of more perishable raw materials to which it is necessary to carry out quality tests prior to be consumed in the chocolate ice cream production process. Also, the facility dependent costs of this study (USD $ 356 000) are 1.96 times higher than the results of this parameter in [21] (USD $ 182 000), which is due mainly to the realization of more batches that lead to more equipment depreciation and maintenance, as well as because the capital costs of this study are higher than those of [21], since the facility-dependent costs and capital costs are intrinsically related to each other, according to [39]. Finally, the miscellaneous and utilities costs are practically the same between the simulation carried out in [21] and this study, which is due to the almost equal consumption of fuel in the boiler, the almost identical demand of steam, chilled water and hot water by the equipment involved in the process flowsheet, while the utilities have the same unit cost in both studies.

3.5 Materials cost

The materials cost is the total cost of all bulk materials (pure components and stock mixtures) and discrete entities (containers, bulbs, bags, etc.) that are utilized as raw materials in a process. These may include:

Bulk materials and/or discrete entities contained in process input streams that are either classified as “raw material” or “cleaning agent” streams.

Bulk materials that are used as heat transfer agents in process operations.

In SuperPro Designer(, the annual cost of each material is calculated by multiplying the corresponding unit cost (i.e., purchasing price) by the corresponding annual amount that is utilized in a process. The user specifies the unit costs of materials, whereas the corresponding annual amounts are calculated by the program as part of the simulation.

Table 10 shows a breakdown of the items included in the materials cost for the simulated strawberry ice cream production process.

The two items that contribute the most to the materials cost are the milk (61.89 %) and containers (26.58 %). In case of milk, this is because it is the raw material with the highest consumption per batch (3 494.34 kg) and thus annually (551 067 L) while the containers are in second place since the relatively high number of containers consumed per batch (( 830) and annually (133 530), as well as because its unit cost (USD $ 0.39). It is worth noting that both the milk and containers items comprise about 89 % of the total cost of materials.

In [21], the cost of materials was USD $ 367 000/year, where milk was the item with the greatest influence on this cost with 29.30 %. This is due to the fact that the milk is the item with the highest annual consumption, with 286 318 L, and also because its requirement (0.255 kg of milk are needed per L of chocolate ice cream produced) is the highest of all the raw materials.

On the other hand, in [22] the cost of materials has a value of approximately USD $ 14 388 million, where milk powder is the item with the greatest influence on this cost with 18.47 %. This is because the skim milk powder has the fourth highest unit cost (USD $ 4.00/kg) and the fourth highest annual consumption (661 196 kg) of all the raw materials used in this study.

Summarizing, the milk is the raw material with the highest cost in this study because it presents the highest consumption per batch and thus annually, while the milk is the raw material with the highest cost in [21] since it exhibits the highest annual consumption. Finally, the skim milk powder constitutes the raw material with the highest cost in [22] because it has the fourth highest unit cost and also the fourth highest annual consumption.

The authors of this investigation consider that the validation error of the simulation model obtained in this study is very low due to the veracity and actuality of the inlet data used during the simulation process, which were obtained either from a real existing ice cream production plant installed in Camagüey city, Cuba that produces strawberry ice cream with the same production capacity per batch than the production capacity used in this study, or from updated bibliographies and references, mostly chemical engineering and simulation handbooks. The accuracy and reliability of the inlet techno-economic data used in this simulation study decreases the validation error of the model obtained to a very low value.

4. CONCLUSIONS

The need to implement profitable and cost-effective production processes is undeniable and imperative at present, which has led to the incremented application of professional simulators to carry out the conceptual design and techno-economic evaluation of chemical, biotechnological, food, water and wastewater treatment, and petrochemical processes of global and national interest. Computer-aided simulation was successfully employed in this work to evaluate for the first time an industrial-scale strawberry ice cream production process from the techno-economic point of view, in order to determine its main profitability and productivity indicators. To achieve this goal, the professional simulator SuperPro Designer( was used as the simulation tool. The main conclusions drawn from the simulation study, based on the investigated objectives, are the following:

The percentage mass composition of the strawberry ice cream obtained through the simulation adequately adjusts to the intervals reported in the literature, classifying it as milk ice cream according to the current Cuban standard.

A total capital investment of USD $ 3 858 million and a direct fixed capital of USD $ 3 469 million are required to build the proposed plant, while the startup cost will be USD $ 347 000.

The unit production cost of one container of 10 L of strawberry ice cream was USD $ 7.04, while the annual operating cost and the annual revenues were of USD $ 847 000 and USD $ 1 803 million, respectively, considering a sale price of USD $ 15.00 for the 10-L container of strawberry ice cream.

Taking into account the values obtained of NPV (USD $ 2 860 000), IRR (24.29 %) and PT (3.94 years) indicators, it is concluded that the proposed strawberry ice cream production plant is feasible and profitable from the investment point of view under the current economic conditions of Cuba.

In this way, process simulation constitutes a powerful tool for the conceptual design of different industrial-scale ice cream production processes, thus involving the selection of the best investment project. In addition to determining the economic parameters of the process, the simulation model obtained in this study allows knowing the mass and energy balances, determining critical techno-economic parameters and their influence on the overall productivity and profitability of the evaluated production process. Also, this simulation study represents a supporting tool for decision making about investment projects involving the selection of profitable ice cream production methods at industrial scale.