Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Tecnura

Print version ISSN 0123-921X

Tecnura vol.15 no.30 Bogotá July/Dec. 2011

Setting parameters in the cold chain

Ajuste de parámetros en la cadena de frío

Victoria Rodríguez1, Itxaso Amorrortu2, María Jesús Álvarez3

1 Ingeniera de producción agroindustrial, doctora en Ingeniera Industrial. Docente de la Universidad de Navarra. Pamplona, España. vrodriguez@unav.es

2 Ingeniera en organización industrial. Docente de Mondragon Unibertsitatea. Mondragon, España. iamorrortu@eps.mondragon.edu

3 Ingeniera agrónoma, doctora en Ingeniería Agrónoma. Docente de la Escuela de Ingenieros Universidad de Navarra. Pamplona, España. mjalvarez@tecnun.es

Fecha de recepción: 30 de mayo de 2011 Fecha de aceptación: 29 de agosto de 2011

Abstract

Breaks in the cold chain are important economic losses in food and pharmaceutical companies. Many of the failures in the cold chain are due to improper adjustment of equipment parameters such as setting the parameters for theoretical conditions, without a corresponding check in normal operation. The companies that transport refrigerated products must be able to adjust the parameters of the equipment in an easy and quick to adapt their functioning to changing environmental conditions. This article presents the results of a study carried out with a food distribution company. The main objective of the study is to verify the effectiveness of Six Sigma as a methodological tool to adjust the equipment in the cold chain. The second objective is more specific and is to study the impact of: reducing the volume of storage in the truck, the initial temperature of the storage area in the truck and the frequency of defrost in the transport of refrigerated products.

Key words: Cold chain, control, parameter setting, six sigma methodology.

Resumen

Las rupturas en la cadena de frío representan importantes pérdidas económicas en las empresas farmacéuticas y alimentarias. Muchos de los fallos en la cadena de frío se deben a un inadecuado ajuste en los parámetros de los equipos, como por ejemplo el ajuste de los parámetros para condiciones teóricas, sin su correspondiente verificación en condiciones normales de operación. Las empresas que transportan productos refrigerados deben ser capaces de ajustar los parámetros de los equipos de una manera fácil y rápida para adaptar su funcionamiento a los cambios en las condiciones ambientales. En este artículo se presentan los resultados de un estudio llevado a cabo con una empresa distribuidora de alimentos. El principal objetivo de estudio es verificar la efectividad de la metodología "Seis sigma" como herramienta metodológica para ajustar los parámetros de los equipos en la cadena de frío. El segundo objetivo es más específico y consiste en estudiar el impacto de: la reducción del volumen de almacenamiento en el camión, la temperatura inicial del área de almacenamiento en el camión y la frecuencia de descarche en el transporte de productos refrigerados.

Palabras clave: Cadena de frio, control, ajuste de parámetros, metodología "Seis sigma".

1. Introduction

Though processes related to the food industry are widely regulated and associated with a series of practices [1, 2], European Standard EC 2073/2005, the application of these practices does not guarantee that a determined product has not suffered a breakage in its cold chain. This fact has triggered constant concern for food distribution companies regarding the control of their cold chain. Even though this control is costly from both an economic and operative perspective [3], it is compensated with the reduction of costs produced by the deterioration of products. An interesting way to improve the quality of the perishable products is to assure the stability of cold chains in the cold chains management [4].

A number of variables intervene throughout the cold chain, such as the temperature and humidity that surround the refrigeration units, maintenance practices and equipment control parameters, among others. Some of these variables are uncontrollable. In transportation, for example, these variables determine the operation of a specific unit used for transporting frozen products. Therefore, it is impossible to establish standard operating parameters for a specific unit. This challenge highlights the need to adjust these parameters in accordance with the specific conditions of each delivery; characteristics such as the type of route to be covered and the geographic area of operation, among others.

Next, results will be presented from a project which had the following objectives: a) to verify the effectiveness of the Six Sigma methodology to quickly define parameter adjustment procedures and b) to study the impact of the truck volume reduction system, the temperature at the beginning of the route and the frequency of defrosting during temperature maintenance in the transportation of frozen products. This paper is structured in the following way: in the first section, the most relevant aspects of the cold chain will be discussed, in the following section the main research question will be presented, followed by an explanation of the methodology used and results yielded. Finally, conclusions will be presented.

2. Theoretical Backgrounds

With the aim of preventing the deterioration and contamination of food, a number of conservation techniques are used, some of which incorporate additives, treatments with microorganisms, subjecting products to high pressure, drastic changes in temperature or cooling [5]. Of all of these techniques, cooling is the least aggressive in terms of how it affects the product [2]. Studies such as the one carried out by [6] reveal that the use of timetemperature indicators can be more effective in regards to product quality control compared to a simple microbiological count.

One of the fundamental objectives of governments worldwide is to increase the level of protection of public health. In order to achieve this, different organizations have been created with the aim of establishing a foundation to boost the security of food products [1, 7]. One of these organizations is the International Institute of Refrigeration, which was created by various governments to raise awareness of all areas of refrigeration worldwide [2]. In accordance with European EC 2073/2005, "the security of food products can be mainly guaranteed through a preventative approach, such as the adoption of sound hygienic practices and the application of procedures based on HACCP principles".

Controlling the cold chain is a fundamental aspect for all companies in the food and health industries. The use of cooling in the food sector has increased significantly over the years due to globalization and an increase in the consumption of pre-cooked products. Pre-cooked products are those whose raw materials undergo a higher rate of manipulation and in which many cases have an extended life cycle [8]. During the last years progress in the control of the cold chain have been directed to transparency, information and tracking, which stems from the development of new technologies [9, 10].

In order to guarantee food quality, it is necessary to ensure that the cold chain does not break along any of its links. Breakage in the cold chain could happen under any of the following circumstances: the doors of the refrigeration unit remaining open for an excessive period of time, equipment fails to cool correctly due to an excessive amount of ice in the cooling coils, failure of the temperature control's thermocouples or if the product is left out of the refrigeration units for an excessive amount of time. The latter case occurs frequently during the loading and unloading of trucks and during the process of product repositioning on store shelves.

Two methods are used to ensure the traceability of a product and the conditions under which it has been stored, one of which consists of measuring the temperature of the product at different points of the cold chain. The second method is based on controlling the air temperature in which the product is being stored. The first method only allows the detection of breakage of the cold chain that occurs moments before measurement and if the breakage significantly alters the product's temperature.

A number of techniques are used to control the storage conditions of the product, such as : a) the manual measurement of selected parameters along different points of the cold chain, parameters such as specific humidity or the temperature of the products at specifc points of the cold chain; b) the use of technologies that allow the monitoring of the product's storage and transportation conditions (tracking) with radio frequency-based technologies (RFID) [11] [12], ZigBee technology

[13] or those based on GPRS. The pharmaceutical industry employs product temperature-slowing strategies based on the introduction of special gel packets into containers [14]. Despite the fact that these measures are fairly effective, the resulting cost increase when applied to food renders these measures to be impractical.

The economic losses suffered by distribution companies due to cold chain breakages is significant; in the health sector, in accordance with graphs presented by a warehouse distribution inspector for the Medicines and Healthcare products Regulatory Agency's (MHRA) 2001 meeting, 22% of serious infractions reported during inspections in 1999/2000 were related to the control and monitoring of in-transit temperatures [14]. Maintaining the cold chain throughout a product's entire life cycle is costly but fundamental as any breakage causes product deterioration. The proper control of the cold chain can be advantageous [9].

Food distributors are able to control the cold chain up to the moment that the product leaves the refrigeration or freezing unit. However, a number of studies show consumers rarely treat products adequately after purchase [15]. This fact highlights the importance of maintaining a rigorous control of product storage conditions on the part of food distributors, as a product in optimum conditions would be able to better withstand being submitted to inappropriate conditions compared to one which has suffered deterioration on a store shelf.

One of the main problems faced by those who maintain the cold chain is the difference between the theoretical behavior of its refrigeration systems and the real behavior of these systems. This difference is a result of the fact that equipment that makes up the system is designed for a theoretical situation; while during daily company activity there is a great number of hard-to-control variables that interfiere with the process and considerably affect the performance of the system. Therefore, those who utilize refrigeration equipment should maintain a permanent relationship with cooling maintenance companies, which are in charge of ensuring the proper performance of cooling equipment.

Uncontrollable variables are of a different type, for example the temperature of a structure encasing the refrigeration unit, the product being stored in the unit, the level of humidity and the loading and unloading methods of trucks, among others. That is why, in the case of the cold chain, it is necessary to adjust equipment performance parameters for real conditions. Furthermore, the system should be permanently controlled to verify if the value of the established parameters is correct. In the food industry, confirmatory studies of real situations are common [16, 6].

Despite the fact that cold chain control is such an important factor to distributors, methodologies and tools to systematize control have yet to be developed from an academic perspective. Tools such as Total Quality Management (TQM) or Six Sigma exist within the quality field, which allow problem resolution systematization.

Specifically, Six Sigma is a tool that can be very useful for organizations because it is based on measurable aspects of problems which a number of authors have considered to be a weak point of the methodology [17]. When it comes to controlling the cold chain, the use of measurable aspects is advantageous because temperature acts as the product quality control parameter and the ability to measure the impact that different practices have on temperature can justify the change of a certain procedure or parameter.

In the case of transportation, it could be said that as a general guideline, distributors subcontract part or all of transportation, which puts stress on the relationship between both the company and the subcontractor as both parts seek to improve the quality of the product at the lowest possible cost.

The impact that any modification proposed during established procedures has on product quality and costs should be clearly justifed, as this often implies renegotiation of certain contractual elements. Considering that the quality of the product (measured in terms of temperature) and costs are measurable aspects, Six Sigma is an appropriate tool to carry out the study.

Six Sigma is a tool that has been successfully utilized by many organizations. However, it is also true that it has failed for many organizations; one of the reasons for these failures resides in the lack of guidelines for the effective implementation of Six Sigma [18]. In the study presented in this paper, Six Sigma has been used as a methodological tool which obtained useful results for the company in question.

3. Project Descriptions

The case presented here was developed for a food distribution company in its transport processes. The first step in the project was to defne the project team, which included two university researchers and one person in charge of the process of transporting frozen goods.

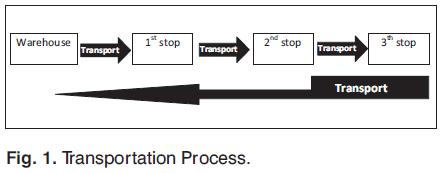

Once the project team was established, the analysis process was studied. The phases of the transportation process can be seen in Fig. 1.

The second step was to identify the factors that could influence the loss of product quality and to define the project. The following project objective was established: to reduce both the number of serious incidents and the variation of temperature during the transportation of frozen products. A serious incident has been defined for this project as one in which the average temperature is above -18ºC. Critical factors can be seen in Fig. 2 and will be described in the following section.

4. Methodology

In this section, the way in which each phase of the DMAIC (Define, Measure, Analyze, Improve and Control) was carried out will be described in the frozen product transportation analysis.

4.1. Define

The first step was to create a definition and commitment page for the project. This document was titled "Project definition." On this page, the project title, description of the problem, quantifed objectives, team and project description appear. The fish-bone diagram, which can be seen in Fig. 2, was essentially the first step in defining the problem and the experiments. It was observed that the factors that could have influenced product quality were controlled by company policy. For example, company policy requires doors to remain closed as long as possible during unloading, while, on the other hand, the refrigeration system must be running during unloading.

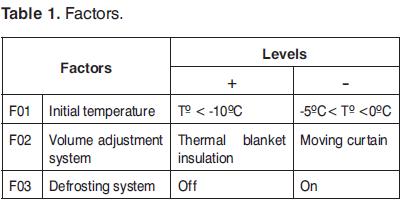

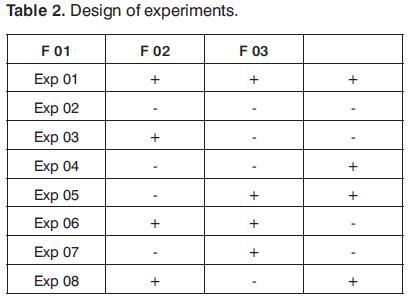

It was considered fundamental during this initial analysis to study the impact that the following factors had on temperature maintenance: refrigeration unit temperature at the beginning of the route, the volume adjustment system and the frequency of defrosting. A complete design of experiments, including three factors at two levels, was chosen to be carried out for the study. Factors with corresponding levels can be seen in Table 1.

The first step was to determine the following: average temperature, percentage of incidents and standard temperature fuctuation. For our purposes, an incident will be defined as any time temperatures exceed -18ºC.

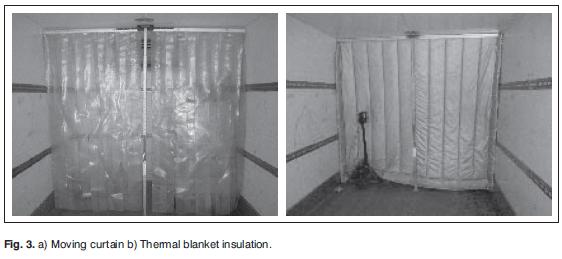

The volume adjustment systems consisted of a moving curtain and thermal blanket insulation. The moving curtain is made up of a series of plastic pieces hanging from a moving rail installed in the ceiling of the refrigeration unit (Fig. 3A), while the thermal blanket consists of one piece of insulation hanging from a moving rail (Fig. 3B).

When it came to the frequency of defrosting, two conditions were chosen for analysis: the equipment default defrosting system and the deactivated defrosting system. The design of experiments can be seen in Table 2.

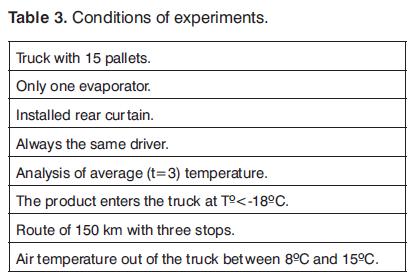

The conditions under which the experiments were conducted can be seen in Table 3a.

Programmable loggers and the GPRS thermocouple installed to control the refrigeration system acted as the instruments of measurement. The exact time at which the first (initial register) temperature gauging and final register, which corresponded with the beginning of the experiment, were carried out were recorded in the loggers. Furthermore, the frequency of the registers was closely watched and temperatures were logged every 2 minutes in every case. Each logger is equipped with two thermocouples, one of which was used to measure product temperature while the other was utilized to measure the temperature surrounding the product.

4.2. Measure

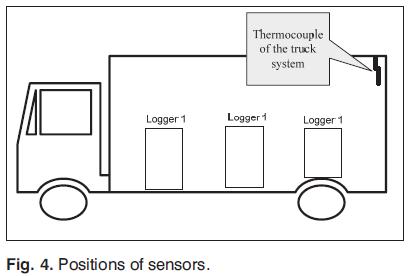

In each experiment, three loggers were placed on the upper part of three pallets located in different positions within the truck. Logger 1 left the truck during the first unloading, Logger 2 during the second and Logger 3 during the last. The positions of all three loggers within the truck can be seen in Fig. 4.

Product temperature was measured by cutting a bar of ice in half and inserting a thermocouple. The ice and the logger were then placed in a Tupperware container. The ice, logger and Tupperware container remained in the frozen product unit from the night before until the time the experiment was conducted. A procedure was es-tablished to define the steps that the driver should take at each stop. This procedure was explained to the driver before the route commenced.

4.3. Analyze

In this phase, average temperature, percentage of incidents and temperature variation were analyzed.

4.4. Improve

Once the parameter values were determined and the performance guidelines defined, they were passed along to everyone involved in the process of transporting frozen food and put into practice.

4.5. Control

Controlling the effectiveness of the measures taken is carried out through the control center of the company, which constantly receives information regarding registered temperatures and incidents. This results in the calculation of the cold indicator.

5. Results

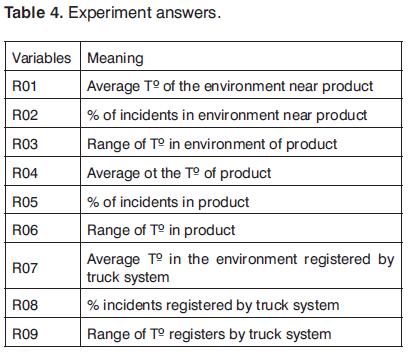

The variables analyzed were the average temperature of every register, the percentage of incidents and temperature variation. These three variables were initially obtained at three points: three pallets at different positions within the truck and the data registered by the truck's GPRS (truck system). Of all the registers taken by the loggers on the multiple-positioned pallets, only the analysis of the last logger to leave the truck was taken into consideration because the loggers unloaded during the frst two stops did not yield sufficient data to carry out the analysis. The analyzed variables can be seen in Table 4a.

After analyzing the effects and interactions of the three factors in the nine variables, it can be seen that the variation of the factors only affects the range of temperatures registered in the environment near the product and the temperatures registered by the truck system (R09). Therefore, factor variation does not impact any of the variables registered inside the product (R04, R05 and R06). This is noteworthy because, in order to achieve temperature variation in the center of the product, the temperature change must be long-lasting, something which never occurred.

On the other hand, it could be observed that para-meter variation affected neither the average temperature nor the percentage of incidents in the environment near the product (R01 and R02). This result was also found in the temperatures registe-red for the truck system (R07 and R08).

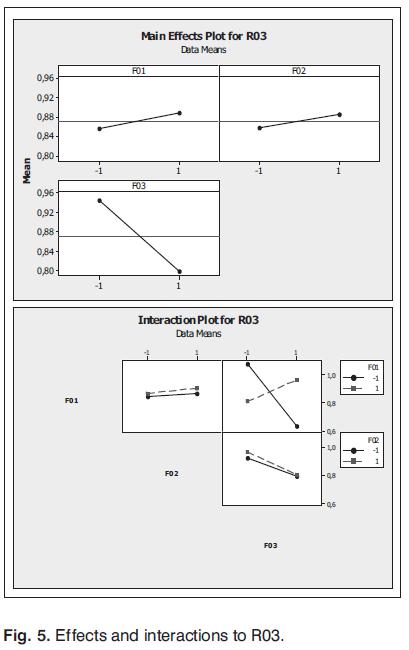

Fig. 5 illustrates that the effect which most impacts temperature variation in product environment is the current state of the defrosting system (F03). Therefore, it could be said that deactivating the truck's defrosting system reduces temperature variation. The interaction between temperature at the beginning of the route (F01) and the defrosting system (F03) (Fig. 5b) shows that having the defrosting system shut on or off produces a greater impact on temperature variation when the temperature of the truck at the beginning of the route is between 0 and -5ºC compared to when it is at a temperature below -10ºC. This is a plausible result, since when the truck starts its route at 0ºC, the system tends to cool at -18ºC, while if the truck leaves at -10ºC, and temperature variation is lower.

In Fig. 6 a and b it can be seen that leaving the defrosting system deactivated (F03) produces, in every case, a reduction in temperature variation in the registers taken by the truck system (R09). It can also be seen that the change in the volume adjustment system (R02) produces a much greater impact on temperature variation when the initial temperature of the truck is between 0 and -5ºC (R01). As was explained in the prior case, temperature during the route tends to stay at -18ºC.

6. Conclusions

In accordance with the results, it can been seen that the variable which most impacts the reduction of environmental temperature variation within the truck, both in the data registered by the truck system as well as in the environment near the product, is the state of the defrosting system. It can be seen that if the system is deactivated, the environmental temperature becomes more stable. In agreement with these results, a subsequent study was proposed to more precisely adjust the parameters of the truck's defrosting system. Not all routes can be covered with the defrosting system turned off as this would have eventually broken the refrigeration equipment. In these experiments, the evaporator was revised at each stop to verify that no icing had accumulated. It could be seen that because of the characteristics of the route (duration and number of stops), it is possible to carry out these revisions without activating the defrosting system.

The experience of this project was very positive for the company involved because it allowed for project development standardization to control the cold chain through the utilization of Six Sigma as an improvement tool. The development of this project has been a learning experience where the team defined a procedure type to develop projects and academics provided the necessary statistical analysis to develop subsequent projects.

7. Acknowledgments

We are grateful to the food distribution company that financed this project, to the employees involved and to the invaluable members of the team.

References

[1] S. Jol, A. Kassianenko, K. Wszol and J. Oggel, "The cold chain, one link in Canada's food safety initiatives," Food Control. vol. 18, pp. 713-715. Nov. 2005. [ Links ]

[2] D. Coulomb, "Refrigeration and cold chain serving the global food industry and creating a better future: two key IIR challenges for improved health and environment," Trends in Food Science & Technology, vol. 19, no, 8, pp. 413-417, 2008. [ Links ]

[3] J. Kuo and M. Chen, "Developing an advanced multi-temperature joint distribution system for the food cold chain," Food Control, vol. 21, no. 4, pp. 559-566, Apr. 2010. [ Links ]

[4] M. Bogataj, L. Bogataj, and R. Vodopivec, "Stability of perishable goods in cold logistic chains," International Journal of Production Economics, vol. 93-94, pp. 345-356, Jan. 2005. [ Links ]

[5] B. Marcos, A. Jofré, T. Aymerich, J. Monfort and M. Garriga, "Combined effect of natural antimicrobials and high pressure processing to prevent Listeria monocytogenes growth after a cold chain break during storage of cooked ham," Food Control, vol. 19, no. 1, pp. 76-8, 2008. [ Links ]

[6] M. Smolander, H. Alakomi, T. Ritvanen, J. Vainionpaa and R. Ahvenainen, "Monitoring of the quality of modified atmosphere packaged broiler chicken cuts stored in different temperature conditions. A. Time- temperature indicators as quality-indicating tools," Food Control, vol. 15, no. 3, pp. 217-229, Apr. 2004. [ Links ]

[7] K. Likar and M. Jevsnik, "Cold chain maintaining in food trade," Food Control, vol.17, no. 2, pp.108-113, Feb. 2006. [ Links ]

[8] S. Beasley, "The current state of the cold chain in the Philippines," United States Department of Agriculture. Trade and Investment Program of Food Industries Division, Foreign Agricultural Service. 1998. [ Links ]

[9] R. Montanari, "Cold chain tracking: a managerial perspective," Trends in Food Science & Technology, vol. 19, no. 8, pp. 425-431, Aug. 2008. [ Links ]

[10] T. Moe, "Perspectives on traceability in food manufacture," Trends in Food Science & Technology, vol. 9, no. 5, pp. 211-214, May. 1998. [ Links ]

[11] E. Abad, et ál, "RFID smart tag for traceability and cold chain monitoring of foods: Demonstration in an intercontinental fresh fish logistic chain," Journal of Food Engineering, vol. 93, no. 4, pp. 394-399, Aug. 2009. [ Links ]

[12] C. Metzger, F. Michahelles and E. Fleisch, "Ambient energy scavenging for sensorequipped RFID," Smart sensing and context- Second European Conference. Berlin. 2007. [ Links ]

[13] A. Carullo, S. Corbellini, M. Parvis, L. Reyneri and A. Vallan, "A measuring system for the assurance of the cold-chain integrity," Presented at the IEEE International Instrumentation and Measurement Technology Conference, Vancouver, May. 2008. [ Links ]

[14] M. Elliott and G. Halbert, "Maintaining the cold chain shipping environment for phase I clinical trial distribution," International Journal of Pharmaceutics, vol.299, pp. 49-54, Aug. 2005. [ Links ]

[15] A. Ovca, and M. Jevsnik, "Maintaining a cold chain from purchase to the home and at home: consumer opinions," Food Control, vol. 20, no. 2, pp. 167-172, Feb. 2009. [ Links ]

[16] H. Rediersa, M. Claesa, L. Peetersa and K. Willemsa, "Evaluation of the cold chain of fresh-cut endive from farmer to plate," Postharvest Biology and Technology, vol. 51, no. 2, pp. 257-262, Feb. 2009. [ Links ]

[17] T. Goh, "A strategic assessment of six sigma," Quality and Realiability Engineering International, vol. 18, no. 5, pp. 403-410, 2002. [ Links ]

[18] S. Chakravorty, "Six Sigma programs: an implementation model," International Journal of Production Economics, vol. 119, no. 1, pp. 1-16, May. 2009. [ Links ]