Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Tecnura

Print version ISSN 0123-921X

Tecnura vol.18 no.spe Bogotá Dec. 2014

https://doi.org/10.14483/udistrital.jour.tecnura.2014.DSE1.a01

DOI: http://doi.org/10.14483/udistrital.jour.tecnura.2014.DSE1.a01

Decision-making model for the development of productive capacity as a component of a knowledge management system

Modelo de toma de decisiones para el desarrollo de la capacidad productiva como un componente de un sistema de gestión de conocimiento

César Amílcar López Bello*, Victor Hugo Medina García**, Lorna Udden***

* Industrial Engineer, Specialization in production engineering, Master of industrial engineering professor Faculty of Engineering. District University Francisco José de Caldas (Bogotá, Colombia). Contact: clopezb@udistrital.edu.co

** Systems Engineer, Specialization in Marketing, MSc in Information Technology, MSc in Management of Web sites, PhD. in Computer Engineering Professor and Director of the Extension Unit of the Faculty of Engineering District University Francisco José de Caldas (Bogotá, Colombia). Contact: vmedina@udistrital.edu.co

*** B. Sc. (Hons) Computer Science, B.A. (open) (Open University), PhD. "Courseware Engineering Methodology for Technology-based Learning" Emeritus Professor of Information Technology System Staffordshire University (Staffordshire, UK). Contact: L.Uden@staffs.ac.uk

Fecha de recepción: June 10th, 2014 Fecha de aceptación: November 4th, 2014

Citation / Para citar este artículo: López Bello, C. A., Medina García, V. H., & Udden, L. (2014). Decision-making model for the development of productive capacity as a component of a knowledge management system. Revista Tecnura, 18 (Edición especial doctorado), 16-29. doi: 10.14483/udistrital.jour.tecnura.2014.DSE1.a01

Abstract

This paper presents a model of mixed integer programming optimization, used to the management and development of productive capacity; it is also used for planning and formulation of strategies for expanding and adjusting organizational activities in the medium and long term.

The model constitutes an element of organizational intelligence and is part of the system of decision support; it provides a tool for analysis and processing of information and help decision-makers to act in an efficient and effective way to solve development problems of productive capacity.

Furthermore, in the article to assess the relevance and consistency of the model presents a prototype manufacturing organization in a scenario that requires the development of capacity in terms of growth in demand for goods and services offered.

Keywords: Business Intelligence, Capacity Management, Decision Support System, Knowledge Management System.

Resumen

En este trabajo se presenta un modelo de optimización de programación entera mixta, que se utiliza para la gestión y desarrollo de la capacidad productiva; además, se utiliza para la planificación y la formulación de estrategias de ampliación y ajuste de las actividades de la organización en el mediano y largo plazo. El modelo constituye un elemento de la inteligencia organizacional y es parte del sistema de apoyo a las decisiones; proporciona una herramienta para el análisis y procesamiento de la información y ayuda para actuar y tomar decisiones de una manera eficiente y eficaz al resolver problemas de desarrollo de la capacidad productiva.

Palabras clave: gestión de la capacidad, inteligencia de negocios, sistema de gestión de conocimiento, sistema de apoyo a la toma de decisiones.

Introduction

The development of organizations producing goods and services in a highly competitive environment depends directly on their ability to make decisions, so it is essential to equip companies with intelligence.

Other features of a learning organization include its ability to adapt to the conditions offered by the environment as well as its promptness to quickly react to the trends and behavior of a changing and highly competitive market.

Providing an organization with intelligence involves creating an infrastructure for companies to develop and sustain within a competitive environment. To this end, organizations must adopt organizational learning models that promote and ease the flow of knowledge to support the efficient and effective accomplishment of organizational actions and decisions.

The infrastructure requires integration of a Decision Support System (DSS) as well as of a knowledge management system to deploy both individual and collective capabilities towards building organizational capabilities.

The construction of decision support systems built from an integral (holistic) approach constitutes an information processing device that allows the generation of knowledge, which, in turn, clarifies and guides the decision-making process.

The purpose of a decision support system is to provide analysis tools and also lay the foundations (information and structure) for management solving problems in organizations producing goods and services.

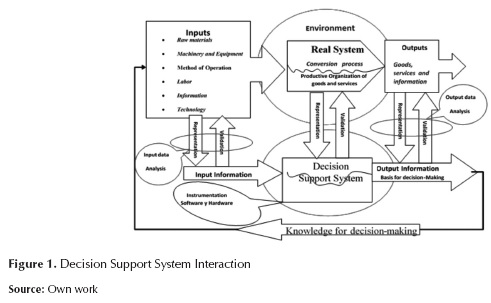

To describe the role of decision-making processes based on a Decision Support System (DSS), a model developed herein is proposed (Figure 1).

The process starts in a first stage that consists of defining the system. This definition establishes the constituent components from observation and analysis.

The second stage consists of representing the real system and its problems using models. In this stage, different models may arise since system can be represented in several ways.

The fundamental building blocks that constitute DSS include the nature of the models (which can be qualitative and quantitative), the selection of tools for the treatment of information, the training of analysts and highly trained staff to deal with decision-making processes, and the knowledge embedded in different organizational actors as well as in the organization as a whole.

The third step consists of various tasks, namely identification of sources of data generation, establishment of corresponding data-capture processes, identification of data-analysis tools, and an evaluation of data validity in order to build the input data to feed the DSS models.

The fourth step involves determining the other inputs required to structure the DSS, namely the tangible inputs such as algorithms, computational tools (software and hardware) and an estimate of the capabilities required by analysts and decision makers.

The fifth step focuses on the design of the information-converting process in the DSS, that is, how to experiment and how to operate in order to produce base knowledge for decision-making (this requires setting scenarios and formulating strategies and alternative solutions).

Building upon the output information, the sixth stage assesses the feasibility and validity of information against the performance characteristics of the real system. To this end, it is necessary to understand the operation and behavior of the real system and also have capacity to assess the impact of a decision on the organization as a whole and on its immediate surroundings.

The seventh step is intended to provide knowledge for the decision maker to act with wisdom during the decision making process, having a positive impact on the organization.

Enough capacity must be allowed for the organization and for people in different dimensions for them to act successfully in an integrated and dynamic way.

The ultimate goal then is to develop methodological processes oriented towards acquiring the necessary skills (capabilities) to make an organization quick and agile when facing decision-making processes as a response to the trends governing the current knowledge-based global economy.

A broader perspective shows how the output information and its corresponding validation build knowledge. This knowledge together with the accumulated knowledge, the interaction with the environment and the training processes integrate as a knowledge management system to support decision-making.

CAPACITY EXPANSION MODEL

One of the stated requirements, on the way to improve the competitiveness of organizations, is the adoption of a proper trading strategy, which is defined for Roger Schroeder (2012), Abdul-Jalal, Toulson, & Tweed (2013) as a view of the operations function that depends on direction or general impetus for decision-making. This vision must be integrated with business strategy and often, but not always, reflected in a formal plan.

The operations strategy should result in a consistent pattern of decision-making and operations and a competitive advantage for the company. Likewise, (Ahmad, Bosua, & Scheepers, 2014), (F. Jacobs, 2010), expressed as an important aspect to consider, that this strategy should specify how the company will use their productive capacities to support the corporate strategy. All this means that operations strategy must emerge from a long term business strategy and, in turn, must be integrated horizontally with the strategies of the other subsystems of the company.

According to this statement and in accordance with (Babnik, Širca, & Dermol, 2014), (Machuca, 1995.), the operations strategy is established as a long-term plan for the operations subsystem, which are set to achieve the objectives and courses of action and allocation resources to different products and features.

This should pursue the achievement of the overall objectives of the company as part of its corporate strategy and constitutes a consistent pattern for the development of tactical and operational decisions of the subsystem. This, no different from the concept of (Schroeder, 2012), who also adds that the trading strategy should be a functional strategy that should guide business strategy and whose heart must be made by the mission, the distinctive competence, objectives and policies.

The system is limited by the availability of resources and conditions imposed by the environment such as market regulation standards, environmental, social, industrial requirements, as well as the perceptions and needs of the client, now depending on management system of the organization and proper decision-making, the system shall be provided an intelligent management system that meets the needs of a demanding and dynamic market.

So to simplify the complexity from this abstraction, we propose a decision support system where in structure available models and optimization tools that provides information and analysis for decision-making at the strategic level, tactical level and operational level.

Are varied and similar approaches regarding the process of planning, scheduling and production control have been treated by several authors such as (Berends, Vanhaverbeke, & Kirschbaum, 2007; Bermell-Garcia et al., 2012), (Zhen, Song, & He, 2012),(Schroeder, 2012), (Tawfik, 1992.), (S. Nahmias, 2009), (Riggs, 1987 ), (Buffa, 1987), (Jack R. Meredith, 2012) among others, who established, in general terms, that starts with forecasts, from which emerge the plans long, medium and short term. According to the authors, this approach presents some shortcomings, as it lacks the integrative concept in the vertical direction, should start in business strategy, and in the horizontal direction, must interact with the other subsystems of the organization.

Other authors such as (Starr, 1979), (R. Companys Pascual, 1989), and (Jacobs, 2010), (Ebert, 1991), offer models of production management that, despite establishing an integrative concept in the vertical, not clearly express the integration horizontally. Maybe they are F. Jacobs (2011), and F. Robert Jacobs (2010), (Machuca, 1995), who, according to the literature, have a better approach, believing integration in both directions. In this regard, the latter author states that the planning and control of production should follow a hierarchical approach, which is achieved vertical integration between the strategic, tactical and operational and also set its horizontal relationship with other functional areas of the company.

The main input of information for decision-making in any organization of production of goods and services is originating from the knowledge of the nature of demand and their patterns of behavior and, based on this knowledge, will determine the resources required to ensure supply efficiently and achieve effectively the goals of the organization.

If the products and services offered have long life cycles and innovation is relatively easy to modify (e.g. presentation, color, size and other qualities that point to customer perception), then from the availability of historical data can be projected demand; however, if the projected demand is growing and perceived needs for increased capacity, it follows that it is necessary to plan the development of capacity at the level strategic and tactical. According to (Lopez B., 2006)in the medium term an analyze the feasibility of increasing the available capacity with scheduling overtime or scheduling new shifts, or definitely is required purchase of new plant and equipment that fill the future needs, here you should think and projector offering new products and services, as discussed in (Lopez B., 2006).

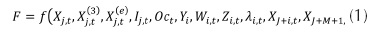

This model aims to assess the technical and economic feasibility of expanding the installed capacity, the best way to use resources, enabling scheduling tree shifts or overtime, whether to increase capacity at each stage of the process and in each point in time, it is noteworthy that the decision to schedule machines in two or three shifts, or overtime for each stage of the process involves additional fixed costs for each recommended decision, and consider additional costs for amortization of the purchase of the new machinery and equipment, and hiring new workers. Then the objective function is structured in terms of production and inventory levels in the decision to buy new machinery and equipment, in the decision to schedule one, two, three shifts or overtime for each process step in each time period and the number of workers required to handle new equipment in those extra shifts and new facilities. Then the production function of the capacity expansion with three levels of economies of scale and overtime is denoted by the equation (1) and is expressed in the equation (2).

Objective: Determine a plan to expand the installed capacity, programming new work shifts or overtime scheduling, oriented utility maximization and expansion of installed capacity.

Objective Function:

Decision Variables

: Production level in regular time of the item "j" in the period "t" (turn one and two)

: Production level in regular time of the item "j" in the period "t" (turn one and two)

: Production level in the third shift of the item "j" in the period "t"

: Production level in the third shift of the item "j" in the period "t"

: Production level in the overtime of the item "j" in the period "t"

: Production level in the overtime of the item "j" in the period "t"

: Binary decision variable expressing the ability to schedule a second shift in the process stage "i" in the period "t"

: Binary decision variable expressing the ability to schedule a second shift in the process stage "i" in the period "t"

: Binary decision variable expressing the ability to schedule a third shift in the process stage "i" in period "t"

: Binary decision variable expressing the ability to schedule a third shift in the process stage "i" in period "t"

: Binary decision variable expressing the ability to schedule overtime in the process stage "i" in period "t"

: Binary decision variable expressing the ability to schedule overtime in the process stage "i" in period "t"

: Binary decision variable expressing the ability to schedule overtime staff in period "t"

: Binary decision variable expressing the ability to schedule overtime staff in period "t"

: The Idle of the machine type "i" in regular time, in the period "t"

: The Idle of the machine type "i" in regular time, in the period "t"

: Leisure of the workforce in regular time in the period "t"

: Leisure of the workforce in regular time in the period "t"

: Leisure of the workforce in overtime in the period "t"

: Leisure of the workforce in overtime in the period "t"

: The Idle of the machine type "i" in the third turn, in period "t"

: The Idle of the machine type "i" in the third turn, in period "t"

: The Idle of the machine type "i" if programmed overtime in period "t"

: The Idle of the machine type "i" if programmed overtime in period "t"

: Number of machines to acquire the type "i"

: Number of machines to acquire the type "i"

: Number of new workers to hire (multipurpose), in the period "t"

: Number of new workers to hire (multipurpose), in the period "t"

Inventory on hand at end of period "t" of the product type "j"

Inventory on hand at end of period "t" of the product type "j"

: Unmet demand for product type "j" in period "t"

: Unmet demand for product type "j" in period "t"

: New machines of type "i" to program in the second turn in period "t"

: New machines of type "i" to program in the second turn in period "t"

: New machines of type "i" to program in the third turn in period "t"

: New machines of type "i" to program in the third turn in period "t"

: New machines of type "i" to program in the overtime in period "t"

: New machines of type "i" to program in the overtime in period "t"

: Operators new to programming in overtime in period "t"

: Operators new to programming in overtime in period "t"

Parameters:

: Unit production cost in regular time (turns one and two) of the article type "j"

: Unit production cost in regular time (turns one and two) of the article type "j"

: Unit production cost of the article type "j" if it occurs in the third turn

: Unit production cost of the article type "j" if it occurs in the third turn

: Unit production cost of the Item type "j" if it occurs in overtime

: Unit production cost of the Item type "j" if it occurs in overtime

: Sale price per unit of product type "j"

: Sale price per unit of product type "j"

: Fixed Cost

: Fixed Cost

: Potential Demand of the Product type "j" in the period "t"

: Potential Demand of the Product type "j" in the period "t"

: Demand required of the Product type "j" in the period "t"

: Demand required of the Product type "j" in the period "t"

: Available capacity in one turn of the machinery in the process step "i" scheduled in the period "t"

: Available capacity in one turn of the machinery in the process step "i" scheduled in the period "t"

: Additional available capacity machine in the process step "i" if a second shift is scheduled in the period "t"

: Additional available capacity machine in the process step "i" if a second shift is scheduled in the period "t"

: Additional available capacity machine in the process step "i" if a third shift program is scheduled in the period "t"

: Additional available capacity machine in the process step "i" if a third shift program is scheduled in the period "t"

: Additional available capacity machine in the process step "i" if scheduled overtime in the period "t"

: Additional available capacity machine in the process step "i" if scheduled overtime in the period "t"

: Available capacity for unit of machine in the process step "i" if the first shift is scheduled in the period "t"

: Available capacity for unit of machine in the process step "i" if the first shift is scheduled in the period "t"

: Additional available capacity for unit of machine in the process step "i" if a second shift is scheduled in the period "t"

: Additional available capacity for unit of machine in the process step "i" if a second shift is scheduled in the period "t"

: Additional available capacity for unit of machine in the process step "i" if a third shift program is scheduled in the period "t"

: Additional available capacity for unit of machine in the process step "i" if a third shift program is scheduled in the period "t"

: Additional available capacity for unit machine in the process step "i" if scheduled overtime in the period "t"

: Additional available capacity for unit machine in the process step "i" if scheduled overtime in the period "t"

: Available capacity of manpower resource in regular time in the period "t"

: Available capacity of manpower resource in regular time in the period "t"

: Available capacity of manpower resource in overtime in the period "t"

: Available capacity of manpower resource in overtime in the period "t"

: Available capacity per worker in regular time in the period "t"

: Available capacity per worker in regular time in the period "t"

: Available capacity for operator if scheduled overtime in the period "t"

: Available capacity for operator if scheduled overtime in the period "t"

: Standard processing time of a product type "j" in a machine in the process stage "i"

: Standard processing time of a product type "j" in a machine in the process stage "i"

: Runtime labor required per unit of product type "j" in the process step "i"

: Runtime labor required per unit of product type "j" in the process step "i"

: Cost of recruitment, hiring and training a new operator.

: Cost of recruitment, hiring and training a new operator.

: Inventory carrying cost per unit of product type "j" in the period "t"

: Inventory carrying cost per unit of product type "j" in the period "t"

: Additional costs for increased production levels to schedule a second shift in the process step "i" in the period "t"

: Additional costs for increased production levels to schedule a second shift in the process step "i" in the period "t"

: Additional costs for increased production levels to program a third shift in the process step "i" in the period "t"

: Additional costs for increased production levels to program a third shift in the process step "i" in the period "t"

: Additional costs for increased production levels by scheduling overtime in the process step "i" in the period "t"

: Additional costs for increased production levels by scheduling overtime in the process step "i" in the period "t"

: Amortized cost for the purchase, installation and commissioning of a machine type "i"

: Amortized cost for the purchase, installation and commissioning of a machine type "i"

: Space required for installation of a new machine, considering the work areas: raw material supply, equipment handling and temporary storage of processed product in the process step "i"

: Space required for installation of a new machine, considering the work areas: raw material supply, equipment handling and temporary storage of processed product in the process step "i"

: Available space for installation of new equipment.

: Available space for installation of new equipment.

: Service factor

: Service factor

Initial Conditions:

: Inventory on hand at the beginning of the planning period of product type "j" (so that it is equal to a constant) where,

: Inventory on hand at the beginning of the planning period of product type "j" (so that it is equal to a constant) where,

Referential Sets:

i: Index that identifies the step of the process and type of machine, where

j: Index that identifies the type of product, where

t: Index that identifies the production period, where

M: Number of process stages or types of machine

J: Number of product types

T: Number of periods of planning horizon

Constraints:

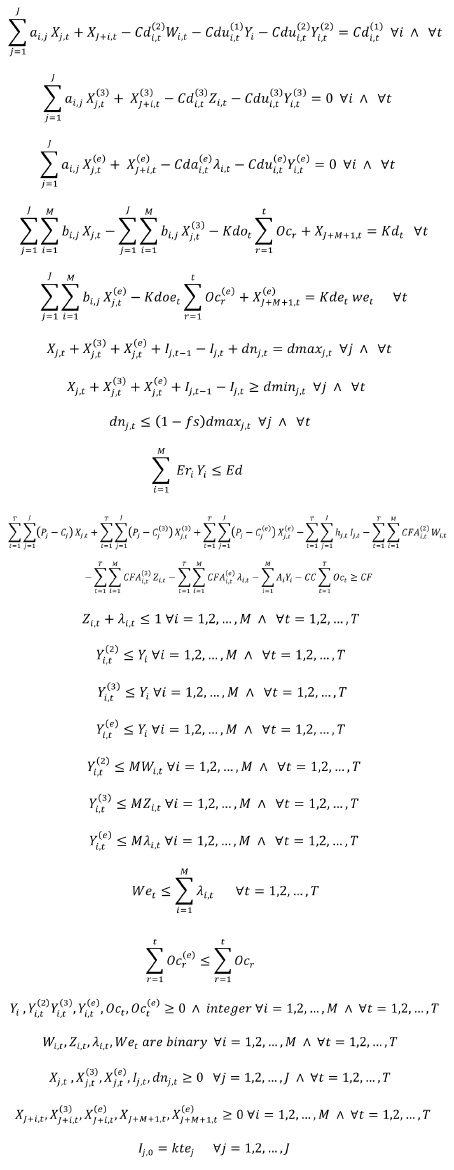

The model of expansion of installed capacity, with three levels of economy of scale for strategic and tactical decisions, scheduling three shifts and possibility of scheduling overtime, includes the following restrictions:

Restricting resource capacity machine and equipment for two turns, in it takes into account the possibility of increasing capacity with the purchase and installation of new equipment, if used one shift, or two shifts which is activated with binary variable associated with this possibility, the restrictive condition is further capacity in regular time (turn one two).

So that the required capacity more leisure slack resource means equals machine capacity available in regular time increased with the possibility of activating the second shift and increased capacity with the purchase and implementation of new places of work, as shown in the equation (3).

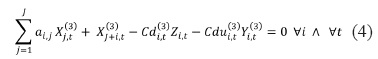

Restriction of production capacity the third shift, this restriction is indicating the possibility of using the turn three in production, where the additional capacity is activated with a binary variable that enables third shift, and the increase caused by the purchase and installation of new machinery and equipment, as shown in equation (4).

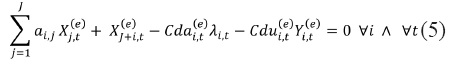

Restriction machine capacity in overtime, where the capacity is related to the production employed in overtime, limited by the availability of programmable machine time in overtime, which is activated by a binary variable, and consider the possibility of using the additional capacity for the acquisition, installation and qualification of new machinery and equipment, as expressed in the equation (5).

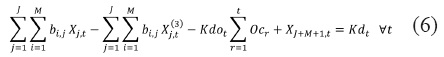

Restriction of human resource capacity, here relates the required capacity of labor in three shifts, with available capacity associated with the current workforce and the ability to be increased by hiring new workers, which implies an increase capacity of labor. This relationship is shown in the equation (6).

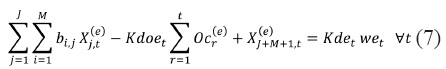

Capacity constraint of manpower resource in overtime, this restriction associated personnel scheduling decision in overtime, provided that overtime is enabled, this option is included in addition to the new hires. This relation is represented by the equation (7).

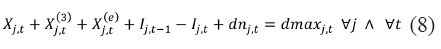

Potential demand constraint, this relationship is expressed with the limits imposed by the market and indicates that the levels of the production and inventory should not exceed the projected potential demand; we see that the difference between demand and supply is unmet demand. This relation is represented by the equation (8).

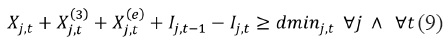

Restriction required demand, this relation is expected to ensure compliance with the requirements demanded of each product at each point in time, using the methods of production in regular time, a third shift schedule or overtime scheduling. These requirements can obey to commitments made to customers or policy of level of customer service and is expressed as the equation (9). It is guaranteed that actual production levels in regular time, in the third shift and in overtime, and initial inventory level available minus the end inventory in each period for each product should be greater than or equal to the minimum required demand.

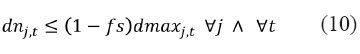

Restriction service level, it is intended to enable a condition to ensure a level of customer service, is used if there is a policy difference between service level with demand required when there are commitments to customers. It indicates unmet demand should be inferred at a fraction of the potential demand, as shown in the equation (10).

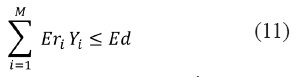

Restriction of physical space, this condition limits the ability to purchase and install new machinery and equipment, depending on the availability of space for installation of new jobs; on the left shows that the sum of the multiplication between the number of machines with the space for installation and operation for each unit type machine should not higher availability of physical space, as seen in equation (11).

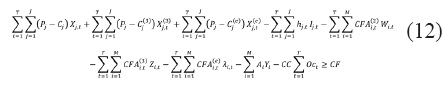

Zero profit constraint, this relationship is specified that the income generated by production levels made in one, two and three shifts and the overtime, less the costs associated with inventory levels, and involve additional costs programming of the second, third shift and overtime, plus costs for a return on investment for the purchase and installation of new machinery and equipment costs exceed fixed programmed for the operation of the organization and is expressed by the equation (12).

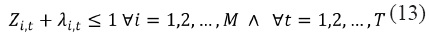

Equation (13) expresses the impossibility of programming simultaneously the third shift with the overtime. This expression is conditioned with the addition of binary variables.

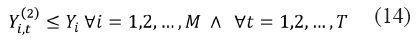

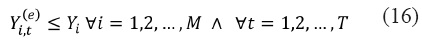

With the equations (14), (15) and (16) ensures that the new machines can be programmed on the second shift, third shift or overtime provided they are purchased.

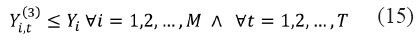

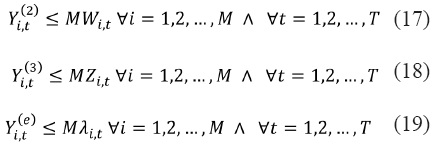

With the equations (17), (18) y (19) ensures that the new machines can be programmed in the respective shifts, as long as the shifts are enabled.

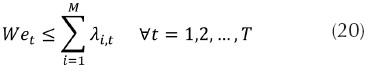

With the equation (20) ensures that the workforce should be scheduled if scheduled overtime at any stage of the process at some period

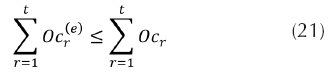

With the equation (21) ensures that operators engaged, may be scheduled overtime long as they are engaged.

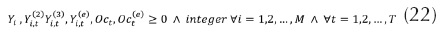

The equation (22) shows the logic condition to be non-negative and integer decision variables, number of machines has to be acquired or enabled in a turn and hired workers and qualified to work in regular time or overtime.

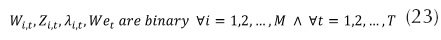

In the equation (23) are shown binary conditions for the decision to schedule a second shift, third shift or overtime in each process step in each time period and the decision to schedule the operators in overtime.

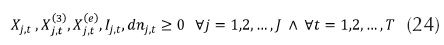

With logical equation (24), expresses the conditions of non-negativity of the variables, production levels in regular time, on the third shift, overtime, inventory levels and unmet demand.

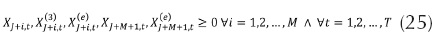

With logical equation (25), expresses the condition of non-negativity of the variables, idle machinery, workforce in regular time, and unused capacity on a third shift or overtime.

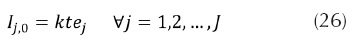

Initial conditions, this equation (26) is specified that the inventory on hand at the beginning of the planning horizon of product type "j" is equal to a constant.

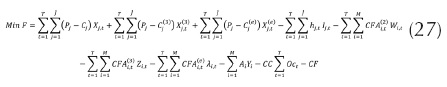

In equation (27) summarizes the mixed integer programming model to evaluate strategies to increase production capacity.

subject to:

PROTOTYPE

Description

Manufacturing firms pose in their strategic development plans the possibility of expanding production capacity, for which you can use strategies such as overtime scheduling, scheduling new shifts or by purchasing, installing and enabling new posts work; additionally, wish to evaluate the technical feasibility of introducing new products to the market.

The Company produces four types of product families, to over three stages of the process, where there are multiple machines (or jobs) by process step the same technology. The company works in one shift of eight hours, six days a week (Monday to Saturday), not working holidays and also collective vacation program corresponding to fifteen business days per year (seven days in December and eight days of January).

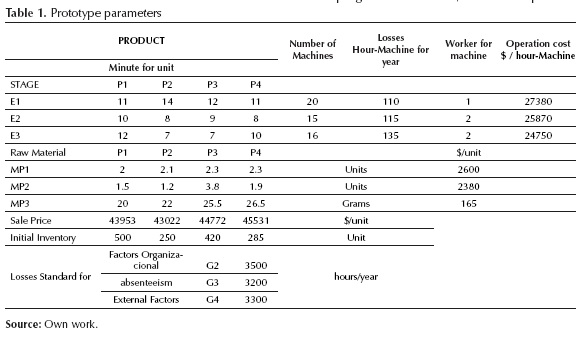

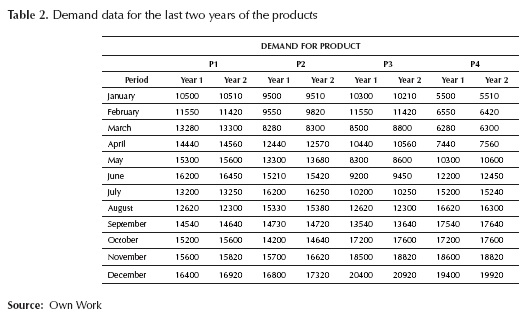

The standard processing time in minutes of each machine per unit of product type by type of machine in each process step, the number of machines available for each type of process step, standard time losses caused by the preventive maintenance of the equipment per unit of each type of machine in hours per year, the number of workers required per job or machine type, the amount of raw material required per unit of product, the cost of operating a machine each type in $ per hour machine, the unit cost of each type of raw material, the initial inventory available for each type of product and the selling price per unit of each product is shown in table 1.

The potential demand is calculated based on the data passed in the previous two years and shown in table 2. If they decide to schedule overtime, the cost of labor is increased by 10%, plus an increase in the fixed cost caused by the need to coordinate and monitor the additional activity, estimated at 10% with the cost fixed; in other words, the cost prorated for periods where scheduling extra time for each stage of the process (e.g. the fixed cost additional incurred in a process step in a period where program overtime is $22.222.222 per month).

Also, if you set a second shift, the labor costs for the two shifts are similar, but the fixed cost increases, as well as whether overtime program., which is $22.222.222 per month by process step where new the shift schedule. The maximum production capacity in the second round is the same as the first, also, increase the losses of time due to equipment maintenance and by several factors, but it is necessary to evaluate the hiring of new workers. You can program a third shift, but in this situation the cost of labor would increase by 25% with additional fixed costs of $25.000.000 a month by step process if they activate the shift. Also effective capacity at the third shift would be only 70% of the capacity of the other shifts, for efficiency and coordination reasons. For this situation it is important to evaluate the hiring of new workers.

The company has a staff of 96 multipurpose workers, the labor time involved an additional 20% for material handling and equipment enlistment. The cost of labor is determined by the salary of each employee which are semi-skilled and up to two statutory minimum wage.

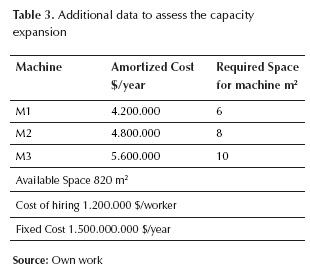

The annual fixed cost of operating the business without considering any expansion, hiring costs, depreciation costs for the purchase, acquisition and installation of new equipment, the area required for the installation and operation of a machine of each type and the area available for the placement of new jobs are shown in table 3.

The inventory carrying cost is charged 2% monthly average inventory at cost (2% per month for the unit cost of the product).

Solution and Experimentation

1. To solve the problem is to construct the information needed by treating the input feature data, then calculate required.

• Production capacity of the machinery by step process in each time period in regular time (one shift, two shifts, three shifts) and in overtime.

• Machine per unit capacity of each type.

• Labor capacity.

• Projected demand over the planning horizon.

• Operating costs, labor costs and material costs.

2. Software requirements: using GAMS (General Algebraic Models System)

Testing and Simulations

The number of experiments that can be performed directly dependent on the configuration of the organization and its features, and the scope of the decision, if you think about evaluating the possibility of expanding the capacity available with strategies such as scheduling more shifts or scheduling overtime, or if the decision is strategic and is planning to expand the installed capacity, with the purchase and installation of new machines and jobs. Then, from the experiments are located bottlenecks resources and is observed as determining the best decisions to modify the availability of resources, for example the space available for installation of new machines. It should be noted that the decision process requires the ability of the decision-maker in terms of understanding of the issues and the knowledge and use of decision support tools, as well as the agility to the analysis and interpretation of results and their validity face the facts presented in the organizational system.

Changes in demand requirements

To the extent that the problem is not restricted to minimum demand, the contribution margin increased to the detriment of the non-production of goods with lower profitability.

If the company wants to meet the demand must increase capacity; in other words, if the problem is conditioned to meet minimum demands, more capacity is needed, now limited to the production system, the alternative is to produce with stra tegies such as overtime or programming a third shift to be far more costly to the detriment of the utility.

Changes in the availability of physical space

If the possibility of installing new equipment due to lack of physical space is restricted, the development of the capacity for what this resource is seen as the limiting or bottleneck that limits the growth and development of productive capacity is truncated. But if the physical space, for example to 1200 square meters for the installation of new equipment and workstations increases, growth in income and resource use more widely seen, so it looks like it absorbs and holds demand.

Changes in costs

Unit costs may grow by the increase in the value of raw materials, the cost associated with labor and operating costs, in addition, inventory carrying costs will increase or decrease depending on the value of the goods. Additionally the costs of preparation and readiness, replacement costs lots in the sequence of operations are crucial to productive activity and influence the preference for the production of a good or another.

Price Changes

The selling price of the products varies with time and depends directly on its life cycle, in addition to regulations imposed by trade and free market competition.

It is perceived that increasing the price of a product contribution margin increases and therefore there is a tendency to prioritize the production of goods; on the other hand, if the price drops, it tends to decrease activity levels for production of this article.

Add other resource constraints

It is important to note that the dynamics and growth of organizations may be affected and limited by the scarcity of resources as the raw material that definitely changes the action plans and the distribution of production activities of goods and services. The production of pollutants and stabilize the environment are critical in the decision process, generating restrictive elements to productive activity. Then it is necessary to add relationships restrictive model that take into account these limitations. It is understood that any restriction that limits on corporate actions caused losses in the profit margin, and any additions and obtaining resources bottlenecks do to increase profits.

Conclusions

The system decision support is configured with a set of models that are used to clarify and obtain information for making efficient and effective decisions in complex environments. Thus, mathematical modeling, optimization tools and techniques and quantitative character tools provide the basis for the system to work in a smart way.

An input of information for decision-making is the identification and characterization of the demand for goods and services, for which there are a number of tools for the prediction, which forms the basis for planning transversely in all functions of the organization and supply chain.

The life cycle of products directly affects the demand for goods and services, and demand is affected by the policies of the State in regulating the conduct of the competition, market trends, and other factors such as price, quality, performance, and characteristics that differentiate the products and services. For all these reasons, there are many techniques and methods for forecasting and estimates based on knowledge of the demand, but it is necessary to determine which model, technique or procedure is appropriate.

The construction of models for analysis and development of productive capacities in organizations is extensive and varied and depends on the type of organization, the state in which it has, besides its own organizational structure, culture and dynamics in response to market trends and environment. But we can start with an archetype that can be adjusted according to circumstances.

References

Abdul-Jalal, H., Toulson, P., & Tweed, D. (2013). Knowledge Sharing Success for Sustaining Organizational Competitive Advantage. Procedia Economics and Finance, 7(0), 150-157. doi: http://dx.doi.org/10.1016/S2212-5671(13)00229-3. [ Links ]

Ahmad, A., Bosua, R., & Scheepers, R. (2014). Protecting organizational competitive advantage: A knowledge leakage perspective. Computers & Security, 42(0), 27-39. doi: http://dx.doi.org/10.1016/j.cose.2014.01.001. [ Links ]

Babnik, K., Širca, N. T., & Dermol, V. (2014). Individuals Learning in Work Teams: Support to Knowledge Management Initiatives and an Important Source of Organizational Learning. Procedia - Social and Behavioral Sciences, 124(0), 178-185. doi: http://dx.doi.org/10.1016/j.sbspro.2014.02.475. [ Links ]

Berends, H., Vanhaverbeke, W., & Kirschbaum, R. (2007). Knowledge management challenges in new business development: Case study observations. Journal of Engineering and Technology Management, 24(4), 314-328. doi: http://dx.doi.org/10.1016/j.jengtecman.2007.09.006. [ Links ]

Bermell-Garcia, P., Verhagen, W. J. C., Astwood, S., Krishnamurthy, K., Johnson, J. L., Ruiz, D. Curran, R. (2012). A framework for management of Knowledge-Based Engineering applications as software services: Enabling personalization and codification. Advanced Engineering Informatics, 26(2), 219-230. doi: http://dx.doi.org/10.1016/j.aei.2012.01.006. [ Links ]

F. Jacobs, W. L. (2011). Manufacturing planning and control for supply chain management. New York: McGraw-Hill. [ Links ]

López Bello, C. A., D. K. (2005). Modelos de medición, análisis, planeación y programación de capacidades en un contexto de múltiples criterios. Ingeniería, 2(1), pp. 26-40. [ Links ]

López Bello, C. A., L. J. (2006). Modelo de planeación de capacidades utilizando programación fraccional lineal en un contexto de múltiples criterios de decisión. Ingeniería, 11(2), pp. 48-60. [ Links ]

López Bello, C. A., (2006). Modelo integral de produccion en empresas manufactureras. Bogotá: Kimpres. [ Links ]

López Bello, C. A., (2009). Modelo de ampliación de capacidades. Revista Ingeniería, 14(2), pp. 67-77. [ Links ]

E E Ebert, R. J. (1991). Production and Operations Management. Prentice Hall. [ Links ]

Elwood S. Buffa, R. K. (1987). Modern Production/Operations Management, 8th Edition. Wiley. [ Links ]

Jacobs, W. L. (2011). Manufacturing planning and control for supply chain management. New York: McGraw-Hill. [ Links ]

Robert Jacobs, R. B. (2010). Operations and Supply Chain Management Global Edition. McGraw-Hill Higher Education; Edition: 13. [ Links ]

Jack R. Meredith, S. M. (2012). Operations Management for MBAs. 5th Edition Wiley. [ Links ]

Johnny Rungtusanatham, S. G. (2012). Operations Management in the Supply Chain: Decisions and Cases. 6th edition. Tata McGraw-Hill India Pvt Ltd. [ Links ]

Starr. (1979). Administración de la producción. Sistemas y síntesis. Madrid: Ed. Dossat S.A. [ Links ]

Machuca, J. E. (1995). Dirección de operaciones: Aspectos tácticos y operativos en la producción y los servicios. Madrid: Editorial McGraw-Hill. [ Links ]

Companys Pascual. (1989). Planificación y programación de la producción. Barcelona: Marcombo S.A. [ Links ]

Riggs, J. L. (1987). Production Systems: Planning, Analysis and Control. Hardcover: Wiley series in production/operations management. [ Links ]

Roberta S. Russell, B. W. (2011). Operations Management: Creating Value Along the Supply Chain, 7th Edition. Wiley. [ Links ]

Roger Schroeder, M. J. (2012). Operations Management in the Supply Chain: Decisions and Cases. McGraw-Hill/Irwin Series, Operations and Decision Sciences. [ Links ]

Nahmias, S. (2009). Production and Operations Analysis. Chicago: Ed. Irwin. [ Links ]

Starr, M. (1979). Administración de la producción. Sistemas y síntesis. Madrid: Ed. Dossat S.A. [ Links ]

Tawfik, L. (1992). Administración de la producción. México D.F.: Ed. McGraw-Hill. [ Links ]

Zhen, L., Song, H.-T., & He, J.-T. (2012). Recommender systems for personal knowledge management in collaborative environments. Expert Systems with Applications, 39(16), 12536-12542. doi: http://dx.doi.org/10.1016/j.eswa.2012.04.060. [ Links ]