Introduction

Most post-consumer tires in the world are not adequately disposed of, accumulated in public spaces of cities, and, sometimes, improperly burned in the open field. This improper handling could cause serious health issues to the population. The use of recycled materials from waste tires in construction materials has been evaluated in the last years as the perfect opportunity for offering practical solutions to waste materials [1]. Through a recycling process, all the raw materials of tires (steel, rubber, or textiles) could be employed in the manufacture of sustainable construction materials. For instance, tire rubber has been reused massively in normal- and high-strength concretes [2], asphalt, playground surfaces, synthetic sports fields, and unique coverings [1].

In the same way, steel fibers recovered from recycled post-consumer tires have been used in concrete pavements [3] or high-performance cementitious composites such as slurry infiltrated fiber concrete [4]. The main methods for extracting steel, textile, and rubber from tires are thermolysis, pyrolysis, incineration, and crushing, being the latter the most widely used by the tire recycling industry. It consists in reducing the tire size to small pieces to separate the rubber from the steel and the textile.

In terms of the mechanical properties of recycled steel fiber-reinforced concrete, Aiello ET AL. [5], Rossli and Ibrahim [6], and Sengul [7] confirmed that adding recycled steel fibers from tires to concrete improves crack resistance, compressive strength, bending strength, tensile strength, and fracture energy of concrete. Centonze et al. [8] observed that load-deflection results from concrete slabs reinforced with recycled steel fibers were comparable to those obtained from concrete reinforced with industrial fibers, which confirms the effectiveness of recycled steel fibers. When combining recycled and industrial fibers, Graeff et al. [3] argued that this hybrid fiber (industrial and recycled) could lead to a reduction of pavement slab thickness by up to 26% since the fatigue strength increases. However, Centonze et al. [9] observed that the existing bonding between concrete and reinforcing bars does not significantly change with the addition of recycled steel fibers. Also, Zamanzadeh ET AL. [10] stated that the deflection achieved using specimens reinforced with industrial fibers was more significant than that developed by specimens reinforced with recycled fibers. This result confirmed that the “bridge effect” exerted by industrial fibers on the surface of the crack of the specimen was more significant than the effect caused by recycled fibers.

This environmental impact of post-consumer tires may be reduced when assessing this material as an alternative reinforcement for concrete. It is widely known that the toughness of steel fiber-reinforced concrete is suitably assessed by energy absorption tests on slabs. The purpose of this paper is to show and discuss the results of a research aimed at assessing the mechanical response of concrete slabs reinforced with recycled steel fibers from post-consumer tires in Bogotá, Colombia. The testing program of the study comprised 31 axial compression tests on cylinders and 15 bending tests on concrete slabs reinforced with nominal fiber dosages of 15 kg/m3, 30 kg/ m3, and 60 kg/m3 of industrial steel fibers or steel fibers obtained from post-consumer tires. Based on the measured response, preliminary design equations are proposed to estimate the mechanical properties of concrete slabs reinforced with recycled steel fibers. The results of this study intend to demonstrate whether this type of material can be considered as a local alternative for the production of structural and non-structural fiber-reinforced concrete elements. They are also expected to increase the reliability of the use of steel fibers from tire recycling as a reinforcement for concrete.

Experimental Program

The experimental program comprised tests on standard cylinders and slabs made of plain concrete, concrete reinforced with recycled steel fibers, and concrete reinforced with industrial steel fibers. The specified compressive strength of concrete was 21 MPa, the maximum size of the aggregate was 38.1 mm, and the specified slump of concrete was 178 mm. The values of the nominal properties of concrete are characteristic of those used for the construction of walls for low-rise housing. Concrete was prepared and provided by a ready-mix company. The steel fibers (recycled and industrial) were mixed in the laboratory using mechanical concrete mixers and a concrete truck mixer.

Description of specimens

Table 1 describes the two types of fibers and the dosages used, where D f - nominal is the nominal dosage of the fiber in kg/m3, and V f is the volume fraction computed as the ratio between Df and steel density (7850 kg/m3) as a percentage. The parameter % D f-min is related to the ratio between D f - nominal and the minimum dosage specified by the ACI-318 [11] and the NSR-10 [12] to replace the minimum shear reinforcement provided by conventional steel in beams (D f-min = 60 kg/m3). The aspect ratio (l f /d f ) of fibers is computed as the ratio between the length (l f ) and diameter (d f ) of the fiber. This paper describes the procedure used to obtain the recycled steel fibers and their relevant geometric characterization.

Table 1 Variables of the Study

| Variable | Description | |||

|---|---|---|---|---|

| Industrial steel fibers | Hook type: | Hooked-end | ||

| Length, l f , mm: | 50 | |||

| Diameter, d f , mm: | 1.05 | |||

| Aspect ratio, l f /d f : | 48 | |||

| Reference: | Fiber recycled from used tires | |||

| Hook type: | No hook | |||

| Recycled steel fibers | Average equivalent length, l f , mm: | 31.1 | ||

| Average diameter, d f , mm: | 0.23 | |||

| Average aspect ratio, l f /d f : | 144.3 | |||

| % D f-min % | 25 | 50 | 100 | |

| Dosages for both types of fibers | D f-nominal , kg/m3: | 15 | 30 | 60 |

| Volume fraction, V f %: | 0.19 | 0.38 | 0.76 | |

Source: Own elaboration.

The experimental program included tests of compressive strength, elasticity modulus, and bending of concrete slabs to identify the mechanical properties of concrete reinforced with industrial steel fibers and steel fibers recycled from tires. Table 2 shows the number of specimens for plain concrete (PC), industrial steel fiber-reinforced concrete (ISFRC), and recycled steel fiber-reinforced concrete (RSFRC). In summary, the experimental program included 31 cylinders having 150 mm diameter and 300 mm height, and 15 slabs measuring 100 x 600 x 600 mm. It was defined that the pc mix was the control mixture.

Preparation of specimens

Two mechanical concrete mixers were used to mix the concrete with recycled steel fibers. The fiber was untangled manually and then introduced into the mixer to avoid clusters of recycled steel fibers. Despite this procedure, the irregular and varied shape of the recycled fibers caused some small clusters of fibers when casting the specimens. On the other hand, industrial steel fibers were directly mixed at the ready-mix company. In the case of the industrial fibers, no fiber clusters were observed [13].

Test setup

The tests of elasticity modulus and energy absorption of fiber reinforced concrete slabs were carried out per ASTM standard C469 [14] and European standard 14488-5 [15], respectively. The setup of the tests used to characterize the mechanical response of the fiber reinforced concrete (FRC) is shown in Fig. 1.

Results and Discussion

Test results are discussed in this section. Test results of the compressive strength and flexural performance of slabs are then compared with results reported in the technical literature.

Geometric characterization of recycled steel fibers

The diameter and length of the steel fibers recycled from tires depend on the method of extraction. As the rubber in the recycled steel fiber decreases, the bonding strength between concrete and fibers increases. So, it was necessary to separate fibers from bonded rubber, rubber granules, and longer fibers by sieving the material through a no. 4 (4.75 mm) mesh. To eliminate the rubber excess of the material, a powerful magnet was used to separate the steel from the rubber granules featuring a diameter smaller than the no. 4 sieve. A sample size of 1,067 recycled steel fibers was determined using statistical analysis. The statistical analysis of the measured geometry was expressed in terms of average (X), coefficient of variation (CV), and minimum and maximum values. The recycled steel fibers are irregular and include fibers having a wide range of lengths. The equivalent length considered here corresponds to the distance between the opposite ends of the fiber. The results of the statistical analysis of the average equivalent length (l f ) are shown in Table 3.

Table 3 Statistical Analysis of the Geometry of Recycled Fibers

| Statistical Parameter | l f , mm | d f , mm | l f /d f |

|---|---|---|---|

| X | 31.1 | 0.23 | 144.3 |

| CV, % | 50.4 | 28.1 | 57.0 |

| Minimum | 9.1 | 0.08 | 34.7 |

| Maximum | 110.5 | 0.38 | 529.3 |

Source: Own elaboration.

Like the equivalent length, the diameter of recycled steel fibers varies in each fiber, and even along the fiber length. In determining the fiber diameter, it was necessary to take three measurements due to a lack of uniformity along the fiber length: two at the opposite ends of the fiber, and another one in the middle. This study relates the diameter of the fiber to the average of the three measurements taken; the results are shown in Table 3. The measured diameters are similar to those obtained in other studies; for example, Centonze ET AL. [8] reported an average diameter of 0.24 mm, and Aiello et al. [5] obtained a value of 0.26 mm.

The aspect ratio of recycled fibers was computed as the ratio between each sample fiber's equivalent length and average diameter. The statistical parameters for the geometric characteristics of the fibers in the sample are also shown in Table 3. The steel fibers recycled from used tires feature small diameter sizes and relatively typical lengths, which causes high aspect ratios in some cases. Section 2.2.1 of ACI 544.1 [16] states, for example, that the fiber's bending capacity is directly related to its aspect ratio, and thus this standard establishes typical aspect ratio values between 20 and 100 for the industrial steel fibers. The calculated ratios used in this research (144.3) are higher than the values recommended by ACI 544.1.

Compressive behavior

Table 4 summarizes the mechanical properties of pc, ISFRC, and RSFRC under compressive stresses. It also shows the measured dosages of fibers used for concrete reinforcement.

Table 4 Compressive Mechanical Properties of Concrete

| Type of Concrete | Statistical Parameter | PC | ISFRC | RSFRC | ||||

| D f-measured , kg/m3 | 0 | 12.7 | 31.5 | 65.2 | 18.6 | 34.0 | 65.1 | |

| V f , % | 0 | 0.16 | 0.40 | 0.83 | 0.24 | 0.43 | 0.83 | |

| f’ c , MPa | X | 42.3 | 41.7 | 40.0 | 32.0 | 41.9 | 42.1 | 41.6 |

| CV, % | 8.3 | 2.5 | 5.2 | 12.0 | 6.6 | 2.0 | 0.9 | |

| E c , MPa | X | 24,039 | 22,185 | 21,983 | 19,900 | 24,688 | 22446 | 23142 |

| CV, % | 17.3 | 0.6 | 2.1 | 2.9 | 3.2 | 2.5 | 1.2 | |

Source: Own elaboration.

Flexural performance from slab tests

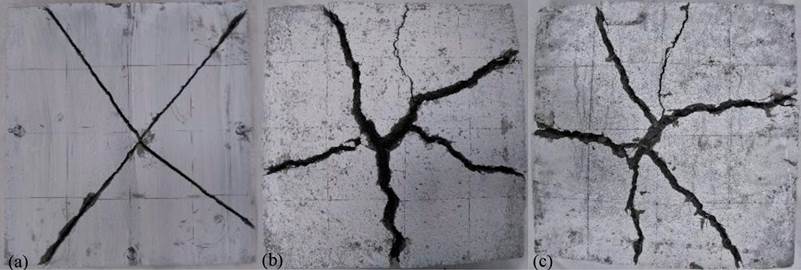

Fig. 2 shows the final cracking patterns of the PC slabs and the steel fiber reinforced slabs using a fiber dosage close to 65 kg/m3. The cracking patterns are similar for the two types of fibers, where the cracks extend from the center of the specimen to the corners and sides. This crack pattern was also reported by Centonze ET AL. [8] for dosages of recycled and industrial fibers of 31.8 kg/m3 and 34.8 kg/m3, respectively.

Source: Own elaboration.

Fig. 2 Final cracking patterns from bending tests on slabs: (a) PC, (b) RSFRC D f = 65.1 kg/m3, (c) ISFRC Df = 65.2 kg/m3.

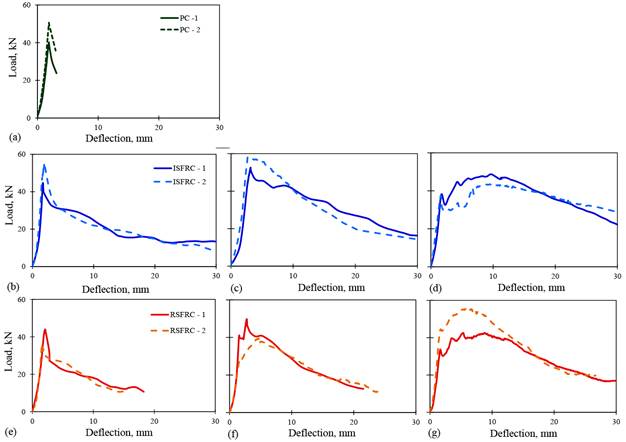

Fig. 3 shows the load-deflection curves obtained from the tests carried out on PC, RSFRC, and ISFRC slabs. The deflections obtained are vertical displacements in the center of the slab; that is, the point at which the load was applied. The basic mechanical parameters to analyze the bending behavior of steel fiber-reinforced concrete slabs are maximum load (Pmax), the deflection associated with Pmax (δmax), ultimate load (Pu), and the deflection associated with Pu (δυ).

Source: Own elaboration.

Fig. 3 Load-deflection curves from bending tests on slabs for different values of D f in kg/m3, PC: (a) 0, ISFRC: (b) 12.7, (c) 31.5, (d) 65.2, RSFRC: (e) 18.6, (f) 34.0, (g) 65.1.

The load-deflection curves in Fig. 3 demonstrated that both fibers contribute to a better structural performance of concrete slabs. For example, for dosages of recycled and industrial fibers near 65 kg/m3, Figs. 3d and 3g show that both types of fibers allow concrete to increase their strength after exceeding the first peak point. However, Figs. 3d and 3g show that industrial steel fibers provide concrete with higher capacity to support deflections compared to recycled fibers. For example, ISFRC showed a deflection of up to 43 mm for a dosage of 65.2 kg/m3, while RSFRC reached a 30 mm deflection for a dosage of 65.1 kg/m3. A similar trend was observed in concretes with other dosages; this trend can be attributed to the hooks of the industrial steel fibers.

Table 5 summarizes the basic mechanical parameters of steel fiber-reinforced concrete slabs. Results in the table are related to the average of the two specimens prepared for each dosage. There is no broad spread of data (CV less than 18.7 %), except for some parameters such as Pu in the industrial fiber and δmax in the recycled fiber, where CV values reach up to 37 %.

Table 5 Flexural Mechanical Properties of Concrete Slabs

| Type of Concrete | Statistical Parameter | PC | ISFRC | RSFRC | ||||

| D f-measured , kg/m3 Vf, % | 0 | 12.7 | 31.5 | 65.2 | 18.6 | 34.0 | 65.1 | |

| P max , kN | X | 45.4 | 49.9 | 55.4 | 46.1 | 39.7 | 44.6 | 49.1 |

| CV, % | 16.3 | 14.6 | 7.1 | 8.1 | 15.1 | 16.4 | 18.7 | |

| δ mox , mm | X | 1.8 | 1.8 | 2.9 | 9.8 | 1.8 | 3.7 | 7.4 |

| CV, % | 0.18 | 9.0 | 11.1 | 2.1 | 20.7 | 37.0 | 25.7 | |

| P u , kN | X | 29.8 | 11.4 | 14.1 | 16.6 | 10.9 | 11.8 | 18.3 |

| CV, % | 28.6 | 22.2 | 11.2 | 27.8 | 3.0 | 10.5 | 10.9 | |

| δ υ, mm | X | 3.1 | 32.9 | 37.2 | 41.7 | 17.0 | 22.7 | 28.3 |

| CV, % | 3.3 | 8.7 | 5.6 | 5.2 | 10.8 | 7.2 | 8.0 | |

Source: Own elaboration.

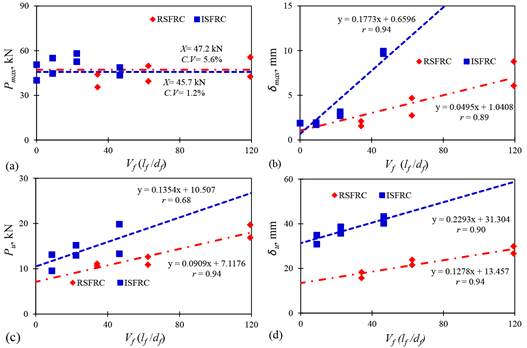

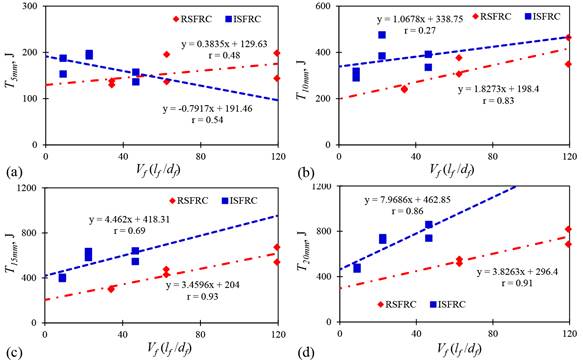

Fig. 4 shows the relationship between the main flexural properties of concrete slabs and V f x(l f /d f ) for recycled and industrial fibers, as well as the trends of the measured properties of ISFRC and RSFRC. A linear regression analysis was also carried out for computing the equations and their relevant r coefficients. The r coefficient calculates the degree of intensity of the relationship between the properties measured and the ones calculated.

Source: Own elaboration.

Fig. 4 Trends of the bending mechanical properties of PC, RSFRC, and ISFRC slabs: (a) Pmax 1, (b) δ max 1, (c) Pu 1, (d) δu 1.

As observed in Fig. 4a, P max for the two types of fibers remains constant upon increasing the dosage of fibers; however, the P MAX for RSFRC is slightly higher than that of ISFRC (47.2 kN and 45.7 kN, respectively). On the other hand, Fig. 4b shows that δmax increases as V f x (l f / d f ) augments for both types of fibers. Centonze ET AL. [8] reported deflections of 3.52 mm corresponding to the maximum load of rsfrc with a dosage of 34.0 kg/m3 of recycled fibers; that is, this deflection was only 5 % lower than that obtained in the bending tests reported herein.

Fig. 4c shows that the ultimate load (P u ) increases as the parameter Vf x (l f I d f ) augments; however, the ultimate load values are higher for isfrc. Carrillo and Silva [17] have also reported this increase; for instance, they stated that P u increases with the dosage of industrial fibers. This trend was attributed to the fact that when the amount of fibers increases, the concrete has higher deflections that elevate the residual strength. On the other hand, Fig. 4d shows the capacity of SFRC to withstand ultimate deflections, δυ increases as Vf x (l f I d f ) arguments for both types of fibers, although the δU values for industrial fibers were higher than those of recycled fibers.

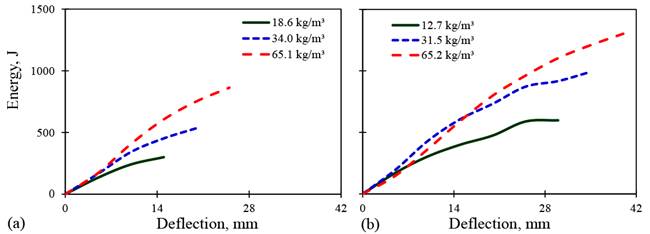

Fig. 5 shows the relationship between the energy and the deflection measured at the center of RSFRC and ISFRC slabs. As observed, the energy absorption increases when increasing the content of recycled and industrial fibers. This increment is due to the ability of fibers of hooking micro-cracks, avoiding significant crack widths before the failure occurs by pulling out the fibers [17]. The ISFRC toughness for all the fiber dosages is always higher than that of the recycled fiber, which indicates that, even though the RSFRC from tires contributes to the better performance of concrete, recycled steel fibers are not able to replace the contribution made by industrial steel fibers. Centonze et al. [8] observed a 22 % drop in the energy absorption capacity of the RSFRC with a D f of 31.8 kg/m3 when compared to ISFRC with a D f of 34.8 kg/m3. In the study reported herein, the energy drop was 45% for dosages of 34.0 kg/m3 of recycled fiber and 31.5 kg/m3 of industrial fibers, which are similar to those studied by Centonze et al. [8]; this reduction is 23 % greater than that observed by those autors.

Source: Own elaboration.

Fig. 5 Energy-deflection curves from slab bending tests: (a) RSFRC, (b) ISFRC.

Based on the requirements specified by en 14488-5 [15] standard, the toughness of SFRC slabs was calculated for deflections of 5, 10, 15, 20, 25, 30, 35, and 40 mm. Fig. 6 and Table 6 show the results of those deflections for RSFRC and ISFRC. The RSFRC toughness always increases as the dosage of fiber is augmented. However, it is observed in Fig. 6a that the ISFRC toughness for a deflection of 5 mm decreases as the fiber dosage increases. In the same way, the energy absorption capacity of ISFRC for deflections greater than 10 mm increases as V f X (l f / d f ) is augmented, being more significant than that of RSFRC (see Fig. 6b). Fig. 6c also shows an increase in the ISFRC toughness as V f X (l f / d f ) is augmented. Fig. 6d shows that ISFRC with a D f of 65.2 kg/m3 reaches a toughness of up to 800 J at a 20 mm deflection, which is 6 % higher than the toughness obtained for RSFRC.

Source: Own elaboration.

Fig. 6 Flexural toughness for PC, RSFRC, and ISFRC slabs: (a) T5 mm, (b) T10 mm, (c) T15 mm, (d) T20 mm.

Table 6 Toughness of Concrete Slabs for Different Deflections

| Type of Concrete | Statistical Parameter | ISFRC | RSFRC | ||||

| Df - measured, kg/m³ | 12.7 | 31.5 | 65.2 | 18.6 | 34.0 | 65.1 | |

| T 5mm , J | X | 170.6 | 195.2 | 147.0 | 134.3 | 166.2 | 171.2 |

| CV, % | 14.2 | 1.9 | 10.1 | 4.4 | 25.1 | 22.6 | |

| T 10mm , J | X | 304.7 | 430.7 | 364.0 | 241.2 | 341.7 | 406.8 |

| CV, % | 6.6 | 14.9 | 11.0 | 1.5 | 14.6 | 20.0 | |

| T 15mm , J | X | 400.6 | 608.1 | 593.5 | 300.3 | 425.3 | 606.1 |

| CV, % | 2.0 | 6.3 | 11.3 | 1.9 | 7.4 | 15.5 | |

| T 20mm , J | X | 475.2 | 733.4 | 800.3 | - | 535.3 | 753.0 |

| CV, % | 2.4 | 2.1 | 10.6 | - | 4.9 | 12.4 | |

| T 25mm , J | X | 588.7 | 871.8 | 961.8 | - | - | 863.3 |

| CV, % | 12.4 | 5.2 | 7.3 | - | - | 10.3 | |

| T 30mm , J | X | 598.4 | 917.1 | 1103.6 | - | - | - |

| CV, % | 0.5 | 1.3 | 2.5 | - | - | - | |

| T 35mm , J | X | - | 992.4 | 1209.3 | - | - | - |

| CV, % | - | 2.1 | 0.19 | - | - | - | |

| T 40mm , J | X | - | - | 1302.0 | - | - | - |

| CV, % | - | - | 2.8 | - | - | - | |

Source: Own elaboration.

Conclusions

The procedure commonly used to extract recycled steel fibers from waste tires makes it very difficult to obtain regular and rubber-free geometries. It was observed in this study that recycled steel fibers have different lengths and diameters. Also, the attached rubber can hinder the bonding between fibers and concrete. Recycled fibers do not have hooks that improve bonding through mechanical interlocking. In the same way, recycled fibers tend to get entangled when mixed with concrete because of their irregular geometry. However, the use of a superplasticizer to increase concrete slump and workability reduced recycled fiber clusters.

The ISFRC and RSFRC slabs showed similar cracking patterns, although the ISFRC performance was, on average, more significant than that of RSFRC. The geometry of recycled steel fibers did not provide the same binding. One of the advantages of industrial fibers is their hook that allows better anchoring between concrete and reinforcement. In the case of recycled fibers, this hook is not present, and the irregular and variable geometry of the fibers makes it difficult for them to have good concrete interlocking. A possible solution for this could be the hybrid mixture of the two types of steel fibers to achieve better concrete performance.

Based on trends of experimental data, preliminary equations are practical tools for analysis and design and can predict the mechanical performance of the ISFRC and RSFRC slabs in terms of parameters such as f’ c and V f x (l f / d f ). These equations apply to concrete with a compressive strength between 35 MPa and 42 MPa, industrial steel fibers and steel fibers obtained from waste tires, dosages of recycled fibers between 10 and 65 kg/m3, and values of V f x (l f / d f ) between 30 and 120.