Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Revista Facultad Nacional de Agronomía Medellín

Print version ISSN 0304-2847

Rev. Fac. Nac. Agron. Medellín vol.66 no.2 Medellín July/Dec. 2013

Development of a New Striker for a Portable Coffee Harvesting Tool

Desarrollo de un Nuevo Impactador para una Herramienta Portátil de Cosecha de Café

Edilson León Moreno Cárdenas1; Carlos Eugenio Oliveros Tascón2; Oscar Alberto Alfonso Carvajal3 and Fernando Álvarez Mejía4

1 Assistant Professor. Universidad Nacional de Colombia - Sede Medellín - Facultad de Ciencias Agrarias - Departamento de Ingeniería Agrícola y Alimentos. A.A. 1779, Medellín, Colombia. <elmorenoc@unal.edu.co>

2 Lead Researcher. Centro Nacional de Investigaciones de Café, CENICAFÉ. Disciplina de Ingeniería Agrícola. Kilómetro 4 antigua vía a Manizales. Chinchiná, Caldas, Colombia. <carlos.oliveros@cafedecolmbia.com>

3 Assistant Researcher. Centro de Investigación en Palma de Aceite - CENIPALMA. Programa de Agronomía. Villavicencio, Colombia.<oalfonso@cenipalma.org>.

4 Titular Professor. Universidad Nacional de Colombia - Sede Medellín - Facultad de Ciencias Agrarias - Departamento de Ingeniería Agrícola y Alimentos. A.A. 1779, Medellín, Colombia <falvarezme@unal.edu.co>

Received: November 29, 2012; accepted: June 07, 2013.

Abstract. Rotary beaters were designed, built and evaluated for use in a portable coffee harvesting tool. The present study was carried out in three phases. In the first phase, preliminary tests were conducted to determine the performance of three rotary beaters. In the second, eleven experimental rotary beater models of various forms were built and evaluated based on the results of phase one, determining the detaching capacity, selectivity, branch damage, fruit dispersion and rotor balance for each one. The analysis was performed using a decision matrix with three qualifying levels (high, medium and low), which resulted in one beater with the best performance. In the third phase, this beater's design was refined using CAD for future evaluations. The deformations and maximum experimental stresses were below the maximum permissible values for the material used in the beater's construction.

Key words: Beater, stress, coffee, portable tool.

Resumen. Se diseñaron, construyeron y evaluaron impactadores rotatorios para ser utilizados en una herramienta portátil, en la cosecha selectiva de café. La investigación se adelantó en tres fases; en la primera se realizaron pruebas preliminares sobre el desempeño de tres impactadores. En la segunda, con base en los resultados de la fase uno, se construyeron y evaluaron once modelos experimentales de impactadores rotatorios de diferentes formas para los cuales se determinó su capacidad de desprendimiento, selectividad, daños causados a las ramas, dispersión de frutos y balanceo del rotor. La evaluación se efectuó por medio de una matriz de decisión con tres niveles de valoración, alto, medio y bajo, de la cual resultó un impactador con el mejor desempeño. En la tercera fase, se tomó el modelo de impactador de mejor desempeño y mediante CAD se realizó el diseño refinado antes de construirlo para futuras evaluaciones. La deformación y esfuerzo máximos experimentados por el impactador fueron inferiores a los máximos admisibles por el material empleado en la construcción.

Palabras clave: Impactadores, esfuerzo, café, herramienta portátil.

Colombian coffee is known for its high quality which depends on various factors including crop variety, climatic conditions, harvest and the wet processing. Currently, harvesting is the activity with the greatest impact on coffee production costs, representing between 40 to 50% of these costs according to FEDERACAFE (2012).

The Agricultural Engineering Department of CENICAFÉ has developed various studies starting in 1998 in order to improve coffee harvest indicators (efficiency, efficacy, quality and losses). In a time and movement study, the activities of coffee collectors, the time used by each one and the most used cycle were identified (Vélez et al., 1999). In addition, based on these studies, collection cycles with fewer microactivities and appropriate devices have been proposed for new collection methods that have increased yield by up to 35% (ibíd). Currently, a device called Canguaro 2M that assists in the manual harvest of coffee is being evaluated and improvements in the coffee harvest indicators have been observed (Buenaventura, 2011 and 2012). Cenicafé has also developed and evaluated devices that are used in other countries for the harvest of coffee and other products by detaching the fruit through direct impact.

According to Shigley et al. (2004), the term impact refers to the collision of two masses with an initial relative velocity, while the term shock is more general and is used to describe any disturbance or suddenly applied force, meaning that the study on shocks includes impacts as a specific case. There are two general approximations for the study of shocks, depending on whether only a statistical analysis is carried out or if a statistical and a dynamic analysis are simultaneously carried out.

The first studies on impact were mainly conducted by the military; however, given the growth and degree of technological complexity achieved by civilian industries, a high demand has been seen in recent years for studies that investigate the behavior of various materials when subjected to loads of short durations. According to Zukas et al. (1992), the study of the impact phenomenon involves several classic disciplines, as seen for the low velocity regime (<250 m s-1) where many problems are studied by structural dynamics and the load and response time are contained in milliseconds. When the velocity is increased (500-2,000 m s-1), the response of the bodies are associated with the behavior of the material in the small impact zone. In this case, the load and response time are in the order of microseconds.

A complete description of the impact dynamic of solids can be generated by taking into account the geometry of the interacting bodies, the elasticity, the plasticity, the propagation of the shock wave, the hydrodynamic flow, the deformation and finite stresses, the friction and thermal effects and the initiation and propagation of the failure in the colliding material (Zukas et al., 1992).

When harvesting coffee, the impact is applied using elliptical or cylindrical shaped elements that are usually made of plastic. Some impact devices can be directed by the collectors to places where they have identified a presence of mature fruits, allowing for a more precise operation and a higher possibility of selective harvesting. This characteristic is very important in Colombia due to the climatic conditions that result in up to 15 flowerings per year as reported by Arcila (2001), meaning that 10 to 15 collection passes are needed each year (Marín et al., 2003). The mechanization of this process is difficult because it is possible to find branches with fruits in different maturation states in each pass.

Among the devices evaluated for semi-mechanized harvesting by impacting the fruits, there was a portable device called mechanical comber-CENICAFÉ-I; designed by Oliveros (1999) for the application of compression cycles on bunches with a high percentage of mature fruits (>50%) in order to apply stress at the principal fruit peduncle and stem peduncle union and resulting in detachment with low amounts of immature fruits. The device, powered by a pneumatic motor, was tested in laboratory conditions with an operating pressure between 5 and 7 bar. The bunches with a high proportion of mature fruits were impacted for a period between 0.30 and 7.7 s, a function of the branch length and the quantity of fruits on the branch.

García et al. (2001) studied the effect of impact applications on coffee branches, for which a prototype was developed and evaluated at the laboratory level. The authors observed a detachment of 90% of the mature fruits present on the branches with the percentage of green fruits in the harvested mass at 23% and a recommended optimal operation time of 2.5 seconds on average in the better treatments.

García (2001) modified an Italian device that was originally designed by the COIMA company for the impact harvesting of olives. The new prototype was called a mechanical comb and was evaluated in high density coffee crops (14,000 trees ha-1) that were planted in lots with slopes between 50 and 100%. Later on, Oliveros (2001) reduced the number of elements of the mechanical comb to two and evaluated its performance in Chinchiná, Caldas, Colombia. Table 1 presents the summary of the results obtained with the three mentioned devices.

Based on the experience with the previous devices, Oliveros et al. (2005) developed and evaluated a device that assisted in the manual harvesting of coffee by impacting fruits called IMFRA 3DC ("Impactador de Frutos y Ramas" or Fruit and Branch Beater). The fruits were detached by the impact of two elliptical Teflon elements that rotated at 1,100 rpm and were powered by a DC motor with rechargeable dry batteries.

The IMFRA 3DC device was evaluated during the principal harvest of 2004 in the municipality of Timbio (Cauca, Colombia) with the Colombia red variety, second harvest, and obtained yields that were above those seen with manual collections, almost three times higher, but with a quality that varied between 10.3 and 4.3% (immature fruits in the harvested mass), values above the recommended standards for this indicator. The efficacy was close to 80%, an acceptable value for this technology.

The present study aimed to explore the viability of selective coffee harvesting by directly impacting the fruits and using various modifications to the geometry of the impact elements. In order in to increase selectivity, the design of the elements included a decrease in contact area with the fruit at the time of impact, thereby attempting to only impact the mature fruits on the bunches that had low and medium concentrations of mature fruits (<50%). This led to the need to properly train the operators so that the selectivity could increase. Simultaneously, the design and number of the elements must also result in the rapid and mass detachment of mature fruits that are found in bunches with a high maturation percentage (>50%), maintaining high yields.

MATERIALS AND METHODS

Location. The exploratory tests were carried out in the Mechanized Harvest laboratory of the Agricultural Engineering Department of CENICAFÉ in the municipality of Chinchiná (Caldas), at an altitude of 1,310 m, an average annual temperature of 21.5 °C and relative humidity of 79.5%. Three branches of Colombia coffee variety were used for the test. The field tests were carried out in lots located at the CENICAFÉ Naranjal Station in the municipality of Chinchiná (Caldas).

Methods. The present study contained three phases. In the first phase, preliminary tests evaluated the performance of three beaters that were developed in CENICAFÉ. In the second, 11 beaters were built and evaluated using a decision matrix with three levels (high, medium and low). Finally, the mechanical behavior (stresses and deformations) of the beater with the best performance was established using the computer assisted design software Mechanical Desktop in the third phase.

Phase 1. Preliminary tests:

Evaluated indicators. The indicators efficiency and quality were analyzed; the coffee branches were classified according to the percentage of maturation, defining two intervals: branches with a percentage of maturation between 50 and 70%, and branches with maturation above 70%. The following mathematical expressions were used to calculate the associated variables:

Efficiency Indicator. Variable associated with the mass (kg) of the coffee detached per hour (YIELD).

Quality. Variable associated with the percentage of green fruits in the harvested mass (GHM).

The following beaters were produced with the idea of reducing the contact area between the coffee fruits and the beater:

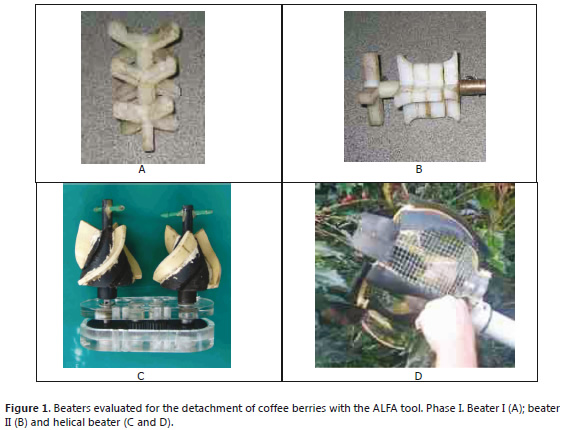

Beater I. Three sets of impactors, each with four blades that varied in length and that were separated by 90º; the form of the blades allows them to be directed toward one target. When all the fruits in the bunches are mature, all the blades must be directed toward the fruits for mass detachment. This beater is seen in Figure 1A.

Beater II. Similar to Beater I but with four concave profiles, similar to the surface of the fruits in the bunches. The upper part was used to detach mature fruits found in the bunches with green fruits. The lower part was used for mass detachment. Beater II can be seen in Figure 1B.

Helical Beater. This beater (Figure 1C) was used for selective detachment, especially where there was a high offering of mature fruits but at low concentrations in the bunches. In this scenario, the work must be done agilely but also with care and precision in order to avoid the detachment of green fruits and shoots; a common situation in the harvesting passes of the principal coffee regions of the country.

The evaluated beater had two sections; one for mass detachments and one for selective detachment. The former had a truncated cone shape with a set of three helical blades. The latter had a circular element placed at the extreme point of the central axle of the beater. When turning, both beaters rotate from the outside towards the inside.

Plastic mesh screens were used with these beaters in order to contain the fruits that were not caught by the utilized baskets.

Observations were recorded with the use of the beaters and screens in the principal harvest in the municipality of Sasaima (Cundinamarca, Colombia) in a lot planted at 1.40 m x 1.20 m with one tree per site and 80% slope.

Phase 2. Development of the beaters

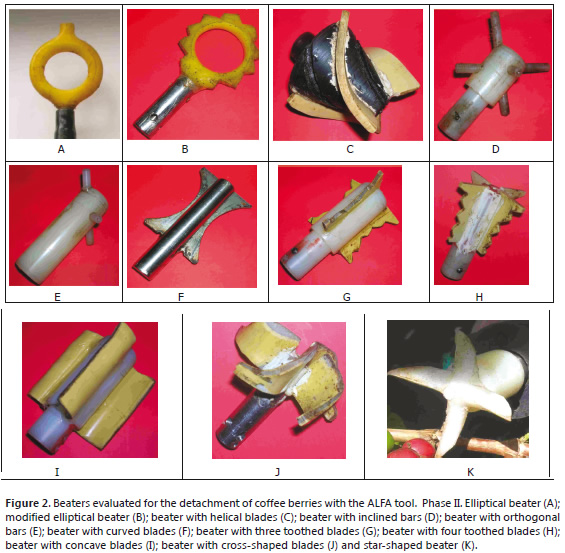

11 beaters with elements for mass and selective detachment were designed based on the beaters studied in phase 1 (one beater was designed by Oliveros et al., 2005). The beaters are shown in the Figure 2.

Elliptical Beater. The biggest axis of the external ellipse of the coffee bunch, calculated by Londoño et al. (2002) with an average of 50.88 mm, was taken into account in the design of this beater (Oliveros et al., 2005). Another important variable in the design was the force necessary to detach coffee fruits with the application of bending moments. For mature fruits of Colombia variety, Alvarez (1998) obtained values between 2.40 and 2.52 N. The force necessary for mass detachment of fruits from bunches was also considered for the design (Londoño et al., 2002). 2005). The force necessary for mass detachment of fruits from bunches was also taken into account for the design (Londoño et al., 2002).

Modified Elliptical Beater. With this beater, a reduction was sought in the contact area with the fruit in regards to the original model, thereby permitting higher selectivity during collection. Said modification can be seen in Figure 2B.

Beater with helical blades. The design consisted of a cone made of prolon with a diameter that ranged from 5 cm to 1.5 cm with 1.5 cm curved PVC blades attached to the surface for detachment from branches with high concentrations of mature fruits. The form of the blades was designed to focus on fruit detachment (Figure 2C).

Beater with inclined bars. A nylon shaft with a diameter of 2 cm and a length of 8 cm was used that had three bars with diameters of 0.5 cm and lengths of 5 cm; distributed at angles of 70 and 90° in relation to the cylindrical shaft, in hopes of higher selectivity (Figure 2D).

Beater with orthogonal bars. The previous beater was used with two orthogonal bars, as seen in Figure 2E. The length of each bar was 5 cm. The bar at the tip was used for improved selectivity and the central bar was used for mass fruit detachment.

Beater with curved blades. A stainless steel shaft with a diameter of 1.5 cm and a length of 8 cm was used with two stainless steel curved blades with lengths of 6 cm, welded to the surface at 180°, with a curvature similar to that reported for coffee fruits in bunches (Figure 2F), Londoño et al. (2002). The higher points were used for selectivity and the blades were used for mass detachment.

Beater with three toothed blades. A nylon shaft was used with three toothed blades attached to the surface (Figure 2G); with a profile similar to that observed in fruits in bunches (Londoño et al., 2002). The blades on the upper part had higher heights (2 cm) in order to better penetrate the clusters and facilitate the selective detachment of mature fruits.

Beater with four toothed blades. This beater was similar to the previous one but with an additional toothed bladed (four) attached to the surface of the nylon shaft (Figure 2H). This design sought to decrease the time spent on the detachment of the coffee fruits.

Beater with concave blades. This design consisted of a nylon shaft with three curved blades with lengths of 6 cm and heights of 2 cm and made of PVC, offering mass detachment (Figure 2 I). The upper points were used for selective detachment.

Beater with cross-shaped blades. This beater used a nylon shaft and four PVC cross-shaped blades with heights of 1.5 cm in the upper part (near the central shaft) and of 0.3 cm in the lower part, seeking to transmit torsional moments to the fruits, allowing for the mass detachment of the fruits and facilitate their capture (Figure 2J).

Star-shaped beater. A star-shaped element with a diameter of 5 cm was used to impact the fruits for high levels of detachment (Figure 2 K). The points were used for the isolated mature fruits. The material used was nylon.

Field tests. The field tests were carried out at the CENICAFÉ-Central Naranjal station in Chinchiná, Caldas. The following characteristics were evaluated: selectivity, massivity and concentration of detached fruits. The evaluation was conducted with coffee trees with branches with fruits of different states of maturation, branches with high maturation and planting distances of 2 m between the rows to facilitate observation, counting and the concentration of detached fruits on the ground. Furthermore, it was verified that the beaters did not cause damage to the coffee trees or the branches. Videos and photos were taken to contrast the field observations, reducing the speed by up to a magnitude of 6.

Phase 3. Design and construction of the selected beater

Computer assisted design. The beater that fulfilled the principal evaluated aspects was selected. Its design began with the creation of the beater with the program Autocad from Autodesk. The measurements that were used for the computer design were taken from the beater selected in phase II. A calibrator was used to take the measurements on a scale of 1:1. Afterwards, the model was exported to the program MSC Visual Nastran Desktop 4D from Autodesk in order to analyze by finite elements and verify the resistance of the design to the forces it would be subjected to.

RESULTS AND DISCUSSION

Phase 1. Preliminary tests

Beaters I and II. Mathematical expression 1 was used to calculate the yield and expression 2 was used for the quality (GHM). 9 branches were harvested with beater I, 4 of which had a percentage of maturation that was between 50 and 70% and the remaining 5 presented a value over 70%. The results obtained for this beater are shown in Table 2.

24 branches were used for the tests with beater II, 14 of which had a percentage of maturation between 50 and 70% and the remaining 10 had percentages over 70%. The results are presented in Table 3.

Although these results are exploratory, they show an improved behavior of beater II, both in yield and in percentage of detached green fruit.

Helical Beaters. The average load in the evaluation was 545 g/tree and the average percentage of maturation was 55.7%. The results are summarized in Table 4.

According to the above tables, the average percentage of harvested green coffee was 4%, a lower value than that obtained with the same IMFRA 3VDC device with elliptical beaters in the same lot and pass, which presented an average value of 6.9% (Álvarez, 2006; Oliveros et al., 2005). However, the harvest time and the percentage of captured fruits were low, implying that the obtained yields were higher than that of traditional manual collection.

Phase 2. Beater development

After the field stage, the videos were analyzed, which allowed for the elimination of some beaters due to a failure to comply with the characteristics of selectivity and mass detachment. The designs that did comply were subjected to laboratory tests to analyze possible misbalances in the devices; a very important factor in continuous work due to the increase in operator fatigue and injuries. Afterwards, an evaluation matrix was applied to each of the beaters.

Creation of the evaluation matrix. The matrix, with each of the evaluated aspects (first column) and the three levels is shown in Table 5. The grade was one (1) if the obtained results were positive, zero point five (0.5) if the obtained results did not comply in all of the evaluations and zero (0) if the results were negative.

The beaters that presented the better results were: with three toothed blades, with four toothed blades and with concave blades, which were used in further field evaluations, in order to obtain the best one (Table 6).

The field tests determined the selection of the three toothed blades beater because the beater with four toothed blades did not show improvements for the harvest but required more work and more materials for its construction. The beater with the concave blades presented lower selectivity and concentrations of the fruit.

Phase 3. Design and construction of the selected beater

The computer assisted design of the three toothed blades beater can be seen in Figure 3 (A-C). The maximum deformation appears in the extremities of the blades and has a value of 0.00441 mm, while the maximum stress is seen at the base of the beater at the opening for the housing of the fastening screw, which attaches the beater to the shaft. Its maximum value is 3.12 MPa, below that of the material used in the beater's construction (Table 7).

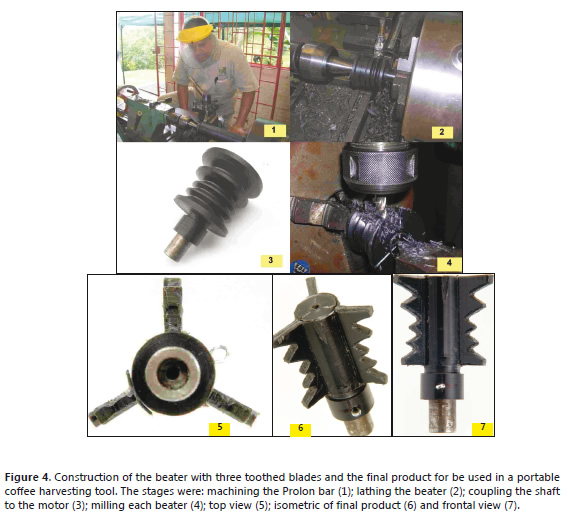

The selected beater (with three toothed blades) was manufactured with Prolon on, an engineering plastic with high thermal and mechanical resistance that offers ultraviolet (Uv) resistance, which is vital for exposed applications.

The different stages for the construction of the beater and final product are presented in Figure 4.

CONCLUSIONS

In the preliminary evaluations with beaters I and II, the harvesting of coffee from branches with medium concentrations of mature fruit, between 50 and 70%, obtained yield values between 10.6 and 14.0 kg/h with 5.4 to 5.7% of green fruits in the harvested mass. These promising results allowed for the analysis of 11 beaters based on the same principle of detachment. The beaters with three and four toothed blades obtained the higher grades when subjected to the evaluation matrix; however, the selected beater was that of the three blades due to the fact that it requires less material in its construction. The computer design allowed for the selection of materials in the construction of the beater with three toothed blades, where the deformation and the maximum stress (0.00441 mm and 3.12 MPa respectively) were below those that are withstood by the material selected for its construction (Prolon).

ACKNOWLEDGEMENTS

The authors wish to thank CENICAFÉ and COLCIENCIAS for their financial support of the present study.

BIBLIOGRAPHY

Álvarez, T.E. 1998. Estudio de las propiedades físico mecánicas del sistema fruto pedúnculo del café variedad Colombia, Trabajo de grado. Facultad de Ciencias Agrarias. Universidad Nacional de Colombia, Medellín. 112 p. [ Links ]

Álvarez, V.A. 2006 Evaluación del equipo de cosecha portátil IMFRA 3VDC. Documento interno. Disciplina de Ingeniería Agrícola. Chinchiná. 14 p. [ Links ]

Arcila, P.J. 2001. Aplicación de la escala BBCH ampliada para la descripción de las fases fenológicas del desarrollo de la planta de café. Federecafé, Cenicafé, Chinchiná. 33 p. [ Links ]

Buenaventura, A. J.D. 2011. Campaña de difusión y adopción de la tecnología CANGUARO 2M. Informe Anual de Actividades. Centro Nacional de Investigaciones de Café - CENICAFÉ, Chinchiná. 16 p. [ Links ]

Buenaventura, A. J.D. 2012. Campaña de difusión y adopción de la tecnología CANGUARO 2M. Informe Anual de Actividades. Centro Nacional de Investigaciones de Café - CENICAFÉ, Chinchiná. 25 p. [ Links ]

Federación Nacional de Cafeteros de Colombia (FEDERECAFÉ). 2012. Costos de producción de café: Zona Central Cafetera. Gerencia Técnica. División de Producción y Desarrollo Social, Santa Fé de Bogotá. 13 p. [ Links ]

García, E.A. F. Álvarez y C.E. Oliveros. 2001. Estudio experimental de la respuesta de la rama de café ante la aplicación de impacto mecánico. Revista Facultad Nacional de Agronomía Medellín 54(1-2): 1187-1209. [ Links ]

García, E.A. 2001. Estudios básicos prototipo italiano peine dinámico. Informe Final ING 0134. "Cosechador Italiano TORDO y Peine Dinámico". CENICAFÉ - COLCIENCIAS, Chinchiná [ Links ].

Londoño, H.D., C.E. Oliveros y M.A. Moreno. 2002. Desarrollo de una herramienta manual para asistir la recolección de café en Colombia. Revista del Centro Nacional de Investigaciones del Café, Cenicafé 53(2): 93-105. [ Links ]

Marín, S.M., P.E. Arcila, E.C. Montoya y C.E. Oliveros. 2003. Escala de maduración para los frutos de cafeto. Avance Técnico, Cenicafé. 315 p. [ Links ]

Oliveros, C.E. 1999. Evaluación de batidores mecánicos para la cosecha de café. Informe Anual de Actividades. Centro Nacional de Investigaciones de Café - CENICAFÉ, Chinchiná. 26 p. [ Links ]

Oliveros, C.E. 2001. Evaluación de un peine mecánico en la cosecha de café. Informe Anual de Actividades. Centro Nacional de Investigaciones de Café - CENICAFÉ, Chinchiná. 47 p. [ Links ]

Oliveros, C.E.; C.A. Ramírez, R. Acosta y F. Álvarez. 2005. Equipo portátil para asistir la cosecha manual de café. Revista Facultad Nacional de Agronomía Medellín 58(2): 3003-3013. [ Links ]

Shigley, J.E., C.H. Mischke and R.G. Budynas. 2004. Mechanical engineering design. Seventh edition. Mc Graw Hill, New York. 1030 p. [ Links ]

Vélez, J.C., E.C. Montoya y C.E. Oliveros. 1999. Estudio de tiempos y movimientos para el mejoramiento de la cosecha manual de café. Boletín Técnico Cenicafé. No. 21. 91 p. [ Links ]

Zukas, J.A., T. Nicholas, H.F. Swift, L.B. Greszczuk and D.R. Curran. 1992. Impact dynamics. Second edition. Krieger Publishing Company, Melbourne, FL. 452 p. [ Links ]