The first worldwide producer of panela is the country of India, which represents 56% of the total production; in second place is Colombia, with 15%. Burma (Myanmar), Brazil and China, followed in importance. In Latin America, the main producers are Colombia, Brazil, Honduras, Mexico, Peru and Venezuela (Rodríguez, 2014).

The cultivation of sugarcane is an agricultural activity of great socio-economic importance in the world. Sugarcane in Colombia has an area of 484,559 ha, of which 45% (218,000 ha) is dedicated to the production of sugar and ethanol and the remaining 55% (266,559 ha), to the panela production (Murcia and Ramírez, 2017). Within permanent crops, sugarcane ranks second in extension, after coffee (Minagricultura, 2004). Panela production is one of the main agricultural activities of the Colombian economy (Ramírez, 2017) among other reasons, because of its significant participation in the gross domestic product (GDP), about 7.3% of the agricultural sector, because it is a source of income for more than 70,000 families of producers and for the generation of rural employment, linking close to 350,000 people (Dane, 2016).

According to DANE (2016), in Colombia was sown 167,711 ha of cane and its production in panela was estimated at 990,908 tons. The panela is characterized by its high concentration of sugars, mineral content and traces of vitamins (Hernández et al., 2002). For Kumar and Tiwari (2006) it is an integral sugar, not refined and without chemical additives, that has a great nutritive and medicinal value.

The genetic improvement of sugarcane for panelera agroindustry is oriented to the substitution of genetic materials with low productive potential, through the introduction and evaluation of high yielding varieties and good agroindustrial performance, adaptable to the management conditions of the panela zones (Insuasty et al., 2003). The new varieties of sugar cane are produced in the country by el Centro de Investigación de la Caña de Azúcar de Colombia-Cenicaña in the department of Valle del Cauca, with the purpose of increasing the production of cane and sugar (Cassalett et al., 1995). These varieties could be good for the production of panela, but when they are planted in different agroecological zones, in soils of low fertility, less luminosity, greater precipitation and height above sea level, among others, they cannot adapt and therefore, their production is lower than that obtained at the place of origin. Because of the sugar content in the cane at the beginning of the harvest has low values, it is convenient to have varieties with high content and early accumulation of saccharose (Cox et al., 1990; Singh and Singh, 2004; Wagih et al., 2004).

The productivity of cane crops in the municipality of San Carlos is very low (30 to 50 t ha-1), compared to the national yield in 2014, of approximately 113 t ha-1 (López JG, 2017, comunicación personal). This is due to the use of low-yielding varieties, low planting densities, lack of adequate renovation and fertilization programs, and the use of cutting by pick out, among others. Therefore, the objective of this research was to evaluate, agronomically and industrially, ten varieties of sugar cane for panela produced by Cenicaña, from the series 85, 92 and 93, using as a control the local variety Co-421.

MATERIALS AND METHODS

The study was carried out in the sugarcane production area of the municipality of San Carlos (Antioquia), in two localities (El Paraguas and La Cabaña), at a height between 800-950 masl, with an average temperature of 22.5 °C, precipitation of 4000 to 5000 mm per year, relative humidity of 85%, average solar brightness of 4.3 h d-1 (IDEAM station Nº 23085220. Average 2010-2014).

The soils where the tests were sown, showed Ar and FArA textures, extremely acidic, with low contents of organic matter (OM), low P availability, low in K, Ca, Mg, S, Zn, B, Cu and rich in Fe and with medium contents of Al (Table 1). In general terms they are soils of low fertility.

Table 1 Chemical characteristics of the soils where the variety tests were established in the municipality of San Carlos (2014).

Two plots were established where the following varieties were evaluated: CC 85-92, CC 92-2188, CC 92-2154, CC 93-4418, CC 93- 3895, CC 85-47, CC 85-57, CC 92-2198, CC 93-3817, CC 84-75 and as control the variety Co-421. The asexual seed (stems) used was divided into pieces of four buds and planted at the bottom of the furrow at a density of ten buds per linear meter, with a furrow length of six m and a furrow distance of 1.4 m, four furrows of six m long; the effective area was 604.8 m2 corresponding to each experimental plot.

pH in water (1:1); soil organic matter (SOM), Walkley and Black; Al, 1 M KCl; Ca, Mg, K and Na, 1 M ammonium acetate; P, Bray II; S, 0.008 M calcium phosphate; Fe, Mn, Cu and Zn, Olsen-EDTA; B, hot water.

Variables to evaluate

The variables studied were tons of cane per hectare (TCH), tons of panela per hectare (TPH), industrial yield (%) and industrial quality represented in total soluble solids (°Brix), pH, saccharose (%), reducing sugars (%), phosphates (ppm) and purity (%). In addition, the sanitary behavior of diseases of economic importance such as ring spot (Leptosphaeria sacchari van B), yellow freckle (Mycovellosiella kopkey Kruger), brown rust and virus, were recorded.

Plant height or stem length (m). Five stems per experimental unit (EU) were randomly picked from each variety and the length at harvest, was measured from the plant neck to the first visible ligule, using a non-destructive method.

Stem diameter (cm). From each variety were taken five random stems per EU at which the diameter was measured at harvest, using a micrometric calibrator, using a non-destructive method.

Population of stems (bunchig). The number of stems present in five linear meters in each variety was counted at harvest.

Overturning (%). The percentage of stems that showed overturning with respect to the total of the population of the EU of each variety was determined. This measurement was made at the time of harvest.

Physicochemical analysis. The content of total sugars was measured from twelve months after sowing and after each month, until reaching the appropriate maturity index for harvest (cutting time), in 10 stems per replicate, of each variety. For this analysis samples of panela (3 units of 170 g each) were weighed in a digital analytical balance (Mettler Toledo model AB204-S/FACT, 0.1 mg precision), with samples of raw juices of cane (200 mL per variety); the soluble solids were determined with a digital refractometer (Anton Paar ref. Abbemat 300, 0.01 °Brix, precision). The percentage ratio between saccharose in juice and °Brix is known as juice purity. The apparent content of saccharaose, expressed as a percentage by weight and determined by a polarimetric method, is called "pol" (Larrahondo, 1995).

For the analysis of pH, saccharose (%), reducing sugars (%), purity (%) and humidity (%), the following equipment was used: a Schott potentiometer model CG842 precision 0,01; Spectrophotometer (Thermo Scientific model Evolution 201, precision 1.0 nm); A Atago polarimeter model OSK 6544, with an accuracy of 0.1 deg. (SI Analytics GMBH model SLR, speed range of rotation of the agitator 100-1,100 rpm, temperature regulation 25-200 °C ± 3 °C). Drying stove for dry matter obtaining (Thelco model 17, series 21AG-6, temperature range 30-225 °C). For these analyzes, 15 kg of cane per EU (per treatment and per repetition) were taken.

Experimental design

An experimental design of a randomized complete blocks, with two replications per locality, was carried out for each variety. The analysis of combined variance and the Duncan's mean test with a significance level of 5% was performed to detect differences in mean between treatments. An average of three cut cycles was obtained for each variable, using the statistical program MSTATC.

RESULTS AND DISCUSSION

Cane and panela production

According to the results contained in Table 2, it was observed that for the variables TCH and TPH, there were significant differences (P≤0.05) between the materials. The varieties that stood out for TCH were CC 93-4418 and CC 93-3895, with 138.9 and 128.4 t ha-1, respectively, followed by varieties CC 92-2154 and CC 92-2198 with 119.0 t ha-1; the control Co-421 was exceeded by the variety CC 93-4418 at 40.4 t ha-1. These data are similar to those found by Ramírez et al. (2014) in Guepsa, Santander with varieties of series CC 92 and 93.

Table 2 Tons of cane and panela per hectare and average yield of three cuts of the variety test, located in the municipality of San Carlos, Antioquia. 2014.

The stems population per ha at harvest, ranged from 61,613 to 90,354 units, with the variety CC 93-4418 being the most productive, with a difference over the control of 16,043 units, followed by the variety CC 92-21188 with a difference of 4564 units, since the control only produced 74,307 units; similar data and in some cases higher than those found by Ramírez et al. (2014), in a variety test in Santander. All the varieties exceeded in thickness to the control, being the material CC 92-2198 the one of thicker stem, but with smaller production of stems; the CC variety 93-4418 (Table 3) is followed in its order and with good stems production and thickness.

Table 3 Results of agronomic evaluations to the harvest of three cuts, in the variety test, located in the municipality of San Carlos, Antioquia. 2014.

The varieties CC 93-3817, CC 93-4418 and CC 93-3895 showed lower percentages of overturning than the control, with a reduction of 33%, 31% and 22%, respectively. As a negative aspect it was observed that the materials CC 85-57 and CC 92-2154, showed flowering percentages of 87 and 44%, respectively, with the control, which did not flower; it is estimated that outstanding genotype should not present blooms higher than 20% (López, 2015)(Table 3).

The severity levels of the evaluated diseases (ring spot, yellow spot, rust and virus), in the three evaluation cycles showed an incidence ranging from 1 to 3, which is considered low.

Physicochemical characterization of juices and panela

The maturity index (MI) in all the varieties was less than 1, except for the control that was superior; according to Duran and Zapata (1992), a variety of cane is considered mature if the MI is between 0.95 and 1, over-ripening greater than 1 and immature lower than 0.95, indicating that all materials were in optimal conditions for their harvest (Table 4).

Table 4 Average results of evaluation of physiological maturity measured in ºBrix to the harvest, of three cuts of the test of varieties of cane, located in the municipality of San Carlos, Antioquia. 2014.

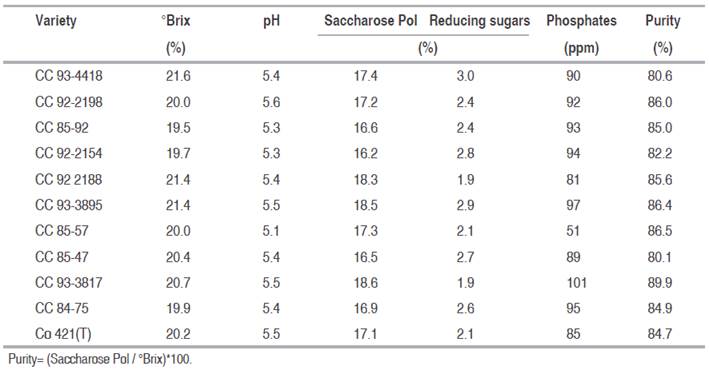

In the juice of the cane are dispersed multiple substances, in addition to saccharose and reducing sugars; the proportion of these substances differs with each variety (Zossi et al., 2011). In the juice, soluble solids content or °Brix ranged from 19.70 for the CC 92-2154 variety and 21.60 for the CC 93-4418. According to Larrahondo (1995) and Duran and Zapata (1992), °Brix of juices should normally fluctuate between 16 and 24, a range in which the varieties evaluated in this study were found, standing out the materials CC 93-4418, CC 92 2188, CC 93-3895 and CC 93-3817 (Table 5); According to Duran and Zapata (1992) these are cataloged as ripe canes.

Table 5 Average values of industrial quality in cane juice at harvest, of three cuts in the varieties assay.

Corpoica (2007) has established minimum and maximum pH values that determine the quality of sugarcane juices to obtain panela with good commercial characteristics; the values found in this study fluctuated between 5.1 and 5.6, indicating that the materials are in the recommended range. The variety with the highest values of pH was CC 92-2198 (5.6) and the lowest one was CC 85-57 (5.1); the average value was 5.41 (Table 5). The results obtained in this study were different to those reported for the other panela areas of Santander, which fluctuated between 5.0 and 5.2 (Table 5). Saccharose Pol (%) in all varieties presented appropriate values, since contents below of 18% can be considered low (Ramírez et al., 2104). The varieties CC 93-3817 and CC 93-3895, with values of 18.6% and 18.5%, respectively, were higher than the control, which only reached 17.1% (Table 5).

Among the simplest sugars are glucose and fructose (reducing sugars), which exist in the juice of ripe canes in a concentration between 1% and 5%. The quality of raw sugar and other products - such as the color and grain (hardness) of the panela - depends in part on the proportion of these reducing sugars, which when increased by deterioration or lack of maturation of the plant, can produce increases in color and defective grain in the panela (Clarke et al., 1986). The reducing sugars in this study fluctuated between 1.9 and 3.0% (Table 5), which were within the values reported by Clarke et al. (1986); however, Corpoica (2007) suggests a range between 0.5 and 1.7%, indicating that the values found in this case are means.

The plots were fertilized in each cut with 1 t ha-1 of dolomitic lime and organic matter, 112 kg ha-1 of nitrogen, phosphorus and potassium, and triple 15 plus 20 kg ha-1 of minor elements. In spite of that, phosphates (P2O5) were low in all varieties, with the highest amount of CC 93-3817 with 101 ppm (Table 5), since, according to Corpoica (2007), the ranges of juice must be between 100 and 700 ppm; low values produce panela with dark colorations. It is important to clarify that the soils tested were very low in P (<10 mg kg-1).

The purity of the juices in most varieties presented values higher than 80%, where the highest was CC 93-3817 with 89.9% (Table 5); according to Corpoica (2007) purity ranges must be between 82 and 95%.

Corpoica (2007) at the Experimental Station Cimpa, established the ranges of physical-chemical parameters that determine the quality of the panela. In this sense, the content of soluble solids or °Brix, for the variety CC 93-3895 was 78 and 70 for the control. According to the same authors, °Brix of the juices, should normally fluctuate between 89 and 95, range in which the varieties evaluated in this study were found, standing out the materials CC 93-3895, CC 84-75 and CC 92 2188 (Table 6).

Table 6 Average values of industrial quality in panela at harvest, of three cuts in the varieties assay.

On the other hand, the minimum and maximum values of pH, recommended by Corpoica (2007), are between 5.5 and 6.5; the values found in this study fluctuated between 5.5 and 6.3, with the exception of CC 85-57 with a pH of 5.3, indicating that most materials are in the recommended range. The variety with the highest pH value was CC 92-2154 (6.6) and the lowest was CC 85-57 (5.3) (Table 6); the average value was 5.7. These data are similar to those reported by Ramírez et al. (2014) in Santander and correspond to those mentioned by the Ministry of Social Protection (2006), established for panela of 5.5 to 6.5.

The values of Saccharose Pol (%) (Table 6) in all materials were adequate for panela, since according to the Ministry of Social Protection (2006), the maximum value that this product must fulfill, as a quality standard, is 83%. The varieties CC 93-3895 and CC 84-75, with values of 78% and 76%, respectively, are outstanding. The final product (panela) of each variety, due to its physical and chemical characteristics, is considered of very good quality.

Reducing sugars in all varieties were high, since the range recommended by Corpoica (2007) is between 5.0 and 14%. The variety CC 93-3895 showed the lowest percentage of reducing sugars and the control, the maximum (Table 6).

The phosphate content of the panela was high in most varieties, with the highest content being CC 92-2154 (652 ppm) and the lowest CC 85-57 (267 ppm). Phosphates are important in the nutritional value of the panela. Moisture percentages were found at the appropriate levels and fluctuated between 4.6 and 7.5% and should be lower than 9%. High percentages reduce panela useful life (Table 6).

CONCLUSIONS

With this study, an advance in the selection of sugarcane varieties for the panelera areas of Antioquia was made; the monitoring of these materials allowed the identification of varieties with potential from the agronomic and industrial view, for the soil and climate conditions of the area of study and are CC 93-4418, CC 93-3895, CC 93-3817 and CC 92-2198, far exceeding the Co 421 control in yield of TCH and TPH.

In this evaluation the outstanding variety was CC 93-4418, both in the agronomic and industrial aspect, being a good material to be recommended for panela production in similar regions. These varieties of sugar cane for panela are of paramount importance for programs of adaptation and evaluation for other panelera departmental zones.