Pig farming is an activity that requires a lot of dedication from the breeder to achieve good productivity levels and, consequently, satisfactory economic results. Indoor air temperature, humidity, and air quality in rearing environment are important factors that can affect the health, productivity, and welfare of livestock and poultry in confined animal feeding operations (Carroll et al., 2012; Kim et al., 2008).

Air temperature is a key environmental factor for pigs because pigs are warm-blooded animals and a constant body temperature is the basis of their normal life (Huynh et al., 2005). Humidity is another important environmental factor that affects pig body heat-regulation. Humidity generally has minor effects on pigs. However, when combined with high ambient temperature, a significant difference in average daily weight gain in pigs was found (Xie et al., 2017).

In the case of the farrowing house, this problem is evidenced by the coexistence within it of two categories with very different environmental requirements. On the one hand is the sow which must be cooled, and, on the other hand are the piglets, which must be heated. The range of thermal comfort in the environment for piglets during the first days of life is between 32 and 34 °C and that for the sow is in the range 16 to 21 °C (Perdomo et al., 1987). The solution of this problem, present in all pig farms, is a priority when seeking to improve the performance of both categories. Thus, within the principles of thermal comfort and animal welfare, the producer is faced with a major problem, where in a small physical space it is required to provide two different microenvironments where otherwise the performance of both the sows and the piglets will be compromised (Pandorfi et al., 2007).

In general, the heating of piglets in maternity phase is a system that consumes a lot of power on the farm. Thus, because of the large amount of electricity that is used in this type of setting, there is a need for further research to enable minimal consumption without harming animal welfare while preserving the environment.

Success in intensive livestock production is directly related to the efficient management of the environment. The control of the housing environment is generally based on measurements of temperature and relative humidity. However, surveys indicate the potential for more accuracy in decisions when physiological responses of animals to environmental stressors are incorporated (Goedseels et al., 1992; Aerts et al., 1996; Lacey et al., 2000).

The difficulty of analyzing the large volume of information relating to all variables involved in the establishment of appropriate conditions for animals in the building has been reported in the literature. The main interest in this area is related to the study of phenomena that exhibit gradual uncertainties and can be modeled by Fuzzy Set Theory. Because of its explanatory and multi-disciplinary power this theory can facilitate the work of the modeler in incorporating specialist knowledge of the area, improving the analysis and understanding of some real situations (Amendola et al., 2004).

Fuzzy methodology has been used in various fields such as data analysis, expert systems, control and optimization, aircraft control and biomedicine (Ribacionka, 1999; Lopes, 1999; Weber and Klein, 2003). In the animal ambient area, various applications indicate its potential use, such as in the study of thermal comfort in poultry (Gates et al., 2001; Amendola et al., 2004; Yanagi et al., 2006) and pigs (Xie et al., 2017; Queirós and Nääs, 2005), besides being used to detect estrus in dairy cows (Firk et al., 2003; Ferreira et al., 2007a).

The fuzzy logic application in the pig farrowing house environment becomes necessary and valid to quantify thermal comfort of piglets and at the same time, the productive performance and physiologic responses of these animals. Thus, this method becomes a reliable tool in the predetermination of the comfort of maternity pigs, helping to reduce errors and increase the productivity and welfare of these animals.

Thus, in view of the enormous importance of the production chain of pigs in Brazil, hence the imperative need to seek more sustainable solutions that ensure the minimization of the impact of this activity on the environment, this paper aims to develop a mathematical model based on fuzzy set theory to predict the production performance and the physiological responses of piglets raised in a farrowing house with different heating systems and to validate that model using field data.

MATERIALS AND METHODS

Characterization of the farrowing house and installation of heating systems

The entire study was conducted during the 2015 summer period, in a pig farrowing house of the experimental center in pig farming at the Federal University of Lavras, in Lavras - MG, Brazil. The city of Lavras is located at 21°14’ latitude south, 40°00’ longitude west of Greenwich. The climate, according to the Köppen climate classification is Cwa, rainy temperate (mesothermal) with dry winter and rainy, subtropical summer, altitude of 918.84 m with an average temperature of 19.4 °C, annual average precipitation 1529.7 mm and 76.2% relative humidity.

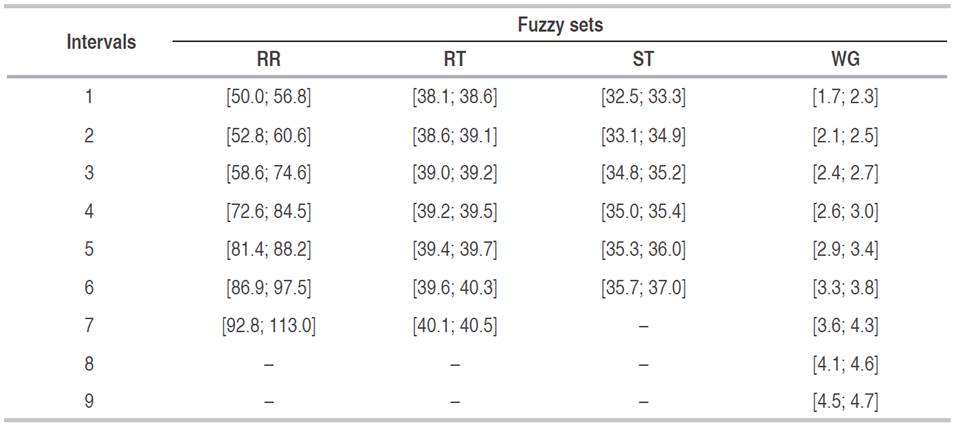

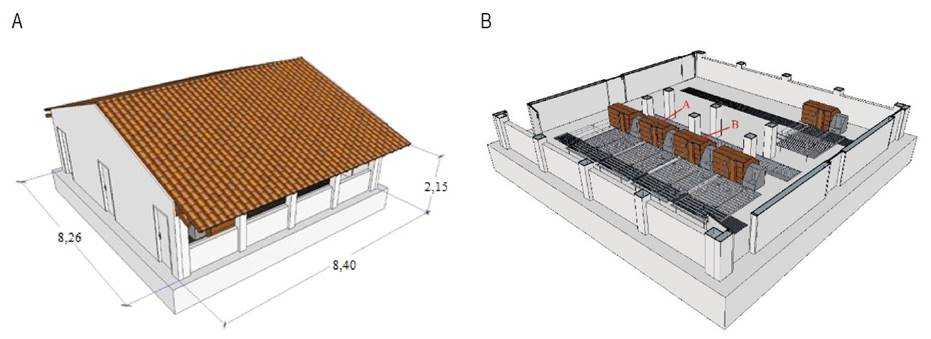

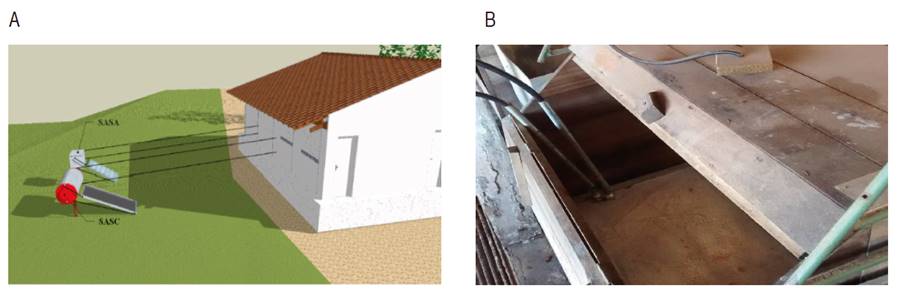

The farrowing house used in this experiment had the following design characteristics: dimensions of 8.26 m wide and 8.40 m long, ceiling height of 2.15 m, gable roof, wood structure, covered with ceramic tiles and East-West orientation. The farrowing house floor was compact concrete with a slope of 2.0% towards the gutters. Five pens 1.80 m long by 1.35 m wide were installed within them, connected to the wooden creep feeders 1.00 m long by 0.68 m wide (Figure 1A), with a shield against the crushing of piglets. Each pen had a perforated floor of durable plastic. A fan/nebulizer was installed inside the farrowing house.

Figure 1 Schematic drawings. A. Of farrowing house with the main dimensions, in meters; B. Of the distribution of the different heating systems within the farrowing house. Caption: A - ASWH and B - CSWH.

In the pig farrowing house evaluated in this study, two different heating systems were installed: a) creep feeder equipped with heated concrete floor, with hot water pipe heating through solar water heater built with alternative materials (ASWH); b) creep feeder equipped with thermal concrete floor heated through hot water pipes by a solar water heater built with conventional materials (CSWH). Distributions of heating systems can be seen by the diagram in Figure 1B.

The conventional solar water heating system (CSWH) had a glass plated solar collector made of aluminum, with internal fins painted in matte black to absorb sunlight and transfer energy to internal piping. The components of the thermal reservoir had internal cylinders and pipes manufactured with stainless steel and rigid expanded polyurethane.

The prototype of solar water heaters manufactured with alternative materials (ASWH) was built with PVC pipes and connections (1/2” diameter), PET bottles and milk cartons (Tetra Pak®). The milk cartons were painted matte black to absorb heat, and retain it within the cylinders to be transferred to water through the PVC pipes which were also painted matte black. In the construction of the alternative solar heater prototype 60 bottles of transparent polyethylene terephthalate (PET) of 2 liters were used. The milk cartons were opened on the upper and lower part, where all the boxes were cut using a cutting jig proposed by CELESC (2010) to maintain a standard in all cases.

In an alternative construction of the hot water reservoir a fiberglass water box of 50 liters was used, coated with polystyrene plates (30 mm), duct tape, and self-adhesive asphalt and aluminum blanket (2.5 mm) to protect the polystyrene plates from the weather. Four 20 mm holes were made in the reservoir, with two holes for circulation of water between the thermal reservoir and the solar collector and the other two holes for water circulation from the heat reservoir to the floor.

In the electrical resistance heater system heater cables were distributed within a masonry floor, and the temperature was controlled by means of an analog thermostat (100 W).

To test the two water heating systems two masonry floors were built with dimensions 74 cm long, 46 cm wide and 7 cm thick. To reduce the heat dissipation at the base of the floors, we used 30 mm polystyrene plates. A 20 mm galvanized steel pipe was placed in the two floors, forming a coil, aiming to uniformly distribute the heat from the water inside the floor. In the third floor heating cables were installed controlled by means of an analog thermostat.

The two solar collectors and water tanks were placed at a distance of about 10 m from the farrowing house to avoid shading them (Figure 2). A low flow water pump (mod. ZC-T40, 12V and 1.05A) was used in each system to force the circulation of water within each system. On each floor a digital controller (thermostat) was used, designed for solar heating applications, which operated to control water flow through the temperature differential between the floor entrance and the thermal reservoir.

Figure 2 A. Functional diagram of the thermal floor and B. Detail of the concrete floor inside the creep feeder.

The pigs used in this study were from sows of the same order of delivery and were equalized in order to eliminate interference factors, maternal ability, number of piglets/litter, etc. Each pen presented between 8 and 12 piglets that, after birth, were relocated by criteria of weight and number of animals so that a fixed number of 10 piglets remained in all the feeders studied.

Measurement and Instrumentation

During all stages of the study, the environmental variables were monitored in the creep feeder, in the environment internal to and external to the farrowing house, through sensors/recorder systems with automated registration. The following variables make up the thermal environment: dry bulb air temperature (Tbs), relative humidity (RH) and air velocity (Vair).

The registration of these environmental variables was performed every 10 minutes for 24 hours daily for the first 21 days of life of the piglets, at a point allocated within each creep feeder.

Sensors/registers of Tbs and RH (Hobo® Mod. U12-012 and accuracy of ±2.5%) were housed inside a perforated guard container, to prevent damage to equipment caused by piglets or excess moisture, and, therefore, the readings were compared to another external sensor outside the protection, to verify any interference of the protection on the reading equipment. The air velocity (Vair) is manually measured by means of a hot-wire anemometer (Testo® Mod. 416 and resolution of 0.1 m s-1). In creep feeders, sensors/registers were fixed in the cover of the creep feeders at a distance of approximately 0.5 m from the floor. In the farrowing house, the environmental variables were recorded within the facility, in the center of the pens that will be studied at a height of 1.3 m from the floor, approximately. In the area outside the premises, sensors/recorders were installed inside a weather shelter, height 1.5 m from the surface, which represented the microclimate of the site.

Physiological responses were evaluated by rectal temperature (RT), skin temperature (ST) and respiratory rate (RR). The RT and RR were measured by two examiners. The RT was obtained with the aid of a digital clinical thermometer (Brasmed® and precision of ±1.0 °C) inserted approximately 2.5 cm into the rectum of animals. A gel-alcohol solution (70%) was used on the tip for asepsis of the digital clinical thermometer. RR was determined from direct visual observation for 15 seconds and then extrapolated for 1 minute. The ST was recorded using a thermographic camera (Instrutemp®, mod. ITTMV-100, accuracy of ±2% of the reading). Thermographic images were obtained covering the entire length of the animal (head, back, lower back and leg). ST was recorded during the morning (9:00 to 11:00) and afternoon (15:00 to 17:00) daily during the first four weeks of the animals’ lives. The images were processed using the software of the camera itself, from points randomly selected. The emissivity of 0.95 was adopted (Montanholi et al., 2008).

The productive performance was assessed by daily weight gain (WG) of the animals. For the determination of WG, five animals were randomly selected and weighed used a digital scale.

Fuzzy model

The fuzzy model developed aimed to generate a system for decision-making on the thermal comfort and productive performance and physiological responses of piglets raised in a farrowing house with a solar heating system. To make this possible, several parameters were evaluated carefully, since the fuzzy system depends on a robust knowledge base to meet the results expected by the user.

To develop the fuzzy system input variables were defined as: the dry bulb air temperature (Tbs) and relative humidity (RH), obtained during the data collection in the environment within the creep feeders. Based on the input variables, the fuzzy system predicts growth performance (weight gain, WG) and physiological responses (respiratory rate - RR, rectal temperature - RT and skin temperature - ST) of piglets raised in farrowing house with solar heating systems.

144 data sets were selected from the data collected in the field experiment for the two different solar heating systems evaluated, where the thermal comfort characteristic behavior was directly influenced by Tbs and RH. Of this total, 33.4% (48 data sets) were used in the development of the relevance functions and rules and 66.6% (96 data sets) were used to test the model developed.

The model was developed in MATLAB® 7.1 through the fuzzy toolbox. The inference method used in the analysis was the Mamdani method, which combines the degrees of relevance for each of the input values by the minimum operator, and adds the rules with the maximum operator (Leite et al., 2010) and is used by various authors (Nascimento et al., 2011; Yanagi et al., 2012; Tavares and Schiassi, 2016). The defuzzification is performed by the center of gravity method. The fuzzy rule system was created based on the database obtained experimentally, on information from the literature and with the help of experts.

Three experts were selected according to the expert fuzzy selection methodology proposed by Cornelissen et al. (2003) and used by several authors (Yanagi et al., 2012; Schiassi et al., 2012). This feature is desired by a specialist (Ayyub and Klir 2006), given its direct influence on reliability and quality of results (Martino, 1993; Preble, 1984).

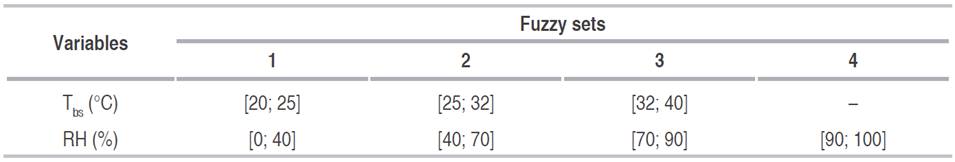

The rule system (Table 1) was developed based on combinations of Tbs and RH, and an expert was consulted to prepare the output result for each combination of the input data. All ratings were established according to the boundary conditions mentioned in the works of Esmay (1982); Nääs et al. (1998).

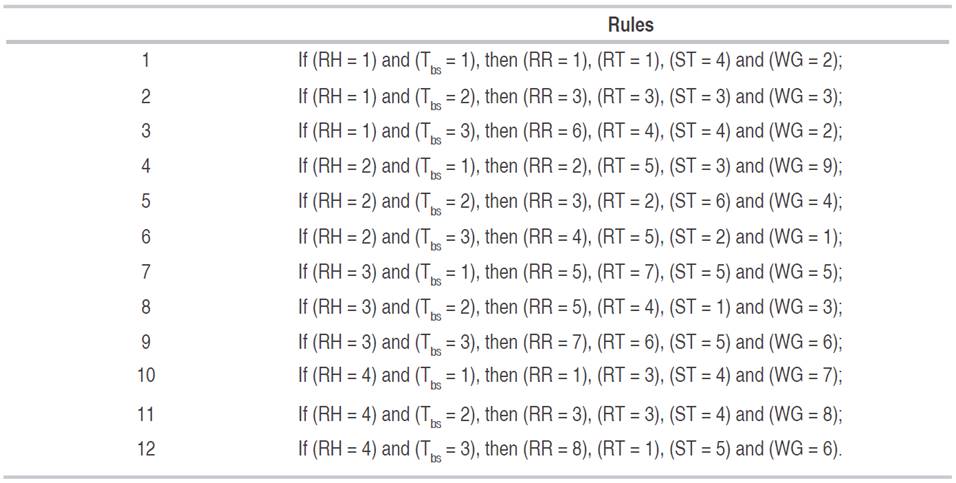

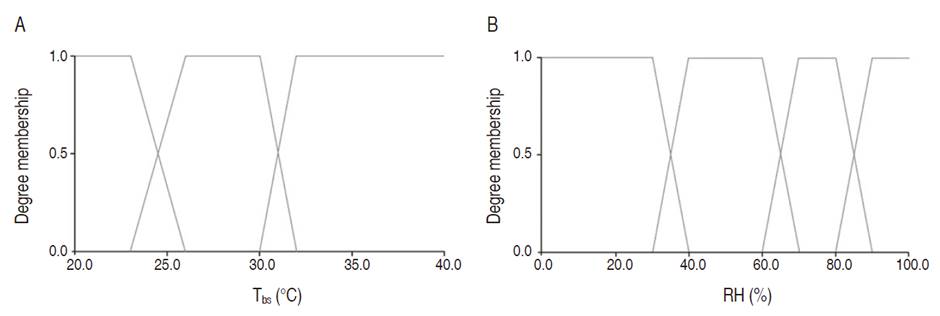

From the relationship between the input variables, a fuzzy model using the Mandani method has been formulated, trapezoidal functions having been selected for input variables (Figure 3), according to Esmay (1982), Nääs (1989); Nääs et al. (1998).

Figure 3 Relevance functions of the fuzzy sets accepted by input variables: A. Tbs, in °C; B. RH, in %.

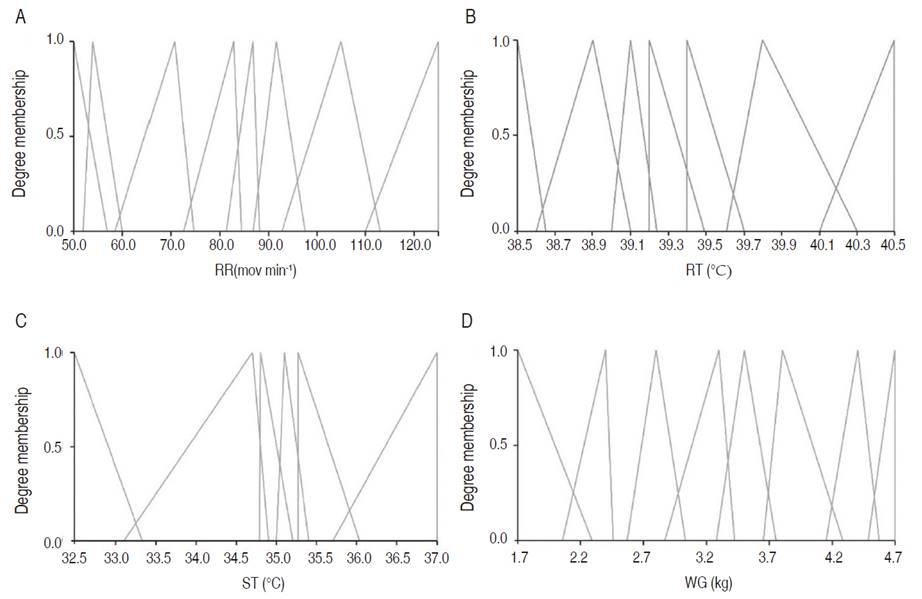

For output variables (RR, ST, RT and WG), the values were grouped according to the characteristic behavioral patterns related to growth performance and physiological responses.

These values were measured with the aid of two experts who were consulted to produce the output result for each combination of input data (Table 2).

After preliminary testing settings, the triangular model was used for the output variable relevance functions (Figure 4).

Figure 4 Relevance functions of accepted fuzzy sets according to the output variables: A. RR, in mov.min-1; B. RT, in °C; C. ST, in °C; D. WG, in kg.

In accordance with combinations of input data 12 rules are defined, as can be seen in Table 3.

RESULTS AND DISCUSSION

The fitting of the fuzzy model was performed based on the interval data collected during the experiment with the range for each relevance function of the output variables adopted in order to result in the lowest possible error when compared with experimentally measured data.

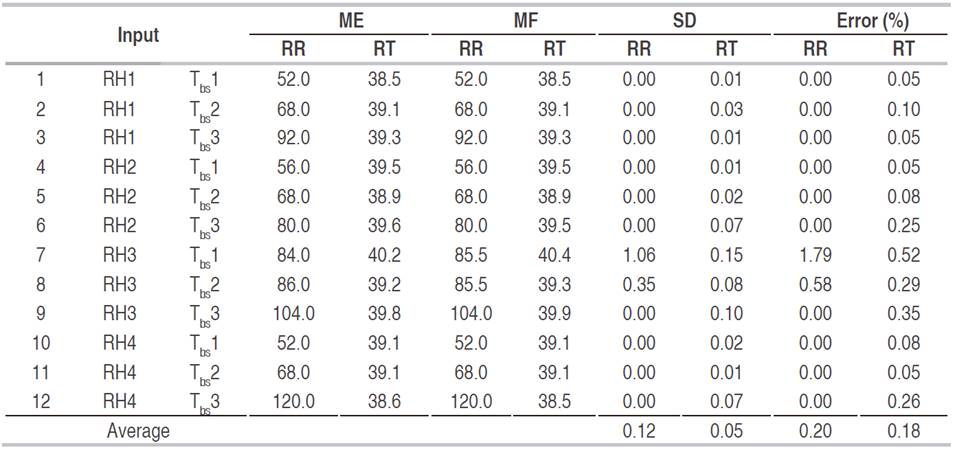

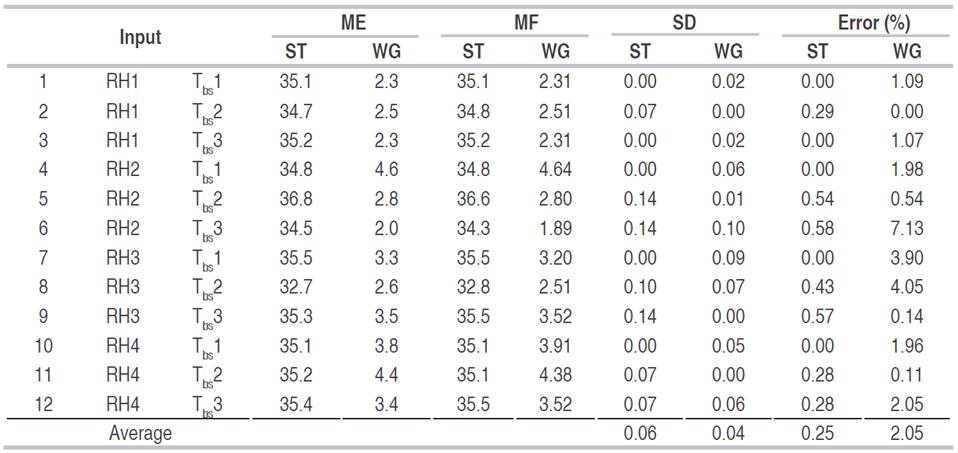

Thus, to test the fuzzy model, measured data of Tbs and RH for the first three weeks of life of pigs were used while model output results were compared with RF, RT, ST and WG values obtained through an experiment conducted in the swine farrowing house with the solar heating systems (Tables 4 and 5).

Table 4 Comparison of the respiratory rate values (RR, mov min-1), Rectal Temperature (RT, °C) obtained experimentally (ME) and simulated (MF) by the fuzzy model.

Table 5 Comparison of the skin temperature (ST, °C) and weight gain (WG, kg) obtained experimentally (ME) and simulated (MF) by the fuzzy model.

According to Pandorfi (2005), the ambient temperature range for comfort during the first week of life of the piglets, is between 32 to 34 °C. In this study, the maximum WG and the best RR, RT and ST were achieved at slightly lower conditions of 32 °C (Tables 4 and 5). Lower values of WG and worse of RR, RT and ST were found with Tbs and RH above 32°C and 70%.

Queirós and Nääs (2005) developed an ideal standard of environmental comfort for pigs in the nursery using the fuzzy methodology. Thus, the authors concluded that the ideal standard for pig production in the nursery lies in Tbs of 29 °C and RH of 75%.

Low temperatures in the farrowing house can cause stressful conditions for piglets. The reduction in Tbs in the environment of piglets below 20 °C can result in decrease of consumption of colostrum and of rectal temperature and therefore generate an increase in heat generation leading to mobilization of body reserves (Dividich and Noblet, 1981). In this study, the heating systems tested had a Tbs above 20 °C (Table 5).

Piglets after birth suffer from a sudden drop in ambient temperature, with a reduction from 1.7 to 6.7 °C in body temperature (Pandorfi, 2005), causing neonatal hypothermia. Under these conditions, the pigs reduce their motor activity and consequently reduce colostrum intake, causing increased incidence of diseases, more crushed piglets and a high rate of rejects at weaning, requiring some special care (Carvalho et al., 2006; Carvalho et al., 2013). Turco et al. (1998) mentions that a suitable environment for lactating sows may facilitate the production of milk and, consequently, allow increased weight gain of the piglets.

The mean standard deviations of the variables RR, RT, ST and WG were 0.12 mov min-1 0.05 °C, 0.06 °C and 0.04 kg, respectively, corresponding to the measured percentage error of 0.20, 0.18, 0.25 and 2.05%, as can be seen in Tables 4 and 5.

Analyzing the physiological responses and productive performance of piglets due to the different values of Tbs and RH evaluated, there is wide variation in the experimentally measured data at the same time that the fuzzy model results developed are suited to these variations, making the precision of this system clear for adapting to different conditions and combinations of database values used in the testing of this model.

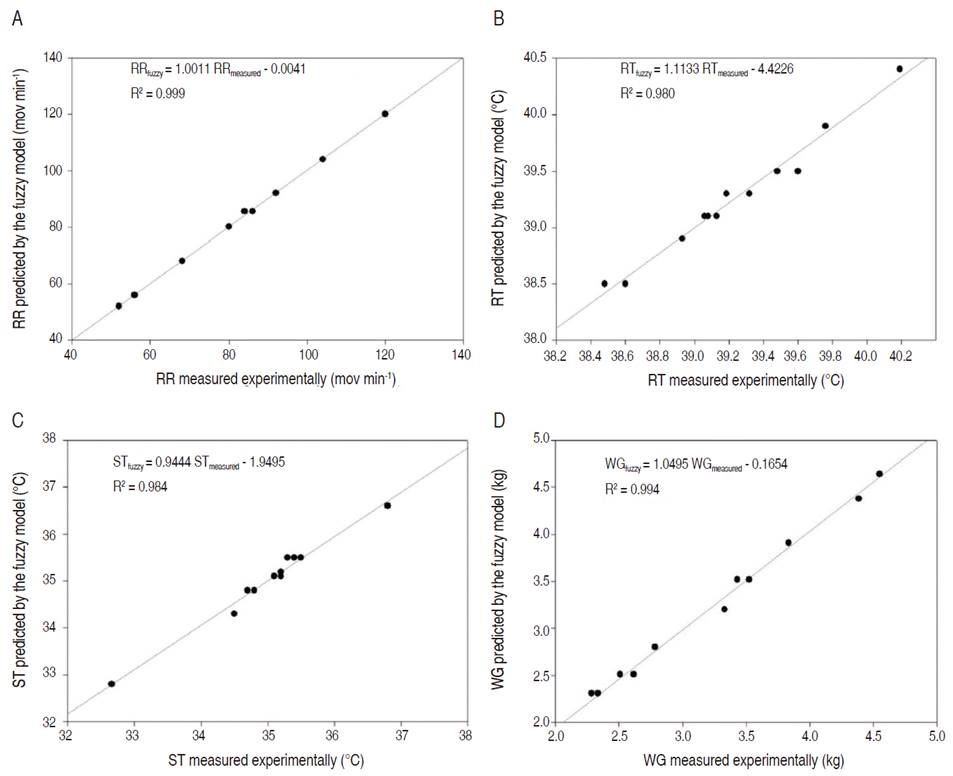

In order to test the accuracy of the proposed model, linear regressions were carried out and the results showed coefficient of determination (R2) equal to 0.999, 0.980 and 0.984 for RR, RT and ST, respectively (Figure 5). These results indicate good accuracy for the fuzzy model evaluated in this study. The operationalization of these results supports the control decision for the heating system in creep feeders, thus ensuring better production.

Figure 5 Linear regressions for the output variables: A. Respiratory rate (RR); B. Rectal temperature (RT); C. Skin temperature (ST); D. Weight gain (WG), depending on the values predicted by the fuzzy model and the values measured experimentally.

Medeiros et al. (2014), in creating mathematical models to estimate CR, WG and CA in adult chickens as a function of Tbs RH and air velocity (Vair), found values of R2 equal to 0.91, 0.89 and 0.72, respectively.

When comparing the WG values simulated by the fuzzy model with those obtained experimentally in maternity pigs in the study (Tables 4 and 5), it was found that the standard deviation of values, percentage error and coefficient of determination (R2) were 0.04 g, 2.05% and 0.994, respectively. These results indicate that the fuzzy model proposed had adequate precision for the prediction of WG in piglets.

Xie et al. (2017) prediction model of NH3 emission from a fattening pig room based on the indoor concentration using adaptive neuro fuzzy inference system observed that percentage error and coefficient of determination (R2) between output and testing data were 0.0436 and 63.5%.

According to Castro et al. (2013), considering that variations in WG would involve making a decision, the fuzzy system could be triggered to emit a warning signal, thus preventing the exposure of piglets to a harmful environment, reducing the heat stress on animals and possible production losses.

Fernandes et al. (2011) in evaluating the physiological behavior and performance indexes of the sows and piglets with the use of floor heating and cooling systems, mention that the heating system provided piglets at the end of the study with a WG increase of 28% (4.890 kg) compared to the control (3.800 kg).

The improved weight gain in breast-feeding will present a positive effect on the subsequent stages of growth of the animals. Thus, the description of the behavior and physiological parameters of lactating piglets is of fundamental importance to propose management techniques best suited to the new genetic lines of pigs in commercial breeding (Ferreira et al., 2007b).

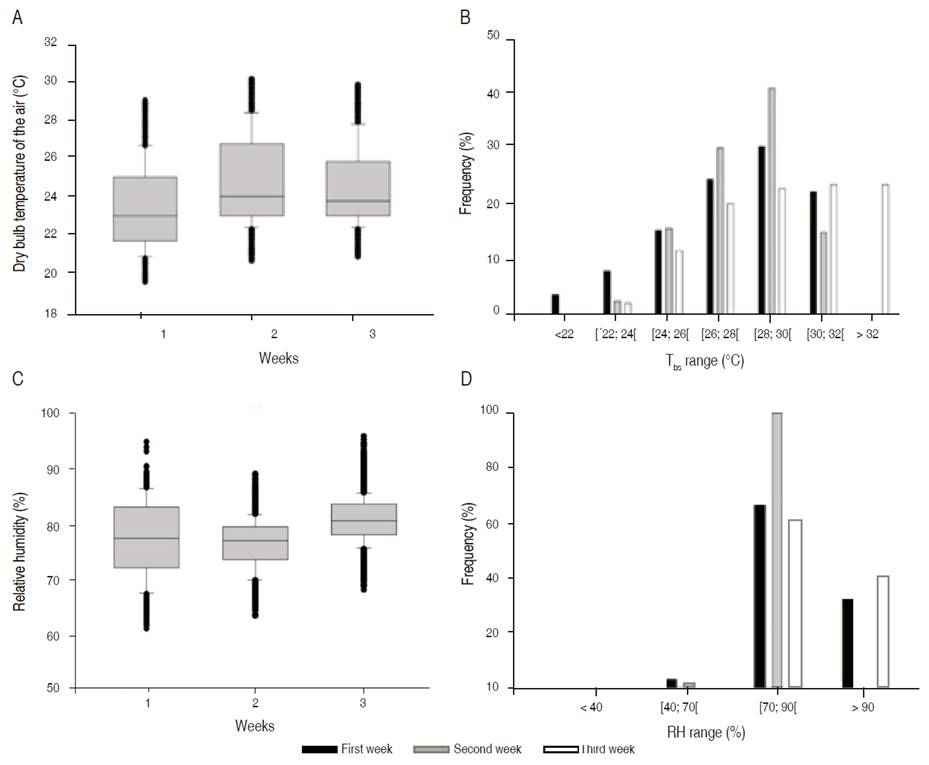

Tbs means in the first, second and third weeks of age for the piglets were 24.94±2.66 °C; 26.07±1.95 °C; and 25.29±1.89 °C, respectively (Figure 6A). Although the mean values of Tbs are contained within the environmental temperature range considered optimal for the second week of life of the piglets, which is 25 to 27 °C (Esmay, 1982; Nääs et al., 1998; Tolon and Nääs, 2005), it appears that, during 25.9% of the time (Figure 6B), the piglets were subject to temperatures outside the comfort range. The Tbs median for the first and third week of life ranged outside the ranges that are considered comfort, 27 to 32 °C and 22 to 24 °C, respectively (Esmay, 1982; Tolon and Nääs, 2005;. Nääs et al., 1998). However, the frequency of time within which Tbs stayed within the comfort range for the first and third week of life of the animals were 74.1 and 2.3%, respectively.

Figure 6 Box-plot and frequency of occurrence of A-B. The dry bulb temperature of the air and C-D. Relative humidity within the creep feeder in the first three weeks of life.

One of the advantages of the heating surface is to promote a more uniform temperature in the pig rest area than the heating by radiant energy (light bulbs), due to the floor-pig conduction process, as can be seen in the surveys conducted by Sabino et al. (2012) and Zhang and Xin (2001). However, if the ambient temperature is too high, the piglets tend to spend less time in this environment. When this occurs, the piglets can be exposed to cold stress conditions, when they are affected by low temperatures in the external environment. This may bring risks to pigs, who may seek to warm up next to the pig’s udder, being exposed to the area of crushing (Mores et al., 1998).

Pereira and Passos (1998), studying newborn piglets in which the variation in body temperature was monitored, concluded that the control of environmental temperature with the use of creep feeders and heating is indispensable to assist newborn piglets in maintaining their homeothermy, which was confirmed by Pandorfi (2002).

Regarding the RH, the median values of 77.40±6.99; 76.63±4.38; and 81.01±4.19% were observed for the first, second and third weeks, respectively (Figure 6C). When analyzing the RH frequencies of occurrence for the three weeks in question, it appears that, for more than 60% of the time (Figure 6D), the piglets were subjected to RH outside the comfort ranges for each week, and the ideal range should be 50% to 70% (Esmay, 1982; Nääs et al., 1998; Tolon and Nääs, 2005). According Nääs (1989), about 75% of body heat exchange with the environment takes place through conduction, convection and evaporation, it is important, therefore, that RH does not exceed 70%. Among the possible implications for animals, we can mention the commitment to homeothermy balance (Moura et al., 2010), which may cause dehydration of the animals, reducing the productive performance, among other undesirable responses. Moreover, the high porcine metabolism associated with high ambient temperatures impedes heat dissipation.

Ferreira et al. (2007) reported that the normal rectal temperature of piglets in the first hours of life ranges around 37.8±0.3 °C. Given this, it can be inferred that piglets can have some physiological or pathological problem when present with rectal temperatures much above 37.8 °C. Taking the value of 37.8 °C as the upper limit for rectal temperature, from which the animal presents thermal problems, it can be seen that in a situation where the Tbs and RH are higher than 30 °C and 60%, respectively, piglets showed average values of RT (39.8 °C) much higher than those mentioned by the authors.

Predictions of WG with the fuzzy model showed that if the piglets were raised under ideal conditions of Tbs and RH during the 3 weeks, the weekly average WG would be 1.89, 3.52 and 4.38 kg, respectively, while in the farrowing house evaluated values of 2.01, 3.52 and 4.40 kg were observed.

CONCLUSIONS

The fuzzy model based on thermal design environment, characterized by the dry bulb air temperature (Tbs) and relative humidity (RH) developed was suitable for prediction of physiological responses and productive performance of piglets raised in farrowing houses with a solar heating system, with low standard deviation and high correlation with the measured data during the conduct of the field study. It can be used as a tool in making the decision to change the thermal environment, avoiding losses and providing better production rates. Because of the large amount of electricity that is used in this type of setting, there is a need for further research to minimize consumption without harming animal welfare while preserving the environment.