Large amounts of waste are generated in the process of food production that can become an environmental and public health problem if they are not adequately treated. Finding new usage for waste is a priority to achieve sustainable development. By-products are those wastes that meet technical specifications and can be used in another production process. By-products of the agri-food industry such as legume pods, fruit husks, and seeds have been considered as potential food by-products because they are a promising source of functional compounds that would satisfy the functional product market and innovate with their presentation (colors and textures) (Estrada-López et al., 2018). The transformation of biomass into value-added products is an intensive and continually evolving field of research, that not only affects the food industry but other sectors of the economy (Duque-Acevedo et al., 2020).

One of the most important food crops in tropical countries is the common bean (Phaseolus vulgaris). It is an essential and economical source of proteins, complex carbohydrates, vitamins, and phenolic compounds (Mojica et al., 2015). In 2018, the production of beans in Colombia was 131,716 t while worldwide production was 30.4 million t (FAOSTA, 2018). In the post-harvest management of beans, large amounts of residues are generated. One of them is the pod, which represents an economic and environmental problem due to its high volumes and disposal costs. The pods constitute 39% of the weight of the fruit (Aigbodion, 2019); therefore, the annual production would generate around 84,211 t of the pod in Colombia and 19.4 million t worldwide.

So far, there are no studies in the literature about the properties of the flour from the common bean pod (Phaseolus vulgaris). However, some results highlight the importance of the broad bean pod (Vicia faba L.) and pea (Pisum sativum L.) as sources of fibers (Mateos-Aparicio et al., 2010a) and whose flours exhibited functionality in the preparation of baking and confectionery products, like good water holding capacity that positively impacts bread texture (Belghith-Fendri et al., 2016a; Martins et al., 2017). The preceding reveals the limited exploration of the potential of pulse pods as by-products in the food industry. Other studies have shown that pea pods are used as potential carbon source for bio-butanol production (Nimbalkar et al., 2018), and nanofiber of bean pods are proposed as material for automobile applications (Aigbodion, 2019). Pulse pods represent an economical raw material that has been underestimated when used exclusively as fuel or fertilizer (Mateos-Aparicio et al., 2010a).

Agro-wastes are materials with high-water content (greater than 80%); therefore, they are perishable. Their utilization depends on the maintenance of their quality as much as possible during storage. One of the ways to meet this need is to carry out a drying treatment to inactivate some enzymes, anti-nutrients and reduce microbiological growth. The drying techniques are also useful to reduce the waste volume to easier lightweight transportation. Some technologies involved are conventional air, microwave, vacuum-freezing, rotary, jet spouted bed, or air jet impingement mechanisms (Yang et al., 2020). The convection drying method is the most common and available. By-product as orange peel (Mello et al., 2020) and jaboticaba peel (Inada et al., 2020) were dried at moderate temperature and showed good properties with this method. Vacuum drying is a technique that exposes the sample to lower temperatures and shorter time, leading to a lesser advance in the detriment of quality properties such as color, aroma, flavor and nutritional value. The vacuum drying was applied to obtain powders from outer cabbage leave (Kuljarachanan et al., 2019) and banana peels (Vu et al., 2017).

The objective of this research was to obtain common bean pod flour (BPF) using two different drying methods and evaluate its color, water and oil holding capacity, ABTS antioxidant capacity, polyphenol content, and compositional and morphological properties.

MATERIALS AND METHODS

Bean pod flour

Fresh common bean pods (Phaseolus vulgaris) were obtained as by-products in a local market in Medellín, Colombia. Samples were selected discarding those with mechanical or physiological damages, then they were washed with deionized water and disinfected with polyhexamethylene biguanide 0.5 mg mL-1 (Bigudex) by immersion for 3 min (Mathurin et al., 2012).

Two drying methods were applied. One sample was dried by convection method with an air oven (BINDER: BD 56) at a temperature of 60±2 °C for 8 h; two trays were used with a size of 360×360 mm2. Alternatively, other samples were vacuum drying in a vacuum drying oven (BINDER: VD 53) at 60±2 °C with a pressure of 5 mmHg for 6 h. Subsequently, the dried samples were ground in an analytical mill (IKA® A1) and sieved in a 60 μm mesh to obtain bean pods flour (BPF). Both BPFs were stored in low-density polyethylene bags for use as needed.

Analysis of color

The color coordinates were measured in a spectrocolorimeter (ColorFIex EZ - HunterLab). Eight grams of sample were weighed in Petri dishes (9 cm in diameter by 1.5 cm in height), and the CIELab coordinates were recorded at room temperature: luminosity (L*), red-green (a*), blue-yellow (b*). Chroma (C*) and tone (*h) parameters were also calculated. The measurements were made in triplicate.

Determination of water holding capacity (WHC) and oil holding capacity (OHC)

WHC was determined by adding 10 mL of deionized water to 1 g of sample; the mixture was dispersed and left to rest for 5 h. Then the dispersions were centrifuged at 2,300 rpm for 30 min. The supernatants were removed, and the centrifuged tube was drained for 30 min to remove the excess of water. The samples were reweighed. WHC was expressed as grams of water held per gram of sample on a dry basis. The OHC was performed using the same steps mentioned above but using canola oil (0.91 g m-1 density) instead of water. OHC was expressed as grams of oil held per gram of sample on a dry basis (Chau et al., 1997).

Water activity (Aw) was evaluated using a water activity meter (Pawkit, Decagon Devices, Washington, DC, USA). An average of 2 g of flour was transferred into the sample container to perform the measurements.

Preparation of extract for determination of total polyphenols and antioxidant capacity

The extraction of the antioxidant compounds from the samples was carried out following the method described by Contreras-Calderón et al. (2016). 0.5 g of sample was placed in 10 mL capped centrifuge tubes together with 8 mL of a 50/50 v/v methanol-water mixture; subsequently, they were stirred at 280 rpm at room temperature for 1 h. Then, the samples were centrifuged at 5,000 rpm for 10 min, after which the supernatant was filtered and collected in a 25 mL amber volumetric flask. The residue was re-extracted with 8 mL of a 70/30 v/v acetone water mixture, and the centrifugation procedure was repeated. The supernatants were combined in the 25 mL amber volumetric flask. Finally, distilled water was added to make the final volume 25 mL, and they were stored at -18 °C and measured before 24 h.

Analysis of total phenols content (TPC)

The TPC was determined using the Folin-Ciocalteu microscale method described by Rover and Brown (2013). 20 μL of the extract was diluted in 1,580 μL of distilled water and mixed with 100 μL of the Folin-Ciocalteu reagent (Merk) and 300 μL of sodium carbonate solution (Merk). The sample was shaken and kept in the dark at room temperature for 1 h. The absorbance was then measured at 725 nm in the UV-VIS spectrophotometer (Thermo Scientific Evolution 60S). Six aqueous solutions of gallic acid (Sigma-Aldrich Chemical) were prepared at levels concentration ranged from 0 to 500 ppm for the calibration curve. Results were expressed as mg equivalents of gallic acid per g of dried sample (mg of GAE g-1 DW).

Analysis of antioxidant capacity (ABTS assay)

The ABTS 2.2'-azinobis (3-ethylbenzthiazoline-6-sulfonic acid) assay was performed following the method proposed by Re et al. (1999). Briefly, 100 μL of extract appropriately diluted with water was mixed with 1 mL of ABTS• + radical solution and incubated at 30 °C for 30 min, after which the absorbance was measured at 730 nm (Thermo Scientific Evolution 60S). The calibration curve was constructed with Trolox solutions at concentrations between 0 and 250 μM. The results were expressed as micromoles of Trolox equivalents per g of dried sample (μmol ET g-1 DW).

Proximate analysis

The proximate analysis was performed according to the methods of the AOAC (2003): Moisture (method 934.01), protein (method 954.01), fat (method 2.057), ash (method 923.03) and total soluble and insoluble fiber (method 991.42). The carbohydrate content was determined by difference.

Microstructure observation by scanning electron microscopy (SEM)

Analysis of the morphology of the flour obtained was performed by scanning electron microscopy (SEM) using a thermionic microscope in high vacuum drying and secondary electron detector in order to obtain high-resolution images (JEOL JSM 6490 LV ). The samples of flours were fixed on a graphite tape and coated with a thin layer of gold (Au) on a Denton Vacuum Desk IV.

Analysis by infrared spectroscopy

In order to molecularly characterize the flour, the FT-IR (Fourier Transform Infrared Spectroscopy) technique was used using an infrared spectrometer (Spectrum One Perkin Elmer Boston USA) at room temperature. KBr pellets were prepared by mixing 1 mg of the sample with 100 mg KBr applying 5 tf pressure with a hydraulic press. The region used was 400 to 4000 cm-1, and commercial pectin was used for comparison purposes.

Statistical analysis

All measurements were performed three times, and the results were expressed as means±standard deviations and reported on a dry matter basis. Analysis of variance (ANOVA) was performed to assess for any significant differences between the means with a level 95% confidence. The Statgraphics Centurion XVII software was used.

RESULTS AND DISCUSSION

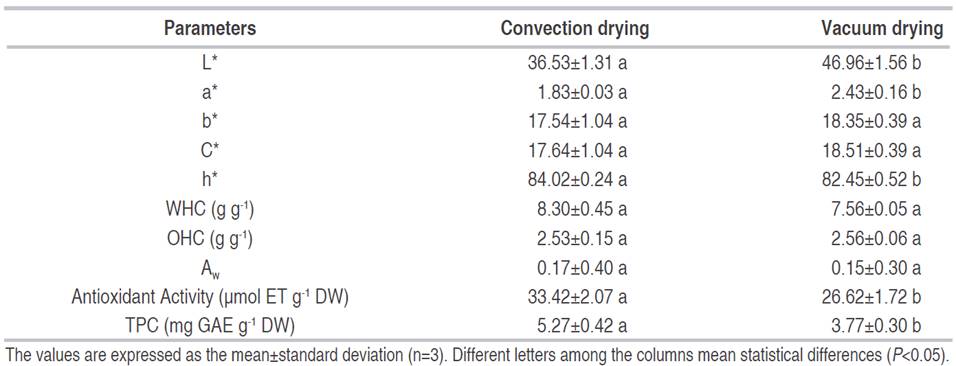

The effect of drying method on some functional properties was assessed. Coordinates of CIELab space chroma (C*) and hue angle (h*) values were determined because the color is an important quality characteristic for many products derived from flours such as bread and pasta. The color parameters, shown in Table 1, indicated that the flours tended to yellow color with a slight red hue since both have higher positive b* values and hight h* values. This resulted suggested the presence of yellow pigments. Significant differences (P<0.05) were found in the parameters L*, a* and h* for the flours obtained by the two drying methods. The vacuum sample exhibited the highest luminosity, which was expected since the water evaporates at a lower temperature in less time, causing less browning (Gómez-Narváez et al., 2017). However, the color differences are small. It could be said that the convective drying does not lead to an undesirable color formation in the BPF.

There have not been previous studies about color parameters for bean pod flour or powder. The results obtained are comparable to those found in wholemeal flours (Hidalgo et al., 2017) and unconventional flours such as dietary fiber powder obtained from the hull of soybean that presents values of L*=58.55, a*=-2, and b*=19.6 (Yang et al., 2014).

The determination of functional properties such as WHC and OHC are important to define the functional profile of the flour and its possible application. Table 1 shows the values of these two functional properties for BPF. The results did not vary significantly between the drying methods.

The value of WHC allows determining the degree of interaction with water. The flours obtained by the two drying processes showed high values of WHC concerning those found in both pea flour (3.69 g g-1) and broad bean (4.46 g g-1) (Belghith-Fendri et al., 2016a); as in the fiber extracted from these two legumes of 4.6 g g-1 and 6.98 g g-1, respectively (Belghith-Fendri et al., 2016b). These results also approximate the values reported by Mateos-Aparicio et al. (2010a), who evaluated the WHC of polysaccharides isolated from the pea pod and broad bean, finding values of 8.96 g g-1and 9.96 g g-1, respectively. Besides, the WHC values obtained for BPF were high in comparison to those reported for grapefruit, lemon, orange, and apple by-products (1.6-2.3 g g-1) (Figuerola et al., 2005); also for those recently reported by Masli et al. (2018) for by-products of diverse botanical origin whose ranges of variation were from 1.3 to 3.9 g g-1, and they are even higher concerning wheat bran (2.7-3.6 g g-1) (Caprez et al., 1986).

The high value of WHC suggests that BPF could be used in products that require hydration processes viscosity or texture development (López-Vargas et al., 2013) in physical stress production processes such as kneading extrusion and homogenization. It also helps to avoid syneresis phenomena during storage (Masli et al., 2018).

Regarding OHC the values found in the present study are high compared to those reported by Belghith-Fendri et al. (2016a) in pea and bean pod flours with values of 1.14 g g-1and 1.42 g g-1, respectively; and those found for the isolated polysaccharides of pea (0.28 g g-1) and broad bean (0.13 g g-1) (Mateos-Aparicio et al., 2010a). They are also greater than orange by-products (2.15 g g-1) (Fernández-López et al., 2009), cauliflower fiber (0.5 g g-1) (Femenia et al., 1997) and wheat bran (1.5 g g-1) (He et al., 2018). However, they are smaller compared with fibers from the rice husk (Sangnark et al., 2004), bagasse from native sugarcane (3.26 g g-1), and asparagus (5.28-8.53 g g-1) (Elleuch et al., 2011).

The OHC is related to surface properties, density porosity size, and hydrophobic nature of the fiber particle (López-Vargas et al., 2013). The values found suggest that BPF could be used for the formulation of emulsions and high-fat food products to improve their physicochemical stability as well as to improve the retention of aromas.

Water activity is an important indicator of flours because it affects their shelf-life. It is important to highlight that Aw values of the BPF obtained by both processes indicated are chemically and microbiologically stable.

The results for the antioxidant capacity by ABTS and total phenols content (TPC) are observed in Table 1. Significant differences were found (P<0.05) between the different drying methods, the flour obtained by convective drying presented greater antioxidant capacity and TPC, which was not expected because bioactive compounds such as polyphenols are susceptible to degradation when subjected to thermal treatment (Cárcel et al., 2019). Therefore, it could be possible that the highest antioxidant activity obtained in this flour may be due to compound formed during the Maillard reaction (Contreras-Calderón et al., 2016; Chua et al., 2019), which can be evidenced with the lower luminosity of flour obtained by convection drying (Table 1).

Both flours exhibited a TPC higher than those found in pineapple by-products (3.74 mg GAE g-1 DW), banana (3.85 mg GAE g-1 DW), papaya (3.15 mg GAE g-1 DW), watermelon (1.46 mg GAE g-1 DW), melon (1.49 mg GAE g-1 DW), and passion fruit 0.86 mg GAE g-1 DW). They were lower regarding by-products from the avocado peel (12.52 mg GAE g-1 DW) (Morais et al., 2015). Antioxidant capacity and TPC in bean pod have not been reported previously.

The high TPC found in BPF was an expected result since phenolic compounds tend to accumulate in the dermal tissues of plants to fulfill a fundamental role in photoprotection against ultraviolet radiation and the defense against pathogens and predators (Gharbi et al., 2017). On the other hand, foods with antioxidant properties are highly valued due to potential benefits in health. Nowadays, the role of food rich in antioxidants in the preventive effect on degenerative diseases is a field of research that has attracted great attention (Contreras-Calderón et al., 2016). Therefore, BPF has a high potential to be used in the development of functional foods or nutraceutical products.

Altogether these results show that the convective drying method is a good alternative for obtaining BPF, which allows preserving its functional properties such as color, WHC, OHC, and antioxidant. Moreover, the convective drying method is an economical and most available method than the vacuum drying method. Therefore, in order to gain insight into the compositional, morphological, and structural characteristic of BPF were performed only in the sample obtained by convection drying.

The proximate analysis of the BPF expressed in g per 100 g dry base gave the following results: Humidity (7.77±0.08%), ash (6.65±0.08%), protein (2.42±0.01%), fat (0.58±0.00%), total dietary fiber (66.93±1.01%), insoluble dietary fiber (59.97±0.68%), soluble dietary fiber (6.96±0.58%) and carbohydrates (15.65%).

The moisture content was found below the maximum limit (15.5%) according to the CODEX standard for wheat flour (Codex Alimentarius, 1985), suggesting a good behavior under storage.

The results show that BPF has a higher percentage of fiber compared to the percentages of total, insoluble and soluble fiber reported for the pea pod (58.6%, 54.4% and 4.2%, respectively) and the broad bean pod (40.1%, 30.8%, and 9.3%, respectively) by Mateos-Aparicio et al. (2010b). However, the percentages of ash protein and fat were lower than those reported in pea pod (8.07%, 13.37%, and 1.06%, respectively) and bean (9.02%, 13.43%, and 0.24%) by Belghith-Fendri et al. (2016a) and also against those found by Mateos-Aparicio et al. (2010b) in pea pod (6.6%, 10.8%, and 1.3%) and broad bean (6.3%, 13.6%, and 1.3%).

The results found, highlight the importance of BPF as a source of fiber minerals and low lipid content.

Regarding morphological analysis, the micrographs show fibrillar fragments with irregularly shaped (Figure 1A), which referred to the high fiber content found in BPF. At higher magnification, the presence of microfilaments aligned in parallel along the particles is observed (Figure 1B).

Figure 1 Micrographs of BPF convective drying method in different magnifications A. 45x; B. 350x; C. 2000x.

A closer approach to the particles shows that they are porous structures (Figure 1C). A similar morphology has been found in the pod of other edible leguminous such as Parkia speciosa (Gan and Latiff, 2011) and rice husk (Sánchez-Safont et al., 2018). The porous morphology supports the high values found in WHC and OHC (Table 1).

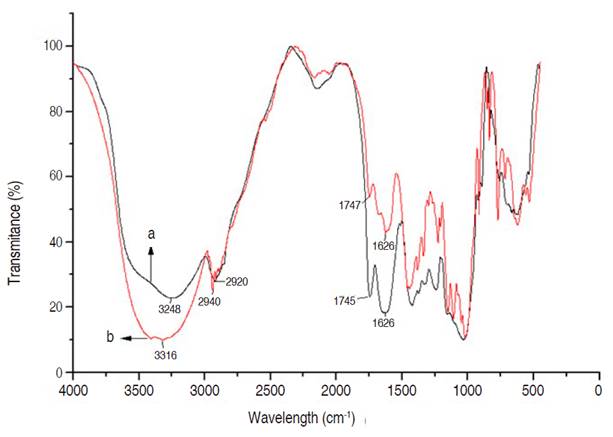

IR spectroscopy is an excellent tool for the analysis of carbohydrates, and since BPF had a high content of these compounds, its IR spectrum was analyzed. Figure 2 shows the spectrum of BPF compared to the spectrum of commercial citrus pectin. BPF spectrum exhibited strong absorption bands that coincide with characteristic signals of the dietary fibers.

Figure 2 IR spectrum with Fourier transform of A. commercial citrus pectin and B. BPF by convective drying method.

The characteristic signals found were broadband at 3400 cm-1 associated with the OH stretch.

The 2950 cm-1 signal due to the stretching of the methyl group. The lengthening at 1750 and 1650 cm-1 indicated the presence of esterified and free carboxylic groups, respectively. The peaks at 1420 -1380 cm-1are assigned to C-H deformation vibrations. The signals in the region comprised between 1200-900 cm-1 are ascribed to C―O, and C―C stretching vibrations of the polysaccharide molecules. The 600 cm-1 signal is associated with C-C-C in-plane bending (Arroyo Salas et al., 2008; Kamarudin et al., 2016). The signals are congruent with cellulose and pectin type fibers, as previously was stated by Stolle-Smits et al. (1999).

CONCLUSIONS

This study provides practical information for the use of the bean pod as a by-product for obtaining flour. The properties of color, water and oil holding capacities were similar for both types of flours from convection and vacuum drying. ABTS antioxidant capacity and polyphenol content were higher when pods were dried by convection. Additionally, it showed that flour obtained by convective drying has a high content of fiber, minerals, and low lipid content. Overall, the results indicated that BPF has considerable potential to be used in the food industry, being interesting for the development of functional foods and value-added products.