Almojábana is a baked food that its composition depending on the geographical place where it is elaborated. Therefore, almojábana may look and taste different due to differences in ingredients and processing. Almojábana is an Arab dessert based on cheese and wheat fIour. Arabs spread the recipe to Spain, where it was modified and brought later to America (De la Granja Santamaría, 1970). In Ecuador, almojábanas have been produced since 1900 by small producers mainly for local consumption, with a recipe that is based on cheese, wheat fIour and Canna edulis starch (Cobo, 2014).

C. edulis is a native plant from America. C. edulis rhizomes are used for starch extraction in tropical and subtropical countries (Caicedo et al., 2000). In Latin America, it is cultivated in Peru, Ecuador, Bolivia, Brazil, Venezuela, and Colombia (Caicedo et al., 2003). According to Caicedo et al. (2000). C. edulis crop has diminished due to the difficulty of the starch extraction process, pests and low economic profit compared to other crops. The low cropping has triggered high-cost C. edulis starch and less availability on the market (Caicedo et al., 2003). Therefore, there are economical and supplying problems for producers of foods based on this starch. Moreover, low planting may lead to the disappearance of a native crop, which has a promising starch for industrial applications (Parra-Huertas, 2012).

C. edulis starch is an important ingredient for the production of Ecuadorian almojábanas. C. edulis starch is also used to make food products like biscuits in Colombia (González, 2012). However, a expensive C. edulis starch with low availability has forced to look for starch substitutes.

C. edulis starch has a granule size between 35 and 101 µm, amylose content that varies from 25 to 45% (Yanuro, 2018) and a gelatinization temperature between 60 and 79 °C (Fonseca-Florido et al., 2016; Aprianita et al., 2014). Potato starch has granule size between 10 and 110 µm (Singh et al., 2003), amylose content that varies from 16 to 24% (Jane et al., 2010) and a gelatinization temperature between 56 and 67 °C. Cassava starch has a granule size between 5 and 45 µm and amylose content that varies from 14 to 19% (Gunaratne and Hoover 2002). Although cassava starch has different properties compared to C. edulis, it may be a good substitute since it has shown good results on the elaboration of baking products such as Pandebono (bread-based on fermented cassava starch) or pão de queijo (cheese bread, from Brazil), both with formulations very similar to almojábana. On the other hand, potato starch has similar properties to C. edulis starch, making potato and cassava starches proper choices for substitution (Salinas, 2014; Intriago and Muñoz, 2014) Both tuber starches are available on the Ecuadorian market. They have lower cost, 2,350 USD t-1 and 800 USD t-1, respectively, compared to C. edulis starch (3,000 USD t-1).

Therefore, the objective of this work was to study the substitution of C. edulis starch by a mixture of potato and cassava starch in the almojábanas making. The specific volume, crumb structure and textural properties (elasticity, chewiness, and hardness) were evaluated in the different almojábanas made with the starch mixtures. A weighing of the variables was used to obtain the best physical characteristics. Afterward, to find out differences between the best treatment and the control (based on C. edulis starch), sensory analyses were performed.

MATERIALS AND METHODS

Wheat fIour was bought from La Moderna S.A. (Ecuador), C. edulis starch from an artisanal producer (Ecuador), potato starch from "Suiza Industrial del Ecuador" (Ecuador) and cassava starch from "Indumaíz del Ecuador" (Ecuador).

Almojábanas baking

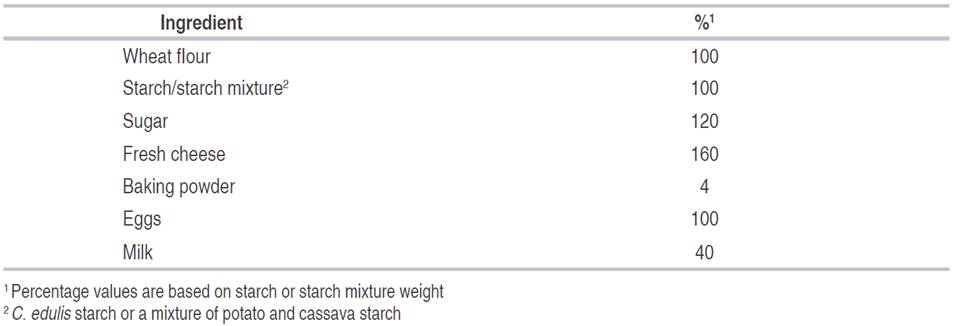

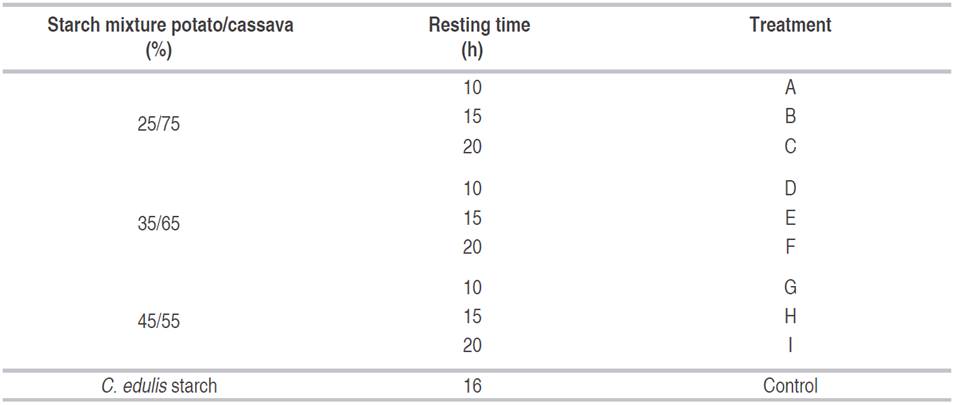

Mixtures of potato and cassava starch were prepared according to Tables 1 and 2. Eggs were stirred in a kitchen mixer (Kitchen-Aid Professional 600, Mexico) at 220 rpm for 5 min, whereas cheese was stirred at 70 rpm for 4 min (Table 1).

Baking powder, wheat fIour, starch or starch mixture (C. edulis for control sample) were blended and stirred at 50 rpm for 2 min. The formed dough was left at room temperature (approx. 16 °C) between 10 and 20 h (resting time). Afterward, milk was added to the dough to obtain a more liquid-like mixture. 70 g of the mixture was loaded to muffin pans and baked at 220 °C for 18 min. After baking, almojábanas were cooled before they were stored in polypropylene bags.

Specific volume and texture profile analysis

Specific volume was determined according to the AACC (2010) in triplicate. Texture profile analysis (TPA) was done according to Steffolani (2010). A texturometer (model CT3, Brookfield, USA) with a compression cell of 245 N, speed of 100 mm min-1, maximum deformation of 40% and a diameter probe of 25 mm were used.

After baking, almojábanas were stored for 24 h before the TPA analyses. Measurements were done thrice testing the central part of the almojábana, which was cut with an electric knife (Oster 2619, U.S.A.). A sample of 25 mm depth, 52 mm height and 62 mm width, was loaded on the texturometer and compressed twice. Hardness, cohesiveness, and elasticity were measured, whereas chewiness was calculated according to equation 1.

Where:

Crumb structure

Crumb structure was determined according to Sciarini (2011). The average cell size, the number of cells per area and total area of cells (%) were determined in triplicate. Two softwares, Fiji and Peakfit (Systat Software, Inc.) were used (Schindelin et al., 2012). Fiji software was used to transform a crumb image into a gray color figure and afterward in a frequency histogram of a gray color scale (256 gray colors). Deconvolution of the frequency histogram was performed by Peakfit software. As a result, two Gaussian curves corresponding to the white and the black color. The intercept of the two curves was used as a limit, values under the intercept were appointed to the black color (crumb wall), and values above the intercept were associated with white color (crumb cell).

Experimental design

A Completely Randomized Design, 32+1, was used. Mixture of cassava and potato starch (25/75, 35/65 and 45/55) and resting time (10, 15 and 20 h) were used as factors (Table 2). A control sample was an almojábana, only baked with C. edulis starch. Hardness, elasticity, chewiness, specific volume, average size cell, number of cells per area and total area of cells were determined.

Table 2 Experimental design. Almojábanas elaboration with resting time and starch mixture composition as study factors

The composition of the starch mixture (Table 2) was decided based on previous assays. A substitution with potato starch above 60% produced an almojábana with low moisture and low elasticity. In contrast, a substitution with cassava with values above 80% produced an almojábana with a different flavor and higher elasticity compared to the control sample (almojábana based on C. edulis starch).

An ANOVA and a Tukey test with a significance level of 5% were applied by using IBM SPSS Statistics 20 software.

Sensory evaluation

The treatments with the best physical and textural characteristics were used to perform a triangle test. In this test, three samples were presented to the panelists simultaneously. Two of them were the same and one was different, the latter being the control sample. The panelist was asked to identify the different sample (Hernández, 2005).

The number of panelists was decided regarding three parameters, α=0.05 (moderate evidence), β=0.1 (90% confidence) and Pd=20% (20% of the population can detect difference among samples).

RESULTS AND DISCUSSION

Specific volume and texture profile analysis

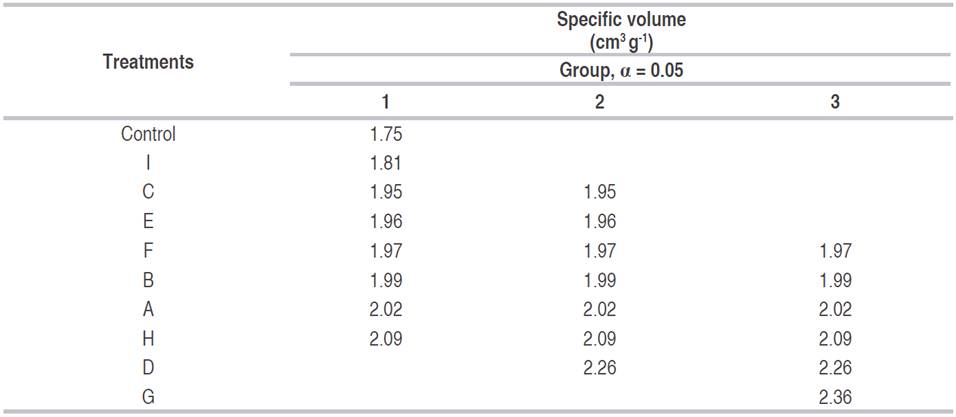

Specific volume showed statistical difference among treatments (P<0.05). Resting time was the only significant factor. According to Table 3, treatments similar to control sample corresponded to group 1, with specific volumes between 1.75 and 2.09 cm3 g-1.

A high specific volume is usually required for baking products; however, almojábanas had a low specific volume. Almojábanas are prepared with similar ingredients than pão de queijo; it has a high amount of starch, cheese and eggs, leading to the formation of heavy dough and, therefore, a food product with low specific volume (Zavareze et al., 2009).

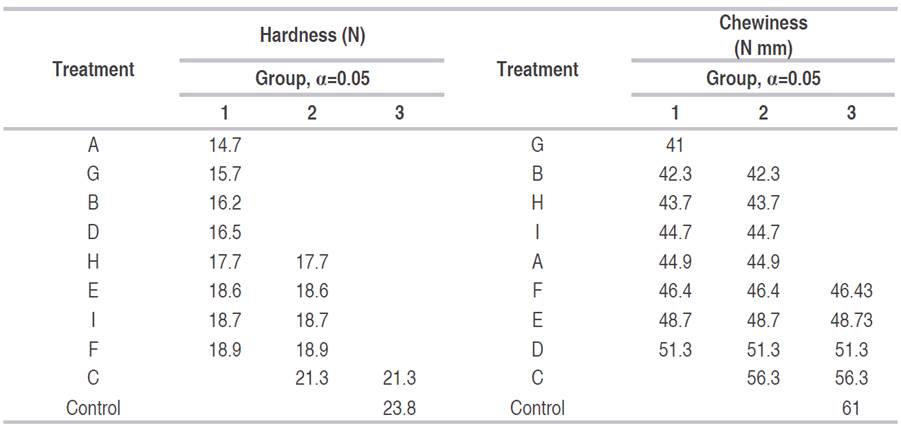

Hardness

Almojábana hardness results are shown in (Table 4). Time of rest was the only factor that influenced almojábana hardness. Results showed that the treatment prepared with 25% potato, 75% cassava and 20 h resting time had a hardness of 21.29 N and was statistically similar to the control (23.80 N). Both samples had higher hardness compared to other samples (P<0.05). Cueto et al. (2011) found that high levels of cassava fIour can generate pancakes and cakes with low hardness.

Different results may be due to the use of single starch or a starch mixture and the type of cheese on the elaboration of almojábana. Indeed, Pereira (1998) found that the type of cheese is responsible of the taste and texture of pão de queijo.

Chewiness

Chewiness results showed differences among treatments. Four treatments were statistically comparable to the control (Table 4), treatment C (25% potato/75% cassava - 20 h), D (35% potato/65% cassava - 10 h), E (35% potato/65% cassava - 15 h) and F (35% potato/65% cassava - 20 h) with chewiness between 46.43 and 61.00 N mm.

Cauvain (2016) showed that changes in chewiness during storage are associated with starch retrogradation. On the other hand, Cuikeisha and Roberts (2009) showed that chewiness decreased proportionally to the quantity of fiber present. Knowing that retrograded starch behaves as fiber (Saaman, 2017), in the present work, mixtures of potato and cassava starch may promote a formation of retrograded starch in different amounts. It could affect the chewiness of the almojábana.

Elasticity

There was no statistical difference among treatments and control sample (P<0.05). However, almojábanas elaborated with long resting times (15 and 20 h) had a lower elasticity. Therefore a low capacity to recover the original size after compression, compared to almojábanas with resting times of 10 h. The control sample had elasticity analogous to almojábanas elaborated with 15 h resting time.

Previous study (Cueto et al., 2011) showed that a high content of cassava starch, the cell size increased. This research showed that almojábanas with the highest content of cassava starch (treatments A, B and C) had cell sizes with intermediate values. Different results could be due to the different ingredients used on food elaboration. The number of cells per area and total area of cells showed no statistical differences among treatments.

Crumb characterization

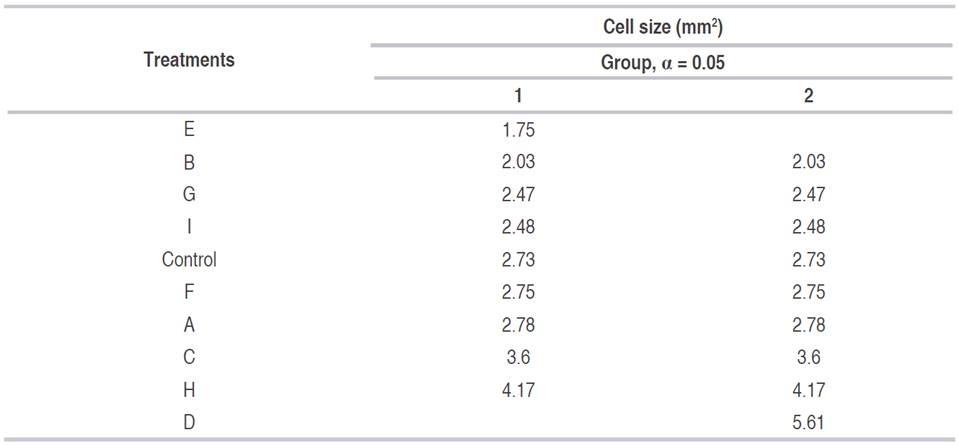

Cell size showed only dependence of the interaction between starch mixture and resting time. Treatment D had the largest cell size (5.61 mm2), whereas treatment E had the smallest one (1.75 mm2) (Table 5). Treatments corresponding to group 2 had cell sizes between 1.75 and 4.17 mm2 and were equal to the control (P<0.05).

In order to obtain a treatment with the best physical characteristics, a weighing of the variables was performed by giving values as follows, 1 for cell size, 2 for specific volume, 3 for hardness and 4 for chewiness. Treatment C (25% potato/75% cassava and 20 h resting time) had the highest score (10 points), and, therefore, it was selected as the best treatment. Moreover, using this treatment, the cost of raw materials (starch) was reduced by about 60%.

Sensory evaluation

In order to know if treatment C had the same characteristics as the control sample, a triangle test was executed. 39 was the number of correct answers to establish a significative difference (Hernández, 2005). A total of 46 panelists correctly identified the different samples, finding that treatment C had a texture similar to the control sample. As an additional comment, panelists evidenced differences between the almojábanas made with a mixture of potato/cassava starch and C. edulis starch.

CONCLUSIONS

The use of a starch mixture, potato (25%) and cassava (75%) for 20 h resting time to elaborate almojábana showed no differences compared to a control sample based on C. edulis starch. Treatment C could be reduced the cost of raw materials (starch) by 60%. Elasticity, chewiness and hardness were not affected by the starch substitution, whereas analysis of the crumb showed that cell size was affected by the starch substitution and the resting time.