Timber from tropical forest species is depleting at a fast rate due to industrialization. Therefore, it is necessary to use wood from fast-growing forest plantation species to be used in different wood applications. However, the wood of such species is often characterized by different problems such as low dimensional stability, low mechanical properties, and low natural durability against bio-deteriorating agents, which makes them undesirable for many economic purposes (Shukla, 2019; Unsal et al., 2011); as is the case of the wood of the pine ocote Pinus oocarpa Shiede ex Schltdl. It presents a high dimensional instability, low mechanical resistance, and it is very susceptible to being attacked by biological agents, which could cause some limitations in structural purposes. The above limitations of wood can be overcome using thermal modification, which is achieved by subjecting the wood to temperatures between 150 and 260 °C with an inert atmosphere or with low oxygen content for times ranging from a few minutes to several hours, depending on the species and the desired degree of modification (Sandberg et al., 2013; Esteves et al., 2014). The thermal modification process is an environmentally friendly treatment without the addition of toxic chemicals showing an improvement in the behavior of the properties of wood, with increases in dimensional stability, density, resistance to biodegradable agents and color change, a very important characteristic for many uses considered as a relevant attribute for marketing, which provides value-added for low-quality woods to substitute certain high-value tropical species (Esteves et al., 2014; Hermoso et al., 2015; Herrera-Builes et al., 2021; and Kubovský et al., 2020).

In most studies on thermal treatments, independent of the species used, there are alterations in the mechanical properties; and the treatment temperature is determinant in the results obtained (Frühwald, 2007).

The new internal properties resulting from thermally modified wood are associated with the degradation of the structure of the cell wall polymers and from the formation of modified extractives, which occur due to changes in the composition of the wood through different chemical reactions (Esteves et al., 2014; Kubovský et al., 2020). In addition, changes in the anatomical structures of wood depend on the wood species and the processing method and conditions used (Boonstra et al., 2006).

In most studies about thermal modification, independent of the wood species considered, there are alterations in the chemical composition, and the heat treatment is determinant in the results. Thus, when applying heat treatments between 170 °C and 190 °C under steam pressure, there is a decrease in holocellulose content caused by its degradation; but, due to said such thermal degradation, lignin and extractives increase because of the formation of carbohydrate conversion products in the modified wood of specimens of Pinus sylvestris, Pinus brutia and Pinus massoniana (Boonstra MJ and Tjeerdsma, 2006; Durmaz et al., 2019; Ates et al., 2009; Wang et al., 2018). However, for Pinus oocarpa themally modified significant differences in chemical components were detected just from 200 ºC temperature (Carvalho et al., 2020).

The changes in anatomical structures of wood caused by thermal modification were evaluated by Jang and Kang (2019) using Pinus densiflora wood, which was subjected to heat treatment at temperatures of 190, 210, and 230 °C; after performing the analyzes, changes were found in the microstructure with cell walls thinned and with an increase in the lumen diameter of the treated wood. For Pinus radiata is suggested that these changes on the tracheid cell walls could be minimized, improving the time-temperature schedules during the process of wood thermal modification (Cabezas-Romero et al. 2021). Bernabei and Salvatici (2016) investigated the response to the anatomical structural changes in the wood Picea abies modified thermally, reporting changes in the tracheid wall thickness and lumen diameter above 200 °C. When treating Thuja plicata wood at 220 °C, increases in lumen diameter and destruction of its tracheid wall were obtained (Awoyemi and Jones, 2011). Effects of thermal modifications at 165 and 185 °C on woods of Pseudotsuga menziesii, Pinus sylvestris, Picea abies and Pinus radiata have been noticed, such as small cracks between tracheids with curved and severed deformations of the lumens (Boonstra et al., 2006).

For Pinus oocarpa wood, thermal modification was shown to improve some physical properties and static bending (Herrera-Builes et al., 2021). This study aimed to analyze the effect of thermal modification on the internal structure and chemical composition of Pinus oocarpa wood, in order to contribute to the knowledge and characterization of this kind of important forest plantation species.

MATERIALS AND METHODS

Materials

Sawn wood from Pinus oocarpa Schiede ex Schltdl var. Ochoterenai was used for the heat treatment experiments, provided by the Empresa Cipreses de Colombia S.A., from mature trees (25 years old) collected from plantations located in the municipality of Yolombó (Antioquia, Colombia) coordinates 6°39'25.4" N 75°04'13.9" W. A total of 30 trees were collected randomly, with a useful shaft with a diameter of 450 mm, from which the first two logs of 2500 mm long were taken, a central plank of 100 mm thick heartwood was cut from each log; then from each plank, slats of 60×60×2500 mm (width, thickness, and length, respectively) were cut, eliminating the pith, which was subjected to air-dry until reaching a moisture content of 12% and samples of 410 mm (Longitudinal) × 25 mm (Tangential) × 25 mm (Radial) were taken.

Thermal modification process

The thermal modifications of 170 °C and 190 °C to which the wood Pinus oocarpa was submitted were made in a prototype flexible oven chamber with a capacity of 3.5 m3 designed for temperatures up to 250 °C (Neumann, Model Lab3.5e, Concepción, Chile). For each treatment, the chamber was loaded with 120 boards of 50 mm wood, which were stacked evenly and placed in layers of equal distance, with 20-mm-thick spacers to allow the steam to move through the pile and distribute the weight vertically from top to bottom; the Pinus oocarpa specimens were stacked inside the middle of the woodpile. They were continuous and without empty spaces to prevent oxygen currents. The prototype chamber operated during the modification steps was under an atmosphere of steam, with a continuous flow without pressure. The dry and wet bulb temperatures, as well as the wood temperature, were monitored according to the configuration and the computerized kiln program (Canelo, Control Total, v8.0, Concepción, Chile). Specifically, the modification process began with a temperature increase rate of 1 °C min-1 up to 100 °C. The temperature was then maintained for 15-22 h, allowing the wood to dry 4-6% of the moisture content. Subsequently, a temperature increase rate of 0.7 °C min-1 was applied up to 170 or 190 °C. In this step, a steam atmosphere was used to reduce air and prevent damages. The treatment temperature (170-190 °C dry bulb or 100 °C wet bulb) was maintained for approximately 2.5 h. The last stage was the cooling and stabilization of the samples for approximately 5-7 h. The temperature gradient between the surface and the center of the samples did not exceed 15-20 °C, in order to maintain the quality of the wood. The treatment time was about 30 h, and the final moisture content of the specimens was 9-11%. Finally, two thermally modified loads (two programmed temperatures) were obtained, and the different samples of Pinus oocarpa were analyzed to characterize the heat-treated material and compare it with the unmodified wood material.

Determination of chemical composition

Samples of unmodified and thermally modified wood were grounded to sawdust. The material used for chemical analysis was classified between 40 and 60 mesh. It was extracted in the Soxhlet equipment with a mixture of ethanol and benzene according to the TAPPI T 204 CM-97 (1997).

The holocellulose content was determined using sodium chlorite according to the procedure of Wise et al. (1946). In a beaker, 150 mL of 1.5% (w/w) sodium chlorite solution were poured into g of wood, and 10 drops of glacial acetic acid and the sample was placed in a water bath at 75 °C for 1 h. After 1 h, 10 drops of glacial acetic acid and 1.5 g of sodium chlorite were added, it was cyclically repeated every hour, for a total period of 4 h. After chlorination, the solution was filtered, and washed with 200 mL of cold water, followed by 10 mL of acetone; the residue was taken to a conventional oven at 105 °C until constant weight.

The lignin content was determined as described by TAPPI T 222 om-02 (2002). 15 mL of 72% sulfuric acid (w/w) were added to 1 g of wood sample, stirring it for 10 min and letting it rest for 2 h. Subsequently, 575 mL of distilled water were added, boiled for 4 h maintaining a constant volume, if necessary distilled water was occasionally added. Finally, it was filtered in Büchner funnels, and the samples were repeatedly washed until the acid residues were removed. Finally, they were brought to constant weight in an oven at 105 °C.

All measurements were made in 12 replicates for each chemical composition determination. Data were presented as percentages on a dry basis.

FTIR spectroscopy

The thermally modified and the unmodified wood were studied using the spectroscopy of the Fourier Transform Infrared (FTIR) technique. The spectra were obtained using a Shimadzu spectrophotometer (model IRTracer-100, Japan) with a range of 12500 and 240 cm-1 with a resolution of 4 cm-1; applying the Attenuated Total Reflectance (ATR) method in wood samples of 10 mm (width) × 10 mm (thickness) × 20 mm (length).

Anatomical measurements

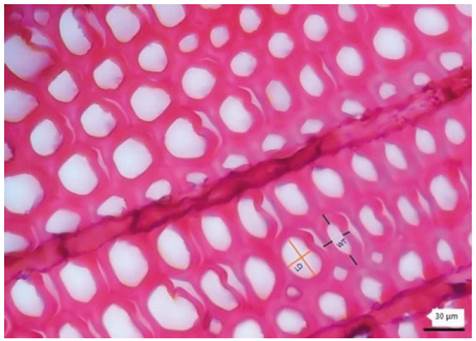

Pieces of samples of unmodified and thermally modified wood were cut into lengths of 20×20×20 mm and soaked in tap water for 36 h. A transverse slice of 20 µm was obtained using a Spencer Model 860 microtome (AO Instrument CO, Buffalo, N.Y, USA). These sections were stained with a 1% safranin solution and mounted on a glass slide and cover glass using Canada balsam and glycerin. Anatomical measurements were performed at the Forest Products Laboratory of the Universidad Nacional de Colombia, Medellín, Colombia. The changes in the cellular structure of wood were examined using a Primo Star light microscope (Carl Zeiss Microscopy GmbH, Oberkochen, Germany). All measurements were made in triplicate. The cell wall thickness and lumen diameter for early and latewood were measured in 12 measurements per sample from heat-treated and unmodified Pinus oocarpa wood (Figure 1).

Data analysis

Shapiro-Wilk and Barlett’s test were performed to verify the normality of data distribution and homogeneity of variance among treatments. Analysis of variance (ANOVA) was performed for each variable, and when the F test showed significant results, a Tukey multiple range test (P<0.05) was performed using the Statgraphics Centurion XVI statistical program. The information was processed based on the methodology described by Gómez (1989).

RESULTS AND DISCUSSION

Chemical composition

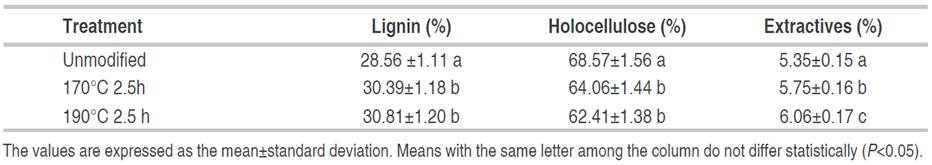

Thermally modified Pinus oocarpa wood presented a higher number of extractives and insoluble lignin than unmodified wood, in addition to presenting lower contents in the polysaccharides formed by holocellulose, also for modified wood (Table 1); the holocellulose content decreased by 7% in the wood treated at 170 °C, similar to those obtained by Durmaz et al. (2019) and Wang et al. (2018) in Pinus sylvestris and Pinus massonica woods; and for thermal modification, at 190 °C decreases of 9% were detected, equal to those achieved by other authors in heat-treated wood (Ding et al., 2011), no significant differences were found between the modified treatments; while, significant differences were found for the treated and untreated wood. These results disagree with those reported by Carvalho et al. (2020) in Pinus oocarpa found less content of holocellulose but heat-modified wood showed a significant decrease of holocellulose only at temperatures above 200 °C. These decreases were due to the deacetylation and formation of acetic acid, which acts as a catalyst for depolymerization reactions and accelerates the degradation of polysaccharides (González-Peña and Hale, 2009).

Decreases in the holocellulose contents of the wood Pinus oocarpa could generate a small increase (apparently not real) in the lignin contents (Batista et al., 2016) by 6% for heat treatment at 170 °C, which is consistent with the results found by Boonstra et al. (2006) and Wang et al. (2018) on thermally modified Pinus sylvestris and Pinus massonica woods, and the lignin content increased about 9% after thermal modification at 190 °C; presenting no statistically significant differences (P>0.5); these results are comparable to those obtained for Pinus sylvestris and Pinus massonica woods (Ding et al., 2011; Wang et al., 2018). These results show significant differences between treated and untreated wood contrary to the results obtained by Carvalho et al. (2020) in Pinus oocarpa, who found higher lignin content but in heat-modified wood showed significant increment only at temperatures above 200 °C. The increase in lignin content during thermal modification is caused by the condensation of by-products that occurs by the degradation of polysaccharides, which become trapped forming a repolymerization of lignin (Tumen et al., 2010).

Heat treated Pinus oocarpa wood had a different effect on the content of the modified wood extractives, which was higher as the temperature increased during the heating process, with statistically significant differences between treatments (P<0.05); thus, for the modification at 170 °C increases of 8% were obtained, equivalent to the results obtained by Boonstra et al. (2006) and Wang et al. (2018); nevertheless, higher increases of extractives were achieved for the modification to 190 °C, which increased by 13%, equal to those obtained in other treated woods (Pinus sylvestris and Pinus bruttia) (Ding et al., 2011; Ates et al., 2009). The increases in the mass content of the extractives were caused by the products formed due to degradation, mainly of the hemicellulose of the wood cell wall (Batista et al., 2016; Esteves et al., 2008; Kučerová et al., 2016). However, Carvalho et al. (2020) in Pinus oocarpa found a low content of extractives and the heat-treated wood showed extractives significative different only at temperatures above 200 °C, which is contrary to the results in extractives with significant differences in thermal treatments with 170 °C and 190 °C.

FTIR spectroscopy

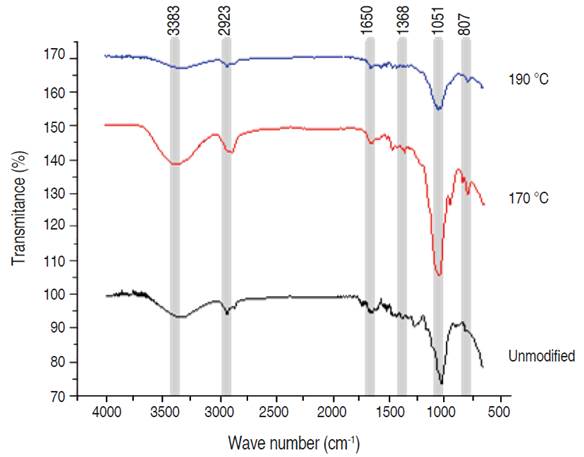

Changes in band intensities or ratios of the ATR-FTIR spectra are shown in Figure 2; comparing heat treatments with wood without modifying the chemical structure of Pinus oocarpa change significantly; the spectral changes that occurred after heat treatment were greater in the treatment at 170 °C; as observed at the peak of 3383 cm-1, which is typical of the stretching vibrations of O-H as a result of the decrease of free hydroxyl groups due to degradation of hemicellulose, providing hydrophobicity to the treated wood (Gérardin et al., 2007; Akgül et al., 2006; Salcedo et al., 2016). The band at 2923 cm-1 corresponds to the stretching vibration C-H that may be related to the presence of methylene (CH2) and methyl (CH3) (Wu et al., 2021). The peak at 1650 cm-1 is related to stretching vibration of C=O caused by the deacetylation and excision of hemicellulose, resulting in the release of acetic acid and aromatic structures (Gérardin et al., 2007; Akgül et al., 2006; Salcedo et al., 2016; Popescu et al., 2013; Wu et al., 2021). In relation to the band at 1368 cm-1, it is related to the C-H deformation in cellulose and hemicelluloses and the complex bonds of lignin carbohydrates from the -CH3 (lignin) and -CH2 (carbohydrates) groups (Missio et al., 2015; Wu et al., 2021; Gérardin et al., 2007). On the other hand, the band of 1051 cm-1 has its origin in the C-O deformation of the holocellulose and the C-O-C symmetric stretching of ether dialkyl and C-H deformation of aromatic lignin, it was more intense in the wood heat treated at 170 °C, it suggests the excision of β-O-4 and the excision of methoxylates from lignin (Wu et al., 2021; Popescu et al., 2013; Bhuiyan et al., 2000). Finally, at the 807 cm-1 band is evidenced the bending vibration outside the CH plane in lignin and organic acids, released during treatment and catalyze the hydrolysis of hemicellulose and cellulose chains (Nuopponen et al., 2003; Gérardin et al., 2007; Wu et al., 2021).

Anatomical measurements

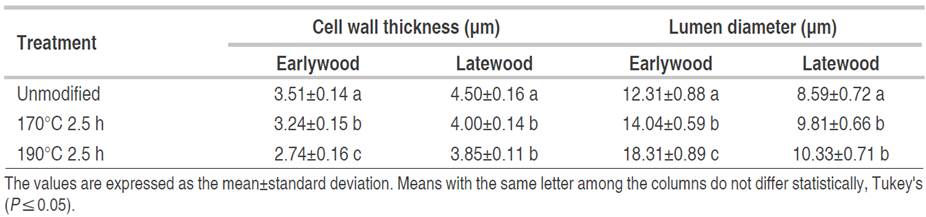

Table 2 shows the anatomical measured values of cell wall thickness and the lumen diameter for the earlywood and latewood of thermally treated and unmodified Pinus oocarpa wood.

Table 2 Anatomical measurements of cell wall thickness and the lumen diameter of the earlywood and latewood of heat-treated and untreated Pinus oocarpa wood.

According to the results, the cell wall thickness of the early wood decreased with the thermal modification of wood by 8% and 22% at 170 °C and 190 °C respectively, showing significant statistical differences between treatments in relation to cell wall thicknesses of latewood; also decreased with thermal modification by 11% for the thermal application of 170 °C and 14% for 190 °C, the difference between treatments was not statistically significant (P>0.05); the decreases obtained were higher than those reported in Pinus radiata and Picea abies woods (Cabezas-Romero et al., 2021; Bernabei and Salvatici, 2016).

The values of the cell lumen diameter resulting from the thermal modification in earlywood, increased by 14% after the application of the 170 °C treatment and 48% after treatment at 190 °C, clearly presenting statistically significant differences between treatments. On the other hand, the modifications presented in the latewood were increased by 14% to 170 °C and 20% for 190 °C, without presenting significant statistical differences between the treatments.The above results were higher than those reported for Pinus radiata, Pinus sylvestris and Picea abies wood (Cabezas-Romero et al., 2021; Kekkonen et al., 2010; Bernabei and Salvatici, 2016).

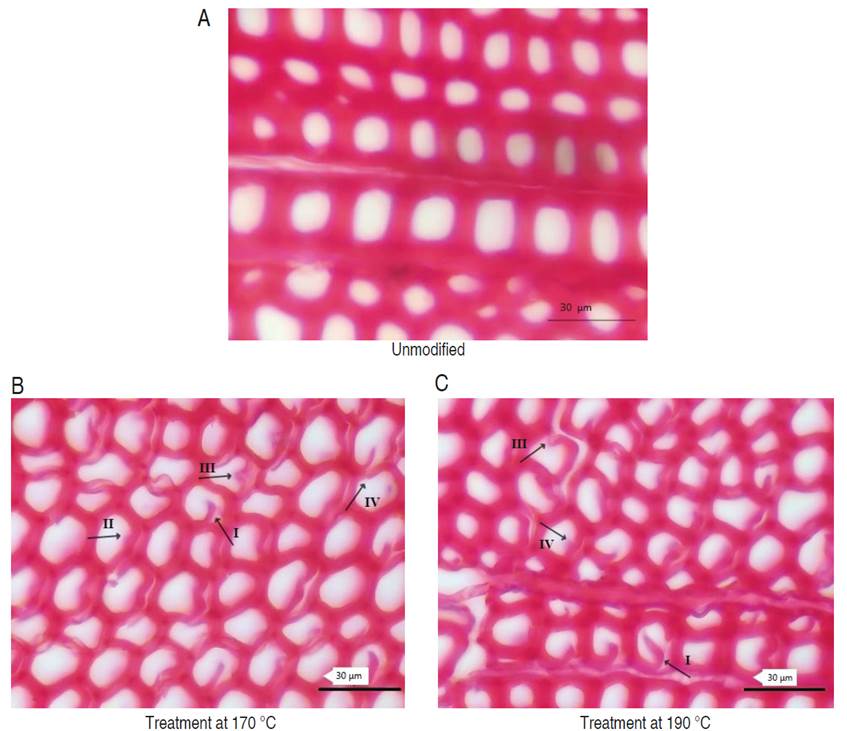

Morphological changes in the anatomical structure of thermally treated Pinus oocarpa wood, compared to the unmodified condition are shown in Figure 3. Cracks and small voids between tracheids were noticed when applied the modification treatment at 170 °C (Figure 3A), in addition, crushing of the cell lumens and cell deformations were noted. Cabezas-Romero et al. (2021) reported for the modified Pinus radiata wood slight crushing of cellular lumens, small cracks and the presence of broken cells and also cell deformations. Through the thermal modification at 190 °C, an increase in the morphological changes of Pinus oocarpa wood was presented, which affects its use and potential assessment due to the presence of higher cell deformations, large cracks, as well as an increase of the breaking and destruction of the tracheid walls; a similar phenomenon was also reported by Awoyemi and Jones (2011) in Thuja plicata wood.

CONCLUSIONS

The thermal modification caused changes in the chemical composition of the treated wood, with increases in lignin and extractives content, as well as a decrease in the holocellulose content (cellulose and hemicellulose). Thickness of tracheid walls decreased, and lumen diameter increased as the modification temperature increased. The treatment at 170 ° C produces better wood quality by obtaining lower degradation degrees and modification of the components of the cell wall. Future studies should focus on the resistance of treated wood to degradation, against the attack of fungi and xylophagous insects, because of chemical modifications found in the decrease of the carbohydrates.