Musa textilis Nee also known as cañamo of manila or abaca by its common name, is a crop with the capacity to produce a natural fiber, extracted from the leaf sheath that surrounds the stem (Lalusin and Villavicencio, 2015; Ferrín and García, 2013). This plant belongs to the same family as the commercial banana and it is native to the Philippines, although it is possible to be found in tropical countries (Barba et al., 2020). The best conditions to grow abaca are temperatures of 22 °C to 28 °C, with precipitation between 1800 mm to 2500 mm during the year, an altitude of 350 masl to 450 masl, and high relative humidity (78-85%) (Zambrano, 2015).

The abaca fiber is the most resistant worldwide natural fiber and it has properties such as a huge resistance to salinity, mechanical strength, brightness, flexibility, durability, and a considerable fiber length (Armecin et al., 2014; Ojeda, 2012). The unique characteristics of this fiber have increased its use in the automotive industry, as a substitute for fiberglass in reinforced plastic components. Besides, it works as a replacement for the synthetic fiber that is in the vehicle which generates a weight decrease and a cost reduction (Llanes-Cedeño et al., 2019).

The economic importance of this crop started around the year 1820 when the first export took place to the United States from the Philippines. However, the abaca trade did not become important until after 1850 and it was not until 1887 that the crop passed sugar as the leading Philippine export (Spencer, 1951). Approximately, during a century, the monopoly of worldwide production belonged to the Philippines. However, since 1921, the USDA began the cultivation of this Musa in Guatemala, Honduras, Costa Rica, and Panamá (Lalusin and Villavicencio, 2015).

Currently, the cultivation of abaca and other Musaceae is threatened by the presence of Fusarium oxysporum f. sp. cubense (Heck et al., 2021) this is one of the most important diseases and has even been considered the most lethal due to the few existing control methods and their persistence in soils (Martínez, 2019), which has led countries like Costa Rica to decree, even internally, a ban on the racking of banana plants and seeds as well as other Musaceae to prevent the spread of the plague between countries and additionally, between the different producing farms of the country (Decree No. 42392-MAG, 2020). The decree was initially valid for one year. However, an extension was approved until the pest enters the country and is controlled, or until it is officially controlled internationally and therefore does not present a threat to national production (Decree No. 43109, 2021).

According to scientists, there are more than 40 different species of abaca in the Philippines, but not all the species are marketable; the more common species are Bungalanón, Tangongón, and Maguindanao (Zambrano, 2015; Jiménez Moreira and Landy Campos, 2013). In Ecuador, there are two varieties: Bungalanón and Tangongón (Pera, 2019). However, in the case of Costa Rica, Guatemala, and Panamá, no data were found on the cultivated varieties.

This review is intended to highlight recent data about the characteristics of the plant and its fiber, crop management, productivity, and the market as an approach for updating the current knowledge regarding the abaca.

Plant characteristics and fiber composition

The botanical classification of abaca plants corresponds to: division Spermatophyta, subdivision Angiospermae, class Monocotyledonae, order Zyngiberales, family Musaceae and genus Musa (Mandegani, Sumarto and Perdana, 2016).

This plant is a perennial herb of approximately 8 m tall that grows in a clump, has cylindrical short corms, and bearing buds that develop short rhizomes with slender adventitious roots that extend about 2-3 m (Hillman, 2004). The plant is composed of a central core that is wrapped in up to 30 sheaves forming the protostome, its stalk is between 2 cm and 6 cm tall and 9 to 30 cm in diameter (Mamun et al., 2015).

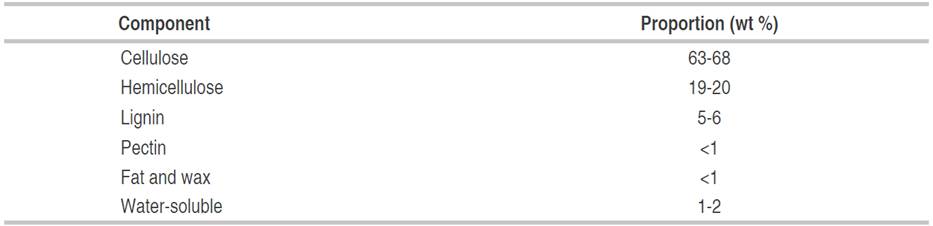

Abaca plant stems are made up of 93% water and 1.3-5% fiber (Hillman, 2004). In addition, the abaca fibers are composed mainly of combinations of basic polymers such as hemicelluloses, celluloses, and lignin (Table 1) and present a high crystalline index (more than 65%) (De Souza and d'Almeida, 2014).

The abaca fiber is thermally stable until 250 °C, this property is desirable when one foresees its use in thermoplastic matrix composites. On the other hand, its tensile properties put the fiber at a high strength with a- medium elasticity modulus (De Souza and d'Almeida, 2014). This means that the fiber of abaca can be used with a high bending stress and with a medium elasticity requirement (Muthu and Gardetti, 2020).

Also, Mamun et al. (2015) mentioned that some characteristics of abaca fiber such as strength, physical properties, and composition depend on the extraction technique used and the position of its leaves. For instance, those leaves close to the center are characterized by being softer, finer, and whiter.

It has been observed that in terms of the weight of the sheets, there is no significant difference between the use of internal (young) or external (mature) sheets, however, when using external sheets, fibers with greater resistance and elasticity are obtained than those obtained from the internal leaves, characteristics that are attributed to the maturity of the fiber (Alemania, Santiago and Gloria, 1982). The application of the mechanical properties and a comparison with other natural fibers are shown in the next section of this review.

Uses of the abaca fiber

The abaca plants and banana plants despite being Musaceaes manifest some differences. For example, they have different uses and their transcendental distinction is that the fruits obtained from the banana can be eaten, but those obtained from the abaca cannot (Pera, 2019; Cerón, 2006). Despite this, the abaca leaves can become fiber, which is used in some industries. In addition, the use of fibers takes more importance worldwide, especially for the advantages that arise for the environment, since they constitute a natural and renewable resource (Pontón and Guerrero, 2010).

Punyamurthy et al. (2012) and Haque et al. (2010) mentioned that abaca has different applications and uses, characteristics such as being inexpensive, durable, resistant to salt water, cheap to produce, abundant, biodegradable, and its potential reinforcement in polymers, have made it, that over the years the fiber is utilized for the manufacture of nets used in fishing, elements of dress, and upholstery. Although it is used mainly for the production of tea and coffee bags, sausage casings, paper, napkins, machine filters, conduction cables, electrical and vehicle coating, money, gloves, caps, it is also a substitute for the bark of trees, being also once the main source of the manufacture of fabrics (Pera, 2019; Cárdenas, 2016). Also, Pontón and Guerrero (2010) mentioned that abaca fiber has industrial applications because it is being used in the field of polymeric matrix composite materials for the manufacture of automobile interior parts.

But this is not the only application in polymeric matrices, there are currently many research teams looking at the possibilities of creating polymers reinforced with abaca fiber, regarding that, Barba et al. (2020) mention that the use of abaca in composite of polymers have benefits for the environment but also economic benefits since they are cheaper than other alternatives such as fiberglass, but in contrast, they present disadvantages like the heterogeneous structure of the fiber, the variation of its physical characteristics which are influenced by crop management, this in addition to their hydrophilic characteristic, which makes them incompatible with a variety of hydrophobic matrices.

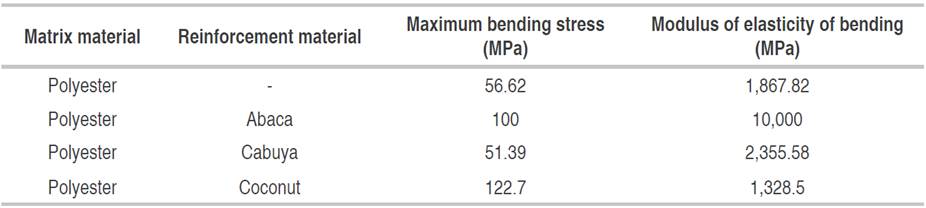

Regarding this, it is mentioned that the use of abaca to reinforce materials and generate polymeric matrices mainly influences the mechanical characteristics corresponding to the modulus of elasticity and the bending stress, obtaining improvements in the elasticity and rigidity of the matrix, thus, when using short abaca fibers, a greater modulus of elasticity is obtained, while when using longer or continuous fibers, the greatest increases in flexural stress are obtained (Pontón and Guerrero, 2010).

The data are reinforced by the studies by Llanes-Cedeño et al. (2019), Karthik and Arunachalam (2020) and Widnyana et al. (2020) in which they evaluate the same parameters for polymers reinforced with abaca, with cabuya, and with coconut fibers. In this case, the data in Table 2 shows that the use of abaca fibers stands out in the modulus of elasticity, but also provides an improvement in bending stress.

Table 2 Mechanical properties to bending of different composite and materials.

Source: Llanes-Cedeño et al. (2019), Karthik and Arunachalam (2020), Widnyana et al. (2020).

Abaca varieties

Despite its cultivation in many countries around the world, abaca genetics are relatively unknown and variations due to differences in phenotypic expression in the field and the subjective nature of morphological characterization schemes further complicate the matter. There is not enough scientific evidence of the existing varieties in Costa Rica, it is believed that there are at least three different varieties that were brought from the Philippines. However, it is estimated that there are around 40 varieties of abaca plants in the Philippines (the world’s leading producer of this crop) (Chamba et al., 2017). Besides, it is important to mention that not all varieties are commercialized. Some abaca varieties examples are Laylay, Inosa, Linawaan, Sinamok, Abuab, Putian, Libuton, Tangongon, Bungulanon and Maguindanao, being the last three the most common ones (Sinon et al., 2011; Galvez et al., 2021; Hidalgo, 1952).

For this reason, research and development in a variety of identification techniques are important, among which it can be mentioned the use of Simple Sequence Repeat (SSR) Markers to evaluate genetic diversity (Yllano et al., 2020); as well as the identification of resistance and susceptibility to diseases like the Bunchy Top Virus using microsatellites markers. Because of this technique, it was possible to identify 18 accessions that were resistant to the Bunchy Top Virus native from Palawan Island in the Philippines (Boguero et al., 2016); in addition, screening is used for molecular characterization and resistance detection of putative mutants lines generated from gamma irradiation (Descalsota et al., 2015).

In general, the use of molecular techniques has been associated with the identification of important traits such as resistance to diseases, however, the molecular characterization directed towards the identification of the different varieties and species has not been reported.

Abaca diseases

Abaca plants can be affected by numerous diseases, one of them being the Panamá disease or Fusarium wilt, which causes a yield reduction and damages in plantations between 5% and 65% (Purwati et al., 2008). This pathogen can survive a long time in the form of a mycelium among the infected plant debris or in the form of chlamydospora in the soil, which makes the control more difficult (Purwati et al., 2008).

Abaca Bunchy Top Disease (ABTD) is another infection, in this case, the disease is produced by a virus of the Babuvirus genus, specifically, the Abaca Bunchy Top Virus which the transmission is done by the banana aphid, the Pentalonia nigronervosa (Sharman et al., 2008). A plant with this disease can be recognized for symptoms such as stunting, bunched and rosette leaves, dark green flecks or vein clearing of the minor leaf veins, and up-curling and chlorosis of leaf margins (Sharman et al., 2008).

Banana Bract Mosaic Virus (BBRMV) is another disease caused by a virus of the Potyvirus genus transmitted by the aphid Pentalonia nigrovenosa and it is capable of producing losses in production up to 40% (Manzo-Sánchez et al., 2014). The symptoms in petioles are yellowish spots or streaks, on the leaves symptoms may or may not be visible and it is possible to observe dark stripes on the pseudostem but the typical symptom that gives the disease its name is a characteristic mosaic in the floral bracts (Manzo-Sánchez et al., 2014).

Fiber extraction

It is important to mention that the abaca fiber is extracted from petioles of abaca leaves by techniques such as stripping or decortication (this implies a blade of decorticator which removes the primary and secondary fibers from the sheath) and it takes place as soon as the stems are cut, while they are still moist. (Radoor et al., 2020; Mamun et al., 2015).

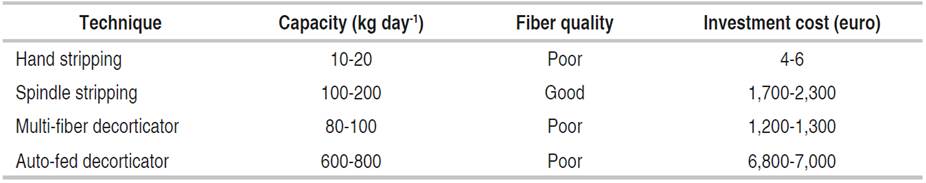

To extract the abaca fiber by stripping technique, two methods called tuxying and stripping are necessary. The first one involves a special knife (tuxying knife) which is inserted between the inner and outer layers of the leaf sheath to separate the fiber, while the second one, is done for cleaning the fibers (Radoor et al., 2020). The technique used to extract the fiber affects directly the fiber quality and investment as shown in Table 3.

In addition, different extraction techniques allow for obtaining short, long, or continuous fibers that vary in their characteristics and application possibilities (Llanes-Cedeño et al., 2019; Karthik and Arunachalam, 2020).

These extraction techniques include hand stripping, the spindle (machine stripping), and decortication. In general terms, the spindle provides a whiter and more resistant fiber (Muthu and Gardetti, 2020). However, poor handling of the machinery generates a significant loss of fiber, as well as a decrease in its quality (Alemania, Santiago and Gloria, 1982).

Muthu and Gardetti (2020) refer to the three types of extraction. First, hand stripping is a process that involves a large amount of work and lower yields, and the quality of the fiber depends on the skill of the worker, as well as the quality of the tools, mainly the density of the teeth of the blades. Meanwhile, the spindle is a process carried out by machines that are designed to apply the necessary pressure and with blades of adequate tooth density to achieve the highest possible yields and quality, also reducing effort and increasing production efficiency. Finally, decortication is the technique that provides the greatest processing capacity in exchange for a lower quality than the spindle, but being a mechanized technique also reduces the effort of the workers.

With this, the spindle method seems to be the most suitable for the stripping of abaca fibers, however, it should be considered that using this method requires an initial investment on the part of the producers, therefore, if the production is not high enough, in some cases it is not profitable and hand scraping continues to be used. Also, if the market needs a large amount of fiber of regular quality, the decortication process can be used.

Crop management and productivity

Theoretically, there are four types of planting material (seeds, corms, suckers, and tissue cultured plants), however, seeds are no longer used and this method is only used in breeding research (Göltenboth and Mühlbauer, 2010). Planting material such as suckers, corms, or pieces of corm with a vegetative bud can be used, however, suckers are rarely used because of the difficulty of transport, so the most common way is the cultivation by corms, which is used in major zones and farmers because of its facility and cost (Jones, 2018).

Abaca plants or "seed pieces" are put in distances between 2.5 m and 3.0 m apart in holes and covered with 5-10 cm of soil. Young plants may be partially shaded for protection from excessive heat (Jones, 2018). It is mentioned that abaca plants commonly grow in loamy soils with a high content of sand, which provides better drainage, and as a consequence, the plant thrives (Spencer, 1951). According to Jones (2018), the time of harvesting depends on some factors such as the cultivar, the soil conditions, and climate, although commonly the plants can be harvested from 18 to 24 months after planting and two or four pseudostems can be harvested from each mat every 4-6 months.

According to Waller and Wilsby (2019) a considerable difference between the ways of bundle extraction exists, for instance, using the hand stripping technique produces about 20 kg of fiber bundles per day, while the spindle stripping technique produces between 80 kg and 120 kg per day, while the decortication technique produces 140 kg per day being the most efficient on terms of quantity but with a lower quality than the spindle method.

As previously mentioned, some conditions are necessary to grow abaca in a better way, this includes temperature, precipitation, altitude, and relative humidity, yet some studies mention that it is also important to know how the influence of shade, water, nutrient availability, and other factors affect the productivity of the crop (Bande et al., 2013; Kumar et al., 2017). Bande et al. (2013), conclude that an increase in light intensity, nutrient supply, and water does not affect the quality of the fiber, however, factors such as reducing the irradiance by applying 50% of shade have a significant impact on the physiological performance of the plant, which means that this directly affects the crop yield. Supporting this, according to the analysis of Araya et al. (2022) the use of a shadowing system shows a potential capacity for increasing proficiency and productivity of the abaca due to the morpho- and physiologic adaptations caused by the variations in the solar radiation perceived by the plant.

On the other hand, it was demonstrated that in crop fields where abaca was cultivated for many years without proper fertilization of the soil, the productivity can decrease, giving bad parameters of fiber extraction per hectare (ha) planted (Romel et al., 2011). To avoid this, an NPK fertilizer can be used to improve the quality of the fibers (Bande et al., 2013).

Regarding crop management for local production, as well as research and development, there is a great lack of information in countries such as Kenya and Indonesia. Regarding Equatorial Guinea, El Ministerio de Agricultura y Bosques, mentioned in 2012 that, during the 1990-2000 decade, there was interest in resuming cultivation, but no concrete action was generated, although they recommend the recovery of the product in the long term, additionally, El Banco Internacional de Reconstrucción y Fomento (2019) affirms that abaca is a commercial crop with great potential, but that the country does not have a transformation industry to take advantage of it.

For their part, Costa Rica and the Philippines were part of the diversification and expansion project of the sustainable Abaca initiative, which consisted of supporting small producers during the years 2017-2020 with training, disease control, monitoring of results, as well as support in other issues related to the production process. As a result of this, there was an important growth in cultivation and production (GIZ, 2018) and thus, increase their importance in the market, as detailed in the next section.

Abaca fiber market

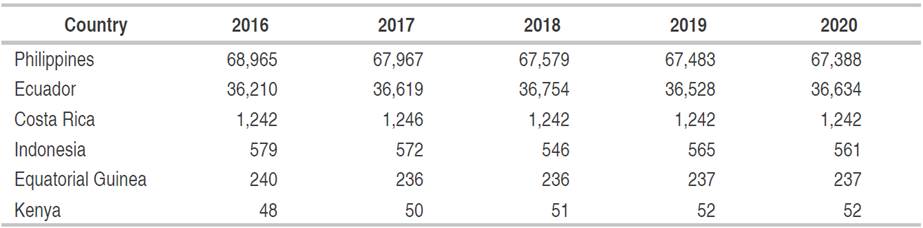

The abaca has a high potential as a crop, since sowing it can take from two to three years to have a biannual harvesting using few resources of pesticides and fertilizers which gives way to a non-expensive treatment of the crop (Lacuna-Richman, 2002). Furthermore, according to Global Market Insights (2021), the global market size of the abaca fiber is going to present a strong increment over 2021-2027, due to the accelerating adoption of abaca-reinforced hybrid materials because of its multiple uses and its sustainability. The world production of abaca is valued at $60 billion per year (FAO, 2021). In 2020 the Philippines was the world leader in abaca production followed by Ecuador and Costa Rica. This year, the Philippines produced around 67,388 t of abaca Ecuador produced around 36,634 t as shown in Table 4.

Table 4 Main country producers of abaca from 2016 to 2020 and its production in ton.

Source: FAO, 2022.

Regarding the demand, Waller and Wilsby (2019), mention that productivity is not sufficient to meet the demands of fibers and fiber products on the international market. The gap between the supply and the demand by 2019 year was 25,000 t, this means that with the production of fibers in 2018 (32,000 t) an 80% increase in the supply is needed to meet the demand for 2018 (Waller and Wilsby, 2019).

The Philippine Statistics Authority (2021) mentions that among the countries with the highest imports of abaca fiber are, in descending order, Japan, the People’s Republic of China, the Republic of Korea, Saudi Arabia, and Iran, among other minor import countries. However, abaca is presented as a highly exploitable non-traditional crop option according to the study by Ponce (2015), it is possible to produce abaca with a profit of up to $1982.25 per cultivated ha with a production performance of up to 1456.56 kg, which shows it as a highly profitable crop. Furthermore, during 2020 only in the Philippines, the production of abaca produced an income of USD 1.62 billion in 140,688 ha, which positions this crop as one of the most economically important for this country (Philippine Statistics Authority, 2021; FAO, 2022). Meanwhile, Ecuador produces 27,576 ha of land, which generates approximately USD 36.81 million, being the second largest producer (Torres, 2021; FAO, 2022). Besides, in 2020, Costa Rica harvested 1,070 ha, Indonesia 688 ha, and Equatorial Guinea 1,783 (FAO, 2022), these being minor producers, but with the potential to develop the crop.

It should be noted that Equatorial Guinea harvested a larger area than Costa Rica and Indonesia, however, its production is lower because the yield is 1,329 hg ha-1, while Costa Rica’s yield is 11,607 hg ha-1 and that of Indonesia reaches 8,154 hg ha-1 (FAO, 2022).

Plant breeding

The genetic pool of abaca is highly diverse as indicated by the high Shannon diversity index in some Philippine gene banks, which indicates that it could be a huge resource for breeding. However, there are no publicly available assembled draft abaca genomes for genome comparison studies of the varieties (Galvez et al., 2021). The conventional breeding methods are coupled with the new advances in biotechnology and molecular biology to come up with better solutions to the problems that the abaca industry faces. These methods are used to develop different varieties that possess specific characteristics like good fiber quality, high fiber yield, and a high degree of resistance to major diseases of this plant family (Lalusin and Villavicencio, 2015).

In a study by Kumar et al. (2015), it is mentioned that the necessity to overcome the limitations of the low resistance to ABTV (Abaca Bundry Top Virus) has caused some strategies like transgenic approaches based on the pathogen-derived resistance (PDR) to be explored, strategies using ABTV DNA-R gene or satellite DNA (DNA-S4) resulted in partial resistance to ABTV. Also, mutation breeding using gamma-irradiation has been explored to induce genotyping and phenotyping variation for ABTV resistance (Kumar et al., 2015).

In this sense, Purwati, Harran, and Sudarsono (2007) mention that the improvement of abaca using ethyl methanesulphonate is capable of offering resistance to infection by F. oxysporum. Also, it is important to mention that technological progress that began with breeding, and continued with mechanization, the use of synthetic fertilizers and the tools of genetic engineering to improve plant characteristics must continue, for the natural fiber industries to remain competitive (Townsend, 2020).

Despite the possibilities offered by molecular techniques, the most recent advances in improving quality and yield in abaca plantations occur through crop management and nutrition, light, hydration, and weed management conditions (Araya et al., 2022; Bande et al., 2016).

CONCLUSION

In this review, it was covered information generated over a long period that is related to the cultivation of abaca in diverse aspects, description of abaca as a plant, its uses, and applications, its production and markets, its characteristics as a product but also as a crop, the management that is given to it, as well as the diseases that affect it and the techniques and technologies that have been used to provide resistance to them.

Abaca fiber has great potential to replace other natural and synthetic fibers used in the market such as fiberglass, coconut, and cabuya, however, it is necessary to continue the study around its production since the known information about productivity is a bit sparse and this could be one of the reasons the cultivation is not expanding. Furthermore, there are many knowledge gaps in aspects such as molecular detection and crop management, but also in the information about the crop in countries like Indonesia, Equatorial Guinea, and Kenya.

Also, recent research and development are directed toward the formulation of fiber-reinforced polymeric matrices of abaca rather than breeding the crop itself. With this, abaca fiber is considered a material that can be given a greater number of uses, but at the same time leaves aside the interest in the development of the crop at the field level to improve its quality and yield. The latter allows to consider that for the next few years, around a growing global economy and in search of new production possibilities, producers from different Latin American countries such as Guatemala, Honduras, Costa Rica, and Panamá, should consider abaca as a non-traditional crop that could be highly exploited, but not only this, once this crop expands, it could even reach new countries that meet the necessary conditions for its growth. For this reason, this review will serve as a reference point on the current knowledge about the cultivation of abaca and the production of its fiber and is encouraged research around the great potential that it presents and for this, greater collaboration with research projects by universities is required. To advance more efficiently and increase national productivity, in this regard, the Costa Rican Technological Institute is the only academic institution that is doing research in abaca in the country, and it’s open to collaboration with other national and international universities, and that could contribute significantly to the market and the economy of a variety of countries.