Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

Revista Ingenierías Universidad de Medellín

versão impressa ISSN 1692-3324versão On-line ISSN 2248-4094

Rev. ing. univ. Medellín v.11 n.20 Medellín jan./jun. 2012

ARTÍCULOS

ELECTROMAGNETIC HEATING AS A WAY OF CUTTING COSTS WHILE SAVING ENERGY: TIME EVOLUTION

CALENTAMIENTO ELECTROMAGNÉTICO COMO ALTERNATIVA PARA REDUCIR COSTOS Y AHORRAR ENERGÍA: EVOLUCIÓN

* Mechatronics Engineer. Ph.D.(c) on Electronics Engineering. Universidad Industrial de Santander. E-mail: ivan.amaya2@correo.uis.edu.co.

** h.D. Universidad Industrial de Santander. Professor. E-mail: crcorrea@uis.edu.co.

Recibido: 11/10/2010

Aceptado:: 25/05/2012

RESUMEN

In this review article, an electromagnetic heating time evolution is presented, stating a brief description of the main applications in some of the top fields regarding this technology and striving to indicate fields for further research in an area that becomes more important with each passing day. It was found that the food industry and that plasma related products are the most important branches of this technology, where a vast majority has focused on microwaves instead of using radiofrequency. Some other areas are also discussed and at the end possible future researches are outlined, such as a mixed heating dryer and a sulfur lamp.

PALABRAS CLAVE

Ceramics industry, chemistry, electromagnetic heating, microwave power transmission, plasma applications.

ABSTRACT

Este artículo de revisión presenta la forma como ha evolucionado la utilización de energía electromagnética para generar calentamiento, mencionando algunos campos clave de esta tecnología en aras de indicar nichos y posibles campos de investigación de un campo que cada vez toma más fuerza. Se encontró que las aplicaciones principales se centran alrededor del procesamiento de comida y de aplicaciones de plasma, utilizando en su mayoría microondas en vez de radiofrecuencia. Al final se enumeran algunas áreas que, desde el punto de vista de los autores, merecen mayor nivel de investigación, como son secadores de calentamiento mixto y la lámpara de azufre.

KEY WORDS

Industria cerámica, química, calentamiento electromagnético, transmisión de potencia por microondas, aplicaciones de plasma.

INTRODUCTION

This document provides a brief summary around the most important industrial processes where electromagnetic heating has been used. Some of the common problems researchers have found and the way they have solved them will be mentioned. In the first part, a general overview of the bibliometric search will be exposed, where the reader can find some of the most important topics revolving around electromagnetic heating. Following it, a list of some of the most important breakthroughs since Faraday's discovery will be summarized in order to show the reader for how long this topic has been around. Afterwards, a categorization of the most recent articles will be shown, sorting them by industry type and/or industrial process. Finally, this article will show some of the most promising areas that can become object of further research.

1 GENERAL OVERVIEW

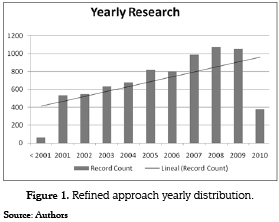

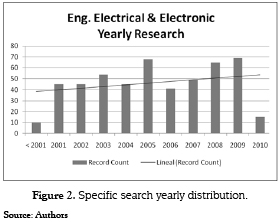

As a first step in recognizing the state of the art that surrounds electromagnetic heating, a global search was performed. Its equation contained around 30 terms mainly connected by OR logical functions. The amount of data returned by the search engine was huge, exceeding a hundred thousand records. A new query consisting of around 5 key terms was submitted to the search engine. After filtering the less industrial research areas, around 7500 results were obtained, whose yearly distribution is shown in figure 1. Moreover, and because of the electronics engineering focus of the dissertation, only the documents related to Electrical & Electronic Engineering (E.E.E) where chosen. It can be seen, in figure 2, that there's a growing trend over the last years.

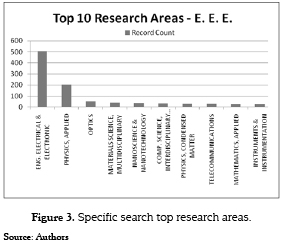

In figure 3, the distribution of the top research areas is shown. Since a filtering by the E.E.E area has been made, all the entries belong to it. Nonetheless, an article can belong to multiple categories at once and, therefore, the record count from this figure surpasses the number of articles. Most of them are also related to applied physics, but it can be seen that materials science plays a major role in the research.

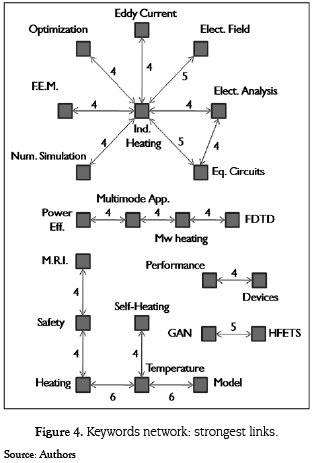

After analyzing these articles, it was found that the main keyword is ''Induction Heating''. Figure 4 shows the data network, where it can be seen that the stronger (i.e. most recurrent) keywords are related to electromagnetic field, temperature, model or similar. The numbers between keywords represent the frequency of appearance of those two terms in an article. It is important to stress that the highest value is six and that values lower than four aren't shown.

2 INTO THE ARTICLES

Besides from the documents previously obtained, some of the most relevant and most cited documents were also analyzed. They were extracted using the most focused search equation (the one restricted to the E.E.E subject area).

2.1 The first steps

Microwave technology began on the 19th century and it was focused ''in the generation, guidance, detection and control of short-wavelength electromagnetic-wave propagation''. As of today, this technology is used in fields ranging from communications to medicine, including industrial processing and power transmission. What began with Faraday's discovery in 1831, found one of the first practical applications with Hull's 1920 invention: the magnetron. Since then, this research field has experienced a continuous growth, being able to define the period from 1935-1945 as ''golden years for advances in microwave technology''. The progress achieved by Brillouin (1922), Okabe (1927), Kilgore (1931), the Varian Brothers (1937), Chu (1938) and several other researchers led to a milestone during the late 1940s, when many patents were issued to Westinghouse, GE and Raytheon regarding heating applications based on microwaves. The final one centered on food cooking and treatment, while the other two directed their efforts to the industry, focusing on the drying process of some production lines. In 1946, the US Federal Communications Commission (FCC) allocated the 915 and 2450 MHz bands for microwave ovens. Since then, its market has been emerging and improvements are being made [1].

2.2 Recent developments

Even if progress is being made, it doesn't mean that all the research areas continue to exist. Through the past 40 years, some of them have lost importance while others continue to exist and, of course, new ones have emerged. Some of the still existing fields include antennas, microwave filters, microwave systems realization and microwave Computer Aided Design (CAD). RFID's and metamaterials are some examples of novel research areas, which also includes the ''blurring of the traditional boundaries between analogue and digital design at microwave frequencies'', which means that, for example, digital techniques can be used to overcome some analog problems. This category is also fit for some older areas which lost interest some time ago but are now reappearing, such as the Doherty power amplifier (dated from 1950s) and the parametric amplifiers [2].

2.2.1 Food Industry

According to [3] , as of 2002 the food industry represented one third of microwave industrial applications. Among them, a bacon cooker was the top equipment. This production line generated around 12.1 billion slices a year and also allowed the commercialization of a sub product (fat), which can be sold to restaurants and institutions. In these machines, there are cavities (about three and a half meters long), where bacon is processed. In order to get the microwaves into the cavity, a rotating antenna (called ''rotawave'') or a rotating three-port (''radaring'') can be used [3].

Another successful application is meat tendering. Its annual production is estimated in 4 billion pounds. The process ''involves raising the temperature from 0° to approximately 27° to permit further mechanical processing such as slicing, dicing, grinding, pressing, and molding of the product''. The machines are similar to the ones previously mentioned, but these ones need to take into account thermal runaway (due to localized ice blocks) to avoid obtaining half-cooked/half-frozen product. Some other interesting lines, which occupy a significantly lower portion of the market, include potato chips, beer pasteurization, wheat conditioning and baking [3]. There is also evidence of microwave heating used in herbal tea processing [4–6] and studies about the influence of dielectric properties of fruits in RF heating [7].

2.2.2 Plasma Applications

In a similar manner to previously exposed, this area occupied, as of 2002, one third of industrial applications. Among the first researches was a microwave torch, and since then some interesting projects have taken place. In 1990, a paper related to a ''cavity-operated electrodeless high-pressure microwave discharge system'' was published [8].

Even if there wasn't any practical application in that document, it served as the basis for the microwave discharge lamps used in curing. This equipment generates UV light more efficiently than UV sources (i.e. less heat and infrared emissions). At that year, the market for this kind of lamp was estimated in around $100 million per year. Another interesting project in this area refers to the sulfur lamp. It is able to generate light similar to the one emitted from the sun and it's powered by microwave energy. Even though the light requires proper directing, it is a promising application. It can be useful to light large spaces and is currently used at the National Air and Space Museum and at the Forrestal building in Washington, DC. As of March, 2002, the only manufacturer of this item was Fusion Lighting, but a web search done in May, 2010 shows some other manufacturers, such as Island Systems Lighting (England) and LG Electronics (who named them Plasma Lighting Systems). As it can be seen from the previous examples, this is a promising area which will grow as new applications are found and as current ones are optimized for home use [3].

2.2.3 Sintering

Sintering is a process that is used in different industrial sectors. However, the objective of heating two pressed elements (generally in the form of powder) near the point of fusion to increase its properties remains the same. The change from electric and gas powered furnaces to ones driven by microwaves has already begun. The Asian industry has been the pioneer at this, obtaining process time reduction of about 90% and energy saves of up to 80% while increasing the properties of the finished product. These savings can be more easily understood if a general analysis is carried out. Since a microwave furnace is significantly smaller than a traditional one, it will require less power and will allow the extra space to be used for other processes. Besides, since it isn't powered by coal, oil or similar, manufacturing costs can be reduced. As a personal note, we consider that if this technology is combined with a renewable source of energy, its environmental impact will be almost zero. Some other entities who have successfully applied this technology are Japan's National Institute of Fusion science (who obtained a 25% time reduction and an 82% energy reduction), Britain's Loughborough University (who obtained an 89% sintering time saving and a 90% energy consumption reduction) and the Penn State Materials Research Center (who managed to reduce sintering time by 90%) [9]

2.2.4 Carbon Nanotubes (CNTs)

An interesting discovery that was made since the 1950s by Radushkevich et.al [10] but which only had a boom until 1991 with Iijima's article in Nature [11] (due to factors like the secrecy derived from the cold war and the research focus of the time), is that carbon filaments can be hollow and have a diameter ranging in the nano-scale [12]. It has been shown that these carbon nanotubes have properties that make them suitable for several applications [13–17]. There have also been some more theoretical studies, such as the one from Yang [18], where he modeled the heat transfer phenomenon on this kind of elements. He began by using a single nanotube, followed by an array of them and finalizing with a composite whose surface contained some of these elements. He found that due to the anisotropic characteristic of the nanotube's thermal conductivity, it can serve as a cooling device. One of the main problems found when modeling heat conduction of elements at this scale, is that the separation between molecules can't be disregarded, so the compound is no longer continuous and therefore the traditional heat transfer equations cannot be used with a standard Finite Element Analysis (FEA). A solution found by Yang is that a molecular simulation can be performed to upscale the discrete based thermal conductivity to a continuous equivalent, enabling the use of the FEA.

CNTs possess great specifications, such as an elevated Young's modulus and a Poisson's ratio of 0.18-0.3 [19–21], but they also represent a great heat conductor (with conductivities around 2500-6000 W mK-1). However, and because of their small size, the junction resistance is generally high. Last year, Xu et.al reported two ways of improving it. The first one relates to wrapping the nanotube's interface with a polymer, while the other one propose to connect CNTs using a metal coating. They found that by increasing the contact surface of two CNTs (using any of the two previous approaches) not only the stiffness of the junction is augmented, but also its thermal conductivity [22].

2.2.5 Drying

In the drying industry, some of the microwave applications revolve around pasta [23, 24], wood [25], plastics [26], textiles [27] and green-tea leaf [4, 5]. Regarding this last one, Huang et.al demonstrated in 2007 that by using microwave heating to process the herbal tea leaves, a significant increase in tea quality can be achieved. This is mainly due to better vitamin C and chlorophyll preservation [4].

It has been shown that, at least at lab level, cloth drying is possible [28]. Smith filed a patent in 1995 regarding a machine which is able to dry cloth using microwaves [29]. There exists, however, the chance of damaging it, mainly due to arcing problems, risking the creation of a fire. Therefore, this invention implements a safety that introduces water to increase the moisture when it reaches a critical level. A current search on this application didn't yield any new progress, so it could be an interesting field for further exploration.

2.2.6 Curing

This process refers to the act of increasing the temperature of an additive in order to create cross-linking chains of polymers to increase the toughness of the material. Tanaka et.al [30] published a document in September, 2007 where Variable Frequency Microwave (VFM) was used to cure epoxy-based dielectric films. They compared the results given by this methodology against the ones given by traditional curing and found that by using the novel one, material properties such as elastic modulus were enhanced. They also observed that after the process, the chemical structure of the polymer was modified, concluding that it was the cause of the properties improvement.

2.2.7 Electronics

The applications behind this area are more focused in microelectronics than in its macro version. Noh et. al [31] presented, in 2004, a novel technique to achieve wafer bonding using variable frequency microwave heating. Its intermediate layers are made of parylene (a chemically vapor deposited polymer), which is heated until laminated. The authors report that by using this technique, the temperature and bonding time are reduced if compared to traditional methods found in the literature while the tensile bonding strength is somewhat higher. They also point out that this technique can be used to join two dissimilar substrates. This is mainly because by using variable frequency, selective heating can be implemented.

2.2.8 Rubber Industry

Regarding this field, it was found that microwave heating was used for applications such as tempering, vulcanizing and preheating of rubber [3]. However, a more recent search returned that the focus on this field has migrated towards nanocomposites [32], without fully leaving aside more traditional applications like vulcanizing [33].

2.2.9 Foundry

In this area, microwave heating has been used to dry sand cores, in order to avoid wet elements from entering the furnace [3]. A more recent research indicates that by using microwaves in the hardening process, it is possible to obtain a greener, faster process. However, this exposes the product to big moisture absorbability, which detriments its surface stability and its compression strength. This, precisely, is why the authors consider that a good approach for making this application a practical one is to focus on creating a ''water-proof coating of sodium silicate bonded sand and a new type moisture-resistant modified sodium silicate binder'' [34]

2.2.10 Ceramics

Regarding ceramics, tons of papers have been written, especially at the American Ceramics Society (ACS) and at the Materials Research Society (MRS). As of May, 2010 a quick search on the second website returns about 800 publications, while in the other case returns 118 entries for the Ceramic Engineering and Science Proceedings, published by Wiley. Besides magnetrons, some of the articles also report results using Traveling Wave Tubes (TWTs), klystrons and gyrotrons, which yielded interesting results but aren't practical to implement from an economic point of view [3]. However, it is possible that in a near future these alternatives are reevaluated to check their environmental benefits.

There are reports of studies dated on February, 2008, such as the one realized by Canada's Ontario Energy Agency, where they estimate that if that province's ceramic industry totally converts to microwave heating, they would annually save enough money to build a 350 MW coal plant [9].

2.2.11 Chemistry

As in the case of beer, general pasteurization plays an important role in the chemistry industry powered by microwave energy. Some other interesting applications include sterilization, pharmaceutical drying (which differentiates from general drying in the ultra low humidity levels required) and Microwave Enhanced Reactions (MER) in general [3]. Regarding the pharmaceutical field, Larhed et.al [35] performed a study in 2001 where they analyzed the applicability of microwave energy to high-speed chemistry. They found that even though it isn't viable to use microwave heating in every process, there exists a big enough set of compounds that are worth exploring with microwave heating, basically striving to reduce reaction time and optimize substance production. This research was also analyzed five years later, when in 2006, Mavandadi et.al [36] determined the impact of microwave heating in some areas of drug discovery. They concluded that it is, indeed, an emerging trend and that companies are quickly adapting to this technology. They also point, however, that is necessary to optimize the remaining stages of the drug development process.

Revolving around MER are significant jobs, which includes the one from Eskilsson [37], where a review of Microwave-Assisted Extraction (MAE) comprising a theoretical basis of microwave heating and an extensive literature review is presented. It is also convenient to remark the review performed by Kappe in 2004 [38], where some trends in microwave synthesis are discussed, also analyzing its possible impact for the following years. The immersion of this technology in chemistry has been so important that studies about whether the improvements on the process are derived from thermal or non-thermal features have arisen. A proof of this is the research performed by Herrero et.al [39], where they conducted some tests using a fiber-optic probe as a tool for accurately measuring the temperature. They found that the enhancement exclusively originates from a thermal point of view and that adequate agitation is required in order to avoid non-uniform heating. Some of this year application focused researches are centered on revising the robustness and structural details of a microwave prepared organic framework [40], the enhancement of the dehalogenation reaction of a chloride [41] and the preparation of pentosidine and other Advanced Glycation End products (AGEs) [42].

2.2.12 Waste Remediation

There are some interesting documents referring to this application, where even human waste has been found to be capable of being treated with microwave energy. Nevertheless, as of 2002 it wasn't clear whether or not it had practical application [3]. As of last year, there are reports of some industry related recycling processes that are worth mentioning. Iwasaki et.al [43] published a document where they summarize some lab tests to determine the feasibility of using microwave heating to dehydrate the waste sludge derived from the steelmaking industry, enabling it for a posterior recycling stage that strives to recover minerals such as Fe, Ni and some other valuable resources. They comment that due to an increase in the raw material prices, both, iron makers and steelmakers, will migrate to this technology in order to reduce manufacturing costs.

In a similar manner, Tae et.al performed a research where they focused in finding out the differences between microwave driven hydrothermal processing of blast furnace slag and a traditional one. They found that by using microwave heating, the processing time was reduced and that this technology allowed a higher compressive strength of the product while reducing its porosity ratio [44].

2.2.13 Other Applications

Heating applications aside, there exist some interesting approaches for using microwaves in different fields [3]. An example of this is microwave power transmission, where two main branches can be located. The first one originates with Glaser's research in the 1960s [45], where he came up with the idea of sending a geostationary satellite into space. This satellite would have solar collectors (this because in space solar generation of energy is more efficient than in earth) in charge of energy generation, which will be send to earth by some mean (now it is certain that it could be transmitted using microwaves). The other road relates to power transmission through earth using microwaves and it is called Microwave Power Transmission (MPT). Even though these topics are interesting, they won't be discussed here since they diverge from the main topic of the dissertation in which this review is based: electromagnetic heating. Nevertheless, it is necessary to remark that, at least from the point of view of the authors, combining these two techniques could lead to an important renewable energy source that won't require the presence of transmission lines.

2.3 Applications to come

During the first half of 2002, Osepchuk [3] mentioned some futuristic applications of microwave energy, which included comfort heating, oil recovery from its shale, area heating (which could be used to prevent tornadoes from originating by using high-power microwave beams) and weather modification. This final supposition was based in Bosisio's et al. 1969 research [46], where they demonstrated that it was plausible to use microwaves to protect plants from frosting.

Regarding oil recovery, during the second half of the past year, Hascakir et.al published a paper where they analyzed the feasibility of using microwave heating to stimulate heavy oil samples, striving to increase production. They found that this technology can be applied in this field and that by using high salinity water and high water saturation, the production can be improved. However, the tests performed by them don't allow determining the economic viability of this approach [47]. Almost simultaneously, Hascakir and Akin submitted another document where they generated an analytical model for determining the absorption coefficient of an oil shale. Moreover, they deduced that, in order to efficiently recover oil shales, a mixed heating process should be used. The idea behind it is to take advantage of the fast temperature increase using microwaves to quickly reach the pyrolysis temperature and then change to a conventional heating method to maintain it for a long enough period of time [48].

On the other hand, a paper published by Eastlund et al in 2007 regarding the use of microwave beams as a mean of protection from tornadoes, has been found [49]. However, it doesn't really differ too much from their previous publications in 2001 [50], and therefore it could be said that this field still requires further research.

3 CONCLUSIONS

Throughout this paper we strived to organize some of the major publications regarding electromagnetic heating industrial applications. This list is anything but complete. We encourage the reader to communicate us if he/she has an important reference that wasn't mentioned. Nonetheless, it can be quite useful if the reader is new to this technology.

We've shown that most of the industrial approaches focus in the food and plasma industries, mostly restricted to the use of microwave energy instead of RF (which, from our point of view, could derive from the higher penetration depth present in the first one). However, there also are some interesting applications in other areas, and a lot of new applications can still be found. Among those, a new visit to a microwave cloth dryer can be taken into account, searching to use a combined heating as in the oil recovery case [48], striving to achieve a quick microwave assisted temperature increase and then holding it by conventional means. Some other research alternatives include the Thunderstorm Solar Power Satellite (TSPS) initially proposed by Glaser [45] and revised by Eastlund et.al [49]. However and even though it is an interesting application that could save many lives, budgetary restrictions make it a lowly viable choice. Among other possible applications, the sulfur lamp seems to be very promising. Even though the lamp itself has already been developed, it is susceptible to enhancements like positioning inside a channel whose walls are made of reflective material like polished aluminum or even mirror. Combining microwaves with a renewable energy source is also an interesting field whose importance will grow as time passes, and since microwave assisted sintering requires much less energy than a conventional one, it is possible that this combination find its first applications in the previously mentioned field. Another path derived from this literature review is the one proposed by Jina et.al [34], which separates from the electronics approach of the dissertation.

Something important to stress is that from the literature shown in this article, only the one related to CNTs contained some specific modeling. However, [18] it neglects the effect of heat generation (denoted Q by the author), which can be used to model the effect of an external microwave source in a specific element. Therefore, further research in this field should be considered.

Finally, it would be advisable to revise the TWT, klystron and gyrotron approaches in order to implement a green equipment that, if not from the economical point of view, be an environmentally viable technology.

REFERENCES

[1] H. Sobol and K. Tomiyasu, ''Milestones of microwaves,'' IEEE Transactions on Microwave Theory and Techniques, vol. 50, no. 3, pp. 594-611, Mar. 2002. [ Links ]

[2] R. Sorrentino and T. J. Brazil, ''40 Years of EuMC and Beyond,'' Proceedings of the 39th European Microwave Conference, no. October, pp. 669-674, 2009. [ Links ]

[3] J. M. Osepchuk, ''Microwave Power Applications,'' IEEE Transactions on Microwave Theory and Techniques, vol. 50, no. 3, pp. 975-985, 2002. [ Links ]

[4] Y. Huang, et al., ''Effect of enzyme inactivation by microwave and oven heating on preservation quality of green tea,'' Journal of Food Engineering, vol. 78, no. 2, pp. 687-692, Jan. 2007. [ Links ]

[5] V. Sharma, et al., ''Extractability of tea catechins as a function of manufacture procedure and temperature of infusion,'' Food Chemistry, vol. 93, no. 1, pp. 141-148, Nov. 2005. [ Links ]

[6] E. Chan, et al., ''Antioxidant activity of Camellia sinensis leaves and tea from a lowland plantation in Malaysia,'' Food Chemistry, vol. 102, no. 4, pp. 1214-1222, 2007. [ Links ]

[7] S. Birla, et al., ''Characterization of radio frequency heating of fresh fruits influenced by dielectric properties,'' Journal of Food Engineering, vol. 89, no. 4, pp. 390-398, Dec. 2008. [ Links ]

[8] S. Offermanns, ''Resonance characteristics of a cavity-operated electrodeless high-pressure microwave discharge system,'' IEEE Transactions on Microwave Theory and Techniques, vol. 38, no. 7, pp. 904-911, Jul. 1990. [ Links ]

[9] M. Kirksey, ''Green Technology?: Hi-Temperature Microwave Sintering Reduces Energy Use Up to 80% and Process Time Up to 90%,'' WebWire, 2008. [ Links ]

[10] L. Radushkevich and V. Lukyanovich, ''O strukture ugleroda, obrazu- jucegosja pri termiceskom razlozenii okisi ugleroda na zeleznom kontakte,'' Zurn Fisic Chim, no. 26, pp. 88–95, 1952. [ Links ]

[11] S. Iijima, ''Helical microtubules of graphitic carbon,'' Nature, vol. 354, pp. 56-58, 1991. [ Links ]

[12] M. Monthioux and V. Kuznetsov, ''Who should be given the credit for the discovery of carbon nanotubes?,'' Carbon, vol. 44, no. 9, pp. 1621-1623, Aug. 2006. [ Links ]

[13] E. Thostenson, ''Advances in the science and technology of carbon nanotubes and their composites: a review,'' Composites Science and Technology, vol. 61, no. 13, pp. 1899-1912, Oct. 2001. [ Links ]

[14] V. Popov, ''Carbon nanotubes: properties and application,'' Materials Science and Engineering: R: Reports, vol. 43, no. 3, pp. 61-102, Jan. 2004. [ Links ]

[15] N. D. Hoa, et al., ''Synthesis of porous CuO nanowires and its application to hydrogen detection,'' Sensors and Actuators B: Chemical, vol. 146, no. 1, pp. 266-272, Apr. 2010. [ Links ]

[16] J. Lee, et al., ''Polyurethane/PEG-modified MWCNT composite film for the chemical vapor sensor application,'' Synthetic Metals, vol. 160, no. 7–8, pp. 566-574, Apr. 2010. [ Links ]

[17] S. Demoustier, et al., ''Review of two microwave applications of carbon nanotubes: nano-antennas and nano-switches,'' Comptes Rendus Physique, vol. 9, no. 1, pp. 53-66, Jan. 2008. [ Links ]

[18] X.-S. Yang, ''Modelling heat transfer of carbon nanotubes,'' Modelling and Simulation in Materials Science and Engineering, vol. 13, no. 6, pp. 893-902, 2005. [ Links ]

[19] R. Ruoff, ''Mechanical and thermal properties of carbon nanotubes,'' Carbon, vol. 33, no. 7, pp. 925-930, 1995. [ Links ]

[20] T. Halicioglu, ''Stress calculations for carbon nanotubes,'' Thin Solid Films, vol. 312, no. 1–2, pp. 11-14, Jan. 1998. [ Links ]

[21] G. Van Lier, ''Ab initio study of the elastic properties of single-walled carbon nanotubes and graphene,'' Chemical Physics Letters, vol. 326, no. 1–2, pp. 181-185, Aug. 2000. [ Links ]

[22] Z. Xu and M. J. Buehler, ''Nanoengineering heat transfer performance at carbon nanotube interfaces.,'' ACS nano, vol. 3, no. 9, pp. 2767-75, Sep. 2009. [ Links ]

[23] M. Berteli, ''Evaluation of short cut pasta air dehydration assisted by microwaves as compared to the conventional drying process,'' Journal of Food Engineering, vol. 68, no. 2, pp. 175-183, May 2005. [ Links ]

[24] R. Vadivambal and D. Jayas, ''Changes in quality of microwave-treated agricultural products-a review,'' Biosystems Engineering, vol. 98, no. 1, pp. 1-16, Sep. 2007. [ Links ]

[25] L. Hansson and a Antti, ''The effect of drying method and temperature level on the hardness of wood,'' Journal of Materials Processing Technology, vol. 171, no. 3, pp. 467-470, Feb. 2006. [ Links ]

[26] M. R. Sanborn, et al., ''Microwave sterilization of plastic tissue culture vessels for reuse.,'' Applied and environmental microbiology, vol. 44, no. 4, pp. 960-4, Oct. 1982. [ Links ]

[27] A. S. Mujumdar, Handbook of industrial drying, Third Ed. CRC Press, 2007, pp. 1-1280. [ Links ]

[28] J. P. Kesselring and R. D. Smith, ''Development of a microwave clothes dryer,'' IEEE Transactions on Industry Applications, vol. 32, no. 1, pp. 47-50, 1996. [ Links ]

[29] R. D. Smith, ''Microwave Clothes Dryer and Method with Fire Protection,'' U.S. Patent 5.396.7151995. [ Links ]

[30] K. Tanaka, et al., ''Variable Frequency Microwave Curing of Amide-Epoxy Based Polymers,'' IEEE Transactions on Components and Packaging Technologies, vol. 30, no. 3, pp. 472-477, 2007. [ Links ]

[31] H. Noh, et al., ''Wafer bonding using microwave heating of parylene for MEMS packaging,'' 2004 Proceedings. 54th Electronic Components and Technology Conference (IEEE Cat. No.04CH37546), pp. 924-930, 2004. [ Links ]

[32] T. Pojanavaraphan and R. Magaraphan, ''Prevulcanized natural rubber latex/clay aerogel nanocomposites,'' European Polymer Journal, vol. 44, no. 7, pp. 1968-1977, Jul. 2008. [ Links ]

[33] G. Milani and F. Milani, ''A Numerical Model for the Optimal Vulcanization of 2D Polar Rubber Compounds Using Microwaves,'' Macromolecular Theory and Simulations, vol. 18, no. 6, pp. 336-354, Aug. 2009. [ Links ]

[34] W. Jina, et al., ''Properties of sodium silicate bonded sand hardened by microwave heating,'' China Foundry, vol. 6, no. August, pp. 191-196, 2009. [ Links ]

[35] M. Larhed and A. Hallberg, ''Microwave-assisted high-speed chemistry?: a new technique in drug discovery,'' Drug Discovery Today, vol. 6, no. 8, pp. 406-416, 2001. [ Links ]

[36] F. Mavandadi and a Pilotti, ''The impact of microwave-assisted organic synthesis in drug discovery,'' Drug Discovery Today, vol. 11, no. 3–4, pp. 165-174, Feb. 2006. [ Links ]

[37] C. S. Eskilsson and E. Björklund, ''Analytical-scale microwave-assisted extraction.,'' Journal of chromatography. A, vol. 902, no. 1, pp. 227-50, Dec. 2000. [ Links ]

[38] C. O. Kappe, ''Controlled microwave heating in modern organic synthesis.,'' Angewandte Chemie (International ed. in English), vol. 43, no. 46, pp. 6250-84, Nov. 2004. [ Links ]

[39] M. A. Herrero, et al., ''Nonthermal microwave effects revisited: on the importance of internal temperature monitoring and agitation in microwave chemistry.,'' The Journal of organic chemistry, vol. 73, no. 1, pp. 36-47, Jan. 2008. [ Links ]

[40] P. Silva, et al., ''Fast Microwave Synthesis of a Microporous Lanthanide?Organic Framework,'' Crystal Growth & Design, vol. 10, no. 5, pp. 2025-2028, May 2010. [ Links ]

[41] Y. Tsukahara et al., ''In Situ Observation of Nonequilibrium Local Heating as an Origin of Special Effect of Microwave on Chemistry,'' The Journal of Physical Chemistry C, vol. 114, no. 19, pp. 8965-8970, May 2010. [ Links ]

[42] S. Visentin, et al., ''Microwave-assisted Maillard reactions for the preparation of advanced glycation end products (AGEs).,'' Organic & biomolecular chemistry, vol. 8, no. 10, pp. 2473-7, May 2010. [ Links ]

[43] K. Iwasaki, et al., ''Application of Microwave Technique for Dehydration of Sludge Generated in a Stainless Steel Plant,'' ISIJ International, vol. 49, no. 4, pp. 596-601, 2009. [ Links ]

[44] S.-J. Tae, et al., ''Effect of Microwave Irradiation on Hydrothermal Treatment of Blast Furnace Slag,'' ISIJ International, vol. 49, no. 8, pp. 1259-1264, 2009. [ Links ]

[45] P. E. Glaser, ''Power from the Sun: Its Future.,'' Science (New York, N.Y.), vol. 162, no. 3856, pp. 857-861, Nov. 1968. [ Links ]

[46] R. G. Bosisio and N. Barthakur, ''Microwave Protection of Plants from Cold,'' Journal Of Microwave Power, vol. 4, no. 3, pp. 190-193, 1969. [ Links ]

[47] B. Hascakir, et al., ''Microwave-Assisted Heavy Oil Production: An Experimental Approach,'' Energy & Fuels, vol. 23, no. 12, pp. 6033-6039, Dec. 2009. [ Links ]

[48] B. Hascakir and S. Akin, ''Recovery of Turkish Oil Shales by Electromagnetic Heating and Determination of the Dielectric Properties of Oil Shales by an Analytical Method,'' Energy & Fuels, vol. 24, no. 1, pp. 503-509, Jan. 2010. [ Links ]

[49] B. Eastlund and L. Jenkins, ''Taming Tornadoes Storm Abatement from Space,'' IEEE Aerospace and Electronic Systems Magazine, vol. 22, no. 6, pp. 16-21, Jun. 2007. [ Links ]

[50] B. J. Eastlund and L. M. Jenkins, ''Taming tornadoes: storm abatement from space,'' in 2001 IEEE Aerospace Conference Proceedings, 2001, vol. 22, no. 6, pp. 1/389-1/395. [ Links ]