INTRODUCTION

Due to their metabolic development, microalgae consume much more CO2 than vegetables (Wang et al., 2008; Yen et al., 2013), they also contain a larger concentration and variety of other compounds with high added value. For this reason, microalgae have taken great importance in the biofuel sector (diesel, ethanol, methane and even hydrogen) (Subhadra and Edwards, 2011), wastewater treatment (Mata et al., 2010), CO2 capture, and procurement of bio-products from pigments, proteins, lipids and carbohydrates. Thus, harnessing of microalgae is being foreseen in the development of energy, food and health (Usov et al., 2001; Ho et al., 2011; Koller et al., 2014; Koutra et al., 2020).

Therefore, microalgae have been considered as a promising and attractive raw material, the microalgae could be an interesting source for a biorefinery. A microalgae biorefinery could have different alternatives for technological selection: chemistry, biochemistry and thermochemistry. The set of several process units for microalgae biomass should involve sustainability concepts, wide range of products and profitability (Dimian & Bildea, 2008; Gorry et al., 2018).

In microalgae carbohydrates exist mainly in the form of cellulose and hemicellulose, without lignin in the cell wall structure, which is a great advantage for their utilization over lignocellulosic plants (Ma et al., 2020). Ho et al. (2013) point out that with sufficient nitrates in the cultures, Chlorella vulgaris FSP-E reaches carbohydrate contents of 12,16 %. While the same C. vulgaris FSP-E in culture conditions with nitrite deficiencies, carbohydrate contents can reach up to 54,13 %. The photosynthetic efficiency of algae helps to maintain carbohydrate contents (Yen et al., 2013).

Hu et al. (2008) point out that fatty acids commonly synthesized by microalgae, have saturated or unsaturated molecular chains of 16 to 18 carbons. The unsaturated ones may vary in the number and position of the double bonds. Among Chlorophyceae species of Chlorella vulgaris, 18 % emerge as C16:0, 5 % as C16:1 ω7, 12 % as C16:2 ω7, 2,1 % as C16:3, 9,2 % as C18:1 ω9, 43 % as C18:2 ω6 and 10 % as C18:3 ω3. Previously Chisti, (2007), indicated the oil content on dry basis for Chlorella sp of 28-32 %, for Nannochloropsis sp of 31-68 % and for Dunaliella primolecta of 23%. For the same oil production, microalgae require between 2-4,5 MHa for cultivation, while oil plants require 45 to 1540 MHa, reducing logistic costs by more than 50 %, mainly related to transportation.

Becker (2006), comments that in Chlorella vulgaris, Dunaliella salina, Scenedesmus obliquus and Spirulina platensis, the percentage of protein on dry basis is 51-58, 57, 50-56 and 46-63 % respectively, although there are also amino acids among the nitrogenous constituents. Ursu et al. (2014) found that the essential amino acids (threonine, valine, methionine, isoleucine, leucine, phenylalanine, lysine and tryptophan), for Chlorella vulgaris, amounted to 38 % of the total amino acids using protein precipitations at their isoelectric point and tangential ultra-filtration of alkaline solutions. They also concluded that extractions at pH 12 improve the solubilization of proteins, decreasing the capacity and stability of the emulsions, while at pH 7, the opposite is true.

Iwamoto (2004), using a strain of the microalga Chlorella vulgaris (called C. regularis M-1), succeeded in mutating it by UV radiation to obtain a strain called Y21. This strain, grown heterotrophically in an axenic culture, produced approximately twice as many carotenoids, chlorophyll and other pigments as the original strain. Similarly, he achieved to have a volumetric cell concentration of 360 mL/L in a 10 m3 culture of C. regularis, after 40 h. Using a glucose supply under heterotrophic conditions, with a dry basis content of 7 mg/g carotenoids (3,5 mg lutein, 0,5 mg α-carotene, 0,6 mg β-carotene) and 35 mg/g chlorophyll.

Seyfabadi et al. (2011), mention that the contents of pigments, proteins, lipids, carbohydrates and, in general, the growth of the microalga Chlorella vulgaris depends on lighting conditions. In particular, they commented that augmentation in the duration and frequency of exposure decreased the presence of chlorophyll-a, while the presence of β-carotene increased. Likewise, they stated that the maximum chlorophyll-a content (13,25 mg/mL), was reached at illumination conditions of 37,5 (µmol photons/m2s) and 16:8 h of photoperiod and the minimum amount (7,4 mg/mL) was obtained at 100 (µmol photons/m2s) and 16:8 h. The highest amount of β-carotene 0,07 pg/cell), was obtained at 100 (µmol photons/m2s) and 16:8 h, while the lowest amount observed (0,02 pg/cell), was found at 37,5 (µmol photons/m2s) and 8:16 h.

Obtaining biofuels from microalgae has been considered as third generation (Chowdhury and Loganathan, 2019), but a better use should be directed to the treatment under the concept of biorefineries. Cicci et al. (2018), point out that under this concept, there is a better use of microalgae compounds. They presented results on the use of solvents with hydrophobic to hydrophilic permutable capacity of Scenedesmus dimorphus for extractions. From N,N-dimethyl-cyclohexylamine with CO2, they reached a yield extraction of proteins, carbohydrates and lipids, up to 52, 51,4 and 96,1 %, respectively.

In general, it is clear that there is already a lot of research on microalgae related to crops, compositions and their utilization( Gouveia & Oliveira, 2009; Gouveia, 2011). But, due to the depth and number of them, it is increasingly difficult to locate the queries and select those of greatest interest to a particular user. A good way to have a global overview is to try to systematically map the information in available databases, so that the user can be oriented as to where and towards the research is directed.

This systematic mapping corresponds to the so-called bibliometric analysis. These analyzes offer an approach to study the co-occurrence of the available information, which offers new opportunities to visualize the information. The bibliometric analysis then becomes more than a statistic and allows solving the study problem of simply associating the topics of interest with authors and journals (Ding et al., 2001).

For this reason, the objective of the present work was to make a bibliometric analysis, using widely disseminated database search engines and to evaluate keyword connectors with computational tools.

METHOD

In order to have a general framework on the integral use of microalgae and the progress in simulation in these processes, a general search was initially carried out in Scopus associating the words "biorefinery" and "microalgae". Then, connectors related to the words "process simulation" were added in different ways. The information obtained for all types of documents, was carried out in two periods, the first from 2015 to 2020 and the second from 2012 to 2020. The documents were taken with all information reported on authors, keywords, authors' institutional affiliation, type of document, subject area, number and type of citations, bibliography, financings and year of publication.

The search connector relationships were as follows:

(TITLE-ABS-KEY (biorefinery) W/2 TITLE-ABS-KEY (microalgae)) and (LIMIT-TO ( DOCTYPE , "ar") or LIMIT-TO (DOCTYPE , "re") OR LIMIT-TO (DOCTYPE , "ch") OR LIMIT-TO (DOCTYPE , "cp") OR LIMIT-TO (DOCTYPE , "bk")) AND (EXCLUDE ( PUBYEAR , 2021)) AND (EXCLUDE (PUBYEAR , 2014) OR EXCLUDE (PUBYEAR , 2013) OR EXCLUDE (PUBYEAR , 2012) OR EXCLUDE (PUBYEAR , 2011) OR EXCLUDE (PUBYEAR , 2010) OR EXCLUDE (PUBYEAR , 2009) OR EXCLUDE (PUBYEAR , 2009)) (TITLE-ABS-KEY (microalgae) AND TITLE-ABS-KEY (process simulation)) AND (EXCLUDE (PUBYEAR , 2020)).

Additionally, the search was expanded using the database "Wizdom.ai" with the word "Biorefinery"; considering that this database uses artificial intelligence principles to collect information on the number of citations, publications, funding and scientific journals of scientific importance related to the search topic. Scientific production was also identified geographically from the results of the second search equation in Scopus, proposing an indicator that would relate the number of publications and the number of citations to the documents associated with different countries.

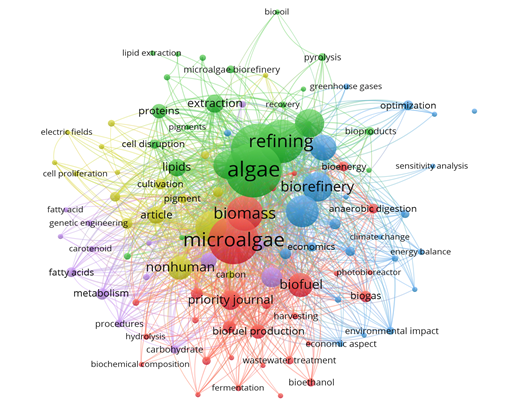

Finally, the information found was systematized in the VosViewer software (version 1.6.14), to visualize networks of association and connection of nodes with 107 words, mainly with the words "biofuel", "biomass", "microorganism", "microalgae" and "biodiesel". The type of analysis was by co-occurrence, with the unit of analysis "All keywords" and with "full counting" (van Eck and Waltman, 2010).

RESULTS

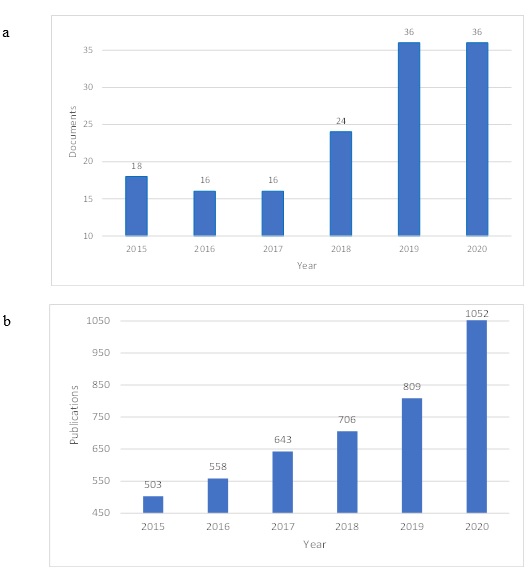

A total of 146 documents was found for the connector equation in the initial search, and 37 documents in the second search. Together, the search performed in Wizdom.ai for the term "Biorefinery" resulted in a total of 4271 documents associated with publications between the period from 2015 to 2020, presenting a sustained trend of increasing publications, which allows inferring the continued interest in the assessed areas of knowledge (Figure 1).

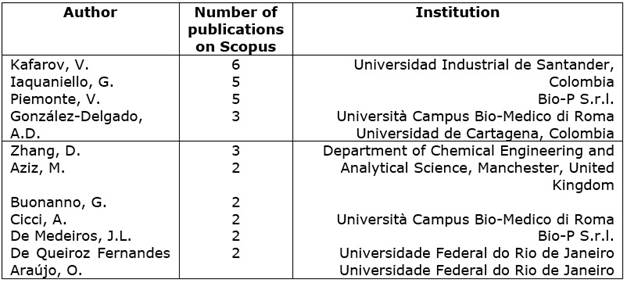

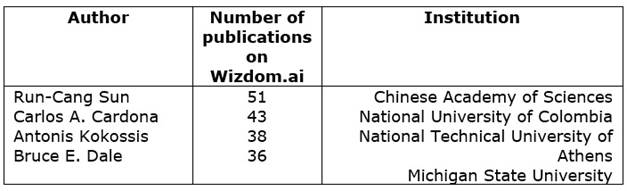

However, the difference in number of publications obtained through Wizdom.ai compared to Scopus reports, for the first equation, evidences those under the concept of biorefineries with microalgae only represented 3 % of the total of publications on Wizdom.ai (Figure 1). In fact, there are not many researchers and institutions that have worked under the concept of biorefineries (Table 1), and even less publications and authors, also involving microalgae, especially in the last nine years (Table 2).

Figure 1 a) Number of documents by year for “biorefinery - microalgae” between 2015 and 2020 - Scopus. b) Number of publications by year for “Biorefinery” between 2015 and 2019 - Wizdom.ai.

Table 1 Authors with highest number of publications on biorefinery studies between 2001 and 2021 - Wizdom.ai.

It could be considered that the increase in publications in recent years on topics associated with biorefineries and microalgae relates to environmental and economic issues. During the last decades, regulations for greenhouse gas emissions, the use of new energy sources and the use of biomass have increased. The biorefinery concept seems to be novel and attractive for the industrial sector, seeking to improve economic elements and product diversification and comprehensive use of its raw materials.

One of the most cited works of Run-Cang Sun is related to the study of the structure of lignin (Sun et al., 1998), whereas initially the concept of biorefinery is based on the use of lignocellulosic biomass. In addition, Colombian researchers Sánchez, O.J. and Cardona, C.A. addressed the study of the biotechnological production of ethanol using different raw materials and is one of their most referenced publications by other authors (Sánchez & Cardona, 2008).

Indeed, Bruce E. Dale and Antonis Kokossis have worked around proposals that allow progress in the techno-economic and environmental sustainability of lignocellulosic biomass and microalgae biorefineries ( Psycha et al., 2020; Liu et al., 2021).

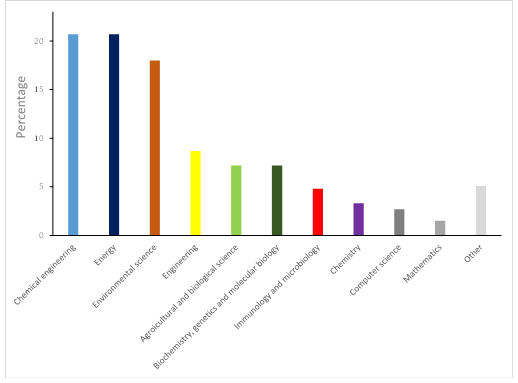

In the last six years, studies related to "biorefinery" and "microalgae", almost 60 % of the research (Figure 2), have been directed to the knowledge areas of chemical engineering (20,7 %), energy (20,7 %) and environmental sciences (18 %). However, exhibiting the multidisciplinary nature of the field of microalgae and biorefineries with research on antibacterial, anticancer, antioxidant and immunomodulatory active compounds (Chu and Phang, 2019; Jacob-Lopes et al., 2019), the participation of disciplines such as "Biochemistry", "Immunology" and "Computer science" is beginning to increase.

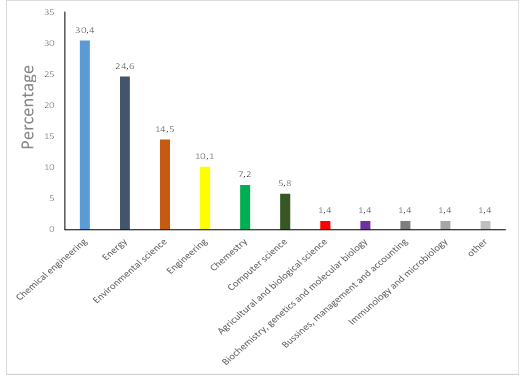

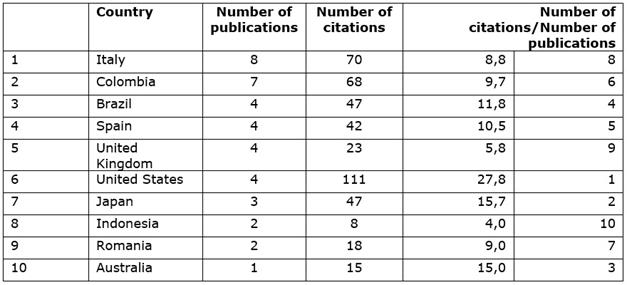

Regarding the results obtained in Scopus concerning "microalgae - process simulation" (Figure 3) the trends are similar, but there are more quantitative differences in the participation of chemical engineering and the other fields of knowledge. It seems that little research is done in process simulation in the basic sciences, representing less than 20 % of the total number of publications in this area. It is interesting to note that South American countries, such as Colombia and Brazil (Table 3), despite being emerging countries, are on a par with the United States and jointly above powers such as Japan and Australia.

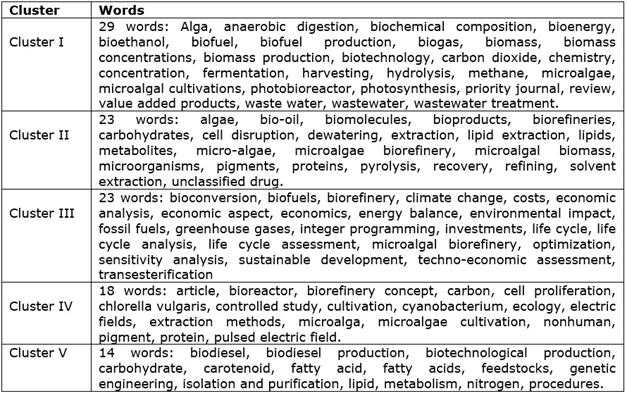

In Vosviewer topic network (Figure 4) there are five identifiable clusters (Table 4). The publications of the smaller clusters, which have few associated topics (14 and 18), do not include the concept of refineries neither that of biorefineries. From the type of keywords, it would seem that the smaller connector group is formed by general publications related to biodiesel production and its possible purification. The group of 18 words seems to be publications related to cultivation of Chlorella vulgaris. In one of the groups with 23 words, one has global aspects of biorefineries from microalgae (cluster III), integrating economics, environment, life cycles, sensitivity analysis, energy balances and sustainable development, but more directed to biodiesel. The other group of 23 words (Cluster II), which also includes biorefineries from microalgae, is more related to engineering processes to obtain various products.

The group of publications with more words (Cluster I) is similar to Cluster II, but is more complete, since it adds collateral processes of crops and wastewater and includes more products, especially energy products. The publications of cluster one, although they are the most numerous and complete of all, especially from the point of view of the engineering processes of biorefineries, lack the global study topics related to cluster III, necessary to have a good evaluation of the social, economic and environmental impacts. Therefore, there is still a lack of studies that integrate not only the global engineering processes, but also those related to the circular economy, the environment and even social aspects in biorefineries from microalgae.

Figure 4 Research-topic network visualization of publications releated to biorefinery - microalgae between 2015-2020.

Table 4 Clusters and words obtained from co-occurrence network analysis of keywords in the search “biorefinery-microalgae” between 2015-2020.

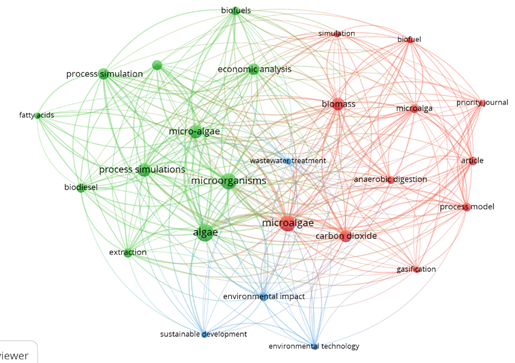

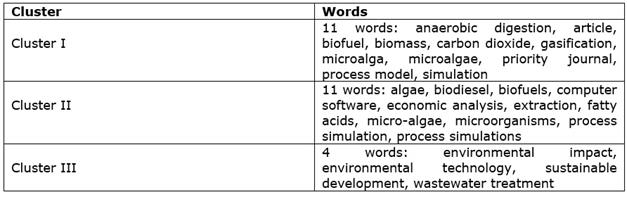

Concerning only connectors related to simulation processes with microalgae, three clusters were identified (See Figure 5 and Table 5). One group of publications (Cluster III), related to water treatment and sustainable environmental development under the environmental concept. The other two are more numerous and with more number of keywords (11). One inclines to economic analyses to obtain biodiesel, while the other seems to tend to the consumption of carbon dioxide gas from microalgae. In these groupings, the research gap in the simulation processes related to the whole use of biomass is even more evident.

Figure 5 Research-topic network visualization of publications related to process simulation and microalgae between 2012-2020.

Table 5 Clusters and words obtained from co-occurrence network analysis of keywords in the search “process simulation-microalgae” between 2012-2020.

Critical processes with microalgae: overview

According to data obtained from Wizdom.ai database (Wizdom.ai, 2022), in the last 10 years about USD 620.000.000 has been invested in projects related to biorefineries. However, Lopes et al., (2019), state the existing difficulties regarding fermentation operations on hydrolysis of polysaccharides and trans-esterification of saturated fatty acids present in the lipids of microalgae, to obtain ethanol and biodiesel. The inclusion of these types of transformation operations is associated with higher CAPEX and OPEX (capital investments and operating expenses), but there is little research on this topic concerning microalgae, compared to the greater experience with fossil fuels. Armshaw P and J T Pembroke, (2015), based on the Calvin cycle biosynthesis metabolic pathway, with concentrations of less than 10 g/L of bio-ethanol, using a genetically modified strain of the cyanobacterium Synechosystis sp. called PCC 6803, were able to improve CAPEX and OPEX. This study was called "DEMA" (Direct Ethanol from MicroAlgae), evidencing that more scale-up trials would be needed to have a more detailed information on possible industrial productions, involving more products.

The most representative bottlenecks in open cultures are, due to large volumes, rapid contamination that usually occurs with other microorganisms and uncontrollable meteorological variations. After harvesting cultures for the extraction of intracellular components, it is important to perform a cell disruption of the microalgae, which is also difficult to find low-cost methods, since efficient lysis requires micromilling, high cavitation, pressures, magnetic or electrical pulses, or non-conventional techniques. Otherwise, the efficiencies of metabolite extractions, such as lipids, proteins and pigments, astaxanthin and β-carotene type, among others, are not good (Brennan and Owende, 2010).

The lipid content in the microalgae has made its extraction attractive to obtain biodiesel through the transesterification process, where fatty acids together with alcohol in the presence of a base form esters and glycerol (Demirbas, 2010; Rangabhashiyam et al., 2017). However, the challenge lies in the need to separate and condition the variety of lipids (mainly unsaturated fatty acids, phospholipids and omegas).

Alcohols can be produced from the carbohydrates in the microalgae, but they must be separated, hydrolyzed and fermented. In chemical hydrolysis there is a need for detoxification. If it is enzymatic with cellulases, hemicellulases, amyloglucosidases, pectinases or mixtures of these, it is difficult to have yields higher than 50 %, although in certain optimizations it has reached 90 % (de Farias Silva and Bertucco, 2016). Research with Chlorella vulgaris (IAM C 534) and Chlamydomonas reinhardtii (UTEX 2247) has reported complex processes of ultrasonic lysis of microalgae, followed by enzymatic hydrolysis and fermentation with the yeast Saccharomyces cerevisiae, in addition to a study of intracellular ethanol production with the dark fermentation technique (Hirano et al., 1997). A distillation process is required to remove water and other impurities in the diluted alcoholic product (10-15 % ethanol), to concentrate it to 95 % (Brennan and Owende, 2010).

In 2011, the company Joule Unlimited (USA), initiated a project to build an industrial plant for the processing of cyanobacteria. The company estimated ethanol productivity at more than 230.000 L/(ha. year) with a production cost of USD $ 0,16/L with subsidies and USD $ 0,32/L without them. Algenol estimated its bio-ethanol productivity at more than 60.000 L/(ha*year) with an approximate production cost of USD $ 0,79/L. In any scenario, the potential application of bio-ethanol production will increase as operating costs decrease permanently (de Farias Silva and Bertucco, 2016).

The accumulation of different components in microalgae (mainly lipids, carbohydrates, proteins and pigments) requires different conditions and separated operating strategies. Which makes it difficult to develop an efficient and low-cost processing sequence for better utilization of biomass. Moreover, it is necessary to involve aspects related to energy, circular economy and life cycle analysis (Yen et al., 2013).

The main parameters for the selection of a pigment extraction technology are speed, solvent use, reproducibility, extraction yields, selectivity, protection of the extracted molecules, costs and facilities (Pasquet et al., 2011). Conventional methods include the use of solvents, which in turn depends on the nature of the pigment. Ethanol, acetone, methanol, n-hexane, diethylether and chloroform have been used to extract pigments from microalgae in combination with different techniques, such as supercritical fluid extraction (SFE). Non-conventional methods comprise the use of electrical techniques, for example, electrical pulses, which do not generate heat during the process. High-voltage electrical discharges, microwaves, and ultrasound-assisted extraction are other methods that have been used (Silva et al., 2020).

The protein content of microalgae is between 50 and 70 % (Chew et al., 2017). There are 20 amino acids of which 8 are essential (isoleucine, leucine, valine, lysine, phenylalanine, methionine, tryptophan and threonine). Microalgae such as Chlorella vulgaris, Scenedesmus obliquus, Spirulina platensis, have percentage values between 1-10 % per amino acid depending on the species (Vanthoor-Koopmans et al., 2013). Proteins can be solubilized in organic solvents with surfactants, maintaining their functional properties, and then can be transferred to aqueous solutions. Conventional techniques use centrifugation or filtration to separate cellular material from the soluble components in the liquid medium, in this sense non-secreted proteins are lost. Using liquid-liquid extraction technology after cell disruption, the products of interest can be extracted from the cellular material, prior to further separations (Vanthoor-Koopmans et al., 2013).

CONCLUSIONS

It is clear that the integral use of microalgae has diversified the production of many products, but there is still a need to integrate more professions, especially those related to basic and medical sciences. Likewise, there are not many countries that have shown a strong interest in conducting research with microalgae.

Although research related to the use of microalgae under the concept of biorefineries has grown by more than 70 % in the last six years, there are still many information gaps in terms of process data, costs, circular economy and environmental impacts that help to simulate the optimization of the systems.

The main difficulties encountered in microalgae processing, start with improving microalgae concentrations in open cultures to lower costs appreciably. The extractive processes of the compounds of interest depend heavily on cell lysis and integral separation strategies of the products of interest.

The prospective technological application of microalgae for environmental matters shows an important tendency towards the treatment of wastewater, the capture of CO2, and life cycle assessment that around the production of biofuels can be applied.