1. Introduction

In the last decades, starch has become one of the most promising materials for the production of biodegradable plastics (Ma et al., 2009), even having the ability to replace applications of materials such as metals, glass and wood (Ruiz, Montoya & Paniagua, 2009). Despite the above, it has some disadvantages when compared to conventional polymers. Its main deficiency is that it undergoes retrogradation processes over time, which prevents its practical use in industry. However, its properties can be modified by adding small amounts of additives (García et al., 2000; Ma et al., 2009), such as glycerol, which can be added as a plasticizer, improving the mechanical properties of the film, increasing its deformability. (Greener and Fennema, 1993) by lowering the glass transition temperature (Vieira et al., 2011).

Around the world 60 million tons of starch is extracted from a wide variety of crops (Torres, Pérez, Marmolejo, Ordóñez, & García, 2010) being corn starch the most widely used at industrial and household levels (Velásquez Herrera, Lucas Aguirre, & Quintero Castaño,2017). In Colombia, some roots, tubers and fruits are characterized by having a high starch content and could be considered as alternatives to replace corn. Among these sources we find cassava (Manihot esculenta Crantz), potato (Solanum tuberosum), plantain (Musa paradisiaca), arracacha (Arracacia xanthorriza), yam (Dioscorea sp.), Achira and sago (Canna edulis). Accordingly, they could be introduced in rations for ruminants particularly at harvest times when prices decrease (Knowles, 2012). Flours and starches obtained from different varieties of yam have certain functional properties, among which the absence of a maximum viscosity and the stability of the suspensions at high temperatures and low pH values stand out. Therefore, they could be used in the elaboration of products that must maintain their stable viscosity during a constant heating phase, such as mixtures for instant soups and puddings (Wang et al., 2007).

On the other hand, natural plant extracts could be viable alternatives for obtaining active compounds that can be incorporated into the polymeric matrices of the films made from starch. These contain a wide variety of compounds with different functions and mechanisms of action. Phenolic compounds, terpenoids, essential oils, and polyacetylenes are among the plant compounds that have antimicrobial and antioxidant characteristics, all of which have particular mechanisms of action (Valero et al., 2016).

In particular, polyphenols composition in oregano essential oil is highly variable mainly depending on the part of the plant that is distilled and, on the species, or subspecies. Thymol and carvacrol are the main compounds (Albado et al., 2001; Bertelli et al., 2003). The high content of polyphenolic compounds has been verified in Origanum vulgare, which provides effective protection in all phases of lipid oxidation (Cervato et al., 2000). Antibacterial activity is also affected by the type, composition and concentration of the essential oil, the type and concentration of the selected microorganism, the composition of the substrate, and the conditions of processing and conservation (Baydar et al., 2004). Therefore, the objective of this work was the comparative study of the properties of active edible materials based on yam and cassava starch with the incorporation of essential oil of oregano (Origanum vulgare) (OEO) for application in grape coating.

2. Materials and Methods

Materials

Yam and cassava starch was obtained from tubers provided by associations of tuber producers San Juan de Nepomuceno-Bolívar (Colombia). Yam hawthorn and cassava Manihotsculenta were used. Oregano essential oil (OEO) was purchased from NOW (United States) in 100% purity. While glycerol and Tween 20 were obtained from Panreac.

Obtaining of Film Forming Dispersions (FFD)

The dispersions were obtained from an initial dispersion of starch and distilled water, with a proportion of 2% starch in water subjected to continuous stirring at 90°C for 15 min. 25% glycerol was added to the starch and it was homogenized with the Ultra Turrax at 30,000 rpm for 15 minutes. Subsequently, the OEO was added in proportions of 1:3 and 5% with respect to the starch. Finally, Tween 20 in a ratio of 1: 3 regarding the OEO. Yam and cassava starch film-forming dispersions with 0, 1, 3 and EY0%, EY1%, EY3% , EY5% , EC0%, EC1%, EC3% y EC5%, respectively.

Contact Angle

This parameter was determined on the surface of celery, lettuce, apple and papaya using a 0.1 mL microdroplet from each FFD. Photographs were taken at a distance of 20 cm from the drop with controlled lighting and background. The photographs were taken at 0, 1, 2.5 and 5 min to observe the change in the contact angle over time. Subsequently, image analysis was carried out using Goniotrans v2.0 software to determine the contact angle formed between the FFD droplet and the analyzed surface. In such a way that the greater the contact angle, the greater the wettability of the dispersion on the surface.

Stability of the FFD

The stability of the FFD was studied using a standard rotary centrifuge in which test tubes with samples of the dispersions studied were introduced in triplicate. They were spun at 3000 rpm and visually inspected every 2 min to identify phase separation. The stability of the dispersions is proportional to the phase separation time.

Obtaining films through casting

Yam and cassava starch with two concentrations of 0E0 (3% and 5%) were used to make the films. They were obtained by the casting method, pouring the FFDs on 400cm2 plates and left at room temperature for 36h until the water evaporated and the films formed. Once the films were formed, they were removed from the mold and conditioned at 53% relative humidity in desiccators with supersaturated magnesium nitrate solutions for 7 days before their characterisation. Yam and cassava starch films with 0%, 3 and 5% 0E0 were named FY0%, FY3%, FY5%, FC0% FC3% y FC5%, respectively.

Film Thickness Measurement

The thickness of each film was measured with a micrometer at 10 different points on the entire surface of the film.

Moisture content of the films

Previously conditioned films were dried in a convection oven at 90°C for 24h, the initial weight and final weight were recorded. The moisture percentage was calculated according to equation 1.

Where % H is moisture content expressed as a percentage; Ww is the weight of water in the sample (initial weight - final weight) and WT is the total weight of the dry sample (final weight).

Water absorption capacity of the films

The test was performed under ASTM-D570, where the dry films were immersed in approximately 20mL of distilled water for 30min and then weighed again to determine the amount of water absorbed. The percentage of absorbed water is calculated according to equation 2.

Internal transmittance and opacity of films

The transmittance and absorbance of the films were determined using a Gold Spectrumlab 54 Thomson UV-VIS spectrophotometer, placing each film in preconditioned 1 cm x 3 cm quartz cuvettes. A wavelength between 190 and 1100 nm was used, and a value of 450 nm was considered for presenting marked differences between the formulations, this analysis was performed in triplicate (Ortega-Toro et al., 2017). For this determination, the films were normalized according to their thickness.

Antimicrobial capacity of films

The protocol described by Seydim and Sarikus (2006) to determine the antimicrobial capacity of films was followed, in which the halos of inhibition of bacterial growth were analyzed by contacting 1cm diameter film disks on Petri dishes inoculated with Bacillus cereus on agar Mueller Hinton for 24h at 37°C. The diameters of the inhibition halos formed were measured and the presence or absence of an inhibition halo was re-ported. Furthermore, pure oregano essential oil was also evaluated in order to confirm its antimicrobial capacity.

Determination of the antioxidant activity of the films

The antioxidant capacity of the films was determined using the 2,2-diphenyl-1-pikryl-hydrazyl (DPPH) reduction method (Brand-Williams, Cuvelier and Berset, 1995). For this purpose, 30 μL of samples diluted in water (1:10 for powder films) were mixed with 1 ml of 0.1 mM DPPH in methanol. The mixture was vortexed and allowed to stand at room temperature in the dark (40 min) before measuring the absorbance at 517 nm. Similarly, according to Re et al. (1999), 30 μL of samples diluted in water (1:10 for the powder films) and 1 ml of the 2,2'-azino-bis- (3-ethylben-zothiazolin-6-sulfonic acid) ammonium solution (ABTS • +) from Sigma Aldrich®, the solutions were diluted in mixed methanol. After 6 minutes of reaction in the dark, the absorbance at 734 nm was monitored using a spectrophotometer (UV Visible Thermo Scientific Genesys 10S). The results were expressed regarding the IC50 parameter. This parameter allows to measure the DPPH • and ABTS • + radical scavenging capacity of the AE with respect to an antioxidant standard. The lower the IC50 value, the greater antioxidant power the analysed sample will have. As a reference, pure oregano oil was employed.

Application of coatings from the FFD on grapes

For this test, grapes were covered in the same ripening state and without mechanical damage. The fruits were washed and disinfected with hypochlorite solution. They were dip coated for 30s using yam and cassava starch FFDs with 0% and 5% 0E0 and uncoated grapes were evaluated, for a total of 5 treatments. Each treatment consisted of 20 evaluated grapes. The weight of each grape was monitored for 21 days, obtaining the speed of weight loss. In the same way, the apparent state of the grapes was noted, such as their dehydration, texture and presence of mould. The tests were carried out at 30°C and 50% H.R.

3. Results and Discussion

Characterization of film-forming dispersions

Table 1 shows the contact angle of the FFD on celery, lettuce, apple and papaya rinds. The yam and cassava starch dispersions showed high wettability on the food crusts studied. It was observed that as time passes the contact angle increased in all cases. The effect of the essential oil on this parameter seems to depend on the nature of the surface, in celery and papaya the addition of oil tends to cause a decrease in the contact angle; in lettuce and apple the contact angle increases with the addition of 1% 0E0, but it decreases at higher concentrations and in papaya it decreases. In general, it is observed that vegetables (celery and lettuce) have higher humidity than fruits (apple and papaya). This may be due to a superficial treatment of the fruits, such as the use of waxes and gums, to preserve them for a longer time (Khorram et al., 2017). Regarding the starch source, it seems to have a little significant effect, it does not pre-sent a clear trend for this parameter.

TABLE 1 CONTACT ANGLE OF THE DIFFERENT FFD OF YAM AND CASSAVA STARCH ON DIFFERENT FOOD CRUSTS

| Formulation | Time (min) | Contact angle (°) | |||

| EY0% / EC0% | Celery | Lettuce | Apple | Papaya | |

| 0 | 68.1±0.8/ 53.1±0.2 | 61.1±0.4/ 66.4±0.3 | 56.1±0.3/ 54±0.3 | 54.2±0.2/ 44.5±0.3 | |

| 1 | 63.2±0.5/ 46.2±0.4 | 53.4±0.4/ 59.4±0.3 | 56.2±0.2/ 48±0.2 | 53.2±0.4/ 37.5±0.2 | |

| 2.5 | 63.3±0.2/ 46.4±0.2 | 53.4±0.2/ 57.0±0.2 | 53.2±0.3/ 48±0.2 | 53.1±0.2/ 37.5±0.2 | |

| 5 | 54.1±0.3/ 46.5±0.2 | 53.0±0.4/ 57.1±0.5 | 53.5±0.3/ 48±0.4 | 43.5±0.3/ 37.1±0.3 | |

| EY1% / EC1% | 0 | 49.2±0.8/ 53.5±0.6 | 72.1±0.3/ 60.2±0.3 | 66.1±0.3/ 79±0.5 | 52.3±0.3/ 37.2±0.4 |

| 1 | 49.5±0.2/ 52.5±0.2 | 52.3±0.2/ 48.5±0.2 | 55.2±0.5/ 79±0.2 | 38.3±0.2/ 37.2±0.4 | |

| 2.5 | 49.6±0.3/ 52.2±0.3 | 52.4±0.2/ 48.5±0.4 | 55.3±0.2/ 71±0.2 | 34.1±0.2/ 37.3±0.5 | |

| 5 | 49.1±0.3/ 50.4±0.4 | 52.2±0.4/ 48.4±0.4 | 55.2±0.3/ 71±0.3 | 32.4±0.4/ 37.4±0.2 | |

| EY3% / EC3% | 0 | 62.5±0.5/ 57.1±1 | 64.4±0.2/ 62.1±0.3 | 41.2±0.3/ 63±0.3 | 30.4±0.5/ 52.2±0.2 |

| 1 | 61.7±0.4/ 49.1±0.5 | 57.2±0.4/ 62.0±0.4 | 37.4±0.2/ 47±0.3 | 30.5±0.4/ 46.5±0.2 | |

| 2,5 | 55.5±0.4/ 49.0±0.5 | 55.3±0.2/ 59.2±0.3 | 34.5±0.2/ 39±0.4 | 27.5±0.2/ 46.5±0.5 | |

| 5 | 45.3±0.8/ 47.2±0.4 | 55.1±0.3/ 57.5±0.2 | 34.5±0.2/ 37±0.5 | 27.3±0.2/ 44.3±0.2 | |

| EY5% / EC5% | 0 | 34.1±0.4/ 44.5±0.2 | 45.4±0.4/ 52.5±0.4 | 33.3±0.4/ 52±0.3 | 43.1±0.3/ 40.2±0.2 |

| 1 | 34.3±0.4/ 32.5±0.3 | 45.5±0.2/ 52.1±0.4 | 30.3±0.2/ 49±0.2 | 41.4±0.2/ 40.3±0.5 | |

| 2,5 | 34.8±0.4/ 32.4±0.2 | 45.2±0.2/ 40.3±0.3 | 30.1±0.2/ 46±0.3 | 38.2±0.3/ 30.5±0.3 | |

| 5 | 32.7±0.2/ 32.5±0.5 | 41.3±0.3/ 40.5±0.2 | 27.2±0.2/ 46±0.3 | 35.5±0.2/ 30.2±0.3 | |

Table 2 shows the results of the stability test of the FFD under centrifugation conditions. Significant differences in the stability of the dispersions were observed de-pending on the starch source, the starch-based dispersions of yams being more stable than those of cassava, especially at 0E0 contents of 5%. The stability of dispersions with essential oils depends on Oswald maturation processes where the particle sizes grow and the phases separate (Guerra-Rosas et al., 2020) All the cassava starch-based dispersions presented instability before centrifugation during 2 min, except those containing 5% 0E0.

TABLE 2 STABILITY OF THE DIFFERENT FFD OF CASSAVA STARCH AND YAM STARCH

| Formulations | Centrifugation time (min) | |||||

| 2' | 4' | 6' | 8' | 10' | 12' | |

| EY0% | Unstable | - | - | - | - | - |

| EY1% | Stableb | Unstable | - | - | - | - |

| EY3% | Stablea | Stablea | Stableb | Stablec | Stable | - |

| EY5% | Stablea | Stablea | Stablea | Stablea | Stable | Stableb |

| EC0% | Unstable | - | - | - | - | - |

| EC1% | Unstable | - | - | - | - | - |

| EC3% | Unstable | - | - | - | - | - |

| EC5% | Stableb | Unstable | - | - | - | - |

a: presencia de un precipitado difuso; b: presencia de un precipitado ligeramente marcado; c: presencia de un precipitado marcado

Physicochemical properties of films

Table 3 presents the mean values and standard deviation for thickness, moisture content and water absorption capacity. It is observed that the yam control film has the greater thickness compared to the rest of the films and its values decrease with the increase of oil, this due to the plasticizing effect of the oil on the polymer matrix. In cassava starch-based films no significant differences in thickness were observed. The values obtained were similar to those obtained by Anchundia (2016) which are in a range between 111 and 170 ^m. Regarding the moisture content, it is observed that in general yam starch films contain more humidity than the base films of cassava starch and that its values tend to decrease with increasing oil content, which was to be expected due to the hydrophobic nature of the oil.

TABLE 3 MEAN VALUES AND STANDARD DEVIATION OF THICKNESS (MM), MOISTURE CONTENT (G WATER / G OF DRY FILM) AND WATER ABSORPTION CAPACITY (G OF WATER / G OF DRY FILM) OF THE FILMS STUDIED

| Formulations | Thickness of the films | Moisture content | Water absorption capacity |

| FY0% | 246 ± 5a | 0.384 ± 0.004a | 0.61 ± 0.03b |

| FY3% | 146.4 ± 1.8b | 0.342 ± 0.006a | 0.700 ± 0.008b |

| FY5% | 116.1 ± 1.9d | 0.304 ± 0.007b | 0.70 ± 0.05b |

| FC0% | 127.3 ± 1.4c | 0.279 ± 0.006c | 0.97 ± 0.19c |

| FC3% | 131 ± 2c | 0.234 ± 0.005d | 1.85 ± 0.11d |

| FC5% | 134.2 ± 1.3bc | 0.218 ± 0.007d | 1.99 ± 0.38d |

Different superscript letters in the same column mean significant differences (p < 0.05)

Regarding the ability to absorb water, it is observed that yam starch-based films absorb significantly less water than those of cassava starch, additionally, there are no significant differences with the presence of essential oil. A remarkable increase in the capacity to absorb water was observed in cassava starch films containing essential oil, this may be due to an increase in the free volume between the polymer chains due to the plasticizing effect of the oil. Consequently, those sites are where the water could penetrate more easily. The previous behaviour can be explained through the difference between the amylose and amylopectin content of both sources, in hawthorn yam starch the amylose content is 28.7% and amylopectin 73.2% (Tejada-Tovar et al., 2018) and in Manihotsculenta cassava the amylose content is 18% and the amylopectin content is 82% (Mera and Carrera, 2005). The higher amylose content provides yam films with a more crystalline, rigid and compact structure, and the higher amylopectin content will provide cassava starch films with a greater capacity to absorb water, flexibility and a more open and amorphous structure ( Cano et al., 2014).

Table 4 shows the mean values and standard deviation for internal transmittance and opacity measured at 450 nm. In general, yam starch films possess lower internal transmittance and slightly higher opacity than cassava starch films. On the other hand, the essential oil content increases internal transmittance and decreases opacity of the films. In agreement the effect of the amylose: amylopectin ratio of starches. This could be explained by the generation of free volume in the polymer matrix with the presence of oil, which acts as a plasticizer in the system. This would cause light to pass through the polymer matrix more easily, being reflected in higher internal transmittance values.

TABLE 4 MEAN VALUES AND STANDARD DEVIATION OF INTERNAL TRANSMITTANCE AT 450 NM AND OPACITY AT 450 NM OF THE DIFFERENT FILMS STUDIED

| Formulations | Internal transmittance | Opacity |

| FY0% | 10.3 ± 6.5c | 8.9 ± 1.0a |

| FY3% | 18.7 ± 1.1bc | 6.1 ± 1.8b |

| FY5% | 21.1 ± 1.0b | 3.9 ± 1.5c |

| FC0% | 18.1 ± 1.6bc | 8.3 ± 1.5a |

| FC3% | 18.3 ± 1.0bc | 5.8 ± 1.8b |

| FC5% | 29.2 ± 3.1a | 4.0 ± 0.8c |

Different superscript letters in the same column mean significant differences (p < 0.05)

The opacity values were very low compared to the work by Zavala et al. (2017), which shows values between 28.1 and 34.7 measures for chitosan films; but values similar to the work of González et al. (2017) which measured the opacity of gellan films with nano silver particles giving values between 3.6 and 7.8.

Active properties of the films

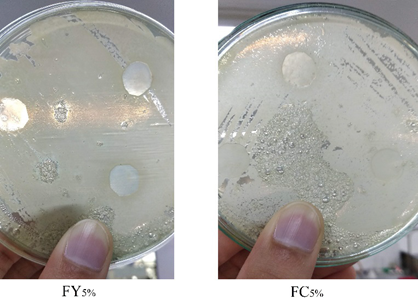

Figure 1 shows the halo inhibition test on Bacillus cereus of the films with 5% oregano essential oil. Remarkable differences are observed in both cases. The yam-based films showed inhibition of the growth of the bacteria about 1 mm from the edge of the film and also inhibition between the film and the agar, and the cassava starch based films showed no inhibition, even the bacteria could grow under the film specimens. This could be due to the different ratio of amylose: amylopectin between both tubers. The amount of amylose in the yam is higher, which allows a more compact and temperature resistant structure, this could promote the retention of OEO in the middle of the polymer matrix during the drying of the film and during the conditioning period. Furthermore, amylose has a linear helical structure whose interior is hydrophobic and allows similar substances such as essential oils to be absorbed (Ortega-Toro et al., 2014).

Figure 1 Inhibition halo analysis of yam starch (left) and cassava (right) based films with 5% oregano essential oil.

Hernández-Ochoa et al. (2011) reported that chitosan and cumin essential oil-based films showed no inhibition against the B. cereus strain (ATCC 11778). The researchers report that it may be due to the low compatibility between the oil and the polymer matrix.

Table 5 shows the mean and standard deviation values of DPPH IC50 and ABTS IC50 of the studied films, ascorbic acid and oregano essence oil. All oregano essential oil (OEO) films showed antioxidant activity by increasing the amount of oil in the matrix. Regarding DPPH, it could be seen that the 5% oil films have about 10 times less antioxidant capacity compared to pure oregano oil and about 22 times less antioxidant capacity than ascorbic acid. There were no significant differences between the starch sources. In the case of the ABTS test, it can be seen that the films presented some considerable differences regarding the starch source, with the yam-based films being more antioxidant. This could be related again to the ability of yam starch to form more compact and stable structures that trap the added oil more efficiently than cassava starch inside (Ortega-Toro et al., 2014). It is also observed that the films with the highest antioxidant capacity (FY5%) have around 5 times less antioxidant capacity than oregano oil and around 13 times less antioxidant capacity than ascorbic acid.

TABLE 5 MEAN VALUES AND STANDARD DEVIATION OF DPPH IC50 AND ABTS IC50 OF THE STUDIED FILMS (MG OF DRY FILM / ML OF DPPH OR ABTS SOLUTION), ASCORBIC ACID AND OREGANO ESSENCE OIL (MG OF SUBSTANCE/ML OF DPPH OR ABTS SOLUTION)

| Formulations | DPPH IC50 (μg/mL) | ABTS•+ IC50 (μg/mL) |

| Ascorbic Acid | 13.6 ± 0.5d | 2.098 ± 0.004e |

| OEO | 28.30 ± 0.2c | 5.298 ± 0.002d |

| FY0% | - | - |

| FY3% | 331 ± 2a | 38.6 ± 1.3b |

| FY5% | 287.4 ± 1.9b | 25.8 ± 0.8c |

| FC0% | - | - |

| FC3% | 348.8 ± 2.3a | 48 ± 2a |

| FC5% | 299.2 ± 0.8b | 29.4 ± 0.5c |

Different superscript letters in the same column mean significant differences (p < 0.05)

During the drying of the films, the essential oil tends to volatilize since the starch does not exert an efficient protective effect, as reported by other researchers (Talón, Trifkovic, Nedovic et al., 2017). As expected, the antioxidant properties of the films are less than those of a pure standard, because in the films there is only a fraction of essential oil. The confirmation of antioxidant activity in these films could open the field to studies of packaging that provide a long shelf life for food products to undergo oxidation processes.

Similar results were reported by López-Palestina et al. (2018) in films made of gelatine with oil rich in lycopene and beta-carotene and by Talón et al. (2012) in starch and chitosan films with the incorporation of essential oils of basil and thyme, citric acid and alpha-tocopherol.

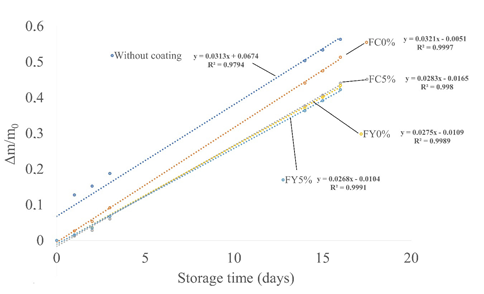

Application of the materiais as grape coatings

Table 6 presents the description of the grapes during the storage time and Figure 2shows the change in weight of the grapes with and without coating during storage. In general, the effects of dehydration, loss of texture and appearance of mould at different times were visually detected. The uncoated grapes presented dehydration appearance sooner, and mould appeared in the uncoated grapes and in those coated with the materials without OEO. The grapes that were coated with materials containing 5% OEO showed an acceptable appearance until the end of the study.

TABLE 6 EVOLUTION OF THE PHYSICAL CHARACTERISTICS OF COATED AND UNCOATED GRAPES.

| Storage time (days) | Description |

|---|---|

| 0 | Good texture and appearance on all grapes. |

| 14 | Slight dehydration which does not affect neither its texture nor its appearance. |

| 16 | Noticeable dehydration that affects the texture and appearance. Slight presence of mould in uncoated grapes and some of the coated grapes without the OEO in the FFD. Better characteristics are observed in coated grapes without significant difference between them. |

| 20 | Remarkable dehydration that considerably affects the texture and appearance. Greater presence of fungus in uncoated grapes and some covered with the films without essential oil. Better characteristics are observed in grapes coated with essential oil. |

| 22 | Remarkable dehydration that considerably affects the texture and appearance. Greater slight presence of fungus in uncoated grapes and some covered with the films without essential oil. Better characteristics are observed in grapes coated with 5% essential oil. |

Regarding weight loss, significant differences were observed between the starch sources, the yam starch coatings being more suitable for protection against dehydration (Figure 2). In the same way, the presence of OEO promoted the decrease in the speed of weight loss. This was to be expected due to the hydrophobic nature of the oil. The grapes that dehydrated most easily were the uncoated grapes (rate of 0.0313g of water/day) and the ones that dehydrated more slowly were those coated with the yam-based material with 5% OEO (FY5% ) (rate of 0.0268g of water/day). The weight loss speed of the grapes with cassava control coating was 0.0321 g of water/ day, when the OEO coating was applied it decreased to 0.0283 g of water/day. While with the yam control coating the weight loss rate is 0.0275 g of water/day and with the OEO-containing coating it decreases to 0.0268 g of water/day.

4. Conclusions

Film-forming dispersions (FFD) and films with active properties were obtained based on yam starch and cassava starch with incorporation of essential oil of oregano (OEO). The contact angle showed that the dispersions satisfactorily wet various fruits and vegetables without differences between the starch sources, while in the centrifugation stability test it was observed that the yam dispersions were more stable than those of cassava, especially with 5 % of OEO. As for the films, those based on yams showed greater thickness, higher moisture content and less capacity for water absorption, these parameters being affected with the increase in OEO. On the other hand, yam starch films showed to be less transparent, in agreement with more compact and crystalline polymeric structures, compared to those based on cassava. Regarding the active properties, the yam starch-based films showed greater antimicrobial capacity against Bacillus cereus, perhaps due to greater efficiency to retain essential oil inside during drying and conditioning. This is related to the antioxidant properties, although all the films showed antioxidant capacity, those with yam starch showed lower IC50 in the DPPH and ABTS test. Finally, grapes coated with yam starch-based films dehydrated at a lower rate than those coated with cassava starch. The above indicates great potential of yam starch as a polymer matrix for the development of active fruit coating materials.