1 Introduction

The production of coalbed methane from a single well is an important target to evaluate the success or failure of the coalbed methane development. However, different coalbed methane wells within the same block have different productivities. Research on the factors that influence coalbed methane production show that it is a result of a coupling action, and the major factors can be restricted to three types: geological, development techniques and production management.

Geological factors include the reservoir burial depth, thickness, gas content, permeability, reservoir pressure, tectonic and hydrogeological conditions, all of which can radically influence the reservoir properties (Kaiser et al., 1994; Pashin and Groshong Jr., 1998; Karacan et al., 2008; Yao et al., 2009a; Lv et al., 2012). Permeability is a major factor used to evaluate the production of coalbed methane from a single well (Li et al., 2011). The natural fractures in the coal are passageways for gas movement (Perera et al., 2013a). The movement of gas is the result of a coupling of gas-liquid-solid flows (Wu et al., 2014), which has a great deal to do with the gas pressure and concentration (Thararoop et al., 2012). The coal matrix swells with increasing gas pressure, especially under low gas pressure conditions (approximately 3.5 MPa), leading to the reduction in coal permeability (Perera and Ranjith, 2012). Although the coal matrix becomes weaker with higher gas pressure, the newly created micro-fractures provide space for gas adsorption, which further enhances the coal matrix swelling (Viete and Ranjith, 2006). However, the increased liquid pressure may result in shrinking of the coal matrix (Perera and Ranjith, 2012). Tectonic movements can promote coalbed methane preservation and secondary hydrocarbon generation (Yao et al., 2009a), but the deformation of the coal mass structure associated with these movements should not be ignored (Li, 2001; Li et al., 2003). The thin-skinned structure can influence the production of coalbed methane wells (Pashin and Groshong Jr., 1998), and the impermeable faults also affect the flow of gas and water from the coal reservoir to the well bores (Karacan et al., 2008). Aside from tectonic movements, gas pressure can also deform the coal mass structure, with higher gas pressure being associated with more serious deformation of the coal structure (Perera et al., 2013b). The mechanical properties of the coal also contribute to the permeability, mainly as a result of the dynamic Young's modulus during the adsorption of gas, especially regarding the adsorption of CO2 (Perera et al., 2013c). When the gas desorbs from the surface of the coal matrix, the elastic modulus controls the coal-stress sensitivity (Karacan, 2009; Tao et al., 2012). Research on the pore structure of 34 coal samples with various maturity from North China has shown that coal permeability is close to the coal pore fractal, especially for middle- and high-ranked coal (Ro,max = 1.47-4.21 %). This permeability may be influenced by the seepage pores and degree of coalification (Yao et al., 2009b; Meng and Li, 2013).

The production of coalbed methane is a coupled process, that involves the desroption and flow of methane, deformation of the coal structure, dynamic change of coal porosity and permeability (Mazumder et al., 2012; Tao et al., 2012; Liu and Harpalani, 2013; Peng et al., 2014; Qu et al., 2014). Additionally, any external fluid could influence the reservoir permeability during fracturing (Gentzis et al., 2009). Essentially, dynamic permeability implies that the state of the coal reservoir varies from the initial to the final time periods (Qu et al., 2014). During the production process, the effective stress of the coal reservoir and the shrinking of the coal matrix will influence the absolute permeability of the reservoir (Durucan and Edwards, 1986; Laubach et al., 1998; Chen et al., 2010; Liu et al., 2010; Tao et al., 2012; Liu and Harpalani, 2013). The permeability of the Fairway wells in the San Juan Basin varies by approximately 100 times over the production period (Palmer, 2009; Mazumder et al., 2012). A study on the production of the coalbed methane wells in the South Qinshui Basin showed that the burial depth of the coal reservoir, the bottom bore pressure and the dewatering rate are the three main factors that control the effective stress of the coal reservoir, which further influences the absolute permeability (Tao et al., 2012). When methane outputs from the bottom of the bore, the extensive underground water does not favor a reduction in pressure, and this water contributes to the groundwater flexibility energy (Wu et al., 2007). This energy can keep the fractures in the coal reservoir open, thereby increasing the permeability of the reservoir, and increasing the performance of the coalbed methane wells (Somerton et al., 1975; St. George and Barakat, 2001; Yao et al., 2009b). The decrease of bottom bore pressure promotes the desorption of coalbed methane, while the rapid decrease of pressure may lead to the gas locking in the reservoir, resulting in reduced flow rates (Tao et al., 2012). The effective stress increases with increasing burial depth (Mazumder et al. 2012), and permeability is more reduced in a deep reservoir is higher than that in a shallow reservoir (Tao et al., 2012).

Conversely, Lv et al. (2012) reported that methane production in a deep coal reservoir is higher than that in a shallow coal reservoir, mostly as a result of the coal thickness and gas content. However, this study did not consider the change in stress state with increasing reservoir burial depth. In the South Yanchuan Block, with a burial depth of 1000 m serving as the demarcation, the reservoir stress characteristics have changed from > σhmnin to σhmax > σv> σhmnin (Wu, 2012). This finding means that the reservoir stress state has changed from tensile to compressive, and there has been an obvious change in coalbed methane production. The methane production at various depths is differs, and this may be influenced by the change in reservoir stress state. In this paper, using the South Yanchuan Block as an example, the reservoir properties that influence coalbed methane production at various depths are discussed, such as pressure and the production characteristics of coalbed methane wells, characteristics and differences of coal reservoir and closure pressures, and coal structure and permeability.

2 Methods

2.1 Geological setting

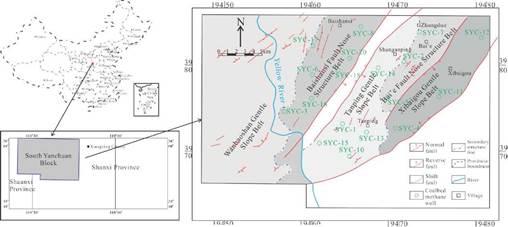

The South Yanchuan Block is situated in the southeast of Ordos basin, China. The study area is a monoclinal structure with a northeast trend and a western dip. Although the Ordos Basin has experienced repeated geologic history, specifically the Indosinian movement, the Yanshan movement and the Himalayan movement, the structure in the study area is simple. The structure can be divided into five third-class structural units, the Xibaigou gentle slope belt, the Bai'e fault nose structure belt, the Tanping gentle slope belt, the Baishansi fault nose structure belt, and the Wanbaoshan gentle slope belt are distributed from east to west (Fig. 1) (Cai et al., 2014; Li et al., 2015; Yan et al., 2015). The South Yanchuan Block was compressed during the three main tectonic movements: NS trending, NW-NE trending, and NE-SW trending movements. The NS trending stress from the Indosinian period established the basement structure. The NW-NE trending stress from the Yanshanian period mainly controlled the structural characteristics, including the four large-scale faults and numerous small-scale faults. The magma activity in Yanshanian period was active, albeit insignificant in the South Yanchuan Block (Li et al., 2015). The hydrodynamics in the study area are complex, including a strong runoff and recharge zone, a weak runoff zone, a stagnant zone, a strong runoff zone, a weak stagnant zone and a deep stagnant zone, situated from the east to west (Cai et al., 2014). The Lower Permian Shanxi Formation (Pjs) No. 2 coal seam is the target stratum for the development of coalbed methane.

2.2 Samples test and data processing

There have been approximately 60 coalbed methane wells in the research area. However, most of these wells are in initial production stages, exhibiting unstable productivity. In order to ensure that the research is scientificity, coalbed methane wells that have stably produced for an excess 150 days were selected.

The proximate analysis of coal samples in this study utilizes the instrumental method of proximate analysis of coal (GB/T 30732 2014, Chinese national standard). The Ro,max tests were carried out using whole-rock maceral analysis (SY/T 6414-1999, Chinese petroleum and natural gas industry standard), and at least 800 points were tested. Reservoir permeability can be acquired from injection/fall-off well tests, experimental test, history matching, geophysical log and constructing permeability prediction models (Palmer, 2009; Li et al., 2011; Ma et al., 2011; Thararoop et al., 2012; Meng and Li, 2013; Perera et al., 2013b; Peng et al., 2014). In this paper, the coal reservoir permeability is acquired from the injection/fall-off well test, and the fitting permeability is acquired from the COMET3 coalbed methane numerical simulation software. COMET3 is a three-dimensional, three-component, two-phase, dual-porosity simulator for modeling gas and water production from a desorption-controlled coal reservoir (Advanced Resources International, 2005). The diffusion, desorption theory and dual-porosity/ single-permeability model are used for the coalbed methane simulation. The following equations are used to calculate the conservation of gas and water.

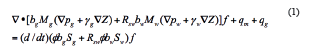

Conservation of gas:

where, f indicates fracture systems, Δ is the gradient operator, Δ• is the divergence operator, bn (n = g or w) is the gas or water shrinkage factor, γn (n = g or w) is the gas or water gradient, Rsw is gas solubility in water, φ is effective fracture porosity and Z is the elevation.

During the simulation process, certain reservoir parameters should be inputted, including coal thickness, burial depth, reservoir pressures, porosity, permeability, gas content, sorption time, Langmuir volume, Langmuir pressure, and aquifers. All of these parameters can be acquired from engineering and experimental tests. If the permeability from the injection/ fall-off well test is influenced by the external fluid, then the permeability is the domain parameter that will be fitted in the simulation software.

Coal structure of reservoir was explained using logging data (Fu et al., 2009). The coal structure is divided into three types, Type I coal is primary texture coal, Type II coal is cataclastic texture coal, and Type III coal is tectonic coal.

3 Results and Discussion

3.1 Coalbed methane well production characteristics

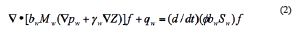

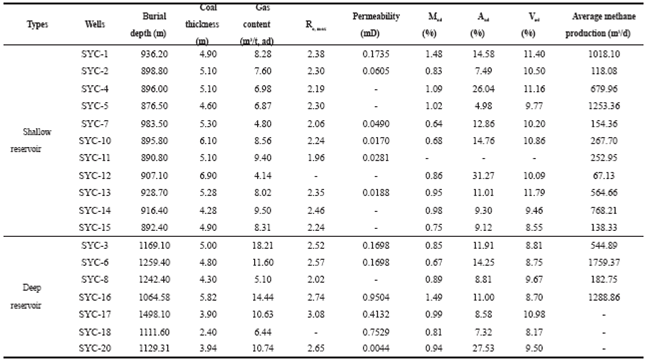

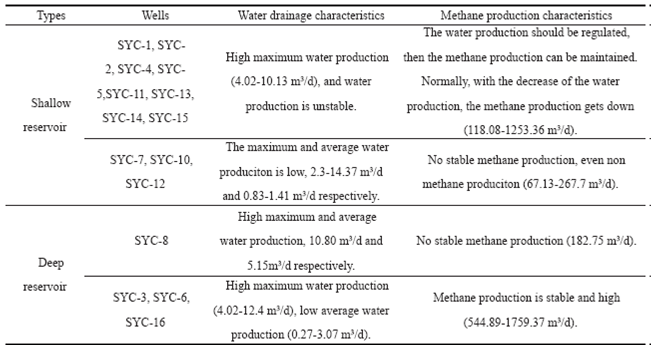

Fifteen coalbed methane production wells are studied in this paper. As shown in Fig. 2, different wells have various methane and water production characteristics. According to the research of Cai et al. (2014), when methane wells are located in the underground water weak-runoff and stagnant zones, the influence of underground water may be weak. The SYC-1 and SYC-6 wells wxhibit high methane production, with the maximum methane production of SYC-6 exceeding 2000 m3/d, while the methane productions of SYC-2 and SYC-10 are low. The output of water decreases the reservoir pressure, allowing for the methane to desorb from the coal. Although the water production fluctuates, the dominant trend is decreasing. It was found that there were significant depressions in the liquid levels at SYC-1 and SYC-6 after the bores began to produce methane, followed by a leveling-out of the liquid levels. However, the liquid levels of SYC-2 and SYC-10 remained steady, indicating that the seepage of liquid is not smooth, a trait that may be related to the coal reservoir permeability.

3.2 Influence of coal properties on methane production

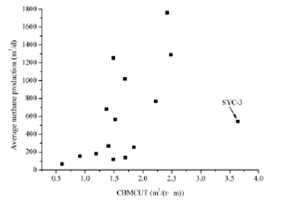

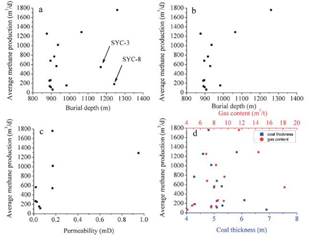

As mentioned above, there are many factors that can influence the production of coalbed methane wells, particularly the permeability and thickness of coal and the gas content (Kaiser et al., 1994; Lv et al., 2012). Generally, the higher the methane content and coal thickness, the higher the coalbed methane production (Lv et al., 2012); however, that is not obvious in South Yanchuan Block. As shown in Fig. 3d, the relationship between gas content and coal thickness in terms of average methane production is weak, meaning that these two factors are not the key controllers of the methane production. With increasing burial depth and coal reservoir permeability, the average methane production increases (Fig. 3a, c), especially when the data from SYC-3 and SYC-8 are removed (Fig. 3b). The low methane production of these two bores will be explained later. When the burial depth exceeds 1000 m, the methane production is quiet high (Fig. 3a, b). This phenomenon may be influenced by the shift of the stress state. To facilitate the discussion, the reservoir burial depth above 1000 m is referred to as the shallow reservoir, while the reservoir burial depth beyond 1000 m is referred to as the deep reservoir. The average methane production in the shallow reservoir is less than 700 m3/d, while the methane production always exceeds 500 m3/d in the deep reservoir, where it reaches 1759.37 m3/d (Table 1).

Figure 3 Relationship between burial depth, permeability, coal thickness and gas content with the average methane production

3.3 Characteristics of reservoir and closure pressures influenced by depth

Generally, the crustal stress will increase with increasing burial depth. Due to the shift in the stress state at 1000 m, the reservoir and closure pressures present typical characteristics. The reservoir in the research area is generally under pressure, with the shallow reservoir pressure is particularly low (Fig. 4a). These low pressures combined with low gas saturation do not favor high production of coalbed methane. At depths of 1050 to 1150 m, the reservoir pressure fluctuates, indicating that depth is within the stress transformation zone (Fig. 4a). Additionally, the reservoir pressure gradient is low, and this is mainly due to the deep stagnant underground water zone (Fig. 4a) (Cai et al., 2014). The closure pressure also presents the same relationship with the burial depth, where the closure pressure in the transformation zone is quite fluctuant, and the maximum closure pressure of SYC-20 is even higher than in deep reservoir (Fig. 4b). In the deep reservoir, while the closure pressure has increased, it is not obvious (Fig. 4b). Where the burial depth of the reservoir exceeds 1000 m, especially in the compression zone, the crustal stress turns to compressive stress, and the closure and reservoir pressure are both high in the deep reservoir. This high reservoir pressure can maintain high stratum energy (Wu et al., 2007), and the high closure pressure can keep the fracture open (Perera and Ranjith, 2012).

With increasing the reservoir burial depth, the reservoir effective stress increases, and the fracture network system tends to close (Laubach et al., 1998; Yao et al., 2009a), which would lead to an exponential decrease in permeability (Somerton et al., 1975; Gray, 1987). The permeability decreases with the increase in effective stress (Fig. 5a), due to the coupling of reservoir and closure pressures. The effective stress is also divided into three sections (Fig. 5b). The low closure pressure gradient indicates high permeability in the deep reservoir. Under the interaction between the low closure pressure gradient and the high reservoir pressure gradient, the permeability of the deep reservoir is generally more than 0.1 mD. This observation has validated the conjecture, which means the coalbed methane geological condition is superior in the deep reservoir.

3.4 Coal structure characteristics influenced by burial depth

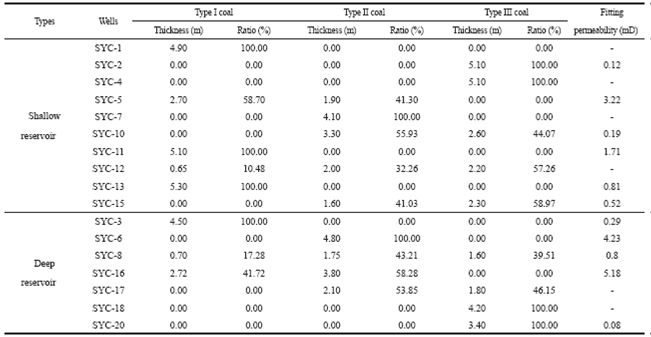

3.4.1 Coal structure proportion

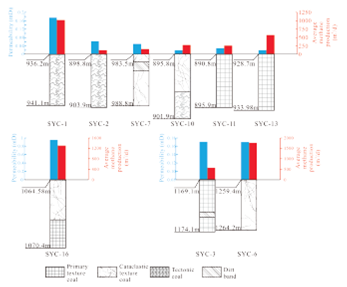

The statistical results show that in the shallow reservoir, the Type I coal proportion reaches 38.18 %, the Type II coal proportion reaches 26.41 %, and the Type III coal proportion reaches 35.41 % (Table 2). In the deep reservoir, the Type I coal proportion reaches 25.25 %, the Type II coal proportion reaches 39.69 %, and the Type III coal proportion reaches 35.06 % (Table 2). The Type III coal is mainly located in the transformation zone coal reservoir. If this section of the coal reservoir is ignored, the proportion of Type I, II and III coal in the deep reservoir will reach 30.14 %, 50.14 % and 19.71 % respectively. High proportions of Types I and II coal is a good basis for high permeability in the deep reservoir (Li et al., 2015). Although the tectonics are simple in the research area, the deep reservoir (especially in the compression zone) coalbed methane wells lie in monoclinal structure. However, the shallow coalbed methane wells lie in the core of the secondary syncline or the wing of the secondary anticline, which would decrease permeability, and can be a disadvantage to the coalbed methane production. The development of Type I coal can maintain the coal mass structure, while the development of Type II coal can increase the permeability of the coal reservoir (Li et al., 2015), and this effect is the main reason for the low methane production at SYC-3 and SYC-8.

Table 2 Statistics of coal structure with the logging data in South Yanchuan, Block

Note: -, no data.

The deep reservoir is mainly composed of the Type I and II coal structures, it has high stratum energy, and the production of coalbed methane is steady. With aslow increase of the effective stress, the fluid can discharge steadily, and the methane production effect is positive (Table 3). Coalbed methane production in the shallow reservoir varies, and the low reservoir pressure results in high effective stress. With the continuing production, the effective stress increases with decreasing reservoir pressure, and the fractures are rapidly closed. Additionally, the development of Type III coal can make the migration of methane difficult, and can result in the methane wells' having low to no productivity (Table 3).

3.4.2 Coal thickness

Generally, the higher the coal thickness, the larger the gas content the coal seam can maintain (Yao et al., 2009a; Lv et al., 2012). However, there is no marked correlation between coal thickness and coalbed methane production (Fig. 3). In the shallow reservoir, the relationship between coal thickness and coalbed methane production is even negative (Fig. 6a); mainly due to the development of Type III coal. The development of Type III coal can damage the reservoir permeability (Li et al., 2015), and desorption of methane adsorbed at the surface of the coal matrix is difficult, resulting in low methane production. When the coal thickness is adjusted to the thickness of Type I and II coal, the methane production increases exponentially (Fig. 6b).

The coal thickness also influences gas content, and the coalbed methane content unit thickness (CBMCUT) can be used (Lei et al., 2012).

where,  is CBMCUT, m3/(t·m); C is gas content, m3/t; h is apparent thickness, m; and α is dip angle, °.

is CBMCUT, m3/(t·m); C is gas content, m3/t; h is apparent thickness, m; and α is dip angle, °.

CBMCUT is a combined reflection of coal thickness and gas content; it increases exponentially with average methane production (Fig. 7). CBMCUT also has a relationship with the coal structure, and decreases with increasing coal thickness. This effect is mainly due to the resistance of tectonic deformation of thick coal; with thinner coal (1-2 m) more easily deformed than thick coal (> 5 m) (Lei et al., 2012).

3.5 Permeability

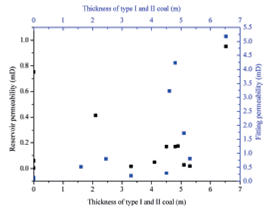

In the shallow reservoir, the development of Type III coal results in the low permeability, as values are always below 0.1 mD (Table 1, Fig. 5). The permeability of SYC-11 and SYC-13 coalbed methane wells with the Type I coal is still low, mainly due to low reservoir pressure, and insufficient stratum energy to keep the fracture open. The deep reservoir has a single coal structure is, and the permeability is higher than that in the shallow reservoir. The development of Type I and II coal can maintain high permeability, which indicates that the Type II coal can promote the increase of permeability (Fig. 8).

There is a positive exponential correlation between the fitting permeability and the thickness of Type I and II coal (Fig. 9). Type III coal in the reservoirs of SYC-2, SYC-4, SYC-7, SYC-10 wells is more developed. The coal structure is complicated, and the incremental multiplier of reservoir permeability is limited after the hydrofracture, which means the fracturing effect is not obvious with the development of tectonic coal (Table 2). With the development of Type I coal in the reservoir of SYC-11 and SYC-13 wells, the permeability increased dramatically (Table 2). Except for the SYC-3 well, the fitting permeability in the deep reservoir increased, and the development of a dirt band in the reservoir decreases the fracturing effect. This high permeability means higher methane production (Fig. 2).

4 Conclusions

The average methane production in South Yanchuan Block increases with increasing coal reservoir burial depth, and coal thickness and gas content are not the key factors influencing methane production. The shift of the stress state makes the reservoir and closure pressure fluctuate, which leads to various coal structure characteristics in the shallow and deep reservoirs, and finally influences the coal reservoir permeability that controls the coalbed methane production. The reservoir in the research area is under pressure, and the shallow reservoir pressure is drastically low, which results in high effective stress. High closure pressure in the deep reservoir keeps the fracture open, and the reservoir permeability is superior. However, the reservoir and closure pressures in the transformation zone in the deep reservoir are fluctuant. The reservoir and closure pressures also influenced the coal structure. The Type III coal in the shallow reservoir is quite developed, while there is Type I and II coal in the deep reservoir. The combination of coal thickness and gas content can significantly influence the average methane content, and this also has a great deal to do with the coal structure. There is a positive exponential correlation between the fitting permeability and the thickness of Type I and II coal. The coalbed methane numerical simulation results show the development of Type III coal can decrease the fracturing effect, while it increases with the thickness of Type I and II coal. Conversely, the development of Type III coal causes the methane production to be unsteady, which is a disadvantage to methane productivity.