1. Introduction

Current statistical data shows that the total global CBM is more than 50 billion m3 of great exploitation potential (Al-Jubori et al., 2009). In the dual-porosity system of Coalbed methane reservoir, the methane is adsorbed in the pore of the matrix (Rogers, R. E., Ramurthy, K., Rodvelt, G., & Mullen, 2007). When the fluid pressure in nature fracture system decreases to some degree, the adsorbed methane will begin to desorb from the surface of micro-pore, diffuse to nature split, and seepage to near well bore area (Schein & Mack, 2007). Hydraulic fracturing with gel should be applied to CBM reservoir as routine, which helps to stimulate the flow channel in the near wellbore zone, to make the gas production commercially viable (McCabe et al., 1999; Cramer, 2008).

The reserves of CBM in QinShui Basin of China are quite promising (Wei et al, 2007), but most of the productions of CBM wells are quite small even after massive hydraulic fracturing (Chen et al., 2009). The measured permeability of the core plugs from Qinshui Basin is minuscule, most of which being less than one mD measured by injection tests (Wang, Tang, Wei, Xu, & Leng, 2006). The clay and calcite mineral observed in the natural fractures of coal seam are to explain the low productivity of gas wells (Puri, King, & Palmer). Therefore, increasing the permeability of natural cleat is the important target for petroleum engineers who should be stimulating the coal bed methane in Qinshui Basin.

Despite the fact that acid fracturing has been proved as an important way to improve oil and gas production for carbonate reservoir with natural fractures (Hill & Schechter, 2000; Perex, D, Huidobro, E., & Avendano, 1998), it has not been applied universally in the stimulation of CBM wells. It was reported that small volume of acid spearhead ahead of the main fracturing had been implemented to clean out the cement deeper into near well bore area and reduce the breakdown pressure of a few CBM wells (Adil, Sharma, & Bhat, 2012). The acid spotting /socking with 1000 gal of inhibited 15% HCl and 10% Acetic acid mix, which react with perforation debris and remove cement invasion, has also been proved successful in India (Pooniwala, 2012). However, it is said in the literature that the coal formations are rather clean with minimum natural deposits in the cleat system, which is entirely different from those in the QinShui Basin.

To evaluate the feasibility of acid fracturing in QinShui Basin, herein a series of tests have been designed to verify that the acid is beneficial to dissolve the carbonate fillings in the coal core of both macroscale and microscale, and the pilot acid fracturing treatments have been performed to demonstrate that the HCl acid pad, the volume of which being much larger than that in literature (Adil et al., 2012; Pooniwala, 2012; Tamayo, Lee, & Taylor, 2007) can remove the carbonate cement of the natural fracture net, and lower the breakdown pressure efficiently as expected. It is learned from the microseismic survey that the stimulated reservoir volume (SRV) is dependent on the application of acid pad before the proppant laden stage, and it is suggested that larger volume of the acid pad is crucial to the success of the stimulation operation in CBM wells with carbonate filling in cleats.

2. Natural Fracture Net and Mineral Contents

2.1 Observation of macro-scale nature fracture

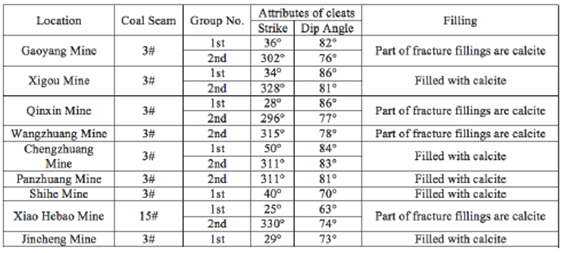

The main pay zones of Qinshui Basin coal bed methane are named as 3# and 15# coal seams. From the observation of working tunnels of down-hole coal mines located in Qinshui Basin, it is found that there are two groups of cleats. The strike of the first group ranges from 20 to 50°, the density of which being unevenly distributed, with the strike of the second group being between 276 and 355°. The dip angle of cleats are more than 70° and can be taken as vertical braces (Liu, Kang, Wang, & Deng, 2008). The mineral identification with HCl acid shows that most of the fillings in cleats are carbonate type, which agrees with the observation of Wei et al.

2.2 SEM Analysis of filling in micro-scale fracture

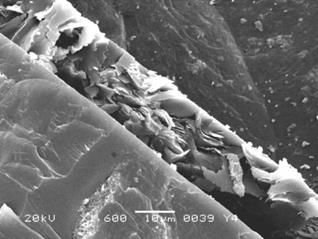

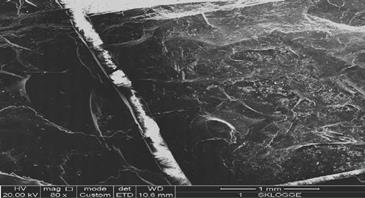

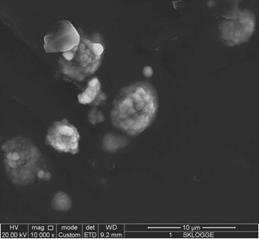

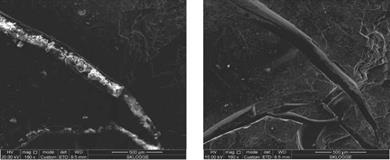

Scanning electron microscope (SEM) is an effective way to observe the occurrence of micro fractures, such as the dimension, filling, and connection.

Since the filling in micropores and cracks is the resistance for the gas to flow, the discrimination of mineral type, current status, and the content can be the theoretical foundation for acid fracturing in the coal seam. The Qunta250 FEG Scanning Electron Microscope made by FEI Co. and INCAx-max20 Energy Dispersive Spectrometers made by Oxford Co. of the National Key Laboratory of Oil and Gas Reservoir Geology and Exploitation are applied to describe the thin sections of the coal seam. The analysis of 3# and 15# coal in Jincheng Mine are as follows:

Clay mineral

Clay mineral is the most widely distributed and abundant mineral in China's coal. It is also found in this investigation that kaolinite, illite, chlorite, mixed layer of smectite and illite are abundant in Jincheng Mining area.

Carbonate mineral

Most of the carbonate minerals in Jincheng CBM Mine area are identified as epigenetic origin (Liu et al., 2008).

2.3 X-Ray Diffraction Analysis of Filling in Micro-Scale Fracture

It is hard for SEM to discriminate every clay mineral sometimes. X-ray diffraction method analyzes diffraction pattern on the photographic plate by making use of X-ray diffraction formed by crystal, so as to clarify the crystalline structures and shapes of minerals, and further analysis can tell the relative content of minerals by quantity.

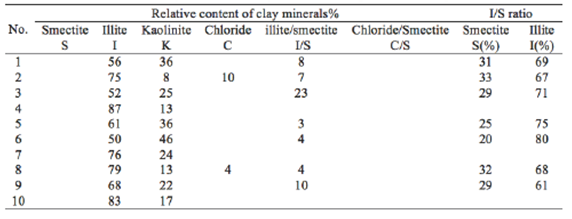

According to Table 2, most of the clay minerals in coal rock are illite and kaolinite, with few illite/smectite mixed layer. It is found from more than 230 reports in Jincheng Mine that the average amount of illite is 68.7%, and that of kaolinite is 24%.

3 Feasibility of Acid Fracturing Stimulation in Coal Bed Methane

Coal bed methane reservoir is typical of the dual-porosity media system; the methane is adsorbed in matrix pore. When coal seam pressure decreases to a certain degree, the adsorbed methane begins to desorb from the surface of matrix pores, and diffuse to macro fracture network through pores and microfracture, and flow to well bore via hydraulic fracture.

Through downhole observations, SEM and X-ray diffraction analysis, we can see fillings in coal fractures as that most of the clay minerals are kaolinite or illite, and the carbonate fillings in both macro-scale fracture and miro-scale fracture are also abundant.

Mingshou Wang et al. measured the temperature of inclusions of fillings existing in coal seam cleat systems of Qinshui Basin and suggested that the filling sequence of minerals is that pyrite precipitates first, then quartz and clay minerals, finally carbonate minerals (calcite and Fe-dolomite). So that is to explain why the carbonate minerals are filled in the center of fractures.

From the 1990s to 2010s, more than 50 CBM wells were tested with the injection-drawdown methods to measure the permeability, and the results showed that the permeability of most of the pay zones is less than 1mD. Because of the relatively low permeability of the natural fractures in 3# and 15# coal seams of Qinshui Basin, the productivity of CBM wells are quite low even if the wells have been stimulated using massive hydraulic fracturing. Therefore, by injecting some kinds of acids into the formation, to get the carbonate mineral in the center of natural fractures resolved, the conductivity of reservoir fractures could be upgraded.

The hydrochloric acid and mud acid are screened at first to simplify the feasibility of acid applied in CBM. At the early stage of the experiment, it is found that the Calcium fluoride precipitation would follow the reaction between Hydrofluoric acid and carbonate. However, the permeability of coal sample soaked in hydrochloric acid increases significantly.

Carbonate minerals react with HCl acid as follows:

3.1 Test Preparation

The coal samples used in the experiment are taken from 3# coal seam of Jincheng mine.

3.2 Porosity Change of Coal Core

There are various methods to test the porosity of coal core, and the most widely used one is using nitrogen flooding.

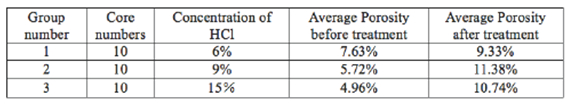

Because nitrogen is inert, the molecule diameter of which is only 0.265 nm and can enter micro-pore of coals, it can cover the micro-pore and fracture. Three different concentrations of 6 %, 9 %, and 15 % hydrochloric acid are used respectively. Coal samples are taken from 3# coal seam in Jincheng mine in Qinshui Basin. Coal cores are divided into three groups, each group with ten cores, to compare the porosity changes before and after treatment with acids.

Experiment Steps

When drying the coal samples before the test, caution should be taken to avoid the destruction of coal plug due to high temperature, and the temperature is suggested as 80 °C (Dabbous, Reznik, Taber, & Fulton, 1974.)

Test the porosity of coal samples of each group before acid treatment.

Have coal samples soaked 6 hours in hydrochloric acid of 6 %, 9 %, and 15 % concentration, respectively.

Test porosity coal samples after treatment.

Porosity changes are compared in Table 3.

It is found that the average porosity increase after the acid treatment. According to the Table 3, if the acid concentration increases, the average porosity will increase accordingly.

3.3 Evaluation of Acid sensitivity

Acid sensitivity is the permeability decline due to the reaction between an acid and some minerals (Hsi, 1984). The minerals sensitive to HCl are iron calcite, iron dolomite, hematite, pyrite, magnesium iron ore, glauconite, hydrobiotite. The minerals sensitive to HF are calcite, dolomite, calcium feldspar, zeolites, and various types of clay minerals. Since pyrite was observed in SEM, the acid sensibility of coal seam samples is measured.

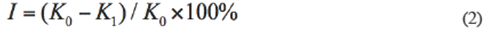

In the experiment, permeability is measured before and after injecting HCl of 15% concentration. The acid-sensitive index is calculated by formula 2.

Where: K 0 is the permeability by distilled water flooding before acidification, K1 is the permeability by distilled water flooding after acidification, is the acid sensitivity index.

Experiments suggest that acid treatment can improve coal seam porosity, and since there are few minerals sensitive to HCl acid in coal seams, the acid sensitive index is relatively low.

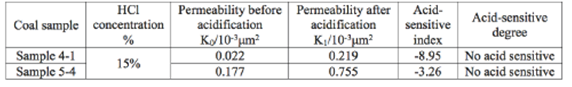

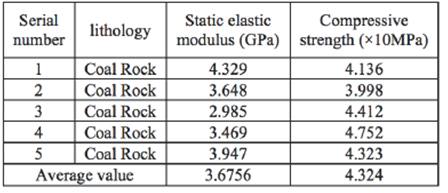

3.4 Geo-Mechanic property changes of coal samples after acid reaction

Because the cement in a fracture in Jincheng Mine can be resolved in acid, the geo-mechanic properties would change accordingly (Huang, Wang, C., Wang, T., & Zhang, Z., 2015). Before this experiment, when preparing the core sample, care should be taken to avoid turbulence which may destroy the core sample because of the fragile nature of coal. The samples listed are numbered from 1 to 10. Half of the samples are soaked in acid for 2 hours before the test, while the others are tested after acid treatment. It can be seen that after acid treatment, the cores are much easier to break down.

3.5 SEM observations before and after acidizing

Through SEM experiment, the changes of minerals in the micro- fractures before and after acid treatment are studied, and the result is shown in Figure 6.

It can be learned from an experiment in the laboratory that, carbonate minerals in natural fractures are dissolved almost thoroughly, the porosity and its connectivity of coal sample increase significantly, and permeability is improved obviously after the acid reaction.

4. Field Application of Acid Fracturing Engineering

4.1. Case of applying acid fracturing treatment

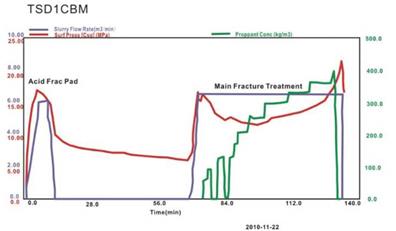

From 2011 to 2012, ten coal bed methane wells were stimulated with acid fracturing in Qinshui Basin ([19]. Herein the fracturing treatment of well TSD1 is given as an example.

Before the operation of TSD1 well, the hydraulic of the abnormally high breakdown pressure. The initial suggestion was to inject HCl for TSD1 well to decrease the breakdown pressure of 3# coal seam, whose measured depth was from 1031.1mracturing stimulation oftwo nearby wells, TSD5, and TDD3 had been proved as a failure because of o to 1037.1m. The operation was carried out on November 22, 2012. The total volume of proppant laden fluid was 452m3, and the pump rate was 6.5m3/min. Before the proppant laden stage, 50 m3 volume of HCl acid was performed as a pad to not only clear the debris of perforation but also remove the carbonate cement of the natural fracture net. The operation curve is shown in Figure 7.

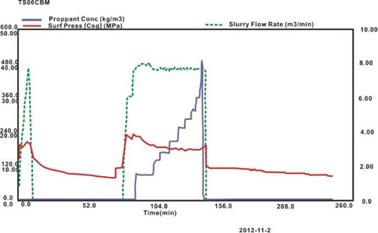

The operation of TS06 CBM well was compared, which was stimulated with guar based polymers, to show the advantage of acid fracturing. The target zone of TS06 well was also 3# coal seam, and the perforation interval depth was 691.6m-698.2m. Instead of the acid pad before the proppant-laden stage, 2% KCl water was pumped as a pad to break down the pay zone for the TS06 CBM well.

It can be learned from the comparison of the curves from both well TSD1 and well TS06 that, since the HCl acid was applied in the pad stage of fracturing for TSD1 well, the peak pressure in proppant-laden stage was 1.5 MPa lower than that in the pad stage, which is the evidence that the HCl acid must have effectively resolved the fillings in natural fracture system. While in the proppant-laden stage of well TS06, the peak fracturing pressure was almost 2MPa higher than that in pad stage, illustrating that the permeability of natural fracture system in well TS06 has not been improved effectively with KCl pad.

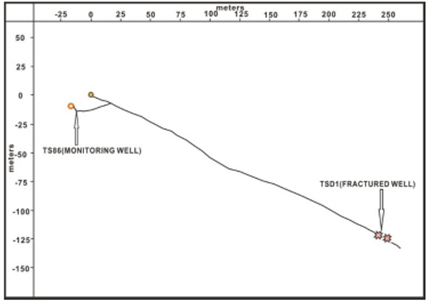

4.2. Acid fracturing monitoring analysis

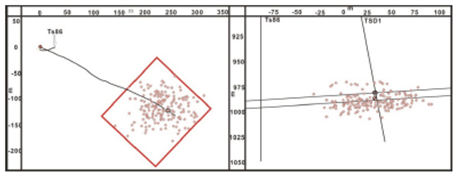

To monitor the acid fracturing situation of TSD1 well, Pinnacle Company was authorized to conduct micro-seismic monitoring during the fracturing operation. Ten Three-Component Geophones, combined with the optical fiber transmission technique and mathematical analysis, were installed in monitoring well TS86 which is about 300 meters away as shown in Figure 9 to measure the position and length of the fracture.

After the acid fracturing pad, it is shown in Figure 10 that the injected acid has filtrated from the hydraulic fracture to the natural cleat net, the stimulated area being approximately 140m wide and 150m long.

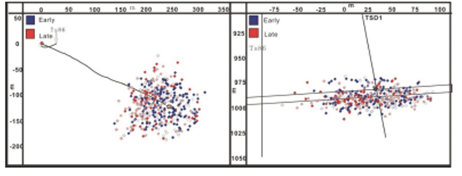

The variation of downhole microseismic events with time is showed in the Figure 11. The Bluepoints labeled as the early stage is representing the SRV after the acid pad stage, and red points labeled as the late stage is representing the SRV after the proppant laden stage. It is also learned that the extension of stimulated reservoir volume has almost stopped after the acid pad stage, which is showed as Figure 11. The total SRV depends on the scale of the early acid pad operation.

5. Conclusions

1. Fillings in 3# coal seam, or the primary production zone of Qinshui Basin, is predominated by carbonate minerals with clay minerals. Through lab tests, it is learned that the carbonate minerals in the center of natural cleat system of coal seam can explain the feasibility of acid fracturing stimulation. If the filling in natural cleat net is clay or quartz with less carbonate, the acid will not do any good to the fracturing stimulation and should be avoided.

2. The hydraulic fracturing can create a high conductivity fracture initiated from the wellbore, but the productivity of well would be quite low if the conductivity of nature fracture has not been increased. Acid fracturing pad in CBM reservoir can increase the permeability of natural fracture net with carbonate filling, and improve the production.

3. It is learned from the microseismic survey that when fracturing the CBM well, the stimulated reservoir volume is dependent on the applied volume of the acid pad, and it is suggested that larger acid fracturing pad is crucial to the success of the whole operation.

4. Massive acid fracturing treatment may contribute to some kinds of contamination in the reservoir, changing the properties of the formation. Thus a series of tests as illustrated herein should be designed before onsite treatment to avoid these damages. It is verified that careful preparation can ensure the success application of large volume of the acid pad in stimulation treatment.