Introduction

The shear modulus and damping ratio, which can describe the dynamic characteristics of gravel, must be used in the equivalent linearisation method in seismic response analysis, the evaluation of interaction of soil-structure systems, and the stability analysis of sites. Therefore, there is an urgent need to study the important parameters of the dynamic shear modulus and damping ratio of the gravel in order to analyse the seismic response of gravel. Many factors can affect these two parameters in all types of soil. The main factors are the soil type (Rollins, Evans & Diegl, 1998), confining pressure (Wang, Geng & Jin, 2005; Ling, Fu & Cai, 2009; Wang, Jia & Deng, 2006; Wan & Yang, 2013), loading time (Sas, Gabrys & Szymañski, 2015), consolidation ratio (Liu, Yang & Chen, 2010; Sun, Gong & Tao, 2013; Sun, Yuan & Gong, 2011), and initial stress state (Wang, Luo & Guo, 2011; Wang, Luo & Guo, 2012), among other factors (Ling, Zhang, Li, An & Wang, 2015; Delfosse-Ribay, Djeran-Maigre, Cabrillac & Guovenot, 2004). Some results on the effect of effective confining pressure, consolidation ratio, gravel content, and granule breakage, among other factors, on the dynamic shear modulus and damping ratio of gravel have been reported. Wang et al. (2005), Ling et al. (2009), and Wang et al. (2006) studied the influences of confining pressure on these two parameters of gravel. Liu et al. (2010) studied, analysed, and proposed the relationship of the dynamic shear modulus and damping ratios with various factors (consolidation ratio, porosity, test grading, etc.) and a comprehensive formula which takes into consideration the consolidation stress ratio, void ratio, and test grading curve, and can be used to calculate the maximum dynamic shear modulus. Rollins et al. (1998) found that, with the increase of gravel content from 0% to 60%, the value of G max can be as high as 38%. Hardin and Kalinski (2005) found that the Gmax value of gravel samples clearly increases through large-scale resonant column tests (specimen height of 300 mm or 150 mm) on different gradations of sand and sand-gravel mixtures. Based on the resonant column tests of soil samples with different grain-size distributions, Wichtmann and Triantafyllidis (2009) pointed out that, for a constant void ratio, the values of G do not change with the variation in the mean grain size d 50 .Sahaphol and Miura (2005) used bender element tests to study the influence of the particle breakage characteristic of volcanic soils on the maximum shear modulus. However, studies on the influence of the granular shape on the macro-physical and dynamic properties are rare.

The effect of the granular shape on the shear modulus and damping ratio of gravel soil cannot be ignored, because the granular shapes and occlusal area are different among the soil particles. Qian, Gray and Woods (1993) found that, under the same conditions (with an effective confining pressure less than 100 kPa), the maximum shear modulus of unsaturated angular sand is 5%-25% greater than that of round sand. Meidani, Shafiee and Habibagahi (2008) found that, under the same conditions, the shear modulus and damping ratio of round gravel are greater than those of angular gravel. The granule shape has a close relationship with the parent soil composition, weathering, transportation, and deposition of the environmental conditions. Tong and Wang Tong, Wang and Yu-Hsing (2014) showed that the shear modulus and damping ratio can also be increased and decreased, respectively, by increasing the particle aspect ratio Ar (i.e., by decreasing sphericity). However, the quantitative relation could be applied to a sand but not sure about gravel soils. Some scholars attempted to use numerical techniques to simulate the effect of granule shape on the mechanical properties (Liu, Xie, Ma & Chang, 2011). These studies are also limited to a general description of the granule shape, such as "granules with a much more regular round shape" and "granules with an irregular shape." A model or formula that calculates the dynamic properties (such as shear modulus and damping ratio) while considering the granule shapes has not been reported to the authors' knowledge. The reason for the current situation is that a standard and simple means to effectively quantify the granule shape is lacking. Many scholars noted the importance of granule shape and performed a series of studies and proposed many types of quantitative methods, such as the Fourier description method and method of fractal theory.

However, the quantitative description of granule shape is still not mature because many aspects continue to present difficulties: (1) the descriptions of individual granules; (2) the characteristic descriptions of the distributions of group shapes; (3) the descriptions of group shapes. This research focuses on examining the differences between the properties conferred on the mechanical characteristics of soil by angular gravel and round gravel. Further, a conventional optical microscope is used to obtain digital images of the granules, which enable us to analyse the test results and discuss the effect of shear characteristics (shear modulus and damping ratio), compression characteristics, and other mechanical indices of the granule shape by performing conventional mechanical tests.

Dynamic Triaxial Test

Test apparatus

The dynamic triaxial test was conducted in the laboratory with DYNTTS soil multifunctional triaxial testing instruments manufactured by GDS Company in the UK. As shown in Figure 1, the instrument is mainly composed of the host, the axial-force measuring system, the axial-deformation measuring system, the axial control system, the confining-pressure control system, the back-pressure control system, the pore-water-pressure measuring system, and the computer system. The systems for measuring the axial-force and axial-deformation, together with the axial control system, are installed in the control cabinet; the host consists of the triaxial cell and the axial loading system; the pressure control system and the back-pressure control system are connected to two volume controllers, respectively. The greatest advantage of this instrument is the loading and pressure control system. By adjusting the pressure of the cap, the soil can be pressed.

This system configuration enables all procedures to be controlled. While collecting and processing the test data, test results can be simultaneously displayed on the monitor. For testing dynamic loads, a load frequency can be selected in the range of 0.01-5 Hz with a sine wave, triangular wave, rectangular wave, or any user-defined waveform.

Test principle

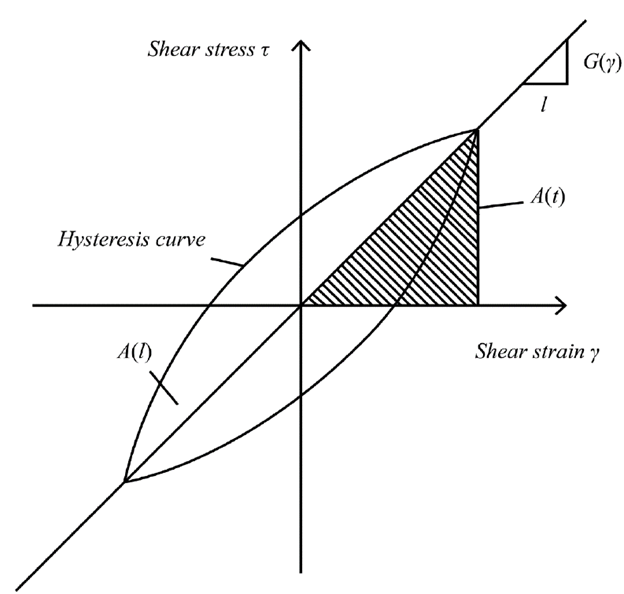

Under cyclic loading, the stress-strain relationship of the soil has distinctly nonlinear characteristics and shows hysteresis. The hyperbolic model, in which the loading and unloading curves are obtained from the Masing rule, is widely used to describe the nonlinear characteristics of soil. In the equivalent linear dynamic viscoelastic model, the equivalent dynamic shear modulus and equivalent damping ratio can describe the nonlinear dynamic characteristics of the soil. In the dynamic stress-strain curve shown in Figure 2, the shear modulus is defined as the slope of a secant line that connects the extreme points on a hysteresis loop. The damping ratio can be computed using the equation

where A(1) is the area enclosed by the hysteresis loop and A(t) is the area of the shaded triangle shown in Figure 2

Tested materials and sample preparation

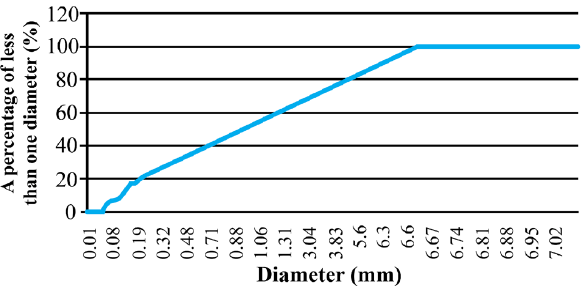

In the present paper, angular gravel and round gravel are used as the research subjects. They have low dry density and low degree of saturation. Their uniformity and curvature coefficients are 2.09 and 1.04, respectively. Gravel samples are prepared using angular gravel and round gravel, respectively, according to Figure 3, which shows the grain-size distribution curve.

The cylindrical reconstituted specimens are sand samples 39.1 mm in diameter and 80.0 mm in height. First, the samples are subjected to the combined saturation method using the hydraulic and back-pressure, where the saturation of samples can be greater than 98%. Second, after the consolidation of the samples has been completed, cyclic loading should be applied to the samples. The loading waveform is a sine wave, and the loading frequency is 0.2 Hz. The unidirectional vibration test is carried out under different amplitudes of stress. In order to avoid the influence of vibration effects on the test results, the vibration times should be minimal, and vibration times should generally be 3-5 cycles.

Testing program

In order to study the effect of the granular shape on the dynamic shear modulus and damping ratio of gravel, the grain-size distribution and consolidation condition of angular and round samples are maintained at constant levels throughout the test. By testing the dry density of the angular and round samples under different relative densities, it is shown that, when the relative density is 45%, the difference of dry density between them is less than 3%. This implies that we can ignore the effect of dry density on the test results. Thus, we maintain the relative density of all samples as 45% during reconstitution. P5 is defined as the content of gravel having a particle diameter greater than 5 mm. The specific testing program is listed in Table 1.

Table 1 Testing program

| Gravel shape | P5/% | Effective confining pressure/kPa | Dry density/gcm3 |

|---|---|---|---|

| Angular sample | 36 | 100,400,600,800,900 | 1.84 |

| Round sample | 36 | 100,400,600,800,900 | 1.83 |

| Angular sample | 44 | 100,400,500 | 1.89 |

| Angular sample | 61 | 100,400,500 | 1.83 |

| Round sample | 46 | 100,400,500 | 1.87 |

| Round sample | 61 | 100,400,500 | 1.84 |

Digital images of granules

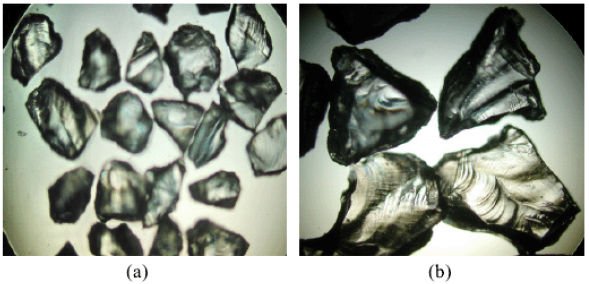

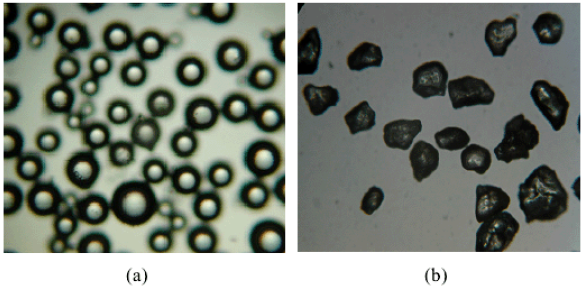

The digital images of the granules were acquired using a conventional optical microscope and are shown in Figure 4 (grains approximately 1 mm in diameter). The ground shapes of the grains are shown in Figure 4(a), and the angular shapes of the grains are shown in Figure 4(b). Because the angular shapes of the grains differ greatly, they are shown in Figure 5 (angular grains approximately 2 and 5 mm in diameter).

Figure 4 Digital images of grains of approximately 1 mm in diameter: (a) round gravel and (b) angular gravel

Results and Discussions

Test results

The loading equipment controlled by a servo motor may lose testing data at the moments of initial and final loading. When processing the test results, we need to select the 2nd, 3rd, and 4th circular data of each loading stage for the calculation in order to avoid this problem. The test results can be obtained by calculating the average dynamic shear modulus or damping ratio. In accordance with the difference of P 5 values, some results can be obtained, such as the dynamic shear modulus G d and the damping ratio I corresponding to different dynamic shear stress amplitudes λ s

When the effective confining pressure is not greater than 300 kPa, under the same conditions and the shear stress amplitude value γ d > 7x104, the round sample has a greater dynamic shear modulus. While with the shear stress amplitude value of γ d ≤ 7x10-4, an angular sample has a greater dynamic shear modulus. When the effective confining pressure is greater than 300 kPa, under the same conditions, the round sample has a higher dynamic shear modulus than the angular one. This is mainly because, under larger confining pressure and shear stress amplitude, the local broken angularity of the angular sample causes the occlusal force to decrease among the granules of the gravel, or local shear dilation phenomenon causes the dynamic shear modulus to decrease.

When the shear stress amplitude value y d ≤ 2x10-4, under the same conditions, the damping ratio of the round sample is approximately equal to that of the angular one. When the shear stress amplitude value y d > 2x10-4, under the same conditions, the round sample has a higher damping ratio than the angular one. The reason is that, when the external profile of granules is more irregular, the occlusal points among the granules are more in number, whereas the contact area of a single occlusal point is less. An increase in the shear stress amplitude would be expected to adversely affect relative sliding or rolling among the granules of the angular sample. Therefore, more energy is required to overcome the occlusal force and finishes the reconstitution of its structure. Thus, under the same conditions, the damping ratio of the angular sample is higher than that of the round one.

The effect of granule shape on the dynamic shear modulus

In order to investigate the effect of granule shape on the dynamic shear modulus, the effective confining pressure is normalised as follows:

where G d is the normalised dynamic shear modulus, d is the dynamic shear modulus, σ ' is the initial effective consolidation confining pressure, and Pα = 100 kPa is the atmospheric pressure.

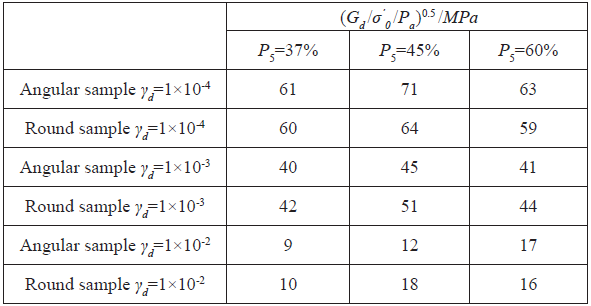

The calculation results of the normalised shear modulus corresponding to P5 and the shear stress amplitude value 1x104, 1x10-3, and 1x10-2 are listed in Table 2. This table indicates that, when the shear stress amplitude is 1x10-4, the angular sample has a greater dynamic shear modulus. The increase in the shear stress amplitude results in a large amount of relative rotation among the granules of the round sample, and much more obvious breakage is observed among the granules of the angular sample, which can lead to a significant decrease of the dynamic shear modulus of the angular sample. When the shear stress amplitude reaches 1x10-2, the large deformation will play a leading role in determining the soil properties but not the granule size and shape. In addition, the difference between the dynamic shear modulus of the round sample and the angular sample is small, but with the increase of gravel content, their dynamic shear modulus will increase.

By using the hyperbolic curve model, the relationship between the dynamic shear modulus G d and the shear stress amplitude y d can be expressed as follows:

when γ d, →0, G dmax . =1/m. Thus, the maximum dynamic shear modulus G dmax of all samples can be calculated.

The increase in the effective confining pressure led to an increase in the maximum dynamic shear modulus of the gravel. However, when the shape and P5 of the gravel are different, the growth rate is also different. When P5 = 37% or 45%, with the increase in the effective confining pressure, the growth rate of the maximum dynamic shear modulus of the round sample is greater than that of the angular one. When the effective confining pressure is greater than 300 kPa, under the same effective confining pressure, the maximum dynamic shear modulus of the round sample is 10% to 15% greater than that of the angular one; when P5 is 60% and the effective confining pressure is not greater than 300 kPa, the growth rate of the maximum dynamic shear modulus of the angular sample is faster, and its value is 3% to 5% greater than that for the round one.

Critical gravel content P 5cr of the maximum dynamic shear modulus

With the increase in gravel content, the maximum dynamic shear modulus of breccia gravel and round gravel all increase first and then decrease. This indicates that the effect of P 5 on the maximum dynamic shear modulus may have a limit. When P 5 reaches the critical value, the maximum dynamic shear modulus of the gravel also reaches its critical value. In order to verify this estimate and determine the critical value, the relationship between the maximum dynamic shear modulus and the confining pressure is investigated. When the effective consolidation pressures are 100, 300, and 500 kPa, respectively, the maximum dynamic shear modulus of the round sample and angular sample showed a significant "parabolic" trend with varying P This indicates that a critical value exists under different values ofP5, and the value is called P5cr, which is the critical gravel content of the maximum dynamic shear modulus. When P 5 is less than the critical value, the maximum dynamic shear modulus of the gravel will increase with increasing P 5 . When P 5 is greater than the critical value, the maximum shear modulus of gravel soil will decrease with increasing P 5 .

In order to investigate the effect of the granule shape on P 5cr , the effective confining pressure is normalized as follows:

where dmax is the normalised maximum dynamic shear modulus, G dmax is the maximum dynamic shear modulus, σ’0 is the initial effective consolidation confining pressure, and P α = 100 kPa is the atmospheric pressure.

The relationships between the normalised maximum dynamic shear modulus and P 5 have been derived. According to the test results, the parabolic fitting effect is appropriate. When the relative density is 45% and the effective confining pressure is not greater than 50kPa, the value of P5cr of the angular and round samples is approximately 51.2% and 48.5%, respectively.

Conclusions

Dynamic triaxial tests on round and angular samples of gravel were conducted to study the effects of the granular shape on the dynamic shear modulus and damping ratio at a relative density of 45%. The main conclusions are as follows:

The effects of the granular shape on the dynamic shear modulus are related to the effective confining pressure and shear stress amplitude. When the effective confining pressure is greater than 300 kPa or y d > 7x10-4, the round sample has a higher dynamic shear modulus than the angular sample. However, when the effective confining pressure is less than or equal to 300 kPa or γ d ≤ 7X10-4, the angular sample has a higher dynamic shear modulus than the round one.

A critical value of P 5 exists for which the dynamic shear modulus of the gravel is maximised. Under the same conditions, the P 5cr of the angular sample is greater than that of the round sample.

When γ d > 2x10-4, under the same conditions, the angular sample has a greater damping ratio than the round one.