Introduction

Cement refers to all kinds of authigenic minerals filling between clastic particles that are precipitated from colloids or true solutions in the sedimentary and diagenetic stages of clastic rocks. The formation of cement was affected by sedimentary environment, weathering conditions, cementitious process and other factors, whose cause of formation and composition are very complex. In recent years, with the development of technology, the research on cementing body has been developed rapidly. Especially in the micro field, with the deepening of the research on the microstructure of soil, it is found that the cement, as the interparticle and interstitial material, has a great influence on the properties of soil.

Some scholars have studied the microcosmic nature, spatial structure, connection mode, metasomatism and other aspects of cement. Cheng, Kang and Xu (1992) proposed that metal oxides and its hydrates deposited between clay particles play a role in cementing the soil mass, and verified the cementing role through microscopic methods and pointed out that the nature of cementing is a kind of chemical bond.

Jiang, Zhou and Chen (2013) simulated the mechanical properties of uncemented sand and cemented sand based on the rock and soil damage mechanics and the micro-damage mechanism, who proposed the constitutive model of anisotropic sand, which reflected the influence of cement on the mechanical properties of anisotropic sand from the side. Li and Shen (2007) studied the microscopic characteristics of structural soils in combination with the macroscopic mechanical behavior in the framework of damage mechanics, who gave the function expression of cementation and proposed the cementing crushing criterion and its mathematical expression. Kong and Guo (2001) further confirmed that the special properties of red clay were determined by its special cementing characteristics and microstructure, and the cementing of free iron oxide was only a part of it. Zhang, Kong, Chen, Li and Liu (2017) conducted in-depth research on Zhanjiang clay, who found that a large amount of iron in the water provided cementing materials for the connection of soil particles, and the acidic environment promoted the free iron oxide to produce cementing effect, thus improving the structural strength of the soil. Yao, Liu and Cheng (2001) calculated the theoretical value of the cohesive force of guizhou red clay by using the microscopic bonding mechanism and model of synthetic gossyte bonded kaolin, which reflected the bonding effect of iron compounds from the side. Gan, Sheng and Tian (2017). analyzed the possible chemical structure of the cementation formed by the adsorption of clay mineral cells on other cementing substances or cations in soil particles in gobi gravel soil, established the micromechanical model of the cementing force action of gobi gravel soil, and provided a beneficial reference for the analysis of the cementing characteristics of other soils.

More and more scholars study the engineering application of cementation. By adding, changing and other physical or chemical actions, the cementing material can be used as curing agent or catalyst to improve the engineering materials, especially for the special soils such as red clay, soft soil (Jian, Zhang, & Huang, 2013), sandy soil (Li & Yu, 2009), calcareous sand (Zhu, Zhou, & Liu, 2014) and industrial raw materials (Jiang, Xiao, Sun, & Wu, 2012; Feng, D. Liu, F. Liu, W. Liu, & Han, 2016; Wei, Yang, & Gao, 2013; Deng et al., 2016).

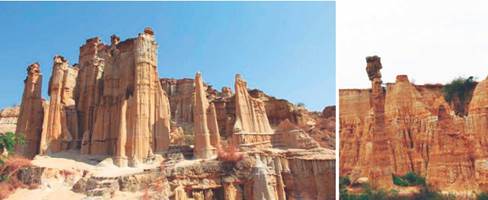

Author's team conducted scientific research on Earth Forest (Qian & Ling, 1989) in Banguo of Yunnan province of China, who found that the height of the cylinder, generally between 8 ~ 30 m, up to 42.8 m (earth forest in Langbapu of Xin hua town) (Fig. 1), which is far more than general soil height of self-reliance. The most important reason is that there are much ferruginous cementation body on the top and internal of the cylinder, which blocks the surface water erosion and enhances the strength of the cylinder. This paper hopes to understand the composition, microstructure, bonding characteristics and development process of the cementitious material by studying the ferric cementitious material in the cylinder of soil forest, so as to provide some theoretical basis for further research.

Methodology

Physical and mechanical test

The existing earth forest in yuanmou area are mainly composed of Wumao earth forest, Banguo earth forest and Langbapu earth forest. Three representative groups of ferruginous cementitious bodies (no less than 6 samples in each group) are selected from the ferruginous cementitious layers (the strata containing ferruginous cementitious bodies) ofthree soil forests.:bg3-®(Banguo), wm1-jj(Wumao), lbp1-®(Langbapu). In addition, three groups of samples were taken from the strata below the ferruginous cementation layer of bangotu forest: bg3-2, bg3-3, and bg3-4 (Fig. 2).

Figure 2 Ban Guo sampling points and partial formation samples (a)bg3 sampling point (b)bg3- ①-1 (c)bg3- ②-1 (d)bg3- ③-1 (e)bg3- ④-1 (f)wm1-jj-4(g)wm1- ⑤-2 (h)lbp1- ①-9 (i)lbp1- ③-3

Firstly, ferritic cementites at different sampling points were compared, and then the most representative bg3 sampling point was selected to compare ferriferous cementitious strata with those without ferriferous cementitious strata (chapter 4 for component analysis).

Due to the high density, large pore ratio and poor integrity of the ferric cement of earth forest, it is easy to disintegrate when cutting. Its own characteristics are irregular, so it is difficult to make standard samples for strength test. In this paper, point load meter and uniaxial press were used to conduct multiple groups of tests on a single sample, and then the relative empirical strength value was converted according to the specifications (Tab.1 ). Then the corresponding scanning electron microscope test was conducted on each group of samples.

Table 1 List of physical properties of each layer

| Sample number | Natural compressive strength (MPa) | Dry compressive strength (MPa) | Saturated compressive strength (MPa) | Water absorption (%) | Porosity (%) | Dry density (g/cm3) | Wet density (g/cm3) | Iithology |

| bg3- ①-1 | 5.92 | 7.59 | 2.88 | 8.60 | 18.29 | 2.13 | 2.32 | Ferruginous cementation |

| bg3- ②-1 | 2.74 | 5.06 | / | 1.88 | 4.07 | 2.17 | 2.21 | coarse sand |

| bg3- ③-1 | 3.83 | 9.67 | / | 8.04 | 14.47 | 1.8 | 1.95 | silty clay |

| bg3- ④-1 | 1.49 | 2.57 | / | / | / | 1.59* | / | breccia |

| wm1-jj-4 | 7.98 | 15.26 | 5.98 | 7.66 | 16.62 | 2.17 | 2.34 | Ferruginous cementation |

| wm1- ⑤-2 | 0.72 | 3.51 | / | 11.4 | 18.48 | 1.63 | 1.82 | silt |

| lbp1- ①-9 | 2.29 | 5.49 | / | 10.83 | 21.38 | 1.97 | 2.19 | Ferruginous cementation |

| lbp1- ③-3 | 2.54 | 4.41 | / | 12.14 | 22.69 | 1.87 | 2.10 | silt |

Note: (1) sample number meaning: bg (sampling area) 3 (sampling point) - ① (stratum) -1 (sample number);

(2) * represents the physical index measured by wax seal method. By comparison, the strength of the samples with ferric cement was significantly higher than that without ferric cement. In addition to the ferruginous cement, the other samples disintegrated rapidly in water, and the saturated compressive strength could not be measured. Standard samples for uniaxial compression were prepared by careful cutting of individual silt samples.

SEM test

The SEM tests were carried out in Yunnan Key Laboratory for Palaeobiology and Yunnan University modern analysis and Testing Center. FEI Quanta 650FEG , the high-resolution field-emission scanning electron microscopy with Energy Dispersive Spectrometer(EDS) was used to get secondary electron imaging(ETD), backscattered electron imaging(BSED) and the elementary composition, from which we could know the changes of microstructure and mineral composition, so as to obtain the important information such as the spatial distribution, growth process and cementation characteristics of ferruginous cement.

Structural features

Earth forest in Yuanmou area were formed in the pliocene ~ holocene from semi-consolidated fluvial and lacustrine sediments cut by flowing water. Its ferruginous cement layer is mainly composed of clastic rock particles, and the interstitial materials are sand, silt, clay minerals and ferruginous cement. The parent rock components of clastic rock particles are mainly sandstone and granite, containing a small amount of mineral debris. The psephicity is mainly sub-circular and sub-angular, with good gradation. Clay minerals are mainly kaolinite and its products in different forms, and a small amount of illite. The ferric cementite has both the lamellar structure of kaolinite and the spherical shape of ferric compound, which is generated by the chemical interaction between the two. The initial form of the ferric cementite monomer is spherical.

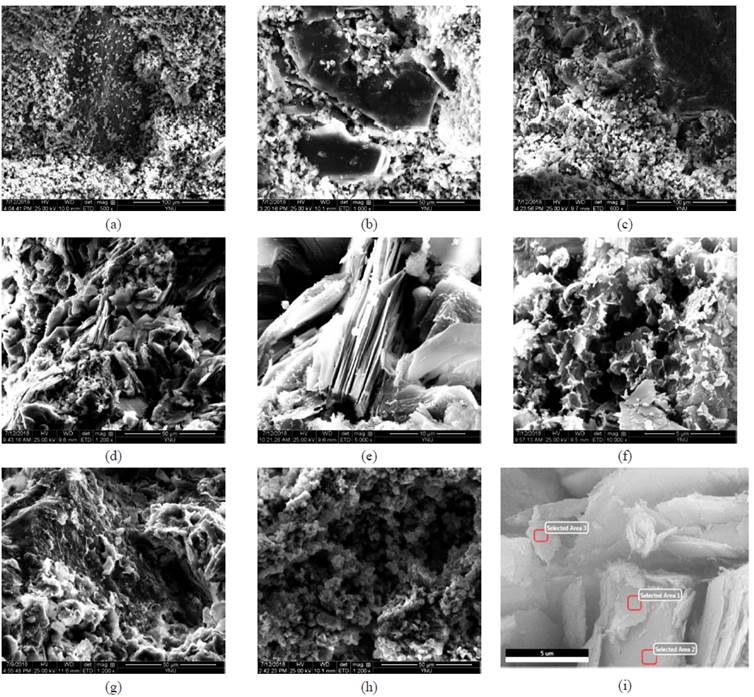

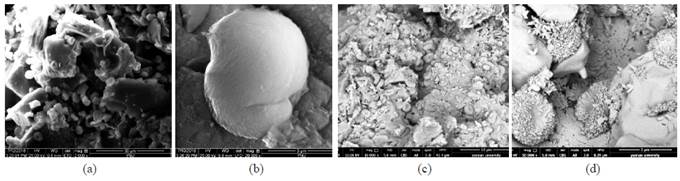

The structure of each component can be observed under an electron microscope. We can find that the cementation type between particles are mainly basal cementation (Fig. 3a) and contact cementation(Fig. 3b). From Figure 3, ferruginous cement with small spheroidal shape are presented obviously, some of which are growing on the surface of quartz grains (Fig. 3a) and the other of which are agglomerating with clay minerals (Fig. 3b, c). The Clay minerals and ferruginous cement fill the void between the particles (Fig. 3a, b, c), which connect and reinforce the particles, and affect the overall strength and failure mode of the soil. During the failure, the fracture surface will avoid the larger particles and rupture along the filling path.

Figure 3 Microstructure characteristics under the microscope of earth forest cementation layer (a) basal cementation (b) contact cementation (c) cement fills pores (d) book page-like and lamellar of kaolinite (e) book page-like kaolinite (f) petal-like kaolinite (g) clay mineral on the surface of quartz particles (h) Conversion of alumina quartz to kaolinite (i) illite

The main components of clay minerals are kaolinite and illite (Fig. 3i, Section 4), which are mainly in the form of cementing materials and come with ferruginous cement. The clay minerals appear as irregular book pagelike (Fig. 3d, e), lamellar (Fig. 3e, I, Section 4) and petal-like (Fig. 3f). Some microscopic processes of chemical interaction can also be observed, such as the transformation of aluminite to kaolinite (Fig. 3h), the continuous growth and entanglement of clay minerals and ferruginous cement (Fig. 3c).

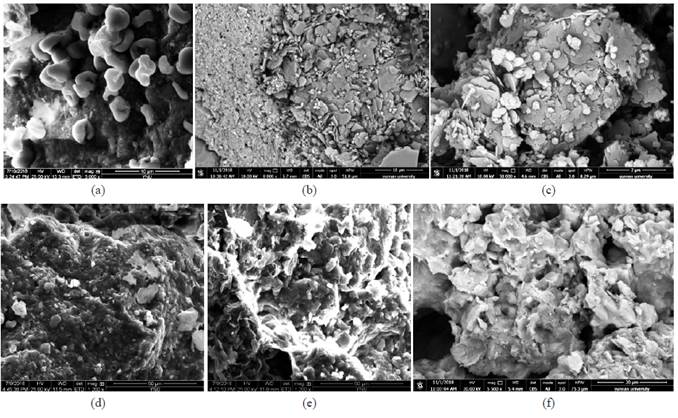

Through electron microscopy scanning test, we found spherical ferruginous cement in the samples collected at three sampling points: bg3- ①-1 (Banguo), wm1-jj-4 (Wumao), lbp1- ①-9 (Langbapu)(Fig. 4a, b, c). However, at the same sampling point, no spheroids were found in the non- ferruginous cement stratum, such as bg3- ②-1, lbp1- ③-3, wm1- ⑤-2. Only a small amount of clay minerals, quartz particles, and granular debris were observed. (Fig. 4d, e, f). Therefore, i ferruginous cement can greatly enhance the strength of soil.

Figure 4 Comparison of iron compounds in the cementation layer (a) bg3- ①-1 (b) wm1-jj-4 (c) lbp1- ①-9 (d) bg3- ②-1 (e) wm1- ②-2 (f) lbp1- ③-3

To sum up, the ferruginous cement stratum is mainly composed of ferruginous cement and a small amount of clay minerals. The ferruginous cement is formed by the chemical interaction between ferruginous compounds and clay minerals. Some clay minerals react with iron oxides to form spherical ferruginous cement and some exist freely in pores.

There were certain differences in the microstructure of the spherical ferruginous cement found at the three sampling points. From Figure 4a (bg3- ①-1), the ferruginous cement was shaped like a red blood cell, with a depression in the center of the sphere and growing on the surface of quartz crystal. From Figure 4b (wm1-jj-4), the spherical ferruginous cement also has depressions in the center of the spheres and is grown in lamellar kaolinit. From Figure 4c (lbp1- ①-9) The shape of spherical ferruginous cement is like a flower bud, and the depression in the middle is not obvious. It is more similar to many small laminated spheres, and also grows in the clay mineral dominated by lamellar kaolinite. The difference of spheroid morphology should be caused by the difference of compound composition, content and development environment.

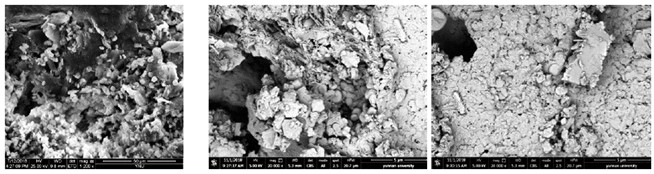

Microstructure and growth process of ferruginous cement

In order to further understand the characteristics of the spherical ferruginous cement, the most typical microstructure of bg3- ① layer was chosen as the research object, whose ferruginous cement looked like red blood cells (Fig. 5a) and had obvious grooves in the central part. Through secondary electron probe and back scattering, flagella and acupuncture protrusion could clearly be seen on the surface of spheroid (Fig. 5b, d). Considering the Angle and the penetration of the electron beam, these ferruginous cements were actually composed of many lamellar structures stacked on top of each other. They were very dense and had a high bonding strength.

Figure 5 Microscopic morphology of iron compounds (a) Secondary electronic image (b) A larger view of Fig. 5a (c) Backscatter electron image (d) A larger view of Fig. 5c

At the beginning, the ferruginous compounds enriched on the particle surface, who reacted with kaolinite gradually to generate small globular individuals. The number of these spheroids whose diameter was only 1 ~ 5 microns were increasing and began to agglomerate in the low depression (Fig. 6a, b). At the same time, these spheroids were entangled with the free clay minerals, especially the lamellar kaolinite, forming a large layered spatial structure to fill the pores between the particles (Fig. 6c). We could clearly see that the spheroids were tightly packed together, compressed and deformed into a single piece, and a flaky structure emerging from the body at the fracture.

Figure 6 The growth of iron compounds (a) Compound aggregation under ETD probe (b) Compound aggregation under CBS probe (c) Gathered in layers under CBS probe

At this point, the space between the particles was filled with dense interstitial materials formed by ferruginous cement and clay minerals, which greatly improved the strength of the ferruginous cement layer.

Energy Dispersive Spectrometer (EDS)

EDS was used to confirm the existence of iron cement and clay minerals while observing the microstructure. However, due to the influence of composition change of the compound itself and electron beam penetration and other factors, the molecular formula of the target compound could not be accurately determined, and its phase composition could only be qualitatively determined.

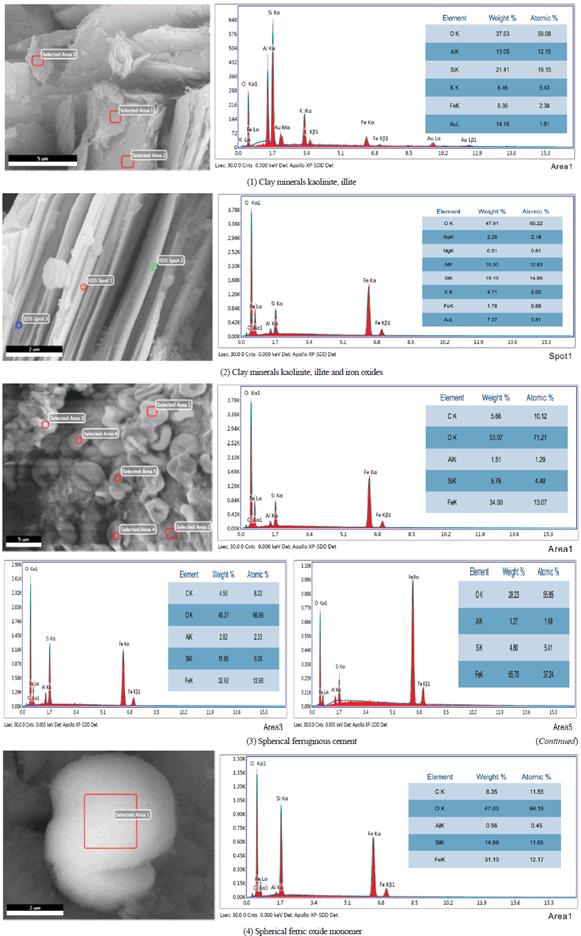

In order to further understand the properties of ferruginous cement, energy spectrum analysis was focused on the samples of bg3-3. The four energy spectra in figure 7 were all from the bg3-3 layer.

In the figure, Weight% represents the mass percentage of each element at the sampling point. Atomic% is the percentage of atoms.

As can be seen from Figure 7 (1) and (2), O, Si, Al, Fe and K were the main cementing substances at this sampling point, with a small amount of Na and Mg.

The Selected Area results show that the mass percentage contents of O, Si, Al, Fe and K were respectivery32.6%~49.7%, 21.4%~26.5%, 8.5%~15.4%, 3.7%~12.5%, 3.0%~9.3%. According to relevant works (Zhang & Yang, 2013) and specifications (Research Institute of Petroleum Exploration and Development, 2014), it could be judged that the cementing materials here were mainly kaolinite, illite (or imonote) and iron oxides. Figure 7 (3) shows the agglomeration area of ferruginous cement. The main compounds were O, Fe, Si and Al, whose mass percentage were respectively: 28.2%~53.1%,17.5%~65.7%, 4.8%~32.8%, 0.91%~3.73%. The content offerrum was obviously high. Figure 7 (4) shows the spherical ferric oxide monomer. It was found that the main elements were O, Fe, Si, C, and a small amount of Al, with the mass content of 47%, 31.1%, 15.0%, 6.53% and 0.56%.

The clay minerals in the ferruginous cement were mainly kaolinite (Al2Si2O5(OH)4), and the structure of unit layer is 1:1 type, that is, a layer of silicon-oxygen tetrahedral sheet and an aluminum -oxygen octahedral sheet are compounded, and the two layers are connected by hydrogen bonds. The pores of the octahedron are easily filled by cations such as Al, Mg and Fe, forming octahedral lamellar structures with common edges. Meanwhile, Si4+ in the tetrahedron and Al3+ in the octahedron are easily replaced by other cations, such as Fe3+. The excess charge generated is easy to exchange with other metal cations and adsorb other cement or soil particles with cations. Therefore, it was most likely that the Si4+ and Al3+ between the original kaolinite layers were replaced by Fe3+ to form new compounds. From figure 5 d, 6 C, the section of the spheroid was observed, whose internal structure was characterized by lamellar clay minerals, while the external morphology has the characteristic of spherical microstructure of ferric oxide (Chen, 2014) (Fig.7 (4)). For the ferric oxide has obvious phase, it can be judged as a new compound formed by the chemical interaction between ferric oxide and kaolinite, whose main elements were O, Fe, Si, C, Al orderly. Due to the difficulty in extracting iron cement and the lack of control materials affecting the effect of XRD, the determination of its molecular formula needs further research.

Conclusion

(1) The main component of earth forest in Yuanmou area is semi -diagenetic conglomerate, whose particles with high strength comes from the mother rock clastics. Its overall strength and failure mode are determined by the ferruginous cement between the particles. The formation strength with ferric cement was obviously higher than that without ferric cement.

(2) The ferric cementation layer contained a large number of ferruginous cement, which were cemented with clay minerals (mainly kaolinite) to form a stable lamellar structure filling between the pores of the particles, greatly improving the strength of the ferric cementation layer.

(3) The microscopic morphology of these ferruginous cement was spherical. Under the microscope, it could be observed that the growth and development of the particles on the surface, agglomeration, entanglement and coiling of the clay minerals, and finally the process of connecting into a sheet. The results of EDS showed that the spheroidal ferric cement was a new compound formed by ferric oxide and kaolinite, whose Al3+ and Si4+ between layers were replaced by Fe3+. The new oxide compound had the lamellar characteristics of clay minerals in the interior and the spheroidal characteristics of iron oxides in the exterior.

(4) The newly discovered spherical ferruginous cement has enriched the research content of ferruginous cement. The next step is to understand its chemical bonding process and analyze its chemical formula. Based on the above results, the further possibility of using it as a natural curing agent should be carried out.