Introduction

As an important part of energy, oil is the foundation of national economic development. In recent years, conventional energy has been unable to meet human needs, so unconventional energy has come into people's vision, and people pay more and more attention to unconventional energy (Luo et al., 2018). As an important part of unconventional energy, the proportion of tight sandstone reservoirs in energy utilization is also increasing. The exploration shows that the geological reserves of tight reservoirs are relatively high, but at present the recovery rate is relatively low, and there is a huge potential for exploration.

The permeability of tight oil reservoir is very low, the pore structure is very complex and the heterogeneity is very serious. Without natural modification, its seepage resistance is large and its natural productivity is very low, which makes it impossible to achieve large-scale and effective development. Although many researchers have conducted in-depth research on the development of tight reservoirs, and at the same time, many development strategies have been put forward, some of which have achieved good results, but there are also some limitations (Guo et al., 2018). When a tight reservoir is fractured, there is mutual interference between fractures, and it is unavoidable. Segmental multi-cluster fracturing technology applied to tight reservoirs can be defined as volume modification technology. Manpower fracture formed by reconstruction measures can activate natural micro-fracture in reservoir and form complex fracture net system (Naik et al., 2018). However, ihe epecific form of complex sewing nets, how to influence productivity, how to give full play to the advantages of sewing nets in reservoir development, so as to reduce the adverse effects of sewing nets, need more in-depth study.

At present, the development of tight reservoirs is still in the exploratory stage. There is no specific description of seepage characteristics near wells of volume fractured horizontal wells in tight reservoirs. It is necessary to study relevant seepage theory and numerical simulation, establish relevant productivity prediction models, analyze the technical methods and fracturing development design methods for improving single well productivity of volume fractured horizontal wells in tight reservoirs, and provides theoretical support for the development of tight reservoirs.

Steady-state productivity of fractured horizontal wells in tight reservoirs

Comparison of productivity models for fractured horizontal wells in tight reservoirs

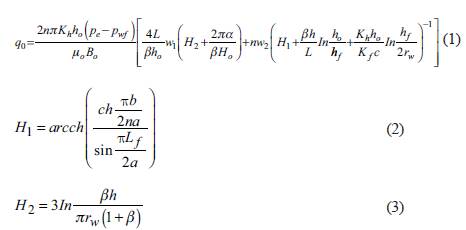

The steady-state solution of rectangular boundary reservoir with vertical fracture is studied. Then, on this basis, the steady productivity formula of fractured horizontal wells is established. The model assumes that a horizontal well exists in the center of a rectangular reservoir, and the streamline flows radially into the horizontal wellbore from the direction perpendicular to the horizontal section. The steady-state productivity formula of fractured horizontal wells can be expressed by image reflection method and superposition principle.

The advantage of Fan Zifei's model is that the equation is simple, which can adjust the thickness ofthe fractured reservoir and consider the heterogeneity of the reservoir. However, the disadvantage of this model is that it does not consider the interaction between fractures and the process of fluid flowing from matrix to wellbore during production.

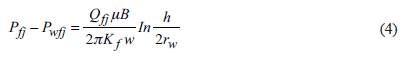

Compared with the radius of horizontal wellbore, the half-length of fracture is larger. When the influence of gravity is neglected, the flow process of fluid in fracture near wellbore can be simplified to plane radial flow, which means that formation thickness is w, flow radius is h/2, boundary pressure is pfj and bottom hole pressure is Pwfj. When the skin factor of crack is neglected, the expression is as follows:

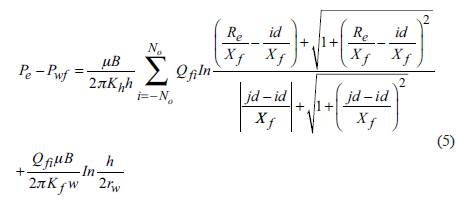

If the pressure at the bottom of all fractures equals the pressure at the bottom of the well, that is to say P wff = p wf , it can be obtained that:

According to the parity of the number of cracks n, the order from -No to No is adopted for j. Therefore, a set of equations can be generated which can be solved in closed form. The output Qfi of each crack can be obtained by using the column principal component Gauss-Jordan numerical solution method.

The numerical value of the production of all fractures and the total production of fractured horizontal wells are as follows:

Ning Zhengfu's model assumes that each fracture has different production values, and the seepage resistance of fluid in the fracture is taken into account. Compared with Lang Zhaoxin's equation, the advantage of this equation is that the hypothetical conditions of the model are more in line with the actual production situation of fractured horizontal wells, so it has stronger applicability (Zhuoheng et al., 2018). At the same time, the disadvantage of this model is that the pressure drop in horizontal wellbore is not taken into account.

Based on the theory of seepage equivalent resistance, Li et al. established the productivity equation of fractured horizontal wells.

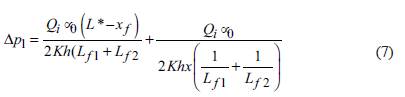

For the formation with fractured horizontal wells, fluid flow from formation to horizontal wellbore can be divided into two stages. In the first stage, fluid flows from formation to fracture. In the second stage, the fluid flows from the fracture to the horizontal wellbore. When n fractures are fractured in horizontal wells, the whole flow area can be divided into n regions. The fracture is the center of each flow area. The pressure drop of fluid flowing from formation to fracture is as follows:

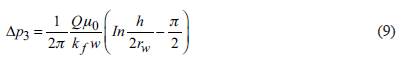

The pressure drop of fluid flowing from fracture to horizontal wellbore is as follows:

The pressure drop produced by fluid flowing into the wellbore in a fracture is:

Since,

It can be obtained that:

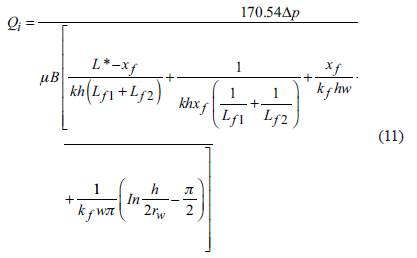

The total flow rate of n vertical fractures is as follows:

The advantage of Li model is that it can control the perforation state of horizontal well section and distinguish the end fracture from the middle fracture. At the same time, the model also has shortcomings. It does not take into account the loss of pressure drop in horizontal wellbore and the decline of fracture conductivity with time.

Establishment of steady-state productivity model

In order to describe the special percolation process of tight reservoir, the model is simplified as a single fracture. At this time, the flow process of crude oil is divided into three stages: the flow in matrix (non-linear flow from matrix to fracture wall), the flow from fracture wall to wellbore (plane radial flow) and the flow in wellbore (pressure drop due to resistance along the way) (Qun et al., 2018). In the solution process, the first two processes are coupled to obtain the equivalent radius of the vertical well and the equivalent diameter in the presence of a single fracture. Then, the multiple fractures are converted into corresponding production wells, and the oil production of each fracture under the condition of multiple fractures is obtained by pressure drop superposition. Finally, the pressure drop flow in the horizontal wellbore is considered and combined with the previous output to carry out the iterative solution (Peng et al., 2018). Finally, the oil production under the control of each fracture can be obtained. The total oil production of horizontal wells after fracturing can be obtained by summing up the production of each fracture, as shown in Figure 1.

If there is no interference between the cracks and the fluid in the matrix flows to the cracks, any crack can be regarded as an elliptical seepage flow.

If any fracture is selected, the oil drainage area formed by fluid flowing from matrix to fracture is elliptical. If the long half-axis of the ellipse is a, the short half-axis is b, and the focal length, that is, the half-length of the crack, be

, the following equation can be obtained.

, the following equation can be obtained.

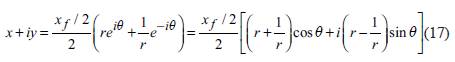

Here, the elliptical flow in z plane is transformed into radial flow in £ plane by conformal transformation.

The transformation coefficient is:

Equation 14 is a Rokovsky equation, in which

If equations 15 and 16 are brought into the upper equation, there are

By calculating the steady-state productivity equations under various conditions, the results are analyzed. The results show that the calculated results by Ning zhengfu's method are the closest to those by the productivity equation deduced in this study, but these results are higher than the actual productivity (Yin, 2018). This is because both methods are based on the assumption that there is no interference from other fractures in the control area of a single fracture. At the same time, the assumed conditions in this equation do not accord with the actual situation, that is, assuming that the formation is homogeneous reservoir, the fracture can completely penetrate the reservoir (Wei-Yao, & Dong-Xu, 2018). Therefore, although the productivity equation in this study can roughly predict reservoir productivity, it needs to be further adjusted to meet the actual situation.

Influencing factors of productivity of volume fractured horizontal wells in dense reservoirs

Reservoir characteristics

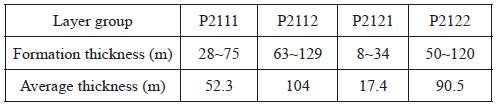

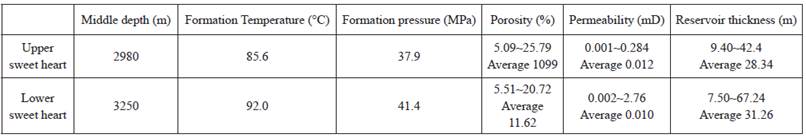

The oil-bearing formation is located in Lucaogou Formation of Permian, which is divided into four units: P2121, P2122, P2111 and P2122 from bottom to top. The thickness of each unit layer group is shown in Table 1.

Upper sweet heart (P222) and lower sweet heart (P212) are developed in Lucaogou group. Reservoir physical parameters are shown in table 2, and the formation thickness between upper and lower desserts is 83.3m~131.7m, with an average of 108.4m. According to pore and permeability distribution, it is a typical tight oil reservoir.

Productivity increasing potential evaluation of volume fracturing horizontal wells

With the continuous development of horizontal wells and fracturing measures, economic development of tight reservoirs has been realized under the multi-stage fracturing horizontal wells. At present, the tight reservoirs developed in China are mainly in Ordos Basin and Songliao Basin. The cluster well development initially adopted has not achieved satisfactory results. In recent years, the application of volume fracturing horizontal wells in tight reservoirs has achieved good results (Long et al., 2018). Based on the characteristics of tight reservoirs, the application research of horizontal wells, conventional fractured horizontal wells and volumetric fractured horizontal wells is carried out in the depletion development of tight reservoirs.

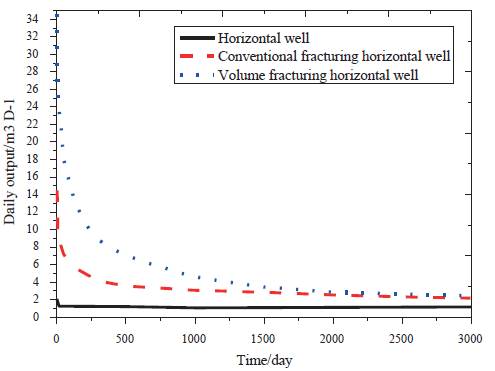

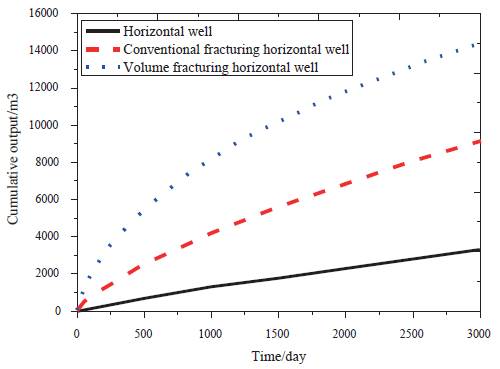

According to the physical characteristics of tight reservoir, the permeability of formation matrix is 0.05mD. Considering formation heterogeneity, Kx = Ky, Kz = 0.1Kx, porosity 10%, effective thickness of reservoir 15m, original formation pressure 18.6MPa, productivity and cumulative production of horizontal well, conventional fractured horizontal well and volumetric fractured horizontal well in tight reservoir are analyzed.

From figures 2 and 3, it can be seen that conventional fractured horizontal wells in tight reservoirs have higher productivity than conventional fractured horizontal wells, while volumetric fractured horizontal wells have much higher productivity than conventional fractured horizontal wells, and the corresponding cumulative production is also much larger. The production of horizontal wells is always at a low level during production. The production of conventional fractured horizontal wells is higher at the initial stage, while that of volumetric fractured horizontal wells is higher at the initial stage, and then decreases with production (Ren et al., 2019). The reason is that in horizontal wells, the use range is small, only near the horizontal wells. Conventional volume fracturing horizontal wells are used only in fracture wave and small area. Volume fractured horizontal wells have higher production and cumulative production because of the role of fracturing net and a wide use range.

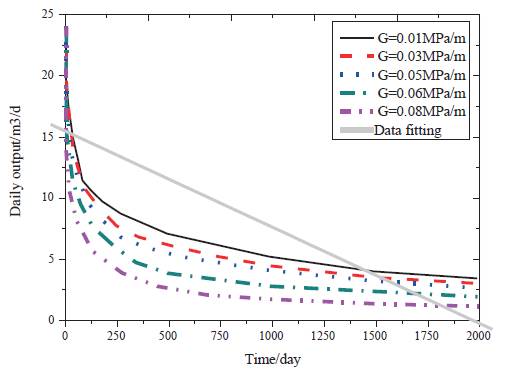

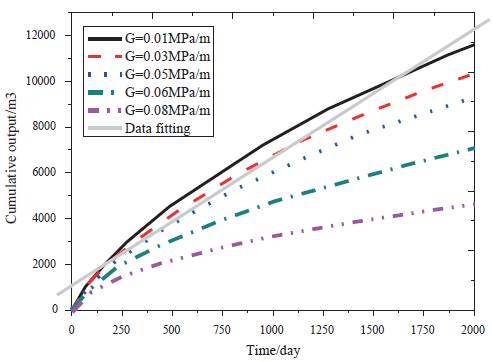

Effect of starting pressure gradient on capacity

Because of the low porosity and permeability of tight reservoirs and the serious heterogeneity, the fluid from static to flowing needs to overcome certain binding force. Only when the pressure gradient exceeds a certain critical value can the fluid flow. The critical value is called the starting pressure gradient. The starting pressure gradient varies with the change of reservoir physical permeability. The starting pressure gradients are taken as G=0.01MPa/m, 0.03MPa/m, 0.05MPa/m, 0.06MPa/m and 0.08MPa/m, respectively. The effect of start-up pressure gradient on productivity of horizontal well in volume fracturing is analyzed.

Figure 4 and figure 5 are daily production curves and cumulative production curves with different starting pressure gradients. From the daily production curve, it can be seen that the daily production decreases with the increase of starting pressure gradient, and the recovery degree decreases with the increase of starting pressure gradient. When the starting pressure gradient is 0.08MPa/m, the productivity and recovery degree are very low. This is because the bigger the start-up pressure gradient of reservoir is, the higher the pressure gradient required for fluid flow in reservoir will be, thus the pressure sweep range will be reduced, the use range will be reduced, and the recovery factor will be reduced.

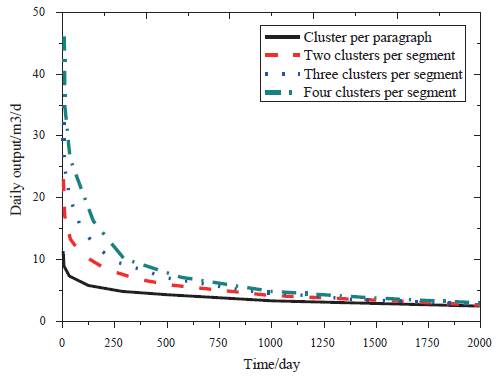

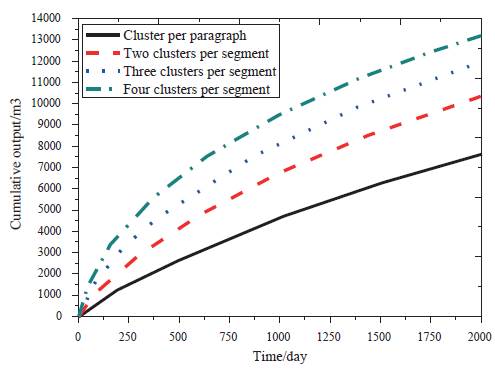

Effect of fracture cluster number on productivity

Volume fracturing is used to fracturing horizontal wells in many stages, and many clusters of fractures are produced in each stage. The number of fracture clusters affects the degree of opening natural fractures in each section and the degree of reformation in the fracturing reconstruction area. The number of fracture clusters in each section is designed as four schemes: 1 piece, 2 pieces, 3 pieces and 4 pieces, respectively. The effect of the number of fracture clusters on the productivity is analyzed.

Figures 6 and 7 are daily and cumulative production curves for each segment with different cluster numbers. It can be seen from the daily production curve that the production increases with the increase of cluster number. Moreover, the number of clusters has a great influence on the initial and intermediate stages of production. The more the number of cracks clusters in each section is, the greater the density of artificial and natural cracks communicated is, the greater the degree of fracturing reconstruction area transformation is, and the greater the productivity is.

Conclusion

According to the characteristics of tight reservoir and considering the characteristics of volume fracturing, according to the basic principles of percolation mechanics and reservoir engineering, experimental research, theoretical derivation, numerical simulation and other research methods have been adopted to comprehensively study the percolation characteristics, productivity evaluation and utilization characteristics of volume fracturing in tight reservoir, analyze the development effects under different well pattern and different development modes, and establish the seepage model and productivity prediction model of horizontal well reservoir with compact oil volume fracturing, and form the productivity prediction module. Compared with the horizontal wells without volume fracturing, the horizontal wells with multi-stage cluster fracturing enlarge the reconstruction volume, reduce the seepage resistance and increase productivity. Because the permeability of tight reservoir is very low, the daily production is higher in the initial stage and the production decreases rapidly. Under the same cluster number, the smaller the cluster spacing between intervals and the cluster spacing within intervals is, that is, the more uniform the distribution of fractures in horizontal wells is, the higher the productivity of horizontal wells is. For the same series, the more uniform the section number distribution is, the higher the production of the oil well is. Therefore, in fracturing operation of tight reservoirs, in horizontal wells, the more uniform the distribution of interval and cluster spacing is, the better.

In view of the seepage characteristics of unconventional tight reservoirs, on the basis of the derivation method of Lang Zhaoxin's equation, considering the starting fracturing gradient, the productivity equation of fractured horizontal wells is derived. The productivity equation takes into account the loss of flow pressure caused by seepage resistance in cracks, and fully reflects the characteristic parameters of actual cracks, such as unequal length, unequal conductivity and unequal spacing. It is closer to the actual situation than the new equation of Lang Zhaoxin, and more suitable for productivity evaluation of fractured horizontal wells in tight reservoirs. The new productivity equation only considers the steady-state flow of single-phase fluid, does not consider the effect of pressure sensitivity on the production of horizontal wells in tight reservoirs, and ignores the pressure loss of fluid flow in horizontal wellbore, so it needs to be more perfect and closer to the actual productivity equation of fractured horizontal wells.