Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería y Ciencia

Print version ISSN 1794-9165

ing.cienc. vol.11 no.21 Medellín Jan./June 2015

https://doi.org/10.17230/ingciencia.11.21.7

ARTÍCULO ORIGINAL

doi:10.17230/ingciencia.11.21.7

Effect of Mixed Liquor Volatile Suspended Solids on Membrane Fouling During Short and long-term Operation of Membrane Bioreactor

Efecto de los Sólidos Suspendidos Volátiles del Licor Mezclado en el ensuciamiento de las membranas durante la operación de un Bioreactor con Membranas a corto y largo plazo

Edson Baltazar Estrada-Arriaga1, Petia Mijaylova Nacheva2 and Liliana García-Sánchez 3

1 Instituto Mexicano de Tecnología del Agua, Morelos, México, edson_estrada@tlaloc.imta.mx.

2 Instituto Mexicano de Tecnología del Agua, Morelos, México, petiam@tlaloc.imta.mx.

3 Universidad Nacional Autónoma de México, Morelos, México, lilian_gs11@hotmail.com.

Received: 13-10-2014 | Acepted: 02-12-2014 | Online: 30-01-2015

PACS: 87.18.-h, 92.40.kc, 87.16.dj, 92.40.Qk, 47.63.-b

Abstract

The aim of this study was to examine the impact of different Mixed Liquor Volatile Suspended Solids (MLVSS) concentrations on membrane fouling, in a submerged Membrane Bioreactor (MBR) at short and long-term MBR operation for wastewater treatment. Three laboratory-scale in a submerged MBR system were operated under critical flux, sub-critical flux, and an intermittent suction time and backwashing conditions. At short-term MBR operation with mixed liquors of 4,200 and 6,150 mg MLVSS L−1, the hydraulic resistance of membranes followed a same trajectory with averages of 5.0E+12 m−1, whereas for 7,940 mg MLVSS L−1, a high resistance of up to 1.7E+13 m−1 was obtained. The result showed that high biomass concentrations decreased to permeability due to a bio-layer formed in the membrane surface and high Extracellular Polymeric Substance (EPS).

Key words: membrane bioreactor; membrane fouling; volatile suspended solid; extracellular polymeric substances

Resumen

El objetivo del estudio fue examinar el impacto de diferentes concentraciones de sólidos suspendidos volátiles del licor mezclado en el ensuciamiento de las membranas en un bio-reactor con membranas sumergidas (BRMS) en periodos cortos y largos de operación durante el tratamiento del agua residual. Tres BRMS a escala laboratorio fueron operados bajo condiciones críticas, sub-críticas y condiciones de succión intermitente y retrolavados. En cortos tiempos de operación de los BRMS con concentraciones de licor mezclado de 4,200 y 6,150 mg SSVLM L−1, la resistencia hidráulica de las membranas se comportó de manera similar con un promedio de 5.0E+12 m−1 , mientras para una concentración de 7,940 mg SSVLM L−1, su obtuvo una alta resistencia con valores de 1.7E+13 m−1. Los resultados mostraron que con concentraciones altas de biomasa la permeabilidad de las membranas disminuye debido a la formación de una biopelícula en la superficie de las membranas y a la presencia de Sustancia Poliméricas Extracelulares (SPE).

Palabras clave: bio-reactor con membranas; ensuciamiento de las membranas; sólidos suspendidos volátiles; sustancias poliméricas extracelulares

1 Introduction

The membrane bioreactor (MBR) is a novel technology that combines biodegradation and membrane separation. Although MBR has many advantages, membrane fouling is still a major problem of the MBR operation, which results in more frequent membrane cleaning and higher operation and maintenance costs. Studies have concluded that the characteristics and degree of membrane fouling are mainly affected by membrane properties, sludge characteristics (Mixed Liquor Volatile Suspended Solid (MLVSS)), and operational conditions [1]. Disadvantages of higher sludge concentrations with respect to conventional activated sludge include limitations of oxygen diffusion, leading to an increased aeration cost, possible mass transfer limitations, and enhanced fouling, which may require more frequent membrane cleaning [2],[3],[4],[5],[6],[7],[8] showing that the adsorption of Extracellular Polymeric Substances (EPS) and Biopolymer Clusters (BPC), leading to further sludge deposition and serious membrane fouling in MBR operation. The major fouling contributors in MBR are EPS, which are excreted by biofilm development over surface membranes [7],[9].

The major challenge for the MBR is the selection and optimization of the operating flux. Since fouling phenomena appears to be inherent to the MBR operation, the concept of sustainable flux is used for long-term operations. This flux is related to critical flux, and it is the one at which the Transmembrane Pressure (TMP) increases gradually at an acceptable rate, so that frequent chemical cleaning is not necessary. Control of the sustainable flux also impacts on the ability to process variable feed flows, such as dry and wet weather. Thus, a constant flux operation under the nominal critical flux is more advantageous for MBRs, as it will prevent excessive membrane fouling [10],[11],[12]. Classic critical flux depends on hydrodynamic factors and feed characteristics [13], and these are likely to control the sustainable flux in an MBR. Thus aeration rate, liquid flow regime, and concentration of mixed liquor can be expected to affect TMP rise and sustainable flux. In order to lengthen the operation period of the MBR, operation under critical flux is often one of the strategies since it reduces the deposition of particles on/into membrane surface. However, the TMP increment is still observed after a critical time even under sub-critical flux operation [14],[15],[16].

Generally, in submerged processes only three strategies are available for limiting fouling: reducing the flux (J), increasing the membrane aeration, or employing physical (backwash) or chemical cleaning. The mini cleans may be backwash or simply intermittent permeation. This intermittent suction appears to be an effective technique for long-term sustainability of moderate fluxes [17],[18]. Various research and papers on membrane fouling in MBR technology has been reported showing the effect that different parameters (e.g. influent, biomass characteristics, membrane properties and operating conditions). However, contradictory results on the effect of these parameters on membrane fouling have been found [4]. The factors influencing the membrane fouling at various operating stages such MLVSS concentration, Hydraulic Retention Time (HRT) and Solid Retention Time (SRT) not well explained at short and long-term MBR operation. The objective of this study was to compare performance the characteristics of membrane fouling with different MLVSS concentrations at short-term operation (sub-critical flux) and long-term operations MBR (HRT of 6 and 12 hours and SRT of 35, 55 and 95 days).

2 Materials and methods

2.1 Laboratory scale MBR

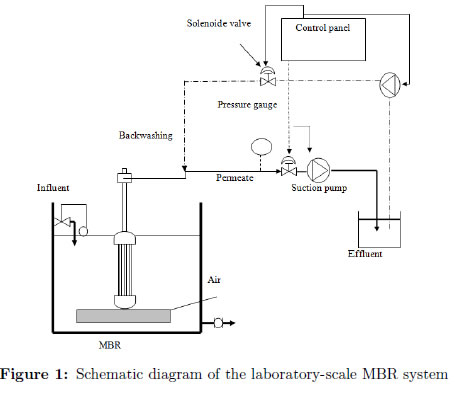

The three laboratory-scale in a submerged MBR systems consisted of an influent tank, 6 L of acrylic bioreactor, Ultrafiltration (UF) membrane, and an effluent tank. The UF membranes used were polysulfone hollow fiber membranes (surface 0.042 m2, 100 kDa molecular weight cut-off) supplied by General Electric (U.S.A.). Air was continuously introduced to the bottom of the membrane module to move and slough membrane fibers, and to prevent fouling. In addition, the air was introduced into the reactor with a macro-bubble air diffuser, and the airflow rate was adjusted by an air flowmeter at 5 L min−1.The permeate was extracted under suction, using a peristaltic pump (MasteFlex), whereas the permeate pressure was measured in terms of Transmembrane Pressure (TMP) using a vacuometer, and flow rates were recorded manually (Figure 1).

The MLVSS concentrations in the bioreactor were controlled at approximately 4,000-8,000 mg L−1.

2.2 Inoculation and operational conditions

The systems were inoculated with aerobic sludge collected from a conventional activated sludge process and operated whit different MLVSS concentrations (4,000 to 8,000 mg L−1). Three stages were evaluated: critical flux, sub-critical flux conditions, and the performance under intermittent suction and backwashing in sub-critical flux. The MBR's were fed with real municipal wastewater.

2.3 Data analysis and interpretation

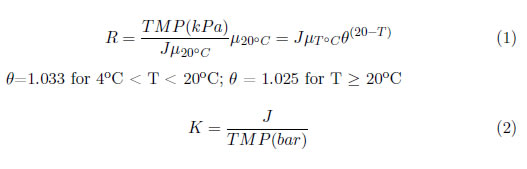

The total filtration Resistance (R) and Permeability (K) was calculated from the measured Flux (J), Transmembrane Pressure (TMP), and Temperature (T) corrected fluid viscosity (Jμ20°C) as showed equations and :

2.4 Critical and sub-critical flux determination

In order to determine the critical and sub-critical flux conditions, three concentrations of biomass were employed: 4,200, 6,150, and 7,940 mg MLVSS L−1, respectively. The concentration of the mixed liquors was selected according to the reports of various researchers [19].The critical flux test -flux-step method- was applied according to a recommendation given by some authors [11],[13],[20].

2.5 Analysis

Protein and polysaccharides concentrations were determinated using the method of Lowry [21] and Dubois [22], respectively. The MLVSS concentrations were analyzed using Standard Methods [23].

3 Results and discussion

In the next section, shows the behaviour of membrane fouling at different MLVSS concentrations at short and long-term MBR operation.3.1 Fouling membrane at different MLVSS concentrations: critical and sub-critical flux test

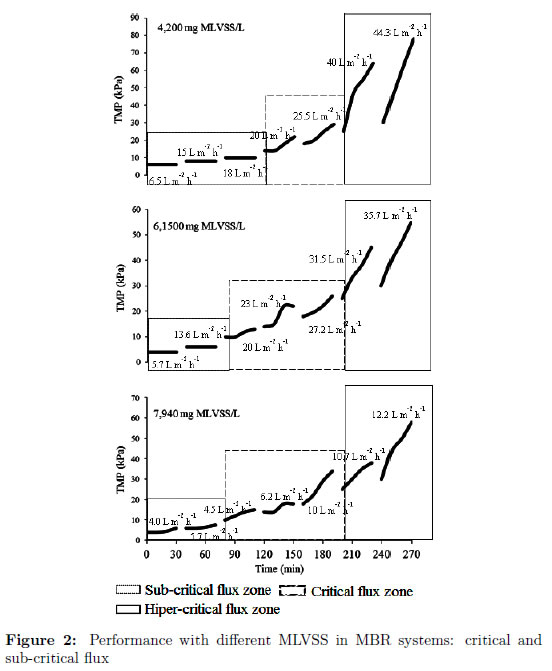

Figure 2 shows three stages: sub-critical, critical and super-critical conditions at three MLVSS concentrations. It was observed that for a biomass concentration of 4,200 mg L−1, the TMP remained constant with values of up to 20 L m−2 h−1 with a TMP of 14 kPa. Above this flux level, the TMP started to increase rapidly in the first minutes of every step of the flux, reaching values of up to 78 kPa with a flux of 44.3 L m-2 h−1. For a VSS concentration of 6,150 mg L−1 a maximum flux of 35.7 L m−2 h−1 was obtained, with a TMP of 55 kPa. When increasing the biomass concentration in around 8,000 mg L−1, the permeate decreased, thus having a flux of up to 12.2 L m-2 h−1. It was observed that above 20 L m−2 h−1 for both biomass concentrations (6,150 and 7,940 mg L−1), the TMP increased, which suggests that above these values, the work is being carried under irreversible conditions and that below this, the TMP and the flux remain constant throughout time.

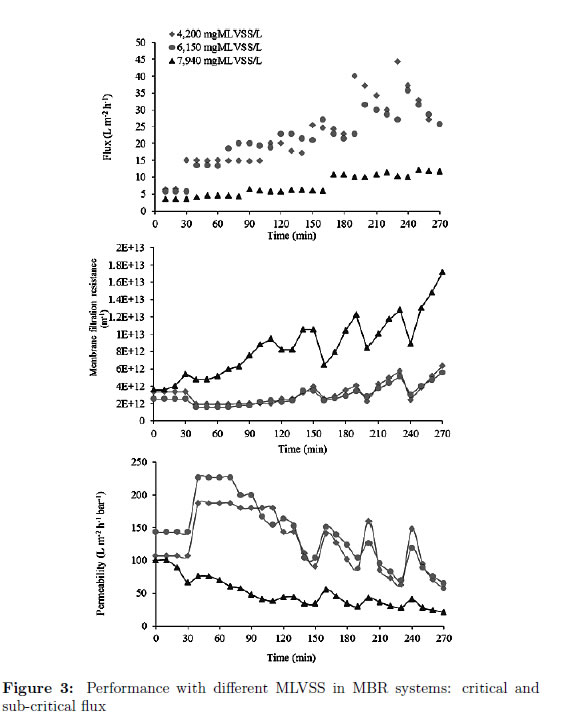

Figure 3 showed the performance filtration effect, resistance, and permeability with different MLVSS concentrations in critical and sub-critical flux test. Whit biomass concentration of the 4,200 and 6,150 mg MLVSS L−1 existed a decline of the flux and an increase in the TMP was observed.

This phenomenon was not observed with a concentration of 7,940 mg MLSVSS L−1, since there was a divergence between the flux and the TMP. This behavior is not coherent with the definition of critical flux [13] but, the parameters such as the resistance and permeability reflect that high fouling potential working with this biomass concentration. With mixed liquors of 4,200 and 6,150 mg L−1, the resistance follows the same trajectory with averages of 5.0E+12 m−1 whereas for 7,940 mg MLVSS L−1 a high resistance of 1.7E+13 m−1 was obtained. The permeability decreased when the TMP increased, which causes a cake compression deposited in the membrane surface.

The result suggested that high biomass concentrations decreased to permeability due to a bio-layer formed in the membrane surface and deposit of EPS; membrane pores blocked rapidly, and thus membrane filtration resistance increased quickly. However, at a lower MLVSS concentration, suspended and colloidal particles were slowly deposited on the membrane surface, thus membrane pores blocked slowly. Furthermore, according to these results, the membrane fouling remained limited below the flux 20 L m−2 h−1 with a concentration of MLVSS between 4,000 to 6,000 mg The result suggested that high biomass concentrations decreased to permeability due to a bio-layer formed in the membrane surface and deposit of EPS; membrane pores blocked rapidly, and thus membrane filtration resistance increased quickly. However, at a lower MLVSS concentration, suspended and colloidal particles were slowly deposited on the membrane surface, thus membrane pores blocked slowly. Furthermore, according to these results, the membrane fouling remained limited below the flux 20 L m−2 h-1 with a concentration of MLVSS between 4,000 to 6,000 mg L−1, and an operating TMP below 10 kPa. L−1, and an operating TMP below 10 kPa.

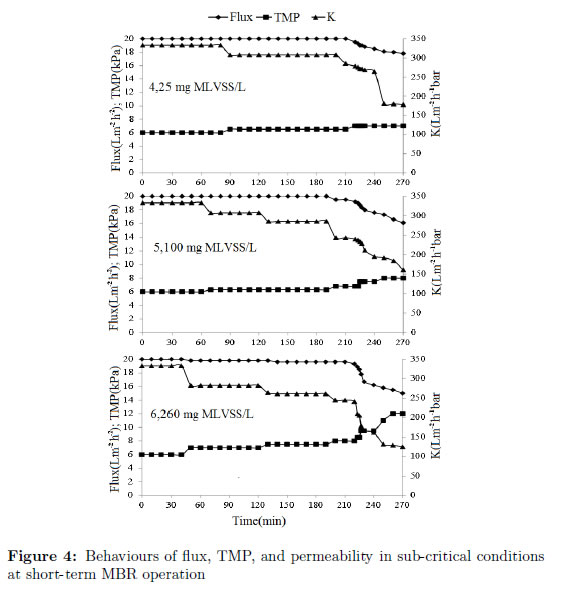

3.2 Operational performance under a sub-critical flux condition at short-term membrane bioreactor operation

Taking the obtained values from the previous experiment, the MBR was operated at short-term (270 min) in sub-critical conditions with flux of 20 L m−2 h−1 and TMP of 6 kPa (Figure 4). Three biomass concentrations were proven: 4,250, 5,100 and 6,250 mg L−1, respectively. Figure 3 shows the performance flux, TMP, and the permeability in sub-critical conditions for three MLVSS concentrations. It is observed that the three parameters follow a same behavior during the first 210 minutes where the flux and the TMP practically remained constant. Above this time, the flux begins to decrease in all the cases, which is related to an increase in the TMP, a decrease in the permeability, and an increase in the hydraulic resistance, which is a typical sign of reversible fouling. Van der Roest [24] has reported that the permeability can take values between 100 L m−2 h−1 bar−1, in this case the averages were of 240 L m−2 h−1 bar−1.In addition, it is observed that with an increase in the biomass concentration, the TMP increased and the flux decreased.

The EPS are complex mixture of proteins, carbohydrates, lipids, DNA and others products that are responsible principal of membrane fouling in MBR [9]. In short-term operation MBR, the proteins and carbohydrates increased from 21 to 36 mg g VSS−1 and 1.9 to 3.0 mg g VSS−1 respectively in relationship with increase MLVSS concentrations (4,250 mg L−1 to 6,260 mg L−1). These results indicate that biomass concentrations increased the EPS values and the fouling membrane increased to. Working under sub-critical conditions did not reduce the biofouling due to dynamics and the viscosity of the sludge.

3.3 Performance of intermittent filtration flux and backwashing frequency

To optimize the intermittent filtration and backwashing frequency, three scenarios were evaluated in a period of 24 hours in sub-critical flux, with a flux of 20 L m−2 h−1. The results are summarized in Table1. This showed that although it did not decrease (>19 L m−2 h−1) when applying several backwashing conditions, the TMP, resistance, permeability, and fouling rate showed a discrepancy. Nevertheless, it is observed that these parameters, using the strategy of the intermittent suction and backwashing, the membrane fouling was reduced in comparison with sub-critical flux without intermittent membrane flux and backwashing frequency.

The best intermittent suction and backwashing condition was scenario 2 with a concentration of mixed liquors of 4,250 and 5,100 mg MLVSS L−1. Whereas for a MLVSS of 6,260 mg L−1 it was scenario 1, which shows that it is necessary to apply short times of filtration and backwashing to maintain the TMP constant and the rest of the parameters. The filter cake reduced the direct contact of small colloidal particles with the membrane and, consequently, reduced the membrane pore blocking (e.g. the adsorption of small colloidal organic particles). Membrane pore blocking is often reported to be more difficult to clean than filter cake, using backwashing [25].

3.4 Evaluation of a long-term membrane bioreactor operation

The MBR operated for a municipal wastewater treatment over 284 operational days with a hydraulic retention time (HRT) of 6.6 and 12.1 hours at different MLVSS concentrations (4,000-6,200 mg L−1). The solid retention time (SRT) in MBR was 35, 55 and 95 days. The MLVSS were purged constantly in order to keep the same concentration inside reactors. In order to limit the membrane fouling, two strategies were employed: (1) physical cleaning continuous by using sub-critical fluxes according to this work (flux <20 L m−2 h−1), low pressure air to maintain a turbulent flow pattern along the vertical membrane fibers and combined with the membranes backwashing with permeate (best scenarios Table 1); and (2) maintenance chemical cleaning with NaClO solution (500 mg L−1). This chemical cleaning was applied for 15 min every 20-30 days depending on operational conditions when the TMP reached values of 25-35 kPa, and it caused a decrease of 10-15 units in the TMP. For a HRT of 6.6 h the start flux was of 20 L m−2 h−1 and for a HRT of 12.1 h, the initial flux was 10.9 L m−2 h−1.

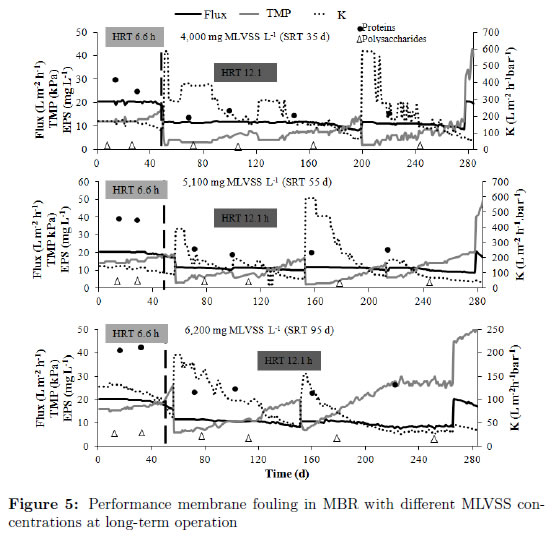

Figure 5 shows the flux evolution, TMP, K and EPS concentration through the reactors at long-term operation. During the first forty days of the reactors operation (HRT of 6.6 h), it was observed that the flux was reduced in about 23% in all the reactors, with an increase of the TMP. This was due to an amount of inert material present in the reactors and by a subsequent increase in the concentration of the biomass and EPS, which was probably accumulated in the surface of the membranes, thus causing the reduction of the flux and the increase of the TMP. Patsios & Karabelas [26] showing that SRT is a major parameter influencing the concentration of dissolved organic matter, soluble microbial products and bound EPS in long-term filtration performance MBR. The inert material formed in this phase can be related to an increase in the total suspended solids (TSS) and a decrease in the VSS during the first twenty days of operation, which was a consequence of the acclimation of the biomass in residual water, thus generating an accumulation of inert material in the systems. This behavior was reflected in the relationship VSS/TSS, which was lower than 0.6 mg−1. Besides, this inert material and the following increased in the concentration of the biomass, which caused the decrease of the flux and the permeability, and an increase of the TMP.

It is noticeable that the permeability with concentrations of biomass under 5,100 mg L−1 is higher with values of up to 590 L m−2 h−1 bar−1. For a biomass concentration of 6,200 mg L−1, the permeability was reduced in about 66% (195 L m−2 h−1 bar−1) showing that biomass concentrations of above 6,000 mg L−1 make more difficult for the water to pass through the membrane.

At a HRT of 6.6 h, the proteins and polysaccharide concentrations with different MLVSS were of 25-42 mg g VSS−1 and 1.2-5.5 mg g VSS−1, respectively. At a HRT of 12.1 h, the EPS concentrations (proteins) decreased to 13 mg g VSS−1 and the carbohydrates concentrations were low regarding the HRT of 6.6 h (0.5-2.3 mg g VSS−1). Whit SRT of 95 d (HRT 6.6 h) MBR had slightly higher EPS concentration than that in the SRT of 35 and 55 d (HRT 6.6 h). Different EPS concentrations were detected with SRT of 35, 55 and 95 d at HRT of 12.1 h. At SRT of 35 d and HRT of 12.1 h, EPS concentrations were lower compared with SRT of 55 d and SRT of 95 d at TRH 6.6 and 12.1 h. The proteins were the predominant species in the EPS. At SRT of 55-95 d, which can lead to endogenous decay of biomass and subsequently, will increase the concentration of carbohydrate and protein.These results indicated that the fouling rate was directly influenced by the HRT, SRT and MLVSS concentrations. Decreasing HRT and increase of SRT, leads to a higher fouling rate due to an increase in EPS concentrations. According to Wu [27], the activated sludge characteristic (MLSS concentrations, EPS properties, SRT-infinity) they are associated with cake layer development and membrane fouling propensity. Different results were presented by Van den Broeck [28] when lower membrane fouling rates in MBR at higher SRT-50 d was observed because the flocculation improves and reduced mean fragment surface fractions in surface membrane.

4 Conclusion

The concentration of mixed liquor volatile suspended solids in the MBR operation is a predominant factor, since it defines the performance MBR in the membrane modules, membrane fouling and intermittent filtration/backwashing frequency. The membrane fouling rate in the experimental laboratory-scale MBR increased with MLVSS concentrations higher than 5,100 mg L−1. The sub-critical flux condition in MBR was of 20 L m−2 h−1 with TMP of 6 kPa. The MBR operated in sub-critical flux condition at short-term, the TMP did not increase, however, high EPS concentrations were detected in MBR at MLVSS concentrations of 5,100 mg L−1. With intermittent filtration flux of 7 min, and backwashing of 30 sec, the fouling rate in the membrane module was low with values minor to 0.0057 kPa h−1. The membrane fouling at long-term MBR operation increased with high biomass concentrations, higher SRTs and shorts HRT because increased the EPS content generating an obstruction onto membrane surface and into the membrane pores. At HRT of 12.1 h, SRT of 35 d and MLVSS concentrations of 4,000 mg L−1, the membrane fouling during long-term MBR operation was reduced. Under these operation conditions, the proteins and polysaccharides content in the mixed liquor they were low, decreasing the membrane fouling.

References [ Links ]

[2] N. Cicek, J. Macomber, J. Davel, M. Suidan, J. Audic, and P. Genestet, ''Effect of solids retention time on the performance and biological characteristics of a membrane bioreactor,'' Water Science & Technology, vol. 43, no. 11, pp. 43-50, 2001. [Online]. Available: http://www.ncbi.nlm.nih.gov/pubmed/11443985 [ Links ]

[3] N. Yamato, K. Kimura, T. Miyoshi, and Y. Watanabe, ''Difference in membrane fouling in membrane bioreactors (MBRs) caused by membrane polymer materials,'' Journal of Membrane Science, vol. 280, no. 1-2, pp. 911-919, 2006. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0376738806001852 [ Links ]

[4] A. Drews, ''Membrane fouling in membrane bioreactors-Characterisation, contradictions, cause and cures,'' Journal of Membrane Science, vol. 363, no. 1-2, pp. 1-28, 2010. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0376738810005132 [ Links ]

[5] K. Xiao, X. Wang, X. Huang, T. D. Waite, and X. Wen, ''Analysis of polysaccharide, protein and humic acid retention by microfiltration membranes using Thomas dynamic adsorption model,'' Journal of Membrane Science, vol. 342, no. 1-2, pp. 22-34, 2009. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0376738809004554 [ Links ]

[6] H. J. Lin, K. Xie, B. Mahendran, D. M. Bagley, K. T. Leung, S. N. Liss, and B. Q. Liao, ''Sludge properties and their effects on membrane fouling in submerged anaerobic membrane bioreactors (SAnMBRs),'' Water Research, vol. 43, no. 15, pp. 3827-3837, 2009. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0043135409003273 [ Links ]

[7] S. C. Wu and C. M. Lee, ''Correlation between fouling propensity of soluble extracellular polymeric substances and sludge metabolic activity altered by different starvation conditions,'' Bioresource Technology, vol. 102, no. 9, pp. 5375-5380, 2011. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0960852410018961 [ Links ]

[8] F.-y. Sun, X.-m. Wang, and X.-y. Li, ''Change in the fouling propensity of sludge in membrane bioreactors (MBR) in relation to the accumulation of biopolymer clusters,'' Bioresource Technology, vol. 102, no. 7, pp. 4718-4725, 2011. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0960852411001179 [ Links ]

[9] Z. Wang, Z. Wu, and S. Tang, ''Extracellular polymeric substances (EPS) properties and their effects on membrane fouling in a submerged membrane bioreactor,'' Water Research, vol. 43, no. 9, pp. 2504-2512, 2009. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0043135409001195 [ Links ]

[10] K.-H. Choo and C.-H. Lee, ''Membrane fouling mechanisms in the membrane-coupled anaerobic bioreactor,'' Water Research, vol. 30, no. 8, pp. 1771-1780, 1996. [Online]. Available: http://www.sciencedirect.com/science/article/pii/004313549600053X [ Links ]

[11] L. Defrance and M. Y. Jaffrin, ''Comparison between filtrations at fixed transmembrane pressure and fixed permeate flux: application to a membrane bioreactor used for wastewater treatment,'' Journal of Membrane Science, vol. 152, no. 2, pp. 203-210, 1999. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0376738898002208 [ Links ]

[12] B. D. Cho and A. G. Fane, ''Fouling transients in nominally sub-critical flux operation of a membrane bioreactor,'' Journal of Membrane Science, vol. 209, no. 2, pp. 391-403, 2002. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0376738802003216 [ Links ]

[13] R. W. Field, D. Wu, J. A. Howell, and B. B. Gupta, ''Critical flux concept for microfiltration fouling,'' Journal of Membrane Science, vol. 100, no. 3, pp. 259-272, 1995. [Online]. Available: http://www.sciencedirect.com/science/article/pii/037673889400265Z [ Links ]

[14] K. Yu, X. Wen, Q. Bu, and H. Xia, ''Critical flux enhancements with air sparging in axial hollow fibers cross-flow microfiltration of biologically treated wastewater,'' Journal of Membrane Science, vol. 224, no. 1-2, pp. 69-79, 2003. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S037673880300348X [ Links ]

[15] S. Ognier, C. Wisniewski, and A. Grasmick, ''Membrane bioreactor fouling in sub-critical filtration conditions: a local critical flux concept,'' Journal of Membrane Science, vol. 229, no. 1-2, pp. 171-177, 2004. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0376738803005313 [ Links ]

[16] A. Pollice, A. Brookes, B. Jefferson, and S. Judd, ''Sub-critical flux fouling in membrane bioreactors-a review of recent literature,'' Desalination, vol. 174, no. 3, pp. 221-230, 2005. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0011916405000585 [ Links ]

[17] T. Ueda, K. Hata, and Y. Kikuoka, ''Treatment of domestic sewage from rural settlements by a membrane bioreactor,'' Water Science and Technology, vol. 34, no. 9, pp. 189-196, 1996. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0273122396008037 [ Links ]

[18] H. C. Chua, T. C. Arnot, and J. A. Howell, ''Controlling fouling in membrane bioreactors operated with a variable throughput,'' Desalination, vol. 149, no. 1-3, pp. 225-229, 2002. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0011916402007646 [ Links ]

[19] J. Nywening, H. Zhou, and H. Husain, ''Comparison of mixed liquor filterability measured with bench and pilot-scale membrane bioreactors,'' Water Science & Technology, vol. 56, no. 6, pp. 155-162, 2007. [ Links ]

[20] P. L. Clech, B. Jefferson, I. S. Chang, and S. J. Judd, ''Critical flux determination by the flux-step method in a submerged membrane bioreactor,'' Journal of Membrane Science, vol. 227, no. 1-2, pp. 81-93, 2003. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0376738803004241 [ Links ]

[21] L. O, N. Rosebrough, A. Lewis, and R. R, ''Protein measurement with Folin phenol reagent,'' Journal of Biological Chemistry, vol. 193, pp. 265-275, 1951.

[22] M. DuBois, K. A. Gilles, J. K. Hamilton, P. A. Rebers, and F. Smith, ''Colorimetric Method for Determination of Sugars and Related Substances,'' Analytical Chemistry, vol. 28, no. 3, pp. 350-356, 1956. [Online]. Available: http://dx.doi.org/10.1021/ac60111a017 [ Links ]

[23] A. P. H. Association., A. D. Eaton, A. W. W. Association., and W. E. Federation., Standard methods for the examination of water and wastewater, 21st ed., A. Eaton, A. Clesceri, E. Rice, and A. Greenberg, Eds. Washington, D.C.: APHA-AWWA-WEF, 2005. [ Links ]

[24] H. Van de Roest, D. Lawrence, and V. B. AG, Membrane bioreactors for municipal wastewater treatment, STOWA Report London, Ed. London: IWA Publishing, 2002. [ Links ]

[25] S.-m. Lee, J.-y. Jung, and Y.-c. Chung, ''Novel method for enhancing permeate flux of submerged membrane system in two-phase anaerobic reactor,'' Water Research, vol. 35, no. 2, pp. 471-477, 2001. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0043135400002554 [ Links ]

[26] S. I. Patsios and A. J. Karabelas, ''An investigation of the long-term filtration performance of a membrane bioreactor (MBR): The role of specific organic fractions,'' Journal of Membrane Science, vol. 372, no. 1-2, pp. 102-115, 2011. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0376738811000755 [ Links ]

[27] B. Wu, S. Yi, and A. G. Fane, ''Microbial behaviors involved in cake fouling in membrane bioreactors under different solids retention times,'' Bioresource Technology, vol. 102, no. 3, pp. 2511-2516, 2011. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S096085241001847X [ Links ]

[28] R. V. den Broeck, J. V. Dierdonck, P. Nijskens, C. Dotremont, P. Krzeminski, J. van der Graaf, J. B. van Lier, J. F. M. V. Impe, and I. Y. Smets, ''The influence of solids retention time on activated sludge bioflocculation and membrane fouling in a membrane bioreactor (MBR),'' Journal of Membrane Science, vol. 401-402, no. 0, pp. 48-55, 2012. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0376738812000579 [ Links ]