Introduction

According to 10 Federación Panamericana de Leche (FEPALE, 2014), milk is the most complete and irreplaceable meal for humans due to its organoleptic and nutritional characteristics. It contains elements that mammals need for construction and maintenance of its body, like fat, protein, and carbohydrates 7,12,21. Nevertheless, these conditions also allowance microorganisms growth and this decreases its useful life and can affect health public due to microorganisms or toxin's consumption. Therefore it is necessary the addition of industrial processes that enable its conservation (eliminating and preventing microorganism's growth), facilitating its consumption and commercialization 23.

Principally to ensure its quality, milk is undergoing to heat process like ultra-pasteurization, which that is defined like heating of milk to a temperature that is between 135 and 145 °C for two and four seconds, with a subsequent packing and the objective is the destruction of potentially pathogens microorganisms of this product 16. UPM's quality depends first: of the physicochemical quality of raw milk, and second that the thermic process it would have been entirely adequate 13,5,25. Also, this is the most common form of milk commercialization in the country 14.

In Colombia, for finals of 2018, monthly milk production was 3'414.000.000 liters, and an average of UPM production of 27'000.000, mostly in Cundinamarca department 17. Due to ultra-pasteurization is the most common process used in Colombia, and is the most common form of consume, is necessary to evaluate physicochemical parameters of regional trademark of this type of milk to determine its quality and demonstrate if it satisfies the national normativity, as Brinez et al., 2002 in Venezuela and Juárez et al., 2015 in Mexico.

These analyses are performed generally following the instructions of the Official Methods of Analysis (AOAC) or national's institutions that stipulate manual processes like Gerber, Kjendal, or evaporation in the stove 7,3,19. Nevertheless, the Fourier-transform infrared spectroscopy (FT-IR) is more relevant daily due to the necessity to obtain quick and confirmability results 5,6,9,1,2,1,5,22,24.

Therefore, the objective of this study was to determine the physicochemical characteristics of four trademarks of ultra-pasteurized milk for human consumption in the Cundiboyacense region and compare the results with the national normativity.

Materials and methods

Type of study

A non-probalistic convenience sampling was performed. The number of samples was selected based in previous studies performed by Juárez et al., 2015. Sampling and processing of the samples were developed between July of 2018 and April of 2019.

Parameters for selection

The parameters determined for selection of the samples were: 1-liter packaging, without fat or lactose extraction, without flavors addition, and the expiration dates for each sample had to be more than six months, taking a count day of sampling. Trademarks were identified like 1, 2, 3 and 4, and all of them were replicated 20 times, which means 20 samples for each trademark. The companies included are independents between them.

Sampling

Eighty samples of four trademarks of UPM produced in the Cundiboyacense region, Colombia, were sampled every 15 days directly from supermarkets in Tunja-Colombia. It was verified that all products it was refrigerated in a temperature of 4 °C (value determined through thermometers in each refrigerator) and that lot fabrication it was different.

Study variables and processing

Were determined the percentage (%) of protein, fat, total solids, not fatty solids and lactose, as well freezing point (°C) through an equipment MilkoScanTM Mars of FOSS company which use FT-IR for analyses of samples. For this, 10 mL of each sample was taken and packaged in an aseptic plastic container to introduce in the equipment. The machine is located at the laboratory of milk quality and mastitis control, of the veterinary medicine and zootechny school of the Universidad Pedagógica y Tecnológica de Colombia, in Tunja-Boyacá.

Parameters of national normativity

The analysis of the mostly ranks determined here was made with the values stipulated through the 18 decree number 616 of the Ministerio de la Protección Social and the technic paper for aliments of Instituto Colombiano de Bienestar Familiar 14. These documents are part of the current national regulations. For the case of the protein the comparison was made following the modified classification effectuated by 8 Calderón et al., 2006, thereby: Excellent (>3.2%), Good (2.8%-3.19%), Moderate (2.6%-2.79%) and Poor (<2.6%).

Data analysis

An analysis of variance (ANOVA) was performed between trademark using comparations of the average of the low significative differences of Fisher's procedure with a confidence level of 95% 15.

Results

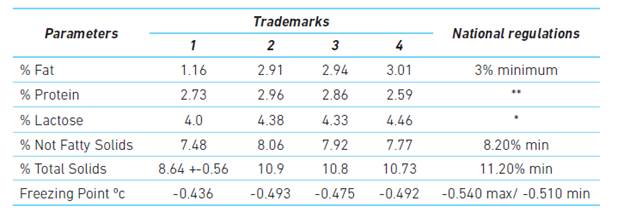

Averages values found for each physicochemical parameter of the trademarks evaluated and the values stipulated in the decree number 616 of 2006 are shown in Table 1. The trademark four has not statistical difference compared with the trademarks two and three; the trademark one is statistically different from the other three trademarks (Table 1).

Table 1 Mean values of the physicochemical composition of four trademarks of UPM and ranks specified by the national normativity and other references

* National normativity does not have ranks for lactose percentage

** Comparison made with parameters of 8

For protein percentage, trademark four is classified in the poor rank (<2.6%) and was statistically different compared with trademarks two and three; on the other hand, trademark one is classified in the moderate rank, and was similar to the trademarks four and three; meanwhile trademarks two and three were classified in the rank good, and are statistically similar, and only trademark one is totally different statistically with the trademarks four and one (Table 1)

For the lactose percentage, only the trademark one was statistically different compared with other trademarks. No one trademark meet national standards related with not fatty solids and total solids percentage. Statistically, trademarks one and two were similarly, compared with trademark four and one, the trademark four was also statistically different from the trademark one. Something similar happened with total solids percentage, however, here only trademark one was statistically different from the other three trademarks. The freezing point neither was satisfied for no one trademark, the trademark one was statistically different from the other three trademarks (Table 1).

Discussion

Only are a few studies, around the world, related to the evaluation of the physico-chemical characteristic of milk pasteurized or ultra-pasteurized, and its comparison with the national normativity. For example, in Mexico, 15 Juárez et al. 2015 performed a similar study with UPM, but in Venezuela 7 Brinez et al. 2002 performed it study in pasteurized milk, while authors like 6 Bernal et al. 2007 performed studies in raw milk.

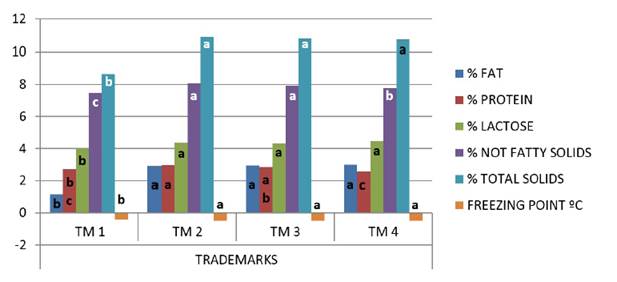

The decree 616 of 2006 18 stipules 3% as the minimum value for the fat percentage for the UPM , only the trademark four satisfies this value; no one other trademark meets this parameter.15 Juárez et al., 2015 in Mexico show that all trademarks of UPM evaluated, meet the national normativity in this country contrary to find in this study, on the other hand, 7 Brinez et al. 2002 for pasteurized milk also find that all trademarks satisfy the Venezuelan normativity related with the fat percentage. This lower fat percentage content can be due primarily to low fat content in raw milk affected by nutrition of animals, or by water addition in any process since storage in farms, transport and UHT process, especially in trademark 1 which present the smaller values for all parameters (Figure 1)

No one trademark is in the classification of excellent for protein percentage, following the ranks of 8, and also are smaller compared with national average stipulated by government (3,66%) 17. In Mexico 15 Juárez et al., 2015 also shows that protein percentage of UPM does not satisfy national normativity, but 7 Brinez et al., 2002 reported that pasteurized milk satisfy the normativity. This nutritional deficiency can be related first with the quality of raw milk (due to season, or mammary glands disease) 2, or the covalent association between serum proteins and proteins of fat globules due to the thermic process 26, process known like maillard reaction.

Colombian normativity does not stipule ranks for lactose content, even when this carbohydrate is part of the not fatty solids and fatty solids of milk, and is highly related with freezing point according to report by 3,27,15. This parameter can be associated also with water addition due dilution factor, this is correlated principally whit trademark 1 which have the lower content of lactose percentage 1.

For the not fatty solids, Colombian normativity stipule 8,20% like reference value, however, no one trademark meets this, these results are similar to reported by 15, in which no one trademarks evaluated accomplish Mexican normativity. For total solids, no one trademarks also meet national normativity. Both values can be affected by water addition in any part of the fabrication process, and therefore affect too freezing point, the results of Table 1 shows that no one trademark satisfy national normativity, and added to values found for not fatty solids therefore, it is highly probable that there was addition of water 4,3,11,20,27.

Figure 1 shows the statistical differences between each parameter of each trademark of UPM, trademark 1 have the smaller value for each parameter and was different compared with others trademarks. These shows two situations, first, even each trademark is elaborated in different parts of the cundiboyacense region, the results for physicochemical characteristics is similar between its, so, the smaller values found for trademark 1 can be due to poor productive practices in some part(s) of the productive process, which shows the importance of raw milk quality and a good transformation process to guarantee the nutritional quality of the product.