Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Tecciencia

Print version ISSN 1909-3667

Tecciencia vol.11 no.20 Bogotá Jan./June 2016

https://doi.org/10.18180/tecciencia.2016.20.3

DOI: http://dx.doi.org/10.18180/tecciencia.2016.20.3

Triad of the Articulation Model of Integrated Management Systems [TAM - (HSEQ)]

Triada del modelo de articulación de sistemas integrados de gestión (HSEQ) - [TMA-(HSEQ)]

René Alejandro Alvarado Rueda1*, Gonzalo Carlos José Pérez Gómez2

1* Universidad Autónoma de Colombia, Colombia raalvarador@gmail.com

2 Universidad Autónoma de Colombia, Colombia perez.gonzalo@fuac.edu.co

* Corresponding Author. E-mail: raalvarador@gmail.com.

How to cite: Alvarado, R.A., Pérez, G., Triad of the Articulation Model of Integrated Management Systems TAM-HSEQ. TECCIENCIA, Vol. 11 No. 20, 19-26, 2016, DOI: http://dx.doi.org/10.18180/tecciencia.2016.20.3

Received: 1 Sep 2015 Accepted: 18 Nov 2015 Available online: 29 Feb 2016

Abstract

Integrated Management Systems include Quality Management Systems (QMS), Environmental Management Systems (EMS), and Occupational Health and Safety Management Systems (OHSMS), which need a continuous and efficient improvement in companies. Many factors hinder achieving quality certifications in environment and occupational safety and health due to dislocation of the corresponding systems. This work aims to propose a model that contributes to the design and integration of these models. This is constructed by studies of unique cases in companies in Bogotá. It was also supported by surveys taking into account the requirements stated by standards such as ISO 9001: 2008, ISO 14001: 2004 and OHSAS 18001:2007. Meanwhile, it was supported with interviews to identify typical problems; and Recursion-Function Matrix between processes and functions. The Triad Model Articulation of Integrated Management Systems [TMA - (HSEQ)] is exposed and designed based on the corresponding standard. The standards OHSAS 18001: 2008 and ISO 14001:2004 are articulated by the norm ISO 9001: 2008 and articulated. This triad should investigate the use of ICT for Integrated Systems Management - (HSEQ) and consider approval of updating future versions of standards (ISO 9001: 2015, ISO 14001: 2015 and ISO 45001: 2016).

Keywords: Quality, Environment, Safety and Occupational Health, Integrated Systems, Integrated Management Systems, HSEQ.

Resumen

Los Sistemas Integrados de Gestión incluyen los Sistemas de Gestión de la Calidad (SGC), Sistemas de Gestión Ambiental (SGA) y Sistemas de Gestión de Seguridad y Salud Ocupacional (SGSYSO) (Health, Safety, Environment & Quality - HSEQ) que precisan de la mejora continua de la eficacia y la eficiencia en las empresas. Existen diferentes factores que dificultan alcanzar las certificaciones de calidad, medio ambiente y seguridad y salud ocupacional debido a la desarticulación de los sistemas correspondientes. El presente trabajo propone un modelo que contribuya al diseño e implementación de los sistemas mediante su articulación. Este se construye a partir de estudios de caso único en empresas de Bogotá, apoyados en la realización de encuestas, teniendo en cuenta el nivel de cumplimiento de los requisitos de los deberes de las normas ISO 9001:2008, ISO 14001:2004 y OHSAS 18001:2007, complementados con entrevistas para identificar problemas tipo y la matriz de Recursión - Función para el cruce entre procesos y funciones. Se expone la Triada del Modelo de Articulación de Sistemas Integrados de Gestión - (HSEQ) [TMA - (HSEQ)] que sirve para el diseño e implementación de las normas correspondientes. Con base en la norma ISO 9001:2008 se articulan las normas ISO 14001:2004 y la OHSAS 18001:2008. Se debería indagar en el uso de las TIC aplicadas a los Sistemas Integrados de Gestión - (HSEQ) y tener en cuenta la aprobación de la actualización de las futuras versiones de las normas (ISO 9001:2015, ISO 14001:2015 e ISO 45001:2016).

Palabras Clave: Calidad, Medio Ambiente, Seguridad y Salud Ocupacional, Sistemas Integrados, Sistemas Integrados de Gestión, HSEQ.

1. Introduction

According to that proposed by Salomé (2008), integrated management systems (HSEQ) are becoming more and more important, but experiences of their design and implementation can be numerous among regions and companies of different types. As reported by Rebelo, Santos, and Silva (2014) in this sense, diverse theoretical approaches have been proposed with respect to the integration of management subsystems, which lead to there not being a common practice for all the organizations, given that different characteristics are encompassed. It is also shown that various tangible and intangible benefits of the organizations are accomplished with the integration of the management systems standardized individually.

Also, Zeng, Shi, and Lu (2007) revealed that different factors exist that make it difficult for companies to accomplish quality certification on safety, occupational health, and environment, partially losing the resources invested for said purpose; a situation that affects the organization in economic, social, and competitive manner. Internal factors include: (1) human resources, organizational structure, (3) company culture, and comprehension and perception. External factors consist of: (1) technical guidance, (2) certification organizations, (3) interested parties and clients, and (4) the institutional environment. Jorgensen, Remmen, and Mellado (2006) indicate that to minimize the factors that keep the organization from certification, the theme should be addressed from the increase of compatibility of the systems elements to the coordination of the generic processes of an integrated management system within a culture of learning and continuous improvement.

Based on the proposals by Rocha, Searcy, and Karapetrovic (2007), integration of Quality management systems (QMS), Environmental management systems (EMS), and Systems of Occupational health and safety management (OHSMS) is considered from a macro level to a prospective at micro level. The macro level perspective emphasizes on an approach of systems to visualize the integrated management system - (HSEQ), while the micro level perspective considers integration on the basis of the corresponding elements. According to Väyrynen (2015), some of the most outstanding current tendencies are high-level harmonization of integrated management systems, which represents the supply chain on HSEQ themes, and sustainability and risk management. As stated by De Oliveira and Coelho (2002), other tendencies analyze the advantages and disadvantages of integrating these systems, unlike those with independent management within the company. Quality management standards (ISO 9000) have evolved toward total quality management as a starting point. Recent revisions have incorporated some of the requisites of the environmental management standard (ISO 14000), as well as those related to occupational health and safety (OHSAS 18001). It is expected for this tendency to include material of systems from different standards to become even more evident in subsequent revisions of the ISO 9000, ISO 14000 standards, and OHSAS 18001 (future ISO 45000).

Based on the results of a survey conducted by Rebelo, Santos, and Silva (2014), models developed standout which are supported on preliminary research carried out through a questionnaire. The strategy and research methods have kept in mind the case study. Among the principal results of the survey, the following can be highlighted: creation of added value for the business by eliminating various residuals from the organization; integrated management of sustainability components; elimination of conflicts among independent management systems; dialogue with principal interest groups and commitment with continuous satisfaction and greater contribution to the company’s competitiveness; and higher valuation and motivation of employees as a consequence of the expansion of the base of knowledge, actions, and responsibilities with consequent empowerment.

Zeng, Xie, and Tam (2011) show that integrated management systems include: (1) reduction in paperwork; (2) diminished management costs; (3) diminished complexity of internal management; (4) simplified certification process; and (5) continuous improvement. Additionally, bearing in mind that presented by Ferreira, Santos, and Silva (2014), we have that the benefits expected from the integrated systems are: elimination of conflicts among individual systems with optimization of resources; creation of added value for the business by eliminating various types of residuals; integrated management of sustainability components within a global market; improvement of associations with suppliers of goods and services; and reduction of the number of internal and external audits.

For Revelo, Santos, and Silva (2014), given the importance represented by measuring the performance of the integrated management systems - (HSEQ), a set of key performance indicators (KPI) constitutes the support, within a perspective of entrepreneurial excellence to monitor the organization’s progress toward the vision and accomplishment of the objectives defined within the context of each component of the model of an integrated system. According to López (2011), to measure the performance of integrated management systems - (HSEQ), the most representative indicators in quality management correspond to strategic indicators of realization and support processes. To design indicators of environmental management, the ISO 14031 standard (Evaluation of Environmental Performance) exists as a reference document; for indicators of occupational health and safety, the Colombian GTC 3701 norm (hygiene and safety) serves as reference document.

Use of the prior indicators is ratified by Ferreira, Santos, and Silva (2014), given that they apply to a generic model of integrated quality management system (QMS), environmental management system (EMS), and occupational health and safety management system (OHSMS), which can be adapted and assimilated progressively to diverse management systems, among which there are: ISO 9001 for quality; ISO 14001 four environment; and OHSAS 18001 four occupational health and safety. However, based on that proposed by Atehortúa, Bustamante, and Valencia (2008), even when within an organization and integrated management system could exist without accomplishing the purpose of integral management, and entity could separately implement the QMS, EMS, and OHSMS and create "integration mechanism", like a "committee of management systems" that meets periodically for those responsible to present a report on the state of the particular management system. Nevertheless, by using software tools that support each of the three systems, this "integration" could be translated into the development of interfaces that will communicate to the different information technology platforms of each system, but not the management. Due to the aforementioned, the articulation model of integrated management systems (HSEQ) contributes to the design and implementation of quality (QMS), environmental (EMS) and occupational health and safety (SS&SO) management systems, which is why a model is required to articulate these systems by improving effectiveness and efficiency in companies.

2. Materials and Methods

The methodology used is qualitative descriptive with systemic approach and focused on the collective case study. It is, thus, possible to identify shared situations according to the context in each company, permitting to increase the generality according to the distinct configurations, to obtain an archetype that offers a concrete solution to the problem of de-articulation of integrated management systems (HSEQ). The population was comprised of companies located in the city region of the Bogotá savanna.

The purpose was to identify common patterns of dearticulation and imbalance of integrated management systems (HSEQ), which can be approached with a model that articulates said systems. An intentional sampling based on criteria was used given that this was a study of cases and exemplary situations, which permits observing the cases necessary to identify archetypes. A convenience sample of 22 companies was selected.

The materials used consist in the elaboration of checklists to measure levels of total, partial, or no compliance with the requisites of duties of ISO 9001:2008 and ISO 14001:2004 standards and OHSAS 18001:2007. The information was collected individually through surveys for each standard and simultaneously for the three standards, depending on whether the company is certified, in one, two, or the three standards.

To cover most of the requisites of the ISO 9001:2008, ISO 14001:2004 and OHSAS 18001:2007 standards, general and specific questions were made aimed at the numerals of each of the standards, as well as questions that integrate the three; considering if the company is small, medium, or large. Direct inquiry on the company’s day-to-day activities is conducted through guided interviews to identify the existence or not of archetypes, supported on the viable system model (MSV) proposed by Beer (1985) and reviewed by Espejo, Schuhmann, Schwaninger, and Bilello (1996), which comprises adaptation and cohesion mechanisms, which interrelated through command, coordination, and monitoring channels establish the interrelation of organizational archetypes of: identity, performance, cohesion, and citizenship.

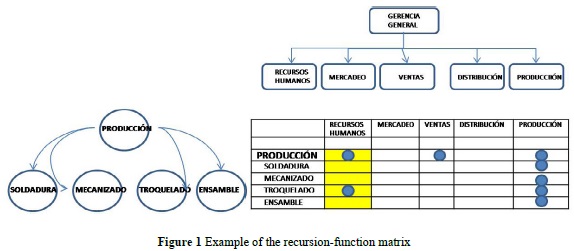

Additionally, based on the recursion-function matrix, according to that exposed by Mendoza (2009), a correlation was established among the company’s recursion (referred to its structure, reflected in its organizational diagram or map of processes) and its functions, as seen in Figure 1. Finally, pertinent information was processed and analyzed.

Source: taken from [1].

The upper part shows the functions of: General Management, Human Resources, Marketing, Sales, Distribution, and Production. The left side presents the production process with subprocesses of: welding, machining, die casting, and assembly. The right side exhibits the recursion-function matrix. The rows show the production first-level recursion with the second-level recursions of: welding, machining, die casting, and assembly. (The crosses show the centralization of recursions in the Production function and the decentralization of Sales, as well as excess centralization in the function of Human Resources with the recursion of die casting.)

3. Results

Based on the companies studied, this work presented the triad of the articulation model of Integrated management systems (HSEQ) - [TAM - (HSEQ)], which includes the stages of vision, diagnosis, and proposal of the system (Figure 2).

Source: author’s construction

The system’s vision stage is supported on that proposed by Aldana and Reyes (2004) by using the TASCOI technique (Transformers, Actors, Suppliers, Clients, Organizers, and Interveners), which consists in representing a system in terms of transformation. The system is set forth as a function of the approach by processes where activities that convert inputs into results are named in terms of transformation. This stage is constituted in its order in the identification phases of: Transformers, Actors, Suppliers, Clients, Organizers, and Interveners.

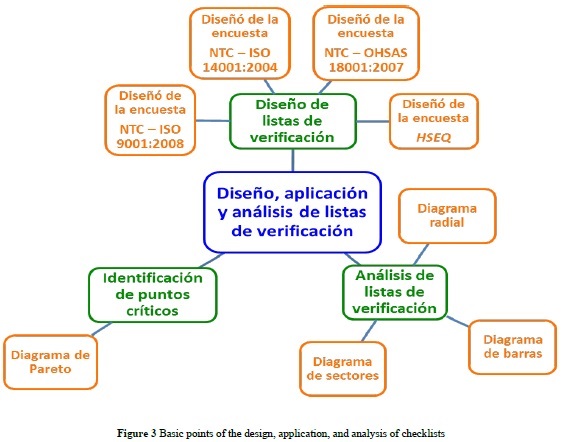

The system’s diagnosis stage is supported on that established in the duties of the standards: ICONTEC (2008) NTC - ISO 9001:2008 - quality management systems (QMS). Requisites; ICONTEC (2004) NTC - ISO 14001:2004 - environmental management systems (EMS). Requisites with user guide; and, ICONTEC (2007) NTC - OHSAS 18001:2007- Management Systems on Occupational Health and Safety (OHSMS); as well as the proposals by Espejo (1999) and Aldana & Reyes (2004); and Reyes (2007), Veeduría Distrital (2007) and Mendoza (2009). It contains the phases of design, application and analysis of checklists, identification and analysis of archetypes, and discretional analysis (Figure 2). The design phase, application and analysis of checklists includes basic points related to these, as well as the identification of critical points (Figure 3).

Source: author’s construction

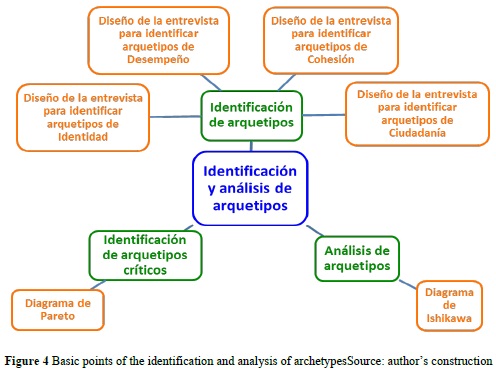

Likewise, the phase of identification and analysis of archetypes contains their basic and critical points (Figure 4).

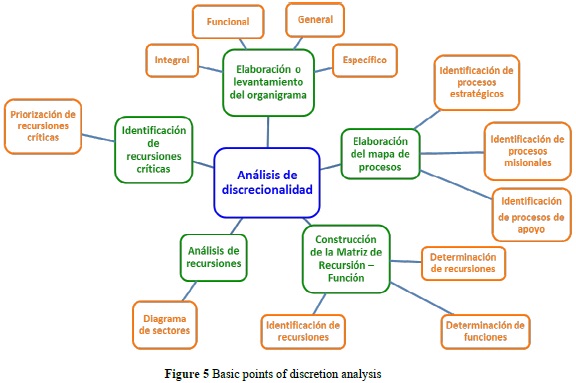

The discretional analysis phase implies the elaboration of the organizational diagram and map of processes, construction of the recursion-function matrix, analysis of recursions, and identification of critical recursions (Figure 5).

Source: author’s construction

The system proposal stage was conducted based on the findings from the diagnostic stage (Figure 2). The elaboration phase of the organizational diagram proposed was carried out by bearing in mind the revision of the company’s current organizational diagram with the changes suggested for the different jobs. The elaboration phase of the proposed map of processes was done based on the analysis of the map, the diagram, and the company’s current process flowchart and value chain. The construction phase of the recursion-function matrix proposed was obtained by using the discretion analysis of the recursion-function matrix actual.

The recursion analysis phase was used to identify the centralization and decentralization of functions proposed through the discretion analysis. The action plan phase required defining the basic guarantees to integrate the system and, thereafter, the articulation model of the integrated management system was designed. The quality management system was defined as a guide that constitutes the core support of the integrated management system (HSEQ) and upon which the environmental management and the occupational health and safety systems are articulated. Then, under the scheme of the articulation method, common requisites among the three systems were integrated and the specific requisites for each were defined. The management phase of Key Performance Indicators corresponds to: strategic indicators, of realization and support processes, of environmental management, and of occupational health and safety management.

Even when sharing the fact that the experiences of designing and implementing integrated management systems differ among regions and companies from diverse sizes and sectors, generating the lack of a common practice for all the organizations, the triad of the articulation model of integrated management systems (HSEQ) - [TAM - (HSEQ)] was ratified for offering the necessary elements to be used in different cases.

Given that the integration has been considered from the macro level to a micro-level perspective, these could be approached more effectively and efficiently by using TASCOI, the viable system model, and the recursionfunction matrix, presented in the [TAM - (HSEQ)]. It can be agreed that most of the models developed are based on a preliminary investigation carried out through a questionnaire in different case studies with results that contribute to achieving the expected benefits; however, no emphasis is made on the use of other instruments to broaden the collection of information, like the interview to identify archetypes and the use of the recursion-function matrix, which contribute to the design, implementation, and articulation of integrated management systems (HSEQ). According to the importance of the key performance indicators (KPI) in supporting the integrated management systems (HSEQ), it was agreed that the indicators of the quality management systems (QMS) correspond to strategic indicators, of realization and support processes, and those established in the ISO 14031 standard for the environmental management system (EMS) and the GTC 3701 standard for the Occupational Health and Safety Management System (OHSMS).

4. Conclusions

Design and implementation of integrated management systems (HSEQ) depends directly on the type of company and the triad of the articulation model of integrated management systems - (HSEQ) - [TAM - (HSEQ)] is applicable to any of these. The systems may be approached by using TASCOI, the viable system model (MSV), the recursion-function matrix to improve its effectiveness and efficiency, and the theories that imply managing the complexity posed by the necessary elements to address the design of an articulation model of integrated management systems (HSEQ). Articulation is accomplished through the ISO 9001:2008 standard and process, given that this is the base that articulates ISO 14001:2004 and OHSAS 18001:2007 standards.

Also, bearing in mind that the key performance indicators (KPI) for the quality management system (QMS) correspond to the strategic indicators, of realization and support processes; those established in the ISO 14031 standard for the environmental management system (EMS) and the GTC 3701 standard for the Occupational Health and Safety Management System (OHSMS), these are adaptable to the triad of the articulation model of integrated management systems (HSEQ) - [TAM - (HSEQ)]; which, in turn, due to its simplicity is didactic and with ease of understanding and application for academics and entrepreneurs. It should be inquired upon the use of ICT applied to integrated management systems, as well as consider the approval of the update of future versions of the standards (ISO 9001:2015, ISO 14001:2015, and ISO 45001:2016).

References

[1] M. Mendoza, Curso de Pensamiento Complejo, Bogotá: INSEDI Instituto de Estudios a Distancia, Especialización en Alta Gerencia de Universidad Militar Nueva Granada, 2009. [ Links ]

[2] E. Aldana Valdés y A. Reyes Alvarado, Disolver problemas. Criterio para formular proyectos sociales, Bogotá, D.C.: Ediciones Uniandes, 2004. [ Links ]

[3] R. Espejo, The Viable System Model and The Viplan Software, Birmingham: Kybernetes, 1999. [ Links ]

[4] Veeduría Distrital, «Guia para la implementacion del Modelo Estándar de Control Interno (MECIi) con enfoque sistemico», 2007. [En línea]. Available: http://www.veeduriadistrital.gov.co/veeduria/media/file/Publicaciones/29_GUIA%20IMPLEMENTACION%20MECI.pdf. [ Links ]

[5] A. Reyes, Seminario de verano sobre Diseño y Diagnóstico Organizacional a partir de Cibernética Organizacional, Bogotá: Universidad de los Andes, Escuela Latinoamericana de Pensamiento y Diseño Sistémico, 2008. [ Links ]

[6] M. Cabrera, «Metodología para estructurar proyectos tecnológicos», 20 Septiembre 2009. [En línea]. Available: http://columbus.uniandes.edu.co:5050/dspace/handle/1992/129. [ Links ]

[7] S. Beer, Diagnosing the System for Organizations, Chichester: Jhon Wiley, 1985. [ Links ]

[8] R. Espejo, W. Schuhmann, M. Schwaninger y U. Bilello, Organizational Transformation and Learning: A Cybernetic Approach to Management, London: Wiley, 1996. [ Links ]

[9] Icontec, Norma Técnica Colombiana NTC-ISO 9001:2008. Sistemas de gestión de la calidad. Requisitos, Bogotá, 2008. [ Links ]

[10] Icontec, Norma Técnica Colombiana NTC-ISO 14001:2004 Sistemas de gestión ambiental. Requisitos con orientación para su uso, Bogotá: Icontec, 2004. [ Links ]

[11] Icontec, Norma Técnica Colombiana NTC- OHSAS 18001:2007 Sistemas de gestión en seguridad y salud ocupacional. Requisitos, Bogotá: Icontec, 2007. [ Links ]

[12] F. J. López Carrizosa, Indicadores de Gestión. La medición de la gestión para el éxito sostenible, Bogotá: Icontec, 2011. [ Links ]

[13] R. Salome, «Integrated management systems: experiences in Italian organizations», Journal of Cleaner Production, vol. 16, nº 16, pp. 1786-1806, November 2008. [ Links ]

[14] T. H. Jorgensen, A. Remmen y M. D. Mellado, «Integrated management systems - Three different levels of integration», Journal of Cleaner Production, vol. 14, nº 8, pp. 713-722, 2006. [ Links ]

[15] M. Rebelo, G. Santos y R. Silva, «Conception of a flexible integrator and lean model for integrated management systems», Total Quality Management and Business Excellence, vol. 25, nº 5-6, pp. 683-701, Abril 2014. [ Links ]

[16] M. Rocha, C. Searcy y S. Karapetrovic, «Integrating sustainable development into existing management systems», Total Quality Management and Business Excellence, vol. 18, nº 1-2, pp. 83-92, Enero 2007. [ Links ]

[17] S. Väyrynen, «Integrated HSEQ management systems: Developments and trends International», Journal for Quality Research, vol. 9, nº 2, pp. 231-242, 2015. [ Links ]

[18] M. Ferreira, G. Santos y R. Silva, «A generic model for integration of quality, environment and safety management systems», TQM Journal, vol. 26, nº 2, pp. 143-159, 2014. [ Links ]

[19] S. X. Zeng, J. J. Shi y G. X. Lou, «A synergetic model for implementing an integrated management system: an empirical study in China», Journal of cleaner production, Vols. %1 de %215 (18), nº 18, pp. 1760-1767, 2007. [ Links ]

[20] S. X. Zeng, X. M. Xie y C. M. Tam, «An empirical examination of benefits from implementing integrated management systems (IMS)», Total Quality Management and Business Excellence, vol. 22, nº 2, pp. 173-186, Febrero 2011. [ Links ]

[21] M. Rebelo, G. Santos y R. Silva, «Conception of a flexible integrator and lean model for integrated management systems», Total Quality Management and Business Excellence, vol. 25, nº 5-6, pp. 683-701, 2014. [ Links ]

[22] J. C. De Oliveira y D. A. Coelho, «The integration of the standards systems of quality management, environmental management and occupational health and safety management International», Journal of Production Research, vol. 40, nº 15, pp. 3857-3866, 15 October 2002. [ Links ]

[23] F. A. Atehortúa, R. E. Bustamante y J. A. Valencia, Sistema de gestión integral. Una sola gestión, un solo equipo, Medellín: Universidad de Antioquia, Gestión y conocimiento, 2008. [ Links ]