Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Tecciencia

Print version ISSN 1909-3667

Tecciencia vol.11 no.21 Bogotá July/Dec. 2016

https://doi.org/10.18180/tecciencia.2016.21.8

DOI: http://dx.doi.org/10.18180/tecciencia.2016.21.8

Biosolids and Biosolid Ashes as Input for Producing Brick-like Construction Materials

Biosólido y Cenizas de Biosólido como Insumo para la Fabricación de Materiales de Construcción como los Ladrillos

William Ricardo Mozo Moreno1*, Adrián Gómez2

1 Universidad Santo Tomás, Tunja, Colombia.

2 Departamento de Materiales y Minerales, Universidad Nacional de Colombia, Sede Medellín, Colombia.

* Corresponding Author. E-mail: ricardomozo8887@gmail.com

How to cite: Mozo Moreno, W. R., Gómez, A., Biosolids and Biosolid Ashes as Input for Producing Brick-like Construction Materials, TECCIENCIA, Vol. 12 No. 21, 45-51, 2016, DOI: http://dx.doi.org/10.18180/tecciencia.2016.21.8

Received: 21 Oct 2015 Accepted: 10 May 2016 Available Online: 31 Aug 2016.

1. Introduction

Wastewater treatment plant biosolids in two states, With No Treatment (WNT) and Ashes (A), were added to ceramic paste for brick manufacturing. The elements were cooked at three different temperatures (950°, 1000° and 1050°C) and the percentages of the content Clay-Biosolid WNT and Clay-Biosolid A, were 0, 5, 10 and 15%. Bricks manufactured with 15% ashes at 950°C were found to have a resistance to compression close to 26 MPa, meeting the Colombian Technical Norm 4205 (NTC) for structural and non-structural masonry of internal use and closing or divisory walls that support their own weight. We carried out a chemical, structural and thermic characterization of the raw materials that were used (clay and biosolid). We also performed a leaching test (TCLP) to evaluate toxicity characteristics to determine the safety values for heavy metals (Cr and Zn) in the biosolid. By meeting the requirements indicated in NTC 4205, we proved that the total percentage of biosolid that can be used as an addition in construction materials such as bricks is at least 15%, representing a substantial positive impact on the environment. These results open the path to the proposal of even larger percentages of ceramic paste replacement.

Keywords: Bricks, Biosolids, Ashes, Compression, Ceramics.

Resumen

Se adicionó biosólido proveniente de una Planta de Tratamiento de Aguas Residuales (PTAR) en dos estados: Sin Tratamiento (ST) y Ceniza (C), a una pasta cerámica (arcilla) para la fabricación de ladrillos. Los elementos fueron cocidos a tres temperaturas diferentes (950 - 1000 - 1050°C) y los porcentajes de remplazo (Arcilla - ST) y (Arcilla - C) fueron de (0-5-10-15)%. Se encontró que los ladrillos fabricados hasta con un 15% de ceniza a 950 °C, tienen una resistencia a la compresióncercana a los 26 MPa, cumpliendo así con la Norma Técnica Colombiana (NTC) 4205 para mampostería estructural y no estructural de uso interior y muros de cierre o divisorios que cargan su propio peso. Se realizó una caracterización química, estructural y térmica a las materias primas utilizadas (arcilla y biosólido). Se llevó a cabo una prueba de lixiviación para evaluar las características de toxicidad (TCLP por sus siglas en inglés) que permite determinar la inocuidad de los metales pesados (Cr y Zn) en el biosólido utilizado. Con el cumplimiento de los ítems señalados en la NTC 4205, se comprueba que el porcentaje total de biosólido que puede ser utilizado como adición en un material de construcción; como los ladrillos; es de por lo menos el 15%, lo que contribuye en un porcentaje alto al medio ambiente. Los resultados obtenidos abren el camino para proponer mayores porcentajes de remplazo de material.

Palabras clave: Ladrillos, Biosólido Seco, Cenizas, Compresión, Cerámicos.

1. Introduction

The function of wastewater treatment plants is to clean the water used in homes, factories, supermarkets, etc., before discharging it into water sources that are part of the ecosystem to which they belong. Through physical, chemical and biological processes, the decontamination of the residual liquid is achieved and as a byproduct of this process biosolids are obtained. Biosolids are defined in Colombia in Decree 1287 of 2014 [1] as:

"The product of the stabilization of the organic fraction of the sludge generated in the treatment of municipal wastewater with physical, chemical and microbiological characteristics that allow their use." (Translation from the Spanish original).

Large quantities of this material are produced, and due to the quantity of nutrients and organic matter it possesses, one of its most common uses is as fertilizer in agriculture or as soil improvement. Despite the potential benefits that could be generated, the process is being abandoned due to the health and environmental problems that the toxins in sludge can generate [2]. Landfills are an easy and common alternative for disposing of sludge or biosolids. However, they can result in technical and environmental problems due to the characteristics of the material. First, its high hydrogen content is absorbed by plants and easily leached and mobilized, thus generating eutrophication and pollution in aquifers [3]. In addition, a landfill requires large areas for disposal or the occupation of available land.

These biosolids are creating environmental problems due to 4 basic types of pollutants: 1) Metals, because of their potential to accumulate in human tissues and their biomagnification; 2) Nutrients and organic matter, due to their eutrophication potential in groundwater and surface waters; 3) Organic contaminants, because of their lack of clarity in the ecotoxicology role on soil-plant-water systems; and 4) Pathogens, due to the presence of bacteria, viruses, protozoa, flukes, tapeworms and nematodes [4].

Currently, Colombian government policies are promoting the increase of discharge treatment levels in municipal sewerage systems. This translates into an increase in the waste or byproducts (sludge or biosolids). Colombian Decree 1287 of 2014 [1] considered some alternative uses for biosolids, based on their category and classification. Among the suggested uses, the decree suggests their use as an input in the manufacturing of building materials. In this study, we evaluate the use of biosolid and biosolid ashes from the El Salitre wastewater treatment plant in Bogotá as raw material for brickmaking. As evidence justifying the choice of our source material we should mention the following: the wastewater treatment plant treats 4 m3/s of wastewater, approximately 4,950 tons of biosolids are generated per month [5] and there has not been an evaluation on its alternative uses in construction materials [6].

The field of construction materials may be a viable alternative in order to give more value to sludge or biosolids. Much prior research has been conducted, for example [7] incorporated ashes from burning sewage sludge to ceramic slurry to produce bricks. Among the results that stand out we find a lower rate of plasticity and drying shrinkage, which results in better-quality elements. Elements with up to 50% ash inclusion meet the required resistance to compression. The authors in [8] made bricks by incorporating dried mud from a wastewater treatment plant as raw material; the goal was the technical and environmental evaluation of the manufactured items. From the results obtained, we can observe an inverse relationship between the resistance to compression and the percentage of incorporation of sludge. The values obtained in the study allowed the classification of bricks as building material suitable for use in engineering. Regarding the environmental evaluation, the TCLP test was performed, which showed that the level of leaching of metals is low, and the amounts of Cr (total).

The authors in [9] evaluated the technical feasibility of using biosolids from wastewater treatment plants in a metropolitan area of Chile as a partial replacement for clay used for brick manufactoring. The authors proposed 3 biosolid states for such replacement: 1) biosolids from zone 1, 2) biodrying biosolids and 3) solar-drying biosolids. The manufactured items are cooked between 950° and 970°C. The results show that the use of biosolids in brickmaking is technically feasible. They obtained items with a resistance to compression of up to 9.2 MPa, meeting the standards for norm NCh 169 of 2001 for a category 3 brick. Finally, in order to obtain better results the study suggests the adjustment and control of key process variables such as cooking curves.

In their research, [10] present a characterization of ashes produced from the incineration of sewage sludge, and evaluate the alternative of recycling them for construction materials such as bricks (as partial replacement for clay). The research results show benefits such as the increase in resistance to compression of the elements made of ash in comparison with those not containing ashes. The aforementioned brought about the research that led to this article, the main objective of which was to evaluate from a technical point of view the alternative of using biosolids With No Treatment (WNT) and Ashes biosolids (A) as input materials in manufacturing construction materials.

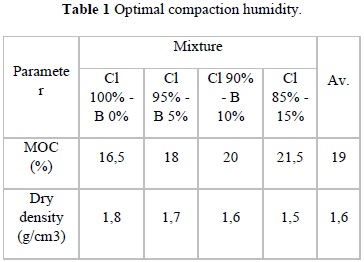

such as bricks. To achieve this purpose, we prepared the Clay-WNT and Clay-A mixtures with replacement percentages as follows: 100% Clay - 0% WNT (A), 95% Clay - 5% WNT (A), 90% Clay - 10% WNT (A), 85% Clay - 15% WNT (A). For each group we manufactured 5 elements for testing resistance to compression, and manufactured a total of 40 bricks. The characterization of the mechanical properties was carried out under the guidelines of the NTC 4205 and NTC 4017 standards.

2. Materials and Methods

2.1 Raw Materials

For brickmaking we used clay (Cl) from the company El Oasis, a brick company located in Boyaca, Colombia. The biosolid was collected from the El Salitre wastewater treatment plant (in Bogotá) and the ash was obtained by burning the biosolids to temperatures of over 550°C in a furnace for manufacturing ceramic elements.

2.2 Characterization of raw materials

The particle size of the biosolids was obtained from historical monitoring records conducted in the El Salitre wastewater treatment plant and supplied by the plant under an agreement with Santo Tomás University. The clay was physically characterized by determining its granulometric composition, specific gravity and natural moisture.

Additionally, we used the following test on Clay-Biosolids: Chemical composition (OXFORD Energy Dispersive Spectroscopy test - EDS), probe connected to a JEOL Scanning Electron Microscope Reference 5910 JSM, Mineral composition (X-ray diffraction - XRD) in a PANalytical X-ray diffractometer, reference X'Pert PRO MPD with a PixCell detector and a Cu tube with a wavelength of 1.5406 Å.

2.3 Process Variables

2.3.1 Size and Dosage

The properties of the ceramic elements depend heavily on the size and distribution of the particles of the raw materials. The particle size affects properties such as plasticity, porosity, specific gravity, homogeneity, permeability and penetrability [11] [12]. The raw materials (Cl - WNT - A) were subjected to a grinding process or downsizing by selecting particles between 70 µm to 1 mm (material that goes through any sieve No. 18 to No. 200). The dosage of the materials was performed on the mixtures by weight and their homogenization was done manually.

2.3.2 Molding

The ceramic elements were molded based on NTC standard 296 (modular dimensions of ceramic bricks), at a rectangular shape with a length of 100 mm, a width of 50 mm and a height of 50 [13]. We also used the uniaxial pressing technique, applying an effort of 60 kgf / cm2.

The humidity content in the mixture is a control variable in the brickmaking process. For fixation, we performed the standard proctor compaction test with the biosolids [14] Table 1 shows the average of the humidity obtained for each of the mixtures. Finally, all ceramic elements were manufactured with a humidity of 19%.

2.3.3 Drying

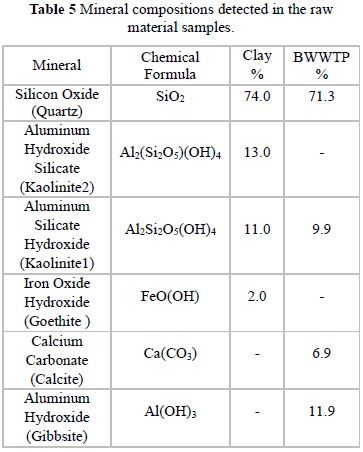

Bigot curves were constructed in order to demonstrate the effect that including biosolids in the ceramic mixture had and in order to control the drying process. For mixtures of clay and biosolids, we evaluated the evolution of shrinkage and weight loss during the drying phase at 60°C.

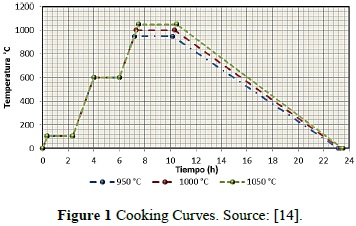

2.3.4 Cooking

For the cooking process we applied the curve shown in Figure 1 [15], with 3 temperature ramps and a rate of increase of 5°C/min each. The first ramp goes up to 105°C and was maintained for 120min in order to evaporate the remaining humidity of the drying process. The second ramp reaches 600°C, and was maintained for 120min. In this phase the organic matter in the ceramic paste decomposes. Finally, we reached the cooking temperature (950-1000-1050°C) and kept it for 180 min. Afterwards we allowed the muffle to cool down to reach room temperature.

2.3.5 Quality of the items manufactured

The quality of the manufactured items was determined based on technical standard NTC 4205 [16] Resistance to compression was evaluated according to the methodology established in technical standard NTC 4017 [17].

3. Methods

3.1 Characterization of Raw Materials

3.1.1 Particle Size Analysis

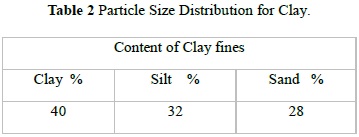

The particle distribution of the fine fractions of the clay was determined by the hydrometer method of particle size analysis according to the standard [18] With these results we established the percentages shown in Table 2.

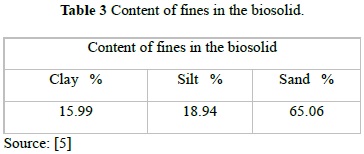

With the percentage of fines obtained (clay, silt and sand), clay is classified as a clayey material rich in fine particles (colloids) of plastic behavior in wet states and as a hard and tough material in dry states. The content of sand, silt and clay in the biosolid can be seen in Table 3. This information was provided by the El Salitre wastewater treatment plant, the entity that performs tests on agronomic parameters with the purpose of use in soils [5]. According to the soil classification system of the United States Department of Agriculture (USDA), biosolids is a sandy loam material in texture, with a high sand content, but with enough silt and clay to have some cohesion [19].The result reveals that the biosolid is a material with degreaser potential within the mixture or the ceramic paste, which would translate into a decrease in plasticity.

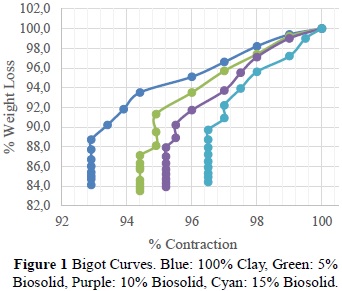

3.1.2 Chemical composition

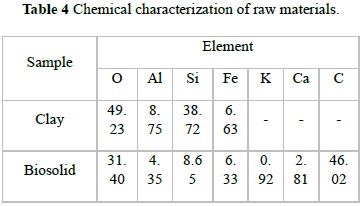

The clay selected for the mixture has the chemical composition shown in Table 4, which makes it suitable for use as raw material for the manufacture of ceramic materials. The high silicon dioxide content (74%) in the clay is an indication of a low percentage of shrinkage in the elements. The chemical composition of biosolids is typical of its origin; it is a material with high organic content (high A - 46.02%).

3.1.3 Mineral Composition

Table 5 shows a comparison table of the different mineral phases identified in the samples with their respective percentages. The results found in the mineral characterization are in the same line as those found in the chemical characterization of raw materials. There is a high quartz content in the clay and biosolids.

The clay used corresponds with a material high in quartz and kaolinite mineral content, which makes it suitable clayey material for the manufacture of traditional ceramic parts and construction materials with medium to high specifications (bricks, tiles, masonry, among others). With the low iron oxide content (Goethite), light brown coloring elements can be obtained.

Biosolids can then be said to be a favorable material with positive cementation features for the construction industry. This is based on the content of mineral phases like gibbsite and Calcite (≈20%).

The percentage of quartz (SiO2) found confirms the hypothesis for its use as a degreaser material, and finally, the presence of kaolinite at 9.9% suggests possible applications in ceramic bricks, since it promotes sintering by being thermally activated [20].

If the chemical and mineral composition of the two materials (clay and biosolids) are observed, enough aluminum-silicate phases are detected to, at high temperatures (higher than 1000°C), potentially form phases such as corundum or mullite, which are very stable and hard ceramic products (compact).

3.1.4 Drying

In order to have greater control in the drying phase of the brick manufacturing process, we created items with different percentages of biosolid inclusion. The purpose of this procedure was to demonstrate the evolution of drying shrinkage and to propose a suitable method for achieving this. Figure 1 shows the Bigot curves. Here we observe that the maximum contraction was 7.1% and it appeared in items that were manufactured with 100% clay - 0% biosolids. Minimal shrinkage was obtained for the elements made from 85% clay and 15% biosolids, at 3.5%. The results show that the incorporation of biosolids into the ceramic paste decreases the drying shrinkage of the ceramic elements, which reinforces the hypothesis regarding the non-plastic and degreaser nature of biosolids.

The results demonstrate that biosolids reduce the plasticity of ceramic pastes and thus the contraction that can be generated in the drying process. This is a very positive effect because it reduces the risk of the occurrence of cracks and deformations in the ceramic prism.

Regarding the weight loss of the elements, the results reveal that in the drying process the water used in forming the ceramic paste is eliminated. All elements made with different percentages of biosolids lose between 17% and 18% in weight, while the remaining 1% belongs to the crystallographic water, chemically bound to the mineral crystals that shape the clay body.

By looking at the Bigot curves, the minimum amount of time to achieve the critical humidity point was determined to be approximately 240 minutes (4 hours), time in which the contraction of the elements reaches its maximum value.

Based on the results described above, the drying of the elements was performed in three stages. In the first stage, we aim for the partial removal of the surface humidity by drying the atmosphere for a period of 12 hours. The second stage took place in an oven for 12h at 60°C. Subsequently, the third drying stage is reached by increasing the temperature up to 105°C in order to achieve a suitable item, ready for being subjected to the different cooking temperatures.

3.1.5 Quality of the manufactured items

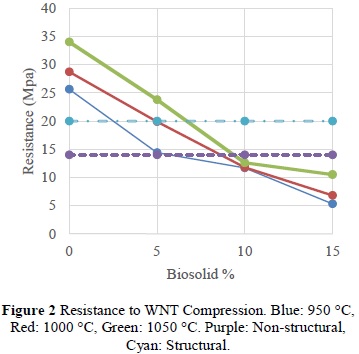

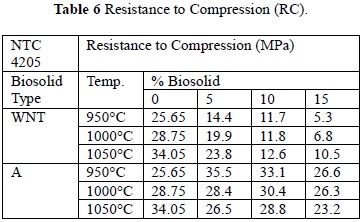

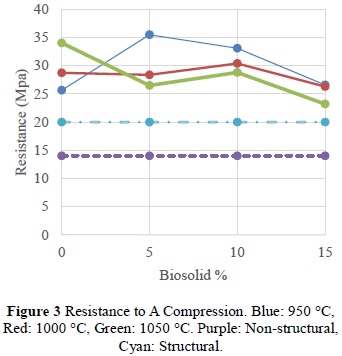

Fired clay masonry units must comply with the minimum resistance to compression specified in the NTC 4205, when being tested according to standard NTC 4017. The standard NTC 4205 requires a resistance to compression of 14 MPa for nonstructural masonry units and of 20 MPa for structural masonry units. In Table 6 we see the average values of 5 units of each experimental group (WNT- A).

Figure 2 shows that the ratio percentage of incorporation of WNT - RC is inversely proportional; items manufactured at 15% show the lowest resistance values. Only the group (1050°C - 5%) meets the requirements for use as structural masonry. Elements made with more than 5% of WNT do not meet any of the limits established in the standard for use in structural and non-structural masonry.

The results in Table 6 indicate that resistance depends mainly on the amount of ashes in the brick and the cooking temperature. The optimum amount of ash that can be mixed with clay to make good-quality bricks is 15% by weight at a cooking temperature of 900°C. With this configuration we achieved resistance near 27 MPa. These elements can be used as structural and non-structural masonry, according to the NTC 4205.

The behavior of elements made from ash (A) in Figure 3 is in line with [21]. In this case the ash acts as a fluxing agent, reducing the sintering temperature and it improves the resistance to compression due to its iron and calcium content.

4. Conclusions

The results of this study have shown that biosolid ash can be included as a substitute for clay in making quality bricks. Biosolids (WNT or A) can be used as degreaser material in the production of bricks, thus helping to minimize the risk of generating cracks and deformations in the brick during the drying process.

The content of gibbsite and calcite found in biosolids make this residue a cementation material suitable for possible inclusion as a raw material in obtaining materials in the construction sector. Ash acts as a fluxing agent, reducing the sintering temperature, and improves the resistance to compression due to its iron and calcium content.

The results of the compression resistance tests indicate that resistance depends on the amount and form of replacement material inclusion and its cooking temperature. The replacement of WNT biosolids does not allow for obtaining quality elements that satisfy the requirements of the standards.

The optimum amount of ash that can be mixed with clay to make good quality bricks is 15% by weight at a cooking temperature of 900°C. With this configuration we reached resistance close to 27 MPa.

The increase in resistance values are explained in the transformations experienced in the ceramic matrix when it reaches the maximum cooking temperature established at (950°C - 1000°C - 1050°C), possibly the formation of new mineral phases (corundum or mullite).

We demonstrated that with a good combination of the cooking temperature and the percentage of addition of biosolid ash, the property of resistance to compression increases compared to elements made with 0% of A. It is thus possible to conclude that biosolid ash can be used as an input for the manufacture of construction materials that meet the requirements in NTC 4205 for structural and non-structural masonry.

References

[1] Ministerio De Vivienda, Decree No. 1287, Criterios Para El Uso De Biosólidos Generados En Plantas De Tratamiento De Aguas Residuales, Colombia, 2014. [ Links ]

[2] Dean, R., & Suess, M., The risk to health of chemicals in sewage sludge applied to land. Waste Management Resources, 251-278, 1985. [ Links ]

[3] Universidad Autónoma de Chihuahua, Manejo de Sólidos residuales o biosólidos, Chihuahua, México, 2012. http://www.oocities.org/edrochac/residuales/biosolidos9.pdf. [ Links ]

[4] Vélez Zuluaga, J. A., Los biosólidos: ¿Una solución o un problema? Producción + Limpia, 57-71, 2007. [ Links ]

[5] PTAR el Salitre, Plegable técnico, Acueducto Agua y Alcantarillado de Bogotá, Bogotá, Colombia, 2011. http://www.acueducto.com.co/wpsv61/wps/html/resources/PTAR/Plegable_tecnico.pdf. [ Links ]

[6] PTAR el Salitre, Acueducto, Agua, Alcantarillado y Aseo de Bogotá, Bogotá, Colombia, 2013. http://www.acueducto.com.co/wpsv61/wps/portal/!ut/p/c5/hY7LDoIwEEW_hS-YofQBS1QEEqBqo1I2pDEEMTxcGBP-XogbN8jM8tx7ZqCAaXvzbmrzaobetJBDwUvXVqkSEUEpyA5jPwhc7tANPdGJa15uQz-iIkGU5IJIMqaOeFYOxs5K-zrf-0mEbO9hLJmXyDS0EdmX__PPHBfGR8iioavgvGLRHuQcNBRi8Vthg26r2txGeHY5. [ Links ]

[7] Lin, D.-F., & Weng, C.-H., Use of sewage ash as brick material. Journal of environmental engineering, 127 (10), 2001. [ Links ]

[8] Weng, C.-H., Lin, D.-F., & Chiang, P.-C., Utilization of sludge as brick materials. Advances in environmental Research, 679-685, 2003. [ Links ]

[9] Navarro Navarro, C. R., Corvalán G., S., & Contreras B., S., Evaluación de la potencialidad del uso de biosólidos originados en las plantas de tratamiento de aguas servidas en la fabricación de ladrillos, Memorias del 8° Congreso Internacional de metalurgia y materiales (pp. 1-9) CONAMET/SAM, Santiago de Chile, Chile, 2008. [ Links ]

[10] Tempest, B. Q., & Pando, M. A., Characterization and Demonstration of Reuse Applications of Sewage. International Journal of GEOMATE, 4(2), 552-559, 2013. [ Links ]

[11] Espitia, C., Quintero, J., Rodriguez, A., Bernal, F., Romero, F., Mojica, J., Ramirez, J., Catálogo de propiedades físicas, químicas y mineralógicas de las arcillas para cerámica roja en los centros urbanos de Medellín, Ibagué y Sabana de Bogotá, Instituto Colombiano de Geología y Minería, Bogotá, Colombia, 2003. [ Links ]

[12] Morales Güeto, J., Tecnología de los materiales cerámicos, Díaz de Santo, Comunidad de Madrid, Spain, 2005. [ Links ]

[13] Instituto Colombiano De Normas Técnicas Y Certificación - NTC 296, Ingeniería Civil y Arquitectura. Dimensiones Modulares de unidades de mampostería de arcilla cocida. Ladrillos y bloques cerámicos, Bogotá, Colombia, 2000. [ Links ]

[14] Instituto Nacional De Vias - I.N.V. E -141-14, Relaciones de humedad - masa unitaria seca en los suelos (Ensayo normal de Compactación), Colombia, 2014. [ Links ]

[15] Chiang, K.Y., Chou, P.-H., Hua, C.-R., Chien, K.-L., & Cheeseman, C., Lightweight bricks manufactured from water treatment sludge and rice husks. Journal of Hazardous Materials, 171, 2009. [ Links ]

[16] Instituto Colombiano De Normas Técnicas Y Certificación - NTC 4205, Ingeniería civil y arquitectura. Unidades de mampostería de arcilla cocida. Ladrillos y bloques cerámicos, Bogotá, Colombia, 2000. [ Links ]

[17] Instituto Colombiano De Normas Técnicas Y Certificación - NTC 4017, Ingeniería civil y arquitectura. Métodos de muestreo y ensayos de unidades de mampostería de arcilla, Bogotá, Colombia, 2000. [ Links ]

[18] Instituto Nacional De Vias - I.N.V. E -124-14, Análisis granulométrico por medio del hidrómetro, Colombia, 2014. [ Links ]

[19] Castro Franco, H. E., Fundamentos para el conocimiento manejo de suelos agrícolas, Instituto Universitario Juan de Castellanos, Tunja, Colombia, 1998. [ Links ]

[20] Cerdeño Del Castillo, F., & Lorenzo P, A., Viabilidad técnica de uso de lodos de estaciones de tratamiento de aguas potables (ETAP) en la fabricación de materiales cerámicos para la construcción. (pp. 89-92.). Conarquitectura, Colombia, 2006. [ Links ]

[21] Wiebusch, B., & C.F. Seyfried, Utilization of sewage sludge ashes in the brick and tile industry. Water Science and Technology, 36 (11), 251-258, 1997. [ Links ]

[22] PTAR el Salitre, Históricos parámetros fisicoquímicos y microbiológicos, Acueducto, Agua, Alcantarillado y Aseo de Bogotá, Bogotá, Colombia, 2011. [ Links ]

[23] PTAR el Salitre, Históricos parámetros físicoquímicos y microbiológicos, Acueducto, Agua, Alcantarillado y Aseo de Bogotá, Bogotá, Colombia, 2014. [ Links ]