1. Introduction

Growing global energy demand, dependence on fossil fuels, and the prevailing need to diminish atmospheric emissions of greenhouse gases, have promoted the study of new fuels and technologies that permit using the renewable resources available [1].

For 2015, global petroleum consumption was approximately 91,300-million barrels per day [2], positioning it as the principal source of primary energy used with 33.2% participation in the global energy generation, followed by coal and natural gas with 24% and 21.1%, respectively. Additionally, 19.1% of the global energy is generated from renewable energies and the remaining 2.6% through nuclear energy [3].

The study of renewable energies, denominated as any type of energy that can be obtained through sources available in nature and in spite of its use can be replaced constantly, has increased in recent years. This increase is reflected in the number of new publications in areas involving renewable energies, which between 1996 and 2016 went from 2,000 to 12,600 articles per year approximately [4][5][6].

Renewable sources consumed globally to obtain primary energy include hydroelectric (26%), traditional wood (23%), biofuels (22%), wind energy (18%), biogas (5%), solar energy (4%), and geothermal energy (2%). According to the aforementioned, 50% of the renewable sources used in the world are based on the use of biomass. In part, this is due to the versatility of its components, which permits obtaining different usable products, according to their physicochemical characteristics [7].

Pursuant to the use and treatment of biomass, it is possible to classify it into two main groups, traditional biomass and modern biomass. Traditional biomass corresponds to that which can be burnt directly, without any type of previous treatment; this biomass is used generally in rural zones for household heating or cooking.

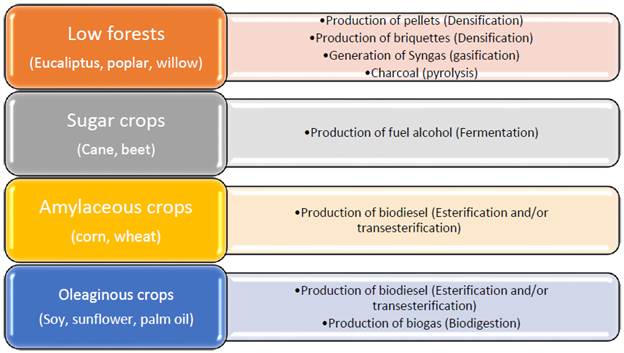

From diverse processes of physical and/or chemical transformation, it is possible to avail of the properties of the different biomass sources available - generating in the market new energy products that diminish part of the energy disadvantages against fossil fuels. This new biomass group used in energy production gave way to what is considered modern biomass, used to obtain intermediate fuels or direct transformation in thermal energy through combustion [1]. Thus, when evaluating the properties of a biomass and following a route of transformation, it is possible to obtain a specific product with higher added value. Figure 1 presents a simple classification of the routes of transformation according to the type of biomass [8].

The use of biomass as fuel is an excellent alternative to generate renewable thermal energy; in spite of this, compared to fossil fuels, it has low calorific value, low density, and high moisture [9] [10], causing difficulties regarding its use and storage. In order to increase the density of the biomass, standardize shapes and sizes, and reduce storage costs, drying processes, shape reduction, and compression are used, giving way to solid fuels elaborated from biomass known as pellets.

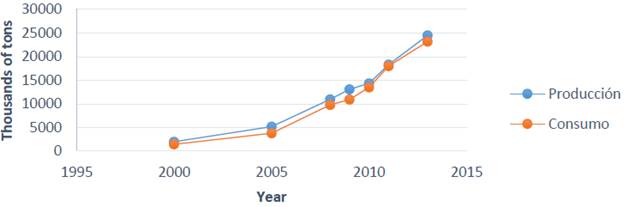

Given the growing energy demand in homes and industry and the multiple advantages attributed to this fuel compared to the traditional biomass, consumption of biomass pellets showed rapid growth from 2- to 37-million tons between 2000 and 2015, with 92% growth rate. From this, it is possible to say that the global market of pellets is relatively recent and growing rapidly [11].

Due to these dynamics, it is expected that by 2020 its global production will be close to 45.2-million tons/year, while the global demand for biomass pellets increases to 59-million tons/year, which generates an unsatisfied market [12] [13] [14]. Considering these figures, the increasing need to promote sustainable energy systems, and low development of the Colombian industry, this work sought to review the behavior of the international market, emphasizing on the principal producer and consumer countries, along with a review of the research trends. This aims at providing more bases to promote research routes and, with this, identify possible industrial developments that diversify the Colombian energy market.

2. Global production and consumption of pellets

Pellets commercialized internationally are elaborated by following multiple criteria that ensure their quality and homogeneity, which is why the principal raw material chosen to produce pellets is sawdust, which is a residue from the wood industry [15]. However, due to variations in the availability of sawdust, new raw materials have been used to produce biomass pellets, hindering international commercialization of pellets, among which it is possible to find agroforestry waste [16] [17], endemic timber species [18] [19], and mixtures of biomass sources [20] [21].

Due to the growing pellet market, countries like the United States and Canada created large plants to produce pellets and promoted transcontinental commercialization through commercial treaties, bringing their product to Europe and Asia, adding to the market a demand of nearly 18-million tons in 2010 [15]. To counter this effect, the installed production capacity globally grew close to 22% with a projection of 28-million tons annually. The effect of these events was only evidenced by 2011 when pellet production and consumption reached equilibrium after many electric power plants made a total transition to biomass as principal fuel. This was the case of the Tilbury Power Station in the United Kingdom, with installed capacity close to 1.131 MW of power by using 100% biomass pellets or the Drax plant also in the United Kingdom, which in 2011 underwent remodeling and promoted the construction of a 300 MW plant that uses 100% biomass [22] (Figure 1).

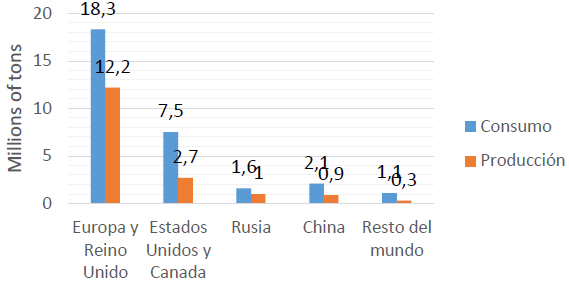

In 2013, the global production was led by the European Union and the United Kingdom with 12.2-million tons, reaching close to 50% of the total produced, followed by the United States and Canada with 31%, China and Russia with 9% and 7%, respectively, and the rest of the world with 4%, for a total of 24.5-million tons (Figure 3). In comparison with the production, consumption was of 23.2-million tons of which 18.3-million were destined for Europe and the United Kingdom, making up approximately 80% of the global consumption of pellets, followed by 2.7-million tons in the United States and Canada (12%), 1- and 0.9-million tons in Russia and Asia, respectively, and the rest of the world with a total consumption of 0.3-million tons [23].

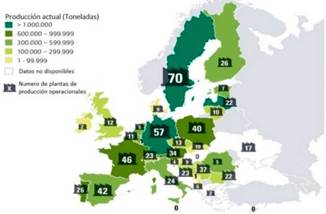

For 2014, Sweden, Germany, and Latvia were the principal biomass pellet producing countries in Europe. These three countries produce about 40% of the European total. Likewise, they have 24% of the total number of pellet production plants in the European Union and the United Kingdom, being Sweden, with 70 plants, the country with the highest number of plants installed (Figure 4).

Further, while Germany continued increasing its production since 2010 (8.4% with respect to the previous year), in 2010, Sweden entered a slow-growth stage (4.4% with respect to 2009), which has triggered competition in importations from countries, like Russia and Latvia.

2.1 Europe and the United Kingdom

2.1.1. Sweden

Since early 1980s, Sweden has used biomass pellets as a means of household heating and it is one of the principal consuming countries at industrial and residential levels.

Likewise, it is the second biggest producer in Europe after Germany [24].

Close to 30% of the final energy used in Sweden comes from biomass [25]. While for 2010 it had 35 plants and an estimated production of 1600 kt/year [26], by 2014 the plants increased to 70.

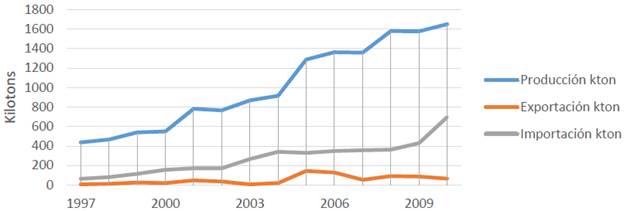

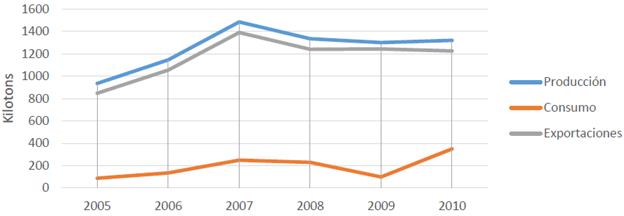

In 1990, Sweden implemented levies on the use of fossil fuels, thus promoting the use of clean and renewable energy sources. The goal for 2020 is to produce close to 51% of the energy through clean energy sources [25]. Pellet production in Sweden has increased slowly over the years; the biggest annual growth occurred between 2000 and 2001, going from 549 to 782 kt with 30% growth rate. While other markets were affected by the economic crisis of 2008, in Sweden this event did not impact strongly. Compared to production, exports of pellets are low, which permits ensuring the existence of a high internal consumption of pellets that tends to increase with the change of seasons [25] (Figure 5).

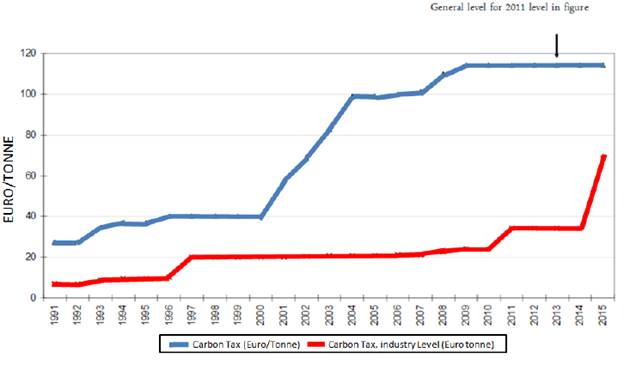

Seeking to regulate internal emissions, in 1991 Sweden established an emissions commerce system to, thus, charge taxes to companies that contaminate. Hence, a tax was enacted on CO2 emissions, which was high for homes and services and low for agro-industrial production sectors (manufacturing, agriculture, forestry, and aquiculture among others), €114 and €34 in 2011 per ton of CO2, respectively. This levy is charged as a function of carbon content in fuels [27].

The CO2 taxes and, recently, tax on energy are some of the charges made that indirectly diminish greenhouse emissions and promote the appropriation of renewable energies and consumption of pellets [22]. Since 1996, Sweden saw a disengagement between its gross domestic product (GDP) and the behavior of the CO2 emissions. Between 1990 and 2013, the GDP for Sweden grew by 58% while CO2 emissions diminished by 23% [28].

2.1.2 Germany

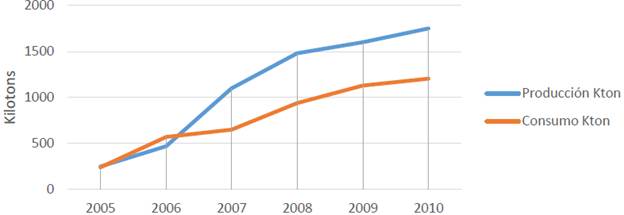

Germany is the main producer of pellets in the European Union. In 2013, it had 57 production plants, an installed capacity of 3.2-million tons and a total production of 1.7-million tons. Between 2005 and 2007, pellet production in Germany grew by approximately 77% going from 250 to 1100 kilotons; this growth was promoted by trade liberalization after the 2006 hike in prices per ton of pellets that went from 177 €/t to 216 €/t, making it possible for the country to become a pellet exporter; nearly 30% of the total production is exported to countries, like Austria, Denmark, Italy, Sweden, France, and Belgium [22](Figure 7)

Since 2007, pellet consumption in Germany has grown rapidly influenced by internal policies, such as the trade incentive program (MAP), which acts as financial support triggering small-scale use of pellets, which - in turn -generates increased consumption in the residential sector [22]. The MAP program pays at least 2000 € when a furnace working with fossil fuels is replaced by a furnace that operates with pellets and, additionally, reduces credit interest rates to home owners [25]. Pellet consumption had a slow growth stage from 2009 due to the freezing of the budget for the MAP program, which generated uncertainty among investors [22]. However, national projections indicate that the market will continue growing according to expectations, while renewable energies gain greater importance.

2.1.3 Latvia

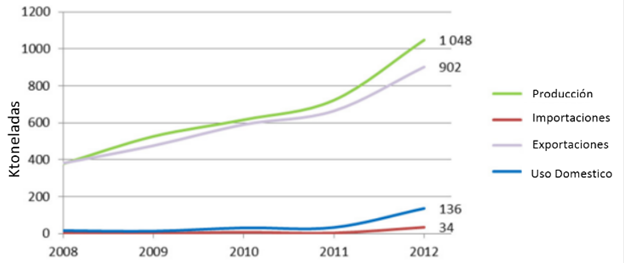

About 60% of Latvia is covered by forests, which is why sawmills constitute one of the main industries in the territory, with the exploitation of lumber being an important source of labor [29]. Pellet production in Latvia began around 1990 driven by Sweden that for the time demanded large amounts of pellets. However, no interest was shown by the government in investigating and increasing short-term production, which is why many pellet production companies are foreign.

In 1998, Swedish Company Lantmannen installed the first industrial plant to produce pellets in Latvia, known as SBE Latvia Ltd. Prior to this date, pellets produced came from small manufacturing industries. SBE was created to supply the domestic pellet market, reaching a production of over 70,000 tons annually.

After wood pellet consumption became popular, Latvia managed to broaden its trade window encompassing markets in Denmark, Estonia, Sweden, and the United Kingdom; countries to which it currently exports nearly 86% of the total production.

Only 14% of the total production is consumed in the country; this corresponds to 136,000 tons of pellets whose consumption is distributed in the following manner: 50% for the residential sector, 35% for public and commercial sectors, and the remaining 15% is destined for the energy industry, where close to 7% corresponds to heat production [30].

In 2011, Denmark increased the demand for pellets by 38.7%, which pushed the production sector in Latvia and, consequently, increased exportations (Figure 7).

The biggest pellet production plants in Latvia have capacities between 35,000 and 180,000 tons/year. Currently, Latvia has an installed capacity close to 1.2-million tons/year.

2.1.4 The United Kingdom

Multiple energy policies triggered in the United Kingdom the consumption of pellets, these promoted generation of energy with low production of emissions, promoting the operation of different plants to produce electric energy with biomass. Likewise, reforms in the electric market were created, permitting funding of businesses that generated electricity from biomass, to allow these to compete in the energy market. Currently, the United Kingdom generates around 2.5 GWh of electric power from biomass, the goal for 2020 is to produce 6 GWh.

Consequential of the new energy policies in effect and of the multiple plants that began operating 100% with biomass, a strong push was generated in pellet consumption in the country, increasing from 176 kt in 2010 to 1000 kt in 2011, equivalent to 82% growth. By 2012, the United Kingdom became the biggest consumer of pellets for production of electric energy in Europe [23] and again pushed the national consumption of pellets, going from 1,400 to 3,850 kt between 2012 and 2013, which represents a 35% increase with respect to the previous year.

2.2 The United States

The United States is one of the countries with the highest consumption of energy in the world, it has a high industrial development; hence, it generates higher amounts of atmospheric emissions.

Although the country has designed alternatives to encourage the use of renewable energies, it still depends largely on fossil fuels. Nearly 37% of the total energy consumed in the country comes from petroleum, 25% from natural gas, 21% from coal, 9% from nuclear energy, 7% from renewable energies, and 1% from liquid biofuels.

The country has a biomass potential estimated at 1.3-billion tons in dry base. The production of pellets is calculated in values close to 7.5-million tons/year [22] of which the country consumes nearly 3.1-million tons of pellets (41%) destined for the residential sector in home heating [11] [31]. The remaining 59% of the production of pellets is exported to Europe and the United Kingdom.

2.3 Canada

Being the third country with the highest production of pellets in the world, Canada has a total of 39 plants for large-scale production. The Pinnacle Pellet B. L. plant has a capacity of 320 kt/year, which is about 10% of the installed total national equivalent at 3262 kt/year.

In Canada, these biofuels are generally used in remote communities and with household heating purposes. According to this dynamic, production of biomass pellets in Canada keeps a close relationship with exports [Figure 8); with changes in foreign markets affecting directly the local production.

Until 2003, Canadian exports took place at a 50-50 ratio toward Europe and the United States. As of then, the United States increased its production capacity, which is why export from Canada to Europe went on to be close to 97% [32]. In 2007, the fall of the euro in relation to the Canadian dollar caused the closing of many production plants, leading to change in the slope in the pellet production curve from positive to negative.

Due to the financial crisis of 2008, when construction of houses diminished and the production of sawdust was affected, growth of the pellet market in Canada showed stable behavior, maintaining its production close to 1300 kt/year. Seeking to increase this behavior, internal policies were generated to promote a domestic market of pellets, triggered by the Canadian Bioenergy association, which grants monetary benefits to inhabitants who changed their ovens and furnaces running on fossil fuels for those running on biomass, which is why in 2009 the internal consumption of pellets increased [22].

2.4. Price of biomass pellets

For pellets, prices set by market depend directly on the price of coal, the seasons, and the availability of raw materials. Given that the raw material for international commercialization is standardized, not every biomass can be used to elaborate pellets and offer them to market. Sawdust is the principal raw material approved, making pellet producers the main clients for sawmills. In case of scarcity of the raw material, the price of pellets will tend to increase and buyers will seek other sources of biomass to meet their needs.

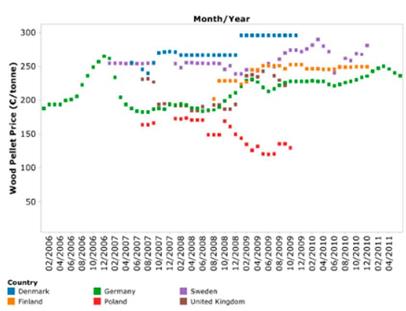

Prices of pellets for Sweden, Germany, and the United Kingdom evidenced a drop in 2008, a product of the economic crisis and then a later recovery (Figure 10).

In countries where the demand for pellets influences strongly on the market and speculations increase regarding increased costs of fossil fuels, there is a drop in the internal sale price of pellets, as in the United Kingdom and Sweden.

Other countries exist in which the external price of pellets does not affect significantly the internal market, given their sufficient production to supply the market without depending on imports. This is the case for Germany and Denmark, which during 2008 were still increasing their production capacity and then were able to recover to, finally, not depend on the foreign market.

Poland, for its part, underwent a drop in its prices between 2007 and 2009 due to the increased offer of pellets and growth of the internal market of pellets.

The direct price of pellets in the Swedish market is higher compared to other countries because of the competition among residential consumers who use pellets for heating and energy plants, given the high consumption of pellets and the import trend an effect is created of pressure on the pellet market, which causes an increase in the internal price [22].

3. Current state systems of research in pelletizing

With the review of specialized databases it was possible to identify four central research hubs referring to research trends related to biomass pellets: a) production of pellets, b) characterization of pellets, c) characterization of pellet combustion systems, and d) market analysis.

3.1. Production of pellets

Several aspects can be studied during the production of pellets; perhaps one of the most worked is the evaluation of the operating conditions to improve the process and obtain high-quality pellets [21] [34] [35]. Works, like that by Nguyen [36], evaluate the influence of the production conditions on the physical and mechanical properties of the final pellet. In this case, during the elaboration of the pellets, temperature, humidity, compression force, and particle shape were controlled to - finally - study which characteristic had the biggest incidence upon the final product by using maple trees as raw material.

Shortage of raw material causes a negative impact on the commercialization of pellets, thus, the evaluation of different raw materials is, currently, a much studied theme.

Raw materials, like rice straw [34], grass [35], olive [37], coconut [38] and wheat, corn and colza [39] are some of the raw materials studied. Zhijia Liu [18] evaluated the production of pellets from bamboo for energy production.

This study is based on prior works, which establish that bamboo does not have the necessary density to obtain a quality pellet, which is why mixtures are made with pine, favoring densification and the pellet's final physical properties, demonstrating that high-quality pellets can be obtained with non-conventional raw materials.

Similarly, Castellano [40] compares among the properties of the raw materials and the final quality of the pellet. Additionally, the author analyzes the composition of nine different raw materials, considering the direct influence of their properties in the pellet's final structure by using scanning electron microscopy (SEM) techniques and elaborating pellets of different particle shapes. This study analyzed the relationship among hardness and amount of lignin and of extracts presents in the biomass, finding that materials with low extracts and high amounts of lignin will be best.

Likewise, pretreatment of the raw material for pellet elaboration is an approach of relevant research. González [41] considered the influence of the drying of the raw material in the fabrication of pellets; that study evaluated physical and chemical quality parameters for pellets made from pine and other conifers. His work permitted characterizing the efficiency of the drying and combustion of said pellets, finding that upon drying the biomass, the pellet's quality increases and its combustion is more efficient.

3.2 Characterization of pellets

Changes in operating conditions can affect directly the mechanisms of densification and, consequently the chateristics of the final pellet, changes in the particle shape impact upon the density, hardness, and durability of the pellets [42] [43]. Hence, globally, studies have been conducted to identify the effect of changes in the fabrication parameters of pellets on their mechanisms of densification and properties. Kristen [44] studied the effect of the change of particle shape on the physical and mechanical properties of the pellets, finding that upon densifying fibrous materials, like previously sieved hay (4-mm mesh), the pellets obtain manage to fulfill requirements of international quality standards in terms of hardness and resistence.

Characterizing the pellets through standards and evaluating their quality is one of the most important research themes. X-ray techniques [45] and generation of prediction models [46] have been developed to facilitate this task.

In addition, characterizing correctly the raw material permits determining its potential and its applicability in pellet production. Liu [47] considered rice husk pellets an alternative for household heating, given the high production of this residue in China, but upon analyzing the raw material, the author found that said material has low calorific value and high production of ashes, making it inefficient.

Thereby, Liu proposed making a mixture between rice husk and bamboo to improve the characteristics of the fuel. Finally, the raw material was characterized by following international norms, obtaining pellets with better characteristics of hardness and calorific value, which permits concluding that bamboo increases the quality of the final pellet and using mixtures of materials permits using residues with low calorific value.

3.3 Characterization of the combustion

Increasing efficiency during pellet combustion is one of the most attractive themes in this area, given that optimizing these processes permits promoting the consumption of pellets. Roy [48] evaluated the combustion process and the resulting emissions when burning pellets in a fixed-bed furnace. This study used four types of pellets from giant grass and sawdust. Proximal and ultimate analysis of each were compared, finding that the emissions profile of four was similar and that the combustion of giant grass pellets is appropriate for energy uses.

In addition, Nunes [49] evaluated different combustion models of pellets to produce energy, considering technologies, like fixed-bed, fluidized combustion and direct combustion calculating efficiency parameters. Furthermore, the study of the combustion of biomass pellets through a transitory simulation with CFD models [50] and prediction of the combustion behavior by using COMSOL software [51] are some of the methods.

Arranz [52] compared among four types of pellets. Properties, like density, ash percentage, hardness, calorific value, and proximal and ultimate analysis were some of the parameters kept in mind. Three of the pellets analyzed were commercial; two of these were made from the pruning of fruit trees (brought form Extremadura, Spain) and the third from pine sawdust (Galicia, Spain) and the last type was elaborated from oak, in the laboratory with semi-industrial equipment (Regiao, Portugal).

As a result of this work, it was found that among the pellets evaluated, those using pine had better characteristics for domestic scale use due to their low production of ashes and of NOx and SO2 emissions, contrasted to their high hardness and calorific value.

The laboratory pellets had acceptable results to be commercialized, but with inferior properties to those evaluated, which led the author to propose optimizing the production at manufacturing scale and promoting research on the study of the properties, materials, and operating conditions for the production of pellets.

González [53] performed a study to characterize the combustion mechanisms of four types of pellets made from the mixture of three types of agricultural wastes (tomato, olive, and edible thistle) and forest residues. Initially, the pellets were characterized through proximal and ultimate analysis. The influence of the type of residue used to make the pellet was evaluated, along with the mass flow, generation of ashes, and air flow within a furnace for household heating.

A TESTO 300 M-I analyzer was used to determine the combustion parameters, such as flame temperature, levels of CO2, CO, O2, and non-fuel gases. Each test was designed by maintaining constant the fuel and air mass flow parameters. As a result of this work, combustion efficiencies were obtained for the different biomass sources used, with 90%, 90.5%, 89.7%, and 91.6% for pellets made from tomato, forest residues, olive, and thistle, respectively. From these results, it was possible to optimize the combustion process in the same furnace; upon making biomass mixtures, 92.4% combustion efficiency was reached with a mixture of 75% tomato and 25% forest residues, maintaining 75% mass flow.

3.4 Market

Finally, market studies make up the fourth axis in the research trends; themes, like economic integration, elaboration of supply chains [54], and studies on the profit in the industrial production of pellets [55] are of interest.

Evaluating the economic and market potential of biomass pellets generates great expectation, given that producing pellets gives added value to materials that are not used in other ways. Hoefnagles [56] conducted an economic study to produce pellets, considering wood of low energy potential. This study used three raw materials: primary forestry residues and sawdust; their characteristics were compared to obtain an estimate to comply with quality parameters regarding moisture and ashes for finished pellets.

The study also considered the product's drying and transport to identify the form of a plant for the production of pellets from these raw materials. After analyzing and determining the form of the plant, it was possible to demonstrate that in large quantities it is possible to produce pellets from wood of low energy potential, with forms of plants between 55,000 and 315,000 ton/year and sale price between 82 and 100 US$/ton.

Market studies, like that by García Maroto [57], permit determining the importance of the domestic market and the qualitative aspects influencing on the commercialization of pellets. These types of works manage to examine methodologies to stimulate the consumption of pellets and characterize existing marketing strategies. This work permitted conducting further research that elaborated profiles of the habitual consumer of pellets and of the population in general.

Thereafter, García Maroto [58] considers factors, like knowledge of the population about renewable energies, the information available on said energies, the intention to adopt systems for pellet combustion, the influence of subsidies from the state in the consumption of pellets, and consumer awareness regarding the effects of using pellets and biofuels. These types of investigations permit determining the elements that influence in the population when adopting a new technology and burning pellets.

4. Conclusions

This study presented a review of the global pellet market, the complexity in the dynamics of consumption, production, prices, and the principal research trends related to this energy source.

From the work conducted and the information gathered, it is possible to ensure that the pellet market is less than 20 years and of rapid growth increasing by 94% between 2000 and 2013. This growth was favored by adopting measures to promote the use of renewable energies around the world.

These policies permitted the creation of large industries that took advantage of the benefits established by the use of biomass as energy source, impacting on the global demand for pellets; this trend created high expectations from the global market with growth estimated in the consumption of pellets at 46.8 Mton/year by 2020, with this consumption being 65% higher than that established in 2015.

Four principal paradigms exist in current research regarding production of biomass pellets, market, combustion, quality analysis, and new materials. Knowing these themes, permits creating a profile of the current needs of producers and promoting commercial growth in this industry. Studying the commercial development of this industry will allow to generate a focus area and promote production to meet the growing demand for pellets.