I. NOMENCLATURE

Aw: Actividad de agua.

TGA: Termogravimetría.

IR FT: Infrarrojo con transformada de Fourier.

DNS: Determinación de azúcares reductores por el método del ácido 3,5-dinitrosalicílico.

°Brix: Grados Brix.

NTC: Norma técnica colombiana.

II. INTRODUCTION

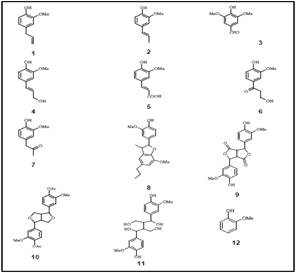

Lignin, a phenolic polymer found in plants, and is, with cellulose, the mechanical support of stems, branches, and leaves, and after cellulose, is the most abundant compound on earth. Lignin may contain 11 monomer fragments (Fig. 1) [1], which depends on the species, crop surface, and climate.

In pulp mills (whether in wood or sugar cane bagasse) lignin is the residue of the cellulose extraction process by the NaOH digestion method [1,2], lignin being used as fuel to generate Steam and electrical energy for the paper and board production process; Is also used in the synthesis of vanillin [3]. Giving new uses to this material represents a challenge [4,5].

Fig. 1 Monomer units constituent of lignin. 1: Eugenol; 2: Isoeugenol; 3: Siringaldehyde; 4: Feluric acid; 5: 4-Hydroxy-3-methoxy--hydroxypropiophenone; 7: 1- (4-hydroxy-methoxyphenyl) -2-propanone; 8: Dehydro-diisoeugenol; 9: Difeluric anhydride; 10: Di-O-acetylpinoresinol; 11: 2,3-bis (hydroxyvininyl) -1,4-butanediol and 12: Guayachol.

Fungi are a group of organisms that because of their very particular characteristics the scientists have segregated them from the vegetal kingdom and placed in a new kingdom, the Fungi. These organisms range from microscopic forms, such as molds and yeasts, to quite bulky forms, such as the so-called shelf fungi that grow on tree trunks [6].

"Agaricus bisporus, Pleurotus ostreatus, Lentinus edodes, Auricularia judae, Flamulina velutipes, and Vovariella volcaceae" are among the cultivable edible fungi currently under commercialization [6,7].

In the class Basidiomycetes, stand out the fungi of the genus Pleurotus, of great nutritive value, little demanding in relation to the substrate and of good development in rustic conditions. Its color is white or brown, although there are bluish and pink varieties. Its flesh is compact fibrous in the hat, and white in the foot with pleasant taste and smell. The edible fungi of the genus Pleurotus, also called mushrooms, are organisms that selectively use lignin for their growth. Pleurotus ostreatus is a saprophytic or parasitic fungus, a decomposer of wood; it grows abundantly on alder, bald, and maple, mainly in the valleys of the rivers. The word Pleurotus comes from the Greek "pleura", which means formed laterally or in the lateral position, referring to the position of the stipe with respect to the petiole; Ostreatus in Latin means in the form of an oyster and refers to the appearance and color of the fruiting body. The cap of this mushroom (fruit body) is rounded with the smooth, convex and convex surface when it is young, the shape of the shells of oysters, for this reason, is commonly called "oyster mushroom", then flattening little to Little, the edge is somewhat rolled at first. The color is variable, cream, white, light gray to brown, taking a more yellowish coloration with time [8].

The edible fungi of the genus Pleurotus, also called mushrooms, are organisms that selectively use lignin for their growth. Because this chemical acts as a barrier to the biological degradation of lignocellulosic residues, they accumulate in large quantities [9]. The alternative of using vegetable residues (RAC) as substrates for mushroom cultivation is important at present because technologies for the production of food for human consumption of acceptable nutritional quality are being implemented, directly affecting a serious problem of contamination [10].

The cultivation of the fungus partially solves three problems facing the world population: food shortages, diseases, and pollution. The cultivation of edible fungi is a process that allows releasing the earth resource as it allows to obtain large productions in relatively little space. It optimizes the use of water and energy because it makes little use of these resources. From the production of fungi on various substrates, there are many scientific works [1,11]. The basic technique has been adapted to the requirements of each type of mushroom. In the seventies, different methods appeared for the cultivation of fungi. The technique was known as "San Antonio" and are four phases [1]:

III. MATERIALS AND METHODS

Production of cellulose from the guadua, and separation of the resulting lignin: The extraction of lignin is carried out by the soda method (a procedure to obtain chemical cellulose from lignocellulosic raw materials using 14% caustic soda, a Digestion time of 2 hours). The digestion is carried out in a reactor powered by boiler steam at 160 ° C, and this is the normal procedure in paper mills (In Colombia the factories use two types of raw materials, they obtain it from wood and in other From sugar cane bagasse) [1].

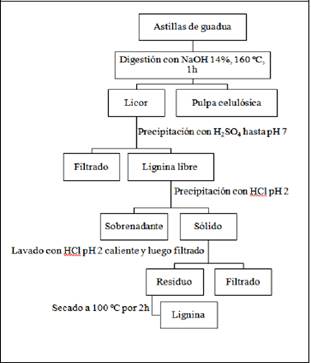

Purification of lignin: From the extracted liquor, the lignin was purified using sulfuric acid and washed with hydrochloric acid, thereby achieving precipitation of lignin (see Fig. 2) [1].

Characterization of lignin: lignin isolated from guadua is examined utilizing infrared spectrometry [1].

Supplementation of PDA substrates with lignin: A microbial culture is made which a solution is containing the NPK nutrients and carbohydrates that are placed in a petri dish and are seeded with the fungus strain [1]. The procedure is as follows [1]:

The PDA agar was selected.

Lignin is added in the proportions of 0%, 10%, 15%, 20%, 30% and 40%.

Sterilization of petri dishes with these substances is done.

Sowing is done with the strain supplied by the CENICAFÉ fungi laboratory.

Leave the petri dishes in an incubator at 27 ° C. Photos are taken every petri dish every 5 days.

Calculate the area occupied by each mycelium of the fungus and compare with the area of the petri dish, this data is given in%. The y-axis is plotted on the% and on the X-axis the time, and this graph is determined by the slope, the growth rate of the fungus will be obtained.

The concentrations obtained were 0.5, 2, 5, 10, 15 and 20% formaldehyde and 1 and 2% hydrochloric acid.

IV. RESULTS AND DISCUSSION

A. Obtaining

Guadua supplied by CRQ is used to quantify and characterize lignin. The culm of 3-year-old guadua angustifolia Kunth was cut into 1 x 1 x 10 cm splinters and dried in the sun.

The lignin isolation procedure is summarized in the flowchart of Fig. 2. Five samples of 0.4 kg of chips of the material were placed in 4 steel containers of 2.5 L capacity, to which was added 14% w/v commercial sodium hydroxide solution in a solid/liquid ratio of 1:5. The material was subjected to digestion in a steam-operated reactor with the following parameters: (a) Time to temperature 20 minutes, (b) Operating temperature 160 ° C, (c) Time at operating temperature 60 minutes, and (d) Time of descent 35 minutes. From the digestion of the lignocellulosic material, 3.7 L of liquor was obtained with a pH of 14.

B. Purification

The liquor from the basic digestion of the chips was subjected to the following procedure: The digestion product constituted by the liquor and cellulose pulp was separated by filtration and pressure to remove the liquor. This was then neutralized with a 20% solution of sulfuric acid, analytical grade until it reached neutral pH, whereby precipitation of the lignin was achieved. The product was then filtered through a glass fiber filter. The separated lignin was washed with water acidulated with hydrochloric acid (pH 2.0) at boiling for 1 h by stirring and decantation of the supernatant liquid to remove most of the remaining hemicellulose. The product that was obtained was dried in an infrared drying oven at 100 ° C for 1 hour [1].

C. Characterization

Table 1 contains the results of the chemical analyses performed on guadua angustifolia Kunth [1].

Lignin isolated from guadua was examined by infrared spectrometry, and the FT-IR spectrum of Fig. 3 shows the major structural characteristics of lignin.

The structural characteristics are:

A very marked band with the maximum at 3430 cm-1 is typical of the voltages O-H of the alcohols, and together with the band of 1600 cm-1, 1507 cm-1 and 1419 cm-1, it is a predominant phenolic structure in the monomeric fragments of lignin,

As for the shoulder present between 2800 cm-1 and 2900 cm-1, it is possible that there is an overlap of CH bands,

In this spectrum it can be verified that the proportion of monomers with carbonyl groups is possibly small compared to the amount of aromatic groups which can be evidenced by the intensity of the carbonyl group (CHO), which is present in the syringaldehyde monomer. Peak at 1600 cm-1 compared to that at 1693 cm-1 (attributed to CO stretches of carbonyl groups).

A C-H elongation band produced by aliphatic chains at 2937 cm-1 that are part of several Monomers.

The 1458 cm-1 peak belongs to the C-H vibrations of methyl or methylene groups attached to an aromatic ring. The syringe units present in the lignin generate the weak band at 1331 cm-1 attributed to the interaction of the syringe ring with a CO group and another that appears 1118 cm-1 (deformation of the CH plane in syringe-like rings) The band at 1216 cm-1 attributed to the interaction of the guaiac ring and the CO stretching and the pronounced at 1041 cm-1 by the C-H and C-O deformation present in almost all monomers.

(f) It is possible That lignin possesses carbonyl groups of acids (usually occurring at 1712) because at the peak at 1693 it is obviously overlapped by the intensity of the peak at 1600. Some very small peaks between 3000 cm-1 and 3100 cm-1 along with the Which appear in the region of 600 cm-1 and 700 cm-1 may be attributable to the presence of aliphatic C = C present in monomers 1, 2, 4 and 5.

D. Supplementation

Culture is first made with the agar and the strain of the fungus Pleurotus ostreatus, without supplementing with lignin, in order to determine how much time the mycelium of this fungus spends in invading the available space in the petri dish without Presence of foreign substances. It is obtained that in 10 (ten) days the mycelium invades the available space in the petri dish.

A further five (5) experiments were carried out in petri dishes and each of the different amounts of lignin mixed with the agar.

It is possible to have the coverage area of each mycelium, and when comparing it with the internal area of the Petri dish, we calculate the growth of the fungus with Ec. 1[1]. The results are shown in Fig. 4.

It is easy to have a correlation between the addition of lignin and the covering of the fungus in the space available in the petri box [1], which is as follows Ec. 2:

With a correlation coefficient of 0.9777.

V. CONCLUSIONS

Lignin was extracted from the guadua supplied by the CRQ (Regional Autonomous Corporation of Quindío), and with the FT-IR spectrum was obtained. The isolated lignin was crystalline, dark brown, odorless, soluble in 1.0% sodium hydroxide solution. There are no bibliographical reports of this substance extracted from the guadua.

The amount of lignin in guadua is similar compared to plants such as bamboo.

The Pleurotus fungus consumes the lignin of the plant material on which it grows, and if it is made with pure lignin (i.e. obtained from the pulp industry process, that of chemical pulp) inhibits growth of the fungus, so it should not be used to replace the carbohydrate that accompanies the nutrients of the fungus.

The Ec. 2 (% growth) = -0.22243 * (% lignin) + 8.62571 was obtained, with a correlation coefficient close to 1.0, which gives us the effect of lignin extracted from guadua on growth of the mycelium of the fungus Pleurotus. Any dosage of lignin to the substrate affects the growth of the Pleurotus fungus, with 40% being the lethal dose.