INTRODUCTION

The tomato (Solanum lycopersicum L.) represents one of the most worldwide cultivated oleraceous, being, therefore considered of great economic importance. Besides having importance as a worldwide commodity, it has its space highlighted on the consumer’s table (Ferreira et al., 2010). Although, it is a plant of difficult conduction, because it demands numerous culture operations, and for its susceptibility to plague attacks and pathogens (Jordão and Nakano, 2002; Herrera et al., 2015).

On the tomato production, the control of arthropods plague is performed, most of the times, through application of chemical insecticides and, when used incorrectly, might harm the establishment and development of natural enemies, causing a reduction of the biological diversity, which may provoke the appearance of new plagues and the outbreak of secondary pests (Santos et al., 2007). This model of plague control might still considerably increases the cost of production, compromise the quality of the fruits through contamination, when incorrectly performed, or even cause intoxication of the applicators in the tillage (Leite et al., 2014).

Due to the increasing demand for products free of residue contamination, a tendency of reduce insecticide use has been observed. Therefore, other less aggressive and efficient control methods are being studied (Lebedenco et al., 2007). The bagging of fruits might be an alternative for the control of borer insects, reducing the need of insecticide application (Lebedenco et al., 2007; Filgueiras et al., 2017). Thus, the bagging may, besides halting the action of insects that cause damage, diminish possible chemical residues from the application of pesticides in fruits (Leite et al., 2014). However, it is fit to highlight that this technique serves of mechanical control and preferably must not interfere on the formation and quality of the fruits, preserving their physicochemical characteristics (Silva et al., 2014).

In this sense, it is of a high priority the knowledge of the fruit maturation processes, which is very complex, genetically directed and contain a wide range of physiological and biochemical alterations that affect, among other characteristics, color, texture, taste and flavor (Ferreira et al., 2010). This process is characterized by changes on the respiration rate, ethylene production, activation of the genes that regulate the carotenoids production, on the flavor development, and, on the fruit texture (Pinheiro et al., 2007). On the organic cultivation of apples (Malus domestica Borkh.), for example, it was observed a good fruit bagging efficiency, avoiding the attack of some arthropods pests, especially fruit-flies Anastrepha fraterculus (Wiedemann) (Diptera: Tephritidae) and maintaining the appearance and the quality of the fruits, not altering the market price (Santos and Wamser, 2006).

The bagging of tomato inflorescence with TNT acted as a mechanical control to the attack of insects and did not alter their color (Santos et al., 2007). However, studies that involve fruit bagging technique have presented divergent results. Huang et al. (2009) working with pear fruits and Yang et al. (2009) with apples, both bagged in paper bags, reported reduction of titratable acidity of the fruits. On the other hand, apple fruits bagged with TNT were not affected on the titratable acidity content when compared to non-bagged fruits (Teixeira et al., 2011). In guavas, the TNT bagging favored the increase of weight of the fruits regardless the diameter in which they were bagged (Azevedo et al., 2016). Therefore, it is observed that the bagging technique may negatively or positively affect the fruits organoleptic quality.

Few the information regarding characteristics of fruits that develop by bagging and, mostly about the proper size of fruits for bagging, aiming to maximize the use of the technique without affecting their postharvest quality (Santos et al., 2013). This paper has as objective to assess the postharvest quality of ‘Valerin’ tomato fruits submitted to bagging with TNT on different fruit development periods, produced with/ without insecticides for pest control, and to determine the most appropriate phenological stage for bagging with less postharvest interference.

MATERIAL AND METHODS

Experimental area

The experiment was conducted in a ‘Valerin’ commercial tomato crop belonging to the salad group, of undetermined growth in a stacked system located on the “Jaburuna” District, “Ubajara”, “Ceará” State (03°51’16” S and 40°55’16” W, altitude: 819 m). This town is located on the “Serra da Ibiapaba” region, northwest of the “Ceará” State of Brazil, 320 km from the capital, “Fortaleza”. Assessments related to the postharvest quality of the fruits were made on the Embrapa Tropical Agroindustry Postharvest Laboratory, “Fortaleza”, “Ceará” State, Brazil.

The experiment was carried out between February and June of 2015. Plants were distributed in a 1.2 × 0.6 m spacing. The staking method used was vertical with a narrow ribbon. All cultivation practices (transplanting, pruning, thinning, hilling fertilizing, etc.) were performed as recommended for the cultivation; irrigation was made through the dripping method (Filgueira, 2008).

The research was performed on two experimental areas, one treated with insecticides and other non-treated, both receiving the TNT bagging (TNTEX Embalagens, TNTEX Industria e Comercio Ltda., Fortaleza, CE, Brazil) at different phenological stages. These areas were selected inside a commercial orchard of staked tomato. Experimental outlining was in randomized blocks (Ensuring homogeneity of the experimental area) of 2 × 4 factorial scheme with five repetitions. Factors correspond to the employment of insecticides: 1- Plants treated with insecticides (utilization of chemical products and the pulverization calendar was determined by the producer, as what is commonly used in the region), and 2- Plants non-treated with insecticides; and the utilization of the TNT bag for bagging tomato bunches: T1- Bagging of the flower, T2- Bagging of fruits with 1.5 cm, T3- Bagging of fruits with 3.0 cm, non-bagged bunches (control)]. The used TNT g was white with 22 × 18 cm dimensions, 17 g knitting and was closed with a rubber band. Each block was represented by a row of 20 plants, five from each treatment, aiming the bagging of fruits. For the insecticide evaluation, 100 plants per area were assessed.

All flowers and/or bunches were weekly marked for identification of the phenological stage of the bagged fruits, so that the harvest was homogeneous, in other words, fruits showing the same maturation time. Three harvests were made, the first one about 110 d after seeding, on 14/05/2015, the second on 21/05/2015 and the last one on 28/05/2015, as the fruits were reaching the same maturation point, identified by the development of color according to scale developed by Alvarenga (2004). Thirty fruits per treatment were harvested concerning the bagging season, 10 every harvest, being this set of fruits considered a sample unit. Harvested fruits were properly identified and transported on the next day to the Embrapa Tropical Agroindustry Postharvest Laboratory, where they were duly sanitized - washed in water and dried naturally at room temperature (23°C) and 60% relative humidity - remaining in this condition inside in the plastic bags during the evaluations for the postharvest quality assessments.

Fruit coloring

Fruit coloring was determined on intact fruits using the colorimeter Minolta Chroma Meter CR 400b (Konica Minolta Sensing Europe B.V., UK), calibrated on a white porcelain surface, that expresses color on three parameters: L (Luminosity), a* and b*, which allowed to calculate the Hue angle (color’s angle; 0° - red; 90° - yellow; 180° - green; 270° - blue and 360° - black) and the chroma (saturation or color’s intensity; 0 - impure color and 60 - pure color). The Hue angle is equal to the [tangent arc (b*/a*)] and the chroma is [(a*2 + b*2)1/2], according to Minolta (2007).

Fruit firmness

Firmness was determined on intact fruits using a manual penetrometer, Magness-Taylor FT 011 model (Facchini Francesco Srl., Brescia, Italy) with an 8 mm tip diameter. Two readings were done on opposite sides of the equatorial portion of each fruit. Values were expressed in Newtown (N).

Total soluble solids (TSS)

The pulp of the fruits was removed on the day after the harvest using a domestic centrifuge and conditioned inside properly identified jars and stored at -20°C for further analysis. After filtering the pulp in a paper filter, the TTS content was determined through a digital refractometer, Atago® PR-101 Pallete model (Atago Brazil Ltda., Ribeirão Preto-SP, Brazil, with scaling between 0 and 32 and automatic temperature compensation. The results were expressed in °Brix (AOAC, 1995).

Total titratable acidity (TTA)

Total titratable acidity was determined in duplicate using 1 g of pulp in 50 mL of distilled water and 3 drops of alcohol phenolphthalein at 1% (AOAC, 1995). Next, titration with NAOH 0.1 M solution was made until obtained the permanent light pink coloration, being the results expressed on percentage of citric acid.

Measurement of pH

The pH was determined directly on the pulp through a digital potentiometer Mettler DL 12 model (Mettler-Toledo, Sao Paulo, Brazil) with automatic temperature adjustment and glass membrane, duly standardized with buffer solutions pH 7.0 and pH 4.0, as the recommended methodology of AOAC (1995).

Determining pigmentation

The lycopene, the ß-carotene and total carotenoids were determined by the Lime et al. (1957) method with the Moretti et al. (1998) proposed modifications. In a 125 mL Erlenmeyer were placed 4 g of pulp and 2 0mL of acetone, followed by 1-min agitation in ULTA-TURRAX. Proceeded to the vacuum filtering, on a Whatmann number 4 paper filter, with aid of a conical flask protected with aluminum paper in order to avoid photo oxidation of the pigments.

After filtering, the flask which the tissue was homogenized twice was washed with 12.5 mL of acetone. To the result of what was filtered 22.5 mL of hexane was added. The content was then transferred to a separation funnel of 125 mL involved in aluminum. It was laid to rest for 30 min after a clear phase separation, followed by the washing of the material with 50 mL of distilled water. This operation was repeated three times.

After the final wash, the pigments-hexane extract was transferred to a volumetric flask of 50 mL where the volume was completed with hexane. Reading of the extract was done in a spectrophotometer with wave-lengths: 503 nm (maximum of absorption for lycopene) and 451 nm (maximum of absorption for ß-carotene and close to the minimum for lycopene).

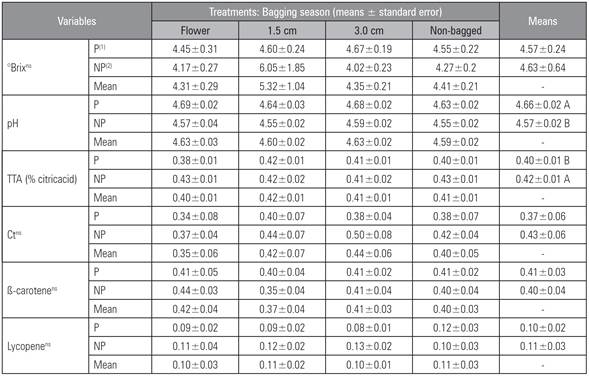

Total carotenoid concentration (mg kg-1) was calculated using the following equation:

where Ct: total carotenoid concentration (mg/100g); A503/451: pigment absorption at 503 and 451 nm; b: path followed by the light inside the cuvette (b = 1 cm); and c: pigment-hexane extract concentration (g L-1).

The results were expressed in mg/50 g of the pulp’s fresh mass. To calculate the ß-carotene and lycopene concentration the constants on the formula above were calculated using ß-carotene specific absorbance at 451 nm (250.3) and 503 nm (51.0), and lycopene’s at 451 nm (195.5) and 503 (292.7).

Statistical analyses

Statistical analyses were carried out with program SASM-Agri version 8.2 (Canteri et al., 2001). Data were analyzed by factorial ANOVA. Multiple comparisons were conducted using Duncan’s multiple range tests at a significance level of 0.05. The lycopene and total soluble solids variables were transformed in [Root of (x + 0.5)] for processing of the analyses.

RESULTS

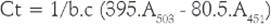

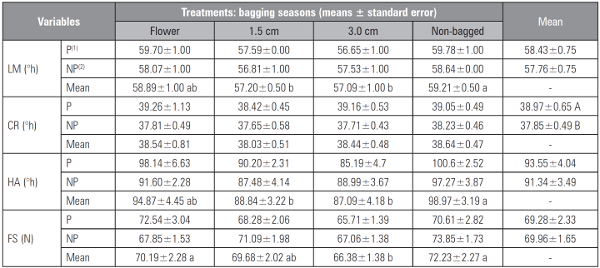

There was no interaction between the pulverization and fruit bagging factors to none of the variables, thus, factors were analyzed in isolation (Tab. 1 and 2). Luminosity, hue angle and firmness were influenced by the utilization of TNT bags (Tab. 1).

Table 1 Luminosity (LM), chromaticity (CR), hue angle (HA), firmness (FS) of ‘Valerin’ tomato fruits submitted to TNT bagging at different phonological stages, “Ubajara”, “Ceará” State, Brazil, 2015.

Means followed by the same lowercase letter on the column do not differ among themselves by the F test (P≤0.05); means followed by the same lowercase letter on the line do not differ among themselves by the Duncan test (P≤0.05); (1)P: associated to insecticide pulverization; (2)NP: without insecticide pulverization.

Table 2 Total soluble solids (ºBrix), pH, total titratable acidity (TTA), total carotenoids (Ct), β-carotene (β-C), and lycopene (LP) of ‘Valerin’ tomato fruits submitted to TNT bagging at different phenological stages, “Ubajara”, “Ceará” State, Brazil, 2015.

Means followed by the same letter on the column do not differ among themselves through the F test (P≤0.05); ns Non-significant; (1)P: associated to insecticide pulverization; (2)NP: without insecticide pulverization.

Bagged fruits with 1.5 and 3.0 cm diameter presented smaller luminosity values and hue angle (Tab. 1). On the other hand, when bagging was performed during the flower phase those variables did not differ from the bagged plants (Tab. 1). Regarding firmness, bagged fruits with 3.0 cm presented less firmness than those non-bagged or bagged during the flower phase (Tab. 1).

Chromaticity, pH and TTA variables were influenced by the pulverization (Tab. 1 and 2). Pulverized fruits with insecticide spray presented greater chromaticity, pH and smaller TTA, when compared to non-pulverized fruits (Tab. 1 and 2). The pH values obtained were inside the 4.7 and 4.6 range, while titratable acidity was from 0.40 to 0.42% of citric acid for pulverized and non-pulverized fruits, respectively (Tab. 2). Total soluble solids, total carotenoid, ß-carotene and lycopene variables did not present significant difference to none of the factors (Tab. 2).

DISCUSSION

The characteristic color of a fruit epidermis is one of the main criteria for consumer acceptance or rejection, indicating maturation degree (Jordão and Nakano, 2002). The colorimetry has been used to characterize the color of different pigments, for example, anthocyanins and carotenoids (predominant in tomato) (Paula et al., 2015). Bagged fruits (1.5 and 3.0 cm) presented coloration between red and yellow, while the non-bagged and those bagged during the flower phase presented coloration between yellow and green.

Alteration observed on the ‘Valerin’ tomato fruits coloration submitted to bagging with TNT might have occurred due to the microclimate formed inside the casing. The bagging of fruits promotes an increase of temperature inside the casing, changing, thus, the microenvironment of fruit development, promoting alterations on quality and anticipating fruit maturation (Wang et al., 2007). Teixeira et al. (2011) assessing the use of transparent microperfurated polypropylene plastic bags and TNT sacks for bagging apple fruits as control method for the main cultivation pests, verified that on both packings the temperature inside the bags was 25.0°C, while for non-bagged fruits was 22.0°C.

Despite the temperature variation inside the TNT bag was not evaluated on this study, the possible change of microclimate inside the casing might have stimulated the early ethylene production, provoking biochemical alterations on the fruit, promoting coloration and firmness alteration. The main effect of ethylene on horticultural products is to induce an increase of respiratory activity, increasing the metabolic activity, anticipating its development. Besides, the TNT bagging might have made difficult the ethylene dissipation, focusing it around the fruit and favoring its action on the maturation process (Chitarra and Chitarra, 2005). Despite the differences of materials used for bagging, this report was also observed in peaches (Prunus persica) bagged with polyethylene plastic bags (Silva et al., 2014).

Tomatoes with a less reddish coloration are identified, by the consumers, as the firmness, while those with a more reddish coloration are presented less firm (Batu, 2004). An important trait for tomato commercialization is the fruit firmness maintenance. Therefore, ‘Valerin’ tomato fruits may be bagged during the flower phase and/or with 1.5 cm diameter, as bagging on these stages do not alter their firmness, being similar to non-bagged fruits. The consumer expects that the tomato fruits, regardless the cultivar, are firm to the tact and not easily deformed (Suslow and Cantwell, 2003).

Bagging, when done at the beginning of the growth phase (flower and 1.5 cm diameter) probably contributed with its adaptation to new temperature conditions related to bagging, differently of what might have happened with fruits bagged with 3.0 cm diameter. The possible temperature increase inside the sacks could have promoted an increase of the respiratory rate and a consequent increase of the activity of the hydrolytic enzymes pectin methyl esterase (PME) and polygalacturonase (PG), that act to reduce fruit firmness (Fachin, 2003). In this sense, the firmness results, like the coloration ones, demonstrate the importance of the phase of development of the fruit to decide the proper moment to bag, without interfering on the final quality of the product.

The tomato fruit maturation involves physiological, biochemical and molecular changes, including chlorophyll degradation and carotenoid synthesis and storage, particularly lycopene (López-Juez, 2007). The use of TNT bags as a mechanical barrier kept the chemical characteristics of the ‘Valerin’ tomato fruits such as: total soluble solids, pH, titratable acidity, total carotenoids, ß-carotene and lycopene similar to those non-bagged fruits. This is due to the fact that the characteristics of the TNT bags used (Jordão and Nakano, 2002) or even intrinsic of the cultivar. The content of soluble solids is one of the fruits main characteristics concerning taste, since it is on this portion that sugars and acids are found. The TTS content is also an indicative of the fruits quality and its byproducts (Shirahige et al., 2010). In table tomato cultivars, such as ‘Raisa’ and ‘Santa Clara’, the total soluble solid content varied between 4.4 and 6.0% (Ferreira et al., 2010) being compatible to those obtained on the present study.

The highest pH and TTA observed on treated (pulverized) fruits, compared to non-pulverized, despite significant differences, was not enough to affect the final quality of the products, since this difference was on the 0.01 scale for pH and 2.0% for TTA. The obtained pH and TTA acidity ranges on this study are similar to those described by Rodrigues et al. (2008) - 4.20 to 4.68 - and Stevens and Rick (1986) - 0.40 to 0.91% of citric acid. These values are inside the variation range that is considered ideal for quality tomatoes (Guilherme et al., 2014). The existing variations among pH and fruits acidity may be explained by the genetic factor, since each cultivar represents a different chemical constitution (Seleguini et al., 2007).

In order to be a tool for plague handling, exogenous additives or bagging must not interfere on the product final quality (Lebedenco et al., 2007; Pereira et al., 2009; Laiton et al., 2012). Thus, attributes related to taste as pH, TTA, TSS content, among others, must be kept aiming to answer the expectations of the consumer.