INTRODUCTION

The sweet chili is a widely diffused vegetable in many regions, especially in tropical climates such as Colombia and the producing areas of Venezuela (Carvalho et al., 2017). It belongs to the Capsicum genus, Solanaceous family, of which there are several cultivated species with variations in the fruit characteristics. The more representative species are C. annuum L., C. baccatum L., C. chinense Jacq., C. frutescens L., and C. pubescens R. & P. (Carvalho and Bianchetti, 2008). Its origins are in the Amazon River basin, and Venezuela is the center of diversity (Moses and Umaharan, 2012). It is used in different culinary recipes because of characteristics that make it attractive to consumers (Quevedo and Laurentin, 2020).

In 2019, global production was 38 million tons from 1.99 million hectares, with average yields of 19 t ha-1. In Colombia, 8,704 ha were sown, which an average of 15.5 t ha-1 (FAO, 2021). The Caribbean region of Colombia had a planting area of 2,925 ha of sweet chili cultivation, which had around 10,000 productive units with an average of 0.25 ha (Agronet, 2018; Correa-Álvarez et al., 2019). The Caribbean Region provides 51% of the domestic harvested area, and the largest chili producer is the Magdalena Department, with 12,288 (Agronet, 2019).

It is very important because it is incorporated into diets and has culinary characteristics such as flavor, aroma, and color that make it attractive to consumers and the regional gastronomy. In addition, the productive tradition in the region is relevant to the rural economy (Correa-Álvarezet al., 2019; Quevedo and Laurentin,2020).

It has great growth potential because of its high consumption worldwide and industrial uses (Duran, 2013; Srivastava and Mangal, 2019; Costa et al., 2019). Estimates by Rugeles (2011) indicated that this crop demands an average of 650 wages per hectare - cycle. Therefore, this crop generates around 1.9 million wages in the region, showing its importance to employment and the ruraleconomy.

For the sweet chili production system in the Caribbean region, no economic studies have been carried out that reveal aspects such as the rationality of the producer in decision-making, allocation of resources for production, technical production efficiency, and technological gaps.

Studies on technical efficiency in production systems have been developed by Márquez et al. (2015) in beans, Colque (2019) in onion, Asravor et al. (2016) in chili peppers in the Volta region of Ghana with modified function models of stochastic frontier cost and production, and Martínez-Reina et al. (2021).

The use of the stochastic frontier technique is recurrent, with estimates using models of functional relationships between inputs and outputs using translogarithmic estimates and Cobb Douglas functions. The stochastic frontier technique has been used in studies on coffee in Nicaragua (Saravia, 2007; Urbina, 2017) and Mexico (Cárdenas et al., 2005), along with modeling of the technical efficiency of rice producers in Bangladesh (Rahman et al., 2012).

Abate et al. (2019) surveyed 385 farmers selected with random sampling and calculated a Cobb Douglas-type stochastic frontier function. The efficiency was 78.80%. It was found that the cultivated area, the seed, the agrochemicals, the animal traction, and the labor explained the production of chili. Likewise, the possibilities of increasing efficiency are conditioned by socioeconomic variables such as age, educational level, land size, distribution of land use, rural extension services, access to credit and market information. These socioeconomic variables affect the technical efficiency of chiliproduction.

When consulting the bibliographic sources, it was evident that, for the allocation of resources for the sweet chili production system, there is no study for Colombia that investigated and explaind the rationale of producers when making decisions and allocating resources for production in the Caribbean Region, analyzing the rationalityof producers with technical efficiency and identifying technologicalgaps.

The working hypothesis is that the rational farmer maximizes production with the proper use of resources, that is, he does not spend more or less than the inputs necessary to carry out production and always seeks to maximize their use (De los Ríos, 2006).

This article is structured as follows: it begins with a general presentation of the sweet chili production system in the region, the estimation of technical efficiency identifying the factors responsible for the inefficiency, and finally ideas are presented as conclusions. The results of this research contribute to researchers and sweet chili farmers in the Colombian Caribbean region because they can be used to improve aspects that make the system inefficient, increasing productivity and efficiency.

MATERIALS AND METHODS

This research was carried out in the Colombian Caribbean Region in the municipalities of San Juan del Cesar and Ponedera, located in the Departments of La Guajira and Atlantico, respectively.

The information collection instrument was a survey with 30 questions divided into three components: technical, socioeconomic and market elements of sweet chili. For the purposes of this research, emphasis was placed on the technological variables that determined the efficiency and on the socioeconomic variables to measure the factors that inhibit it.

The sample size of this study was 62 farmers, classified as small farmers who cultivate with the family farming model, which were obtained from the two surveyed localities using statistics from the Secretaria Economica y Desarrollo Agroindustrial, with 845 from the Caribbean Region. The simple random sampling method was applied using the cultivated area, where 62% corresponded to productive units of less than 1 ha, while 39% had more than 1 ha. The calculations were made according to Rodríguez (2005) by applying the following Equation (1):

Where, n was total number of surveys or sample; Z corresponding to the confidence level chosen in this case, 95%; p proportion of the population that cultivate less than 1 ha, 524 farmers; q the difference between the total population and the proportion of the population that does not meet the characteristic (in this case, units larger than 1 ha), 321 farmers; e maximum permissible error 15%; N population size of 845 productiveunits.

The total number of surveys calculated was 62 productive units applied to expert farmers in thecrop.

Once the surveys were carried out, the second stage of the investigation started, which consisted of a phase of cleaning and processing the data and tabulation through the construction of a database in the SPSS program (IBM SPSS). Data analyses were done by applying descriptive statistics, correlation analysis and the formulation of the Cobb-Douglas function (Douglas, 1976) (Eq. 2)

Where, Y was the total production of sweet chili, kg ha-1; K capital factor; L work; α change in Y

when capital factor changes; β change in Y when the labor factor changes.

The original data were transformed into a natural logarithm to express the value of the parameters as elasticities, that is, the change in the quantity produced by the change in one unit of the variable input. These parameters in the case of α symbols are the cut-off point or zeros of the function, that is, production when the use of inputs does not change; the value of the β parameters are the elasticities of the product in relation to the change of each input. Under these circumstances, in how many units does chili chili production change due to the change in one unit of the input, when this value is greater than 1, yields are presented on an increasingscale.

The field data after defining the variables and the classification into dependent variable and explanatory variables, the parameters were estimated using the Ordinary Least Squares (OLS) method. The linearization of the function was done according to Toro et al. (2010) using natural logarithms.

The proposed Equation (3) was the following:

Where, ln was natural logarithm; Y amount of chili produced, kg; X 1 seed, kg ha-1; X 2 labor per ha; X 3 control weeds used per ha-1;X 4 fertilizer, kg ha-1; X 5 yield, t ha-1; β 0 - β 5 parameters to be estimated (regression coefficients), and ε i compound error term defined as Vi -Ui.

The measurement of inefficiency was understood as the factors that act negatively on efficiency or those that inhibit technical efficiency (4), socioeconomic variables such as age, education, experience, and the size of the area used in the cultivation of the crop were considered.

Where, y was technical inefficiency; α 1 age (years); α 2 experience in cultivation (years); α 3 area cultivated in hectares; ε i error term, and α0 - α3 parameters to be estimated

As in equation 4, the Ordinary Least Squares method was used to estimate the parameters in the Eviews 8 econometric program. The information was obtained from the 62 surveys applied to farmers who are experts in the cultivation of chili in the target area.

The technical efficiency calculations used the variables of real production and potential production, in this case the yield average in tons of sweet chili from the 62 productive units surveyed. Potential production is the result of calculating the elasticities or changes that production undergoes as the result of the change in a unit of input and is obtained by replacing the values of the parameters in the general Equation (5):

There are two values: real production and potential production, and the difference between these two variables gives the technological gap, the difference between real production and potential production, the greater the technological gap (Eq. 6)

The smaller the difference between actual production and power, the higher the efficiency is.

RESULTS AND DISCUSSION

Socioeconomic characteristics of the sample

Farmers who grow sweet chili in the Caribbean Region are small with an average of 0.6 ha and a family model that uses few inputs compared to the market; the majority of activities are done manually with the help of all members of thefamily.

The average age is 51 years, and the average experience is 11 years. 90% of production is destined for the market in the same locality or in the closest consumption centers and the closest markets, such as Barranquilla and Cartagena in the case of farmers in the Departments of Bolivar and Atlantico.

The Cobb Douglas model parameter estimation for sweet chili with least squares regression is in table 1.

Table 1. Estimation of Cobb Douglas model parameters for sweet chili in the Colombian Caribbean Region, 2020.

| Variable | Coefficient | Standard error | t-Statistc | P value P value |

|---|---|---|---|---|

| C | -0.901696 | 1.438868 | -0.626671 | 0.5334 |

| Seed | -1.096501 | 0.375617 | -2.903716 | 0.0053 |

| Labor | 0.394575 | 0.553753 | 0.794790 | 0.4301 |

| Fertilizer | -0.090041 | 0.527581 | -0.062280 | 0.9506 |

| Weeds | 0.860351 | 0.504737 | 1.349500 | 0.1826 |

| Yield (t ha-1) | 1.104786 | 0.135733 | 8.221480 | 0.0000 |

The coefficient related to labor, understood as the number of wages per productive unit in each crop cycle, was 0.394575, suggesting that an increase in the use of labor will increase production. This productive system is part of a rural economy and is intensive in the use of labor, which, in many cases, is an implicit cost since it does not imply disbursements of money by the producer.

The other component or factor that was considered in the model was fertilization. It is not a very common practice. The value of the parameter was -0.090041 and indicated an inverse relationship between increases in production and increases in fertilization. When fertilization is done without a soil analysis and without considering the nutritional requirements of the crop, this factor can be underutilized, which is the presumed case for sweet chili.

Weed management presented a coefficient of 0.860351, indicating a direct relationship between production increases and weed management, which is mostly done manually and is environmentally friendly. In addition, there is a rational management of chemical inputs.

Yield is the factor that makes a productive unit have favorable production levels for the producer. A value for this parameter of 1.104786 with a positive sign indicates great influence and contribution to total production to the extent that a biophysical response given all the inputs that were involved in production. With the yields obtained here, the expenditure of both energy and the same inputs were compensated, explaining the directrelationship.

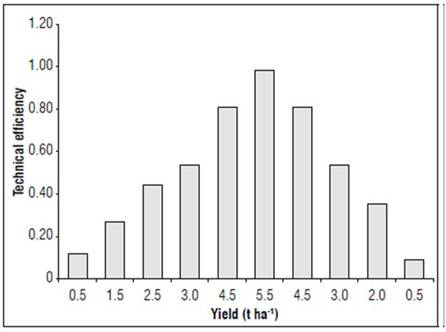

As defined above, technical efficiency results from relating real production to potential production. Where the potential production is less than real production, technological gaps are generated in sweet chili production, as can be seen in figure 1.

Figure 1. Analysis of technical efficiency in the cultivation of sweet chili in the producing regions of the Colombian Caribbean.

The real production was 4.5 t ha-1 of chili, while the potential production was 5.5, which indicates that, to reach production efficiency, this value must be equal to 1. With yields of 4.5 t ha-1, the efficiency was 0.81, which means 0.19 more was needed to reach an efficient yield of 5.5 t ha-1, generating a production gap of 1 t ha-1. Thus, despite being close to 1, the efficiency value, even with real yields, cannot be reached, which is explained by factors such as seed and fertilizer, where the use of these factors is presumed to be underutilized.

Determinants of technical inefficiency

Socio-economic variables are used to determine the possibility of increasing or decreasing efficiency since they depend more on human will and the decisions made by the producer, as well as the environment in which the production is carried out.

In this case, variables such as age, experience, education, and the size of the productive unit represented in the cultivated area were considered. The output of the regression is in table 2.

Table 2. Variables that explain the inefficiency of the production system of the sweet chili production system in the Colombian Caribbean Region, 2020.

| Variable | Coeficiente | Standard error | t-Statistc | P value P value |

|---|---|---|---|---|

| C | 3.421659 | 2148258 | 1592760 | 0.1168 |

| Age | -0.390733 | 0.509836 | -0.766391 | 0.4467 |

| Experience | -0.112180 | 0.156577 | -0.716452 | 0.4767 |

| Education | 0.151720 | 0.436409 | 0.347655 | 0.7294 |

| Area | 1.077874 | 0.122439 | 8803341 | 0.0000 |

The measurement of production inefficiency, understood as those variables that inhibit the process and that act negatively, were in table 2. In this case, a parameter value with a positive sign indicates that the variable has a negative effect on efficiency, and a negative sign of the parameter indicates that the variable positively influences efficiency. Next, each of the variables selected for the model wereanalyzed.

The age parameter had a value of -0.390733, meaning that age can positively influence production efficiency, perhaps the methods used and transmitted by family members make it more careful in the use of inputs, and the older the age is, the greater the possibility of increasing efficiencyis.

Experience is closely related to age: the older the farmer is, the more experience and efficiency the farmer has. The parameter value of -0.112180 showed this relationship between experience and efficiency, as more experience is less likely to see mistakes when allocating resources, resulting in greaterefficiency.

The cultivated area presented a coefficient of 1.077874, which indicates that increasing the cultivated area does not increase efficiency, the presence of economies of scale in agriculture as demonstrated by Martínez-Reina et al. (2021), in the case of yams or Perdomo and Hueth (2011), in the case of coffee in Colombia.

One characteristic of this production system is that it is done under the productive model of a peasant economy with traditional technology and a strong family incidence, responding to external factors such as lack of income, scarce technology, and adverse weather conditions (FAO, 2014). Family farming is characterized by a small and strongly diversified scale of production where the products are intended for self-consumption or sale and is the main source of employment and income for the rural population (Fonseca-Carreño et al., 2019).

Socioeconomic variables, such as age, education, and experience, in this study included farmers with an average age of 56 years, similar to characteristics found in other production systems in the Caribbean region (Martínez-Reina et al., 2019). Results reported for cowpea beans in Nigeria showed that the average age of producers was 35 years, with a similar handling time of 15 years (Joshua et al., 2019). On the other hand, 58% of the producers had up to basic primary schooling (Martínez-Reina et al., 2019), while 78% of cowpea bean producers in Nigeria completed basic primary (Joshua et al., 2019).

The average age of farmers was over 50 years, which can be a threat to the socioeconomic and technical sustainability of the cultivation of sweet chili. Some similar information was found by Orewa and Izekor (2012) in the yam production system in Nigeria, who reported an average age of 59 years. In this same production system (yam), Martínez-Reina et al. (20219 found an average age of 57 years, indicating a general aging trend in agriculture.

There was a negative relationship between technical efficiency and the age of the farmers, which can be interpreted as being directly associated with the experience of the farmers; these results coincide with those of Tef in Ethiopia (Abate et al., 2019). However, there are other studies that contradict the results, reporting a positive relationship with respect to the age of farmers and technical efficiency, that is, the older the farmer is, the less efficient the productive system is (Asravor et al., 2016).

The behavior of the seed coefficient, which also presented a negative effect (-1.096501), had a t value of -2.9037160, suggesting a decrease in this factor would result in a decrease in yield, contrary to the findings of Wahid et al. (2017) in a study estimating the technical efficiency of tomato producers in Malakand, Pakistan, which showed that seedlings have a very significant effect on production with a coefficient of 1.02, meaning that increasing the number of seedlings by 1% there will increase production by 1.02%.

When analyzing the results of the yields and technical efficiency (0.81) in this study, it could be inferred that it is possible to improve the production system of sweet chili by intervening in factors such as seeds and fertilizers, as well as improving pest management, disease control and other agronomic practices that were not included in this study. Authors such as Wahid et al. (2017) and Abate et al. (2019) in studies on tomatoes in Pakistan and peppers in Ethiopia respectively indicated that technical efficiency in the short term could increase by reducing the inputs used in production and using technically efficient practices.

The seed coefficient also presented a negative effect (-1.096501) and had a t value of -2.9037160, meaning a decrease in this factor would result in a decrease in yield, contrary to the findings of Wahid et al. (2017) in a study estimating the technical efficiency of tomato producers in Malakand, Pakistan that showed that seedlings have a very significant effect on production, registering a coefficient of 1.02, meaning that increasing the number of seedlings by 1% there will increase production by 1.02%.

For the fertilization variable, an increase in this variable decreases yields, as seen in studies carried out by Ismail (2010), who confirmed that excess fertilization and water deficits, among other factors, reflected a decline performance. However, production is not only related to soil fertility but also to a plant's genetics and relationships with the environment.

In this study, there were no economies of scale but there were increasing returns to scale explained by labor and weeds. The absence of returns on a decreasing scale was evidenced in empirical studies by Orewa and Izekor (2012). In this same study, yields on an increasing scale were seen, as reported in studies by Márquez et al. (2015), with a value of 0.81, Martínez-Reina et al. (2021), on the yam production system with a value of 0.9, and Rahmanet al. (2012), on the cultivation of rice in Bangladesh (0.88).

The results of technical efficiency in the cultivation of sweet chili showed a very low technological gap, close to one (0.81), which corresponds to a difference of one ton. This situation is very similar to that found by Márquez et al. (2015) in the case of beans in the State of Portuguesa in Venezuela, with a similar technologygap.

CONCLUSION

There was rationality in the sweet chili farmers when assigning production factors, as reflected in the technological gap of 0.82, very close to the ideal of 1, because the real production was very close to potentialproduction.

The direct relationship between labor inputs, weeds, and yields made the technological gap close to zero, meaning the work is efficient. An inverse relationship between seeds and fertilizer was evidenced, which indicates the underutilization of these production factors.

With the modal yields of 4.5 t ha-1, it is possible to generate economic surpluses, in addition to the presence of yields on an increasing scale due to the positive relationship between the use of inputs and increases in production, a difference is also appreciated minimum between actual production and potential production.