Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.35 no.2 Bogotá May/Aug. 2015

https://doi.org/10.15446/ing.investig.v35n2.45289

DOI: http://dx.doi.org/10.15446/ing.investig.v35n2.45289.

EEWES: An energy-efficient wireless sensor network embedded system to be applied on industrial environments

EEWES: Un sistema integrado para red de sensores inalámbricos con eficiencia de energía aplicado en entornos industriales

F. Oliveira1, R. Semente2, J. Fernandes3, S. Júnior4, T. Melo5, and A. Salazar6

1 Felipe Denis Mendonça de Oliveira. Degree in Information Systems, Universidade Estácio de Sá, Brazil. Msc in Electrical and Computer Engineering, Universidade Federal do Rio Grande do Norte, Brazil. Affiliation: Universidade do Estado do Rio Grande do Norte, Brazil. E-mail: fdenis_natal@yahoo.com.br.

2 Rodrigo Soares Semente. Degree in Computer Engineering, Universidade Federal do Rio Grande do Norte, Brazil. Msc in Electrical and Computer Engineering, Universidade Federal do Rio Grande do Norte, Brazil. Affiliation: Universidade Federal Rural do Semi-Árido, Brazil. E-mail: rsemente@yahoo.com.br.

3 Jefferson Doolan Fernandes. Degree in Technology in Industrial Automation, Instituto Federal de Educação, Ciências e Tecnología do Rio Grande do Norte, Brazil. Msc in Sciences & Oil Engineering, Universidade Federal do Rio Grande do Norte, Brazil. Affiliation: Instituto Federal de Educação, Ciências e Tecnología do Rio Grande do Norte, Brazil. E-mail: jefferson.fernandes@ifrn.edu.br.

4 Serafim do Nascimento Júnior. Graduating in Computer Science, Universidade do Estado do Rio Grande do Norte, Brazil. Affiliation: Universidade do Estado do Rio Grande do Norte, Brazil. E-mail: serafim.snj@gmail.com.

5 Tálison Augusto Correira de Melo. Degree in Computer Engineering, Universidade Federal do Rio Grande do Norte, Brazil. Affiliation: Universidade Federal do Rio Grande do Norte, Brazil. E-mail: talisonaugusto@hotmail.com.

6 Andrés Ortiz Salazar. Degree in Electronic Engineering, Universidad Nacional de Ingeniería, Peru. Msc & Dsc in Electrical Engineering, Universidade Federal do Rio de Janeiro, Brazil. Affiliation: Universidade Federal do Rio Grande do Norte, Brazil. E-mail: Andrés@dca.ufrn.br.

How to cite: Oliveira, F., Semente, R., Fernandes J., Júnior, S., Melo, T., & Salazar, A. (2015). EEWES: An energy-efficient wireless sensor network embedded system to be applied on industrial environments. Ingeniería e Investigador), 35(2), 67-73. DOI: http://dx.doi.org/10.15446/ing.investig.v35n2.45289.

ABSTRACT

Nowadays, the vast majority of information monitoring in industrial plants is still carried out by wired technologies, in which the installation and maintenance cost is high. However, in outdoor applications, such as those used in the oil and gas industry, the use of Wireless Sensor Networks (WSN) is increasing due to mobility, reliability, and low cost of the sensor nodes that make up the network. Moreover, this solution reduces the risks of workers in classified areas (regions with high probability of accidents occurrence) to the extent that the equipment maintenance is optimized. This paper proposes the development of the EEWES, an energy efficient wireless sensor network embedded system, which can be applied on industrial environments. This development approach significantly reduces the energy consumption of the sensor nodes by using a method that alternates sleep periods of the transceiver/sensor set with data transmission/reception periods, which reduces the duty cycle while keeping the desirable parameters of the service quality (QoS). The results presented in this paper will be confirmed by field tests.

Keywords: Energy efficiency, wireless sensor network, IEEE 802.15.4, EEWES.

RESUMEN

Actualmente, la gran mayoría de información de monitoreo en plantas industriales es transmitida a través de tecnologías alámbricas cuyo costo de instalación y mantenimiento es alto. Sin embargo, en aplicaciones outdoor tales como las utilizadas en la industria del petróleo y el gas, el uso de la red de sensores inalámbricos (WSN) ha ido creciendo debido a la movilidad, confiabilidad y bajo costo de sus nodos sensores. Esta solución reduce los riesgos de los trabajadores en las áreas peligrosas (regiones con alta probabilidad de accidentes) en la medida en que el mantenimiento de los equipos se ha optimizado. El presente artículo propone el desarrollo de EEWES - Sistema Integrado para Red de Sensores Inalámbricos con Eficiencia de Energía, que se puede aplicar en entornos industriales. El consumo de energía de los nodos sensores se reduce significativamente mediante el uso de un método que alterna períodos de apagado de su subsistema de detección y comunicaciones con los períodos de transmisión y recepción de datos, reduciendo el ciclo de trabajo mediante el mantenimiento de los parámetros deseables de calidad de servicio. Los resultados presentados en este trabajo serán confirmados experimentalmente mediante pruebas de campo.

Palabras clave: Eficiencia energética, red de sensores inalámbricos, IEEE 802.15.4, EEWES.

Received: August 29th 2014 Accepted: Frebruary 18th 2015

Introduction

Due to the number increase of controllers, sensors, and actuators in industrial systems of conventional instrumentation, the complexity of wired connections has incremented, meaningfully increasing the implementation time and the maintenance cost of the systems. Wireless networks can be the solution for replacing wired networks, because they allow faster layout changes and maintenance time (Petersen et al, 2007; Gungor, 2009).

Four key requirements have to be satisfied to make possible WSN applications to be reliable in industrial environments (Willig, 2008; Zurawski, 2009): Scalability, Reliability, Timeless and Energy Efficiency.

In environments with limited energy resources, measures that ensure energy efficiency in WSN require more attention because limited data retransmissions and power levels of the signal decreases the network reliability (Gungor, 2009).

It is possible to prolong battery lifetime in scarce environments of energy by using several different energy efficiency techniques. There are approaches based on power saving techniques such as data compression (Distribution Compressive), improvements to routing algorithms (Heo, Hong and Cho, 2009; LoBello and Toscano, 2009) and the method of hibernating of the sensor node.

Several researches have been developed to improve the communication efficiency and reduce the energy consumption in instrumentation systems based on WSN.

In Ontiveros et al. (2010) it was proposed a change of the MAC layer of the IEEE 802.15.4 standard, in order to the power saving of a WSN, called "PCF + Sleep". The proposed power saving consists of inserting intervals of data transmission with shutdown intervals of the transceiver of each sensor node that make up the WSN, so it consumes energy only at the time in which it is transmitting information to the network coordinator node. The QoS parameters used in this work were the period in which the sensor nodes remain in sleep, its energy consumption, and the average delay in communication. It was compared to the SMAC (Ye, 2002), and it looks more efficient in all the parameters of quality of service measured. The authors, however, do not described important parameters, such as the distance between the nodes, the transmitter power, and the WSN architecture used to build the simulated scenario with only five sensor nodes.

The energy efficiency techniques used in the papers above were entirely tested in a simulated environment, and they do not reflect the real behavior when the WSN is physically subjected to external factors (temperature and humidity, for instance), which can excessively influence on the QoS parameters of this network.

In instrumentation systems based on WSN, the amount of sensor nodes can increase to a level in which the use of routing protocols can be needed. Routing protocols for geolocation, such as GPSR (Karp and Kung, 2000) can be used in WSN in which the concern with power saving is not a crucial factor, considering that the use of GPS requires the sensor nodes to remain turned on, and then inhibiting the development of any efficient power saving technique.

The main contribution of this work is the conception and implementation of the Energy-Efficient Wireless Sensor Network Embedded System (EEWES), a low cost system based on the IEEE 802.15.4 standard to be applied on industrial environments for monitoring and controlling processes.

This work is divided into four sections. This section presents the theoretical basis and objectives. The section II shows the communication method designed for the EEWES. The section III discusses about some of the main performance indicators that must be considered for provisioning QoS on remote sensing networks that include energy efficiency, range, delay, and packet loss. Such parameters were determined by field tests that compared the performance of the EEWES with the main routing protocols usually used in WSN systems. The obtained results provide the desirable characteristics of QoS of the embedded system developed in this work. The section IV presents the conclusions of this paper.

Overview of the EEWES

This section describes how EEWES and regime of communication architectures are implemented with the purpose of improving the energy consumption.

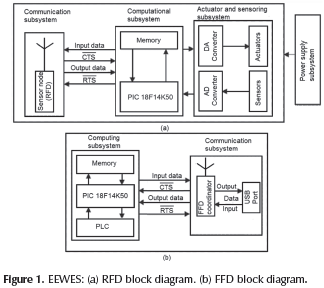

System Architecture: EEWES is organized into subsystems according to Vieira et al. (2003), as shown in Figure 1:

-

Power Subsystem: RFDs are composed, each of them, by a set of ten alkaline batteries with 1.2 V x 4400 mAh, supplying 12 V, at total. The power saving technique for RFDs by sleep cycles is described in the Computational Subsystem. The FFD is powered by a lead-acid battery with 12 v x 20 Ah and a solar battery charger that is also responsible for providing energy for the PLC that is responsible for controlling the plant (Figure 1(b)). Due to extensive energy availability provided for the FFD and as it acts as a sink, no sleep mechanism was implemented for it.

-

Actuator and Sensor Subsystem: it performs data acquisition of sensors and receives the controls for the actuators as a result of the communication of RFDs with the Computational Subsystem (Figure 1(a)).

- Computational Subsystem: It consists of a flash memory and a PIC 18F14K50 microcontroller that is present in all the nodes. This microcontroller was chosen because it is low-priced and easy to find in the Brazilian market. The present functions in this PIC are: A/D conversion in pressure sensors, battery voltage verification, actuator driving (I-P converter), digital input verification for piston sensors, storage of the latest sensor data, timer (responsible for the sleep cycle of 5 s and transmission of 33,6 ms from the set of transceivers/sensors of each RFD). The sleep technique used in the timer function is described in the subtitle of this chapter that is entitled as "firmware". It guarantees the power saving that enables the use of the proposed embedded system. The connection of the Computational Subsystem with the Communication Subsystem allows the sending and the receiving of data from RFDs by wireless (Figure 1(a)).

In the Computational Subsystem of the FFD (Figure 1(b)), a PLC commands the actuators needed for the control of the plant. The PLC also carries out the Modbus communication with the Communication Subsystem via RS-232 port, where the control orders of the actuators go from and where the sensing data arrive, originated from each sensor attached to a RFD, via wireless. An USB port was made available to collect the measurement data sent to the coordinator coming of each RFD.

4) Communication Subsystem: It is composed by eight radiofrequency modules (RF) - according to the IEEE 802.15.4 standard (Figure 1(a) and 1(b)) - operating in 2.4 GHz.

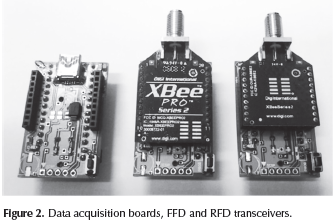

Figure 2 shows, on the left side, the double-sided printed circuit board specifically developed for the EEWES and where the Computational Subsystem and the Actuator and Sensor Subsystem are found. In the center, the board with the transceiver XBEE-PRO attached on it is found, thus composing the communication subsystem of the FFD; and on the right side, the transceiver XBEE is connected to the board, composing the communication subsystem of the seven sensor nodes (RFDs). It is important to remember that, in the EEWES, the security and encryption features of the ZIGBEE communication protocol were disabled. This guarantees an increase of power saving of each sensor node.

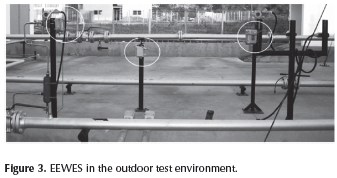

The RFDs were installed outdoor in a plant designed by Quintaes (2006) that simulates the measurement and control of water contamination and sediments that are in oil wells by the technical specification known as BS&W (Basic Sediment and Water). Figure 3 shows three of the seven RFDs in an explosion-proof box due to the risk of it in industrial environment where the EEWES was designed to be used.

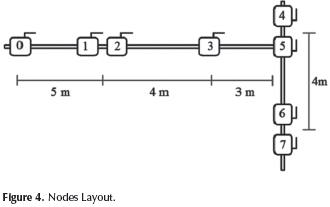

The distribution of all sensor nodes with the approximate distances used in the tests are shown in Figure 4. The figure shows the FFD coordinator (node 0), three pressure sensors (nodes 2, 5, and 6), two temperature sensors (nodes 1 and 4), and two solenoid valves as actuators (nodes 3 and 7), thus forming a process control system, performed by the EEWES.

Firmware: Figure 5(a) shows the FFD coordinator flowchart. The coordinator will always be waiting for an event at a time, it does not matter if it was originated from the nodes, from the PLC (via Modbus), or even from some device connected to USB; and also keeps checking if there is some change of status of the actuators which are controlled by the PLC. In case of a status change (represented by the expression "Yes"), it responds and carries out the actions described in Figure 5(a).

RFD devices operate according to the flowchart shown in Figure 5(b). In the beginning, a sleep status of 5 s is introduced. This cycle does not only disable the transceiver and the PIC, but also the sensor of each node, and in consequence, a timer controlled by the PIC turns off its energy supply.

The sleep time was estimated based on the dynamics of the plant. Different sleep times can be set depending on the application to which the EEWES intends to be applied.

Actuators have interlocking mechanisms which allow them keeping with the latest values sent before the occurrence of the sleep mode. This procedure ensures the synchronization of communication and minimizes the duty cycle and then causes a battery power saving. After the end of the sleep period, the transceiver, the microcontroller, and the sensor/actuator start working again.

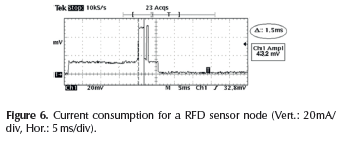

When the latency timing is done, the microcontroller acquires sensor data and sends it to the transceiver, or receives data to control the actuator from the FFD. The 33.6ms period of communication was obtained by measuring two variables: the first measures the communication time (1.5 ms) and the data reception time from the receiver (0.6 ms), as it is shown in the graph of Figure 6; the second measures the response time of each sensor/actuator.

Experimental Results

To certify the EEWES Quality Service (QoS), some of WSN key performance metrics were used, such as energy efficiency, coverage, delay, packet loss and the lifetime of sensor nodes (Ganesan et al., 2004; Song, Wang and Pei,2003).

The transceivers used in the EEWES work with the ZIGBEE communication protocol, which has two routing protocols: AODVjr, that is flat; and HTR, that is hierarchical (Zigbee, 2007). Depending on the network layout, the ZIGBEE protocol chooses which of the two protocols is the most appropriate, or if none of them will be used, then allowing the MAC layer of the IEEE 802.15.4 standard to be responsible for performing the communication of the nodes from the WSN. Therefore, QoS tests of the EEWES were carried out based on routing protocols used by the ZIGBEE protocol and comparing them with the communication carried out only by the MAC layer (without routing). The purpose of this analysis is to verify which communication schemes are efficient for industrial applications with similar characteristics to the one used in this study.

For data collection, a CASE software was developed. It counts the packet loss, the packets sent, and the time events of all the WSN. The data were stored in text files. To improve the accuracy of the tests, 10 rounds of 1 hour (3600s) were carried out. The graphics that reflect the average of these 10 rounds in each test were plotted to summarize the data.

The parameters of the outdoor tests are the following ones: topology: star; maximum distance between FFDs and the RFD node: 14 m; distance between FFD sensor nodes: see in Figure 4; packet length: 40 bytes; header length: 20 bytes; transmission time: 33.6 ms; sleep time: 5s; communication time: 3600s x 10 rounds.

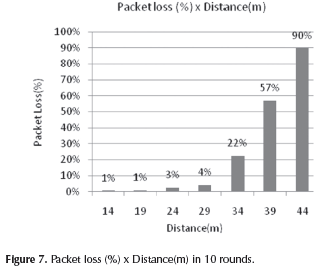

Packet loss according to the distance: To verify the reliability of the WSN communication link, the first metric to be tested is the coverage area of the coordinator related to the sensor nodes. The network was placed in continuous communication by star topology and the packets sent by the farthest sensor node (node 7, 14 m) and received by the coordinator were recorded. It was found that, in this regard, the number of lost packets was acceptable (0.6%). After that, the coordinator was positioned to 19 m from node 7, varying the distance from 5 to 5 meters until the value of 44 m, in which the amount of lost packets became critical (89.8 %) as it can be seen in Figure 7.

With the maximum value of about 5% of packet loss, it is noted that, until the value of 29 m, the communication link is suitable for remote sensing applications, which the topology does not need to have repeaters (intermediate FFD nodes).

Jitter: As the time between two consecutive samples can vary, the packet loss may occur. In this regard, the jitter is defined as the difference of time variation between two consecutive samples, as it is shown in Equation (1). This is a way to measure the communication delay between nodes in a WSN.

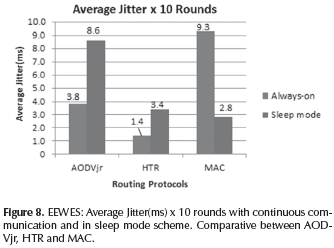

The first set of tests consists of obtaining the average jitter of the communication between sensors and actuators of the EEWES in "always-on" scheme. It is noticed that in the HTR as well as in the AODVjr, the jitter was less than 5 ms, thus showing its viability in applications on continuous communication mode, as it can be seen in Figure 8. The average jitter of 9.3 ms when the EEWES uses only the communication techniques of the MAC layer is considered high and then not recommended for real-time applications in which the communication needs to be continuous. This is due to the fact that no routing is being carried out, so the number of packets sent simultaneously implies to a high rate of loss, thereby increasing the delay in communication.

The same test was repeated by enabling the power saving scheme (sleep/wake up technique) of the EEWES that was discussed in the subsection entitled "Firmware". As seen in Figure 8, the average jitter increased when the ad hoc routing protocol AODVjr was used.

The average jitter of 8.6 ms of the AODVjr reflects its routing approach in which, at every restart of communication, it needs to update the routing tables of the nodes, thus consuming more time between communications when compared to the HTR. In the HTR hierarchical routing protocol, the average jitter was about 3.4 ms, what indicates the need for less routing packets at each restart of communication, thus making its use appropriate for industrial plants where there is the need to expand the nodes, either by the larger geographical area or by the larger amount of sensor nodes required for its operation. The lowest jitter was obtained when it was not used any kind of routing (2.8 ms), considering that the quantity and the distance between the sensor nodes distributed in the plant were enough for the MAC layer to carry out satisfactory communication.

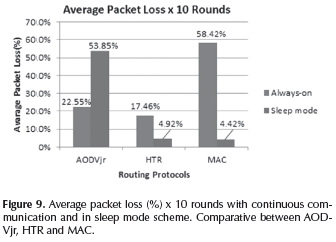

Packet loss: One of the most important metrics in real time remote sensing networks is the packet loss. In Figure 9, the routing protocols tested presented a greater packet loss in always-on mode. The AODVjr protocol presented 22.55% of losses due to the creation and maintenance of routing tables during the recognition phase of the WSN nodes and then generating a latency that implied to the greatest amount of losses if compared with the HTR (17.46%), which indicates that the hierarchical routing can work better in plants larger than or similar to the one used in this paper. This is because this protocol groups sets of sensor nodes in which each cluster is responsible for managing the communication of its nodes.

The EEWES, without routing in always-on mode, got the highest percentage of packet loss (58.42%), showing that in WSN, where the communication is continuous, the routing is necessary. Due to attempts to simultaneous communication of multiple sensor nodes, the bottleneck is inevitable. The MAC layer is unable to handle the bottleneck effectively, and because of it it is need to use a routing protocol that is implemented at the network layer.

Different results can be observed when the packet loss in communication is analyzed under the condition of power saving (sleep mode). In this communication scheme it is inappropriate to use the AODVjr protocol. This protocol has to reconfigure the routing tables of each node of the WSN, which increases the latency. So the latency becomes larger than the window of time required for the trans-mission of data packets from each of the sensor nodes, which leads to a huge loss of 53.85%. The HTR protocol remained at a significantly lower percentage of losses compared with AODVjr while maintaining the maximum limit of packet loss accepted in this network (4.92%). This is due to the fact that the HTR protocol carries out hierarchical routing, which divides communication in clusters reducing the workload of the sink, which reinforces the indication of the possibility of using the EEWES in larger WSN.

In sleep-mode, the lower percentage of packet loss happens when no kind of routing is applied. In this plant, the coverage area is enough to allow the communication scheme in the power saving approach. Thus, the percentage of 4.42% obtained by the EEWES is below the maximum percentage of packet loss allowed in this application. Another important factor is that the power saving generated by this method does not affect the reliability of the information transmitted and received. In environments where the lack of abundant sources of energy is high and the plant to be monitored has similar characteristics to the ones used in this study, the use of this sleep technique is justified.

Lifetime: To estimate the maximum lifetime of a node of this WSN, two variables were considered: the average consumption of the transmitter in each of the schemes tested and the power supply of each sensor node by an alkaline battery with the capacity of 4400 mAh. The average consumption of each device can be obtained by the energy consumption and the time that each action takes to be executed, that is, hibernating, waking up, setting the communication parameters, measuring, and communicating.

In all cases, the instantaneous current of each operation is approximately 0.018 mA (hibernating), 14 mA (waking up and configuring), 14 mA (measuring), and 43.8 mA (communicating). The current and the acquisition time were obtained by measuring the voltage by a resistance of 10 by using an oscilloscope connected in series with the source that powers the devices, and then directly resulting in the current consumed by the system and the time obtained in each operation. The Figure 6 shows a cycle of waking up, configuring the network, measuring, communicating, and hibernating of the EEWES. This means that each operation respectively lasts 14 ms, 6.7 ms, 1.8 ms, and 2.5 ms, thus consuming a total time of 25 ms.

For each communication carried out between the WSN nodes, the total time is 37.9 ms, which corresponds to three attempts to send (sensors) or receive (actuators) data, respectively.

The calculation of the average current consumption is made by the sum of consumption of each activity divided by the total time, given by Equation (2).

The transmission and configuration times of the WSN can vary depending on the protocol used. The times are 11.6 ms and 15.7 ms for AODVjr; 5 ms and 8.4 ms for HTR; and 2.5 ms and 6.7 ms, respectively, when no routing is used.

From these results, it is possible to estimate the lifetime for continuous communications and with 5s of sleep by dividing the battery capacity by the average consumption.

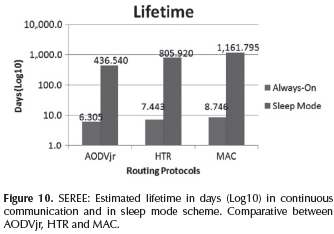

The Figure 10 shows the lifetime through days (in logarithmic scale) of the protocols used and the MAC layer in continuous and in sleep mode communication. With measured values between 6.3 and 8.7 days, the continuous communication is not suitable for this application and for similar applications that do not use any battery charging system.

In a communication scheme with sleep enabled, the lifetime of all protocols increases significantly. It is noticed that the shortest time was registered by the AODVjr protocol (436.54 days), which indicates that the routing tables consume plenty of memory of the transceiver, directly impacting in the consumption of each sensor node; on the other hand, the HTR protocol had an acceptable lifetime of 805.92 days what candidates it to be the most appropriate routing protocol for larger networks with similar characteristics to the ones of this study. By not keeping any routing scheme, the lifetime of 1161.8 days obtained by the MAC layer was the highest, but the scalability factor is impaired, so that the MAC layer, by itself, is unable to handle a large number of communication requests coming from a larger WSN.

Conclusions

This paper presented the EEWES, an energy-efficient wireless sensor network embedded system of low cost based on the IEEE 802.15.4 open standard. The EEWES is developed to be applied on industrial applications for monitoring and controlling processes by ensuring three of the four essential requirements expected of a WSN, which are reliability, availability, and in particular, energy efficiency. This wireless sensor network ensures these requirements using a system based on the communication technique for rational sampling of time, which alternates periods of data acquisition with sleep periods, thereby reducing the duty cycle of the sensor nodes.

The experimental results, such as lifetime, jitter, and packet loss, confirmed the viability of the EEWES by using sleep periods and intermittent communication techniques carried out by a timer and then ensuring a significant improvement in consumption of the set of sensor nodes (transceiver and sensors/actuators attached). Thus extending the maximum values which made possible the use of the EEWES not only in environments similar to the one used in this study, but in other industrial environments where the number of sensor nodes is larger. This is because the EEWES works satisfactorily without routing and operates efficiently with the HTE hierarchical routing protocol.

Techniques to ensure improvement in consumption of the EEWES by the use of solar panels can be cited as future works.

References

Ganesan, D., Ceipa, A., Ye, W., Yu, Y., Zhao, J., Estrin, D. (2004). Networking issues in wireless sensor networks. Journal of Parallel and Distributed Computing -JPDC, 64(7), 799-814. DOI: 10.1016/j.jpdc.2004.03.016. [ Links ]

Gungor, V. C., Hancke, G. P. (2009). Industrial wirelless sensor networks: challenges, design principles, and technical approaches. IEEE Transactions on Industrial Electronics,56, 4258-4265. DOI: 10.1109/TIE.2009.2015754. [ Links ]

Heo, J.-Y., Hong, J.-M., Cho, Y.-K. (2009). EARQ: Energy aware routing for real-time and reliable communication in wireless industrial sensor networks. IEEE Transactions on Industrial Informatics, 5(1), 3-11. DOI: 10.1109/TII.2008.201 1052. [ Links ]

Karp, B., Kung, H. T. (2000, August). GPSR: Greedy perimeter stateless routing for wireless networks, Paper presented at 6th annual international Conference on Mobile Computing and Networking - MobiCom, Boston, USA, 243-254. [ Links ]

LoBello, L., Toscano, E. (2009). An adaptive approach to topology management in large and dense real-time wireless sensor net-works. IEEE Transactions on Industrial Informatics, 5(3), 314-324. DOI: 10.1109/TII.2009.2025656. [ Links ]

Ontiveros, J. M. H., González, E. I., Tiznado, J. E. O., López, J. J. S., Figueroa, P. A. R., Wilson, C. C. (2010). 802.15.4 MAC protocol applied to efficient energy consumption. Ingeniería e Investigación, 30(1), 71-74. [ Links ]

Petersen, S., Doyle, P., Vatland, S., Aasland, C.S., Andersen, T.M., & Dag S. (2007, September). Requirements, drivers and analysis of wireless sensor network solutions for the Oil & Gas industry. Paper presented at Emerging Technologies and Factory Automation - ETFA, Patras, Greece, 219-226, 25-28. [ Links ]

Quintaes, F.D.O. (2006). Estudo da estimativa da incerteza de medição para determinação do BS&W e da vazão aplicado no laboratório de avaliação de medição do petróleo (Master thesis, Universidade Federal do Rio Grande do Norte, Natal, RN, Brazil). [ Links ]

Song, X., Wang, C., Pei, J. (2012, March). 2ASenNet: A multiple QoS metrics hierarchical routing protocol based on swarm intelligence optimization for WSN. Paper presented at IEEE International Conference on Information Science and Technology (ICIST), Hubei, China, 531-534. DOI: 10.1109/icist.2012.6221703. [ Links ]

Vieira, M.A.M., Coelho Jr., C.N., Silva Jr, D.C., & Mata, J.M.(2003, September). Survey on wireless sensor network devices. Paper presented at Emerging Technologies and Factory Automation - ETFA, Lisbon, Portugal, 537-544. [ Links ]

Willig, A. (2008). Recent and emerging topics in wireless industrial communications: A selection. IEEE Transactions on Industrial Informatics, 4(2), 102-124. DOI: 10.1109/TII.2008.923194. [ Links ]

Ye, W., Heidemann, J., & Estrin, D. (2002, June). An Energy-efficient MAC protocol for wireless sensor networks. Paper presented at 21st Annual Joint Conference of the IEEE Computer and Communications Societies - INFOCOM, New York City, NY. 1567-1576. [ Links ]

ZigBee specification standard. (2007). ZigBee Alliance. [ Links ]

Zurawski, R. (2009). Networked embedded systems: An overview, Paper Presented at Networked Embedded Systems, Deutschland, 1.11-1.16. DOI: 10.1201/9781439807620.ch1. [ Links ]