Introduction

Polymers derived from plant feedstocks are increasingly replacing plastic materials, reducing their environmental impact (S. Lambert and Wagner, 2017; T. Lambert and Perga, 2019; Mierzwa-Hersztek et al., 2019). Polymers of industrial interest include cellulose, starch, alginic acids, natural polypeptides such as gelatins, and bacterial polyesters (Heidemann et al., 2019). The biodegradation of contaminated plastics under composting conditions has been reported as an effective method to reduce plastic contamination (Bher et al., 2019). However, biodegradable polymers offer the possibility of reducing the environmental impact of chemical waste from landfills, which is due to their degradation speed under composting conditions at the site of final disposal (Castro-Aguirre et al., 2018). However, some biodegradable polymers such as polylactic acid (PLA) do not biodegrade as quickly as other organic waste during composting (Lv, Zhang, et al., 2017), since their degradation depends on the action of microorganisms (Pattanasuttichonlakul et al., 2018) and hydrolysis reactions that can break lactic acid chain monomers into smaller molecules such as lactide. Consequently, the low degradability of PLA has affected its general acceptance in industrial composting. Blends of PLA with other biomolecules such as corn starch have been widely documented (Shogren et al., 2003), and blends of 4032D PLA with cassava starch (TPS) have been reported in recent years for packaging and food service applications. In these compounds, due to the effect of biodegradation, each of the components is converted into biomass, which returns to the environment in the form of carbon dioxide (CO2), methane (CH4), and water. During this process, the polymer or blend undergoes structural changes implying the loss of mechanical properties due to disintegration, fragmentation, and mineralization (Salazar-Sánchez et al., 2020). The objective of this work was to study the biodegradation of a blend of cassava starch and PLA under natural environmental conditions.

Materials and methods

Sample preparation

The plastic film was produced in the rheology laboratory of Universidad del Cauca. The film is a polymer obtained from renewable sources such as cassava starch (Manihot esculenta Crantz) and PLA. Three films were used: a film of thermoplastic starch from Cassava (TPS), a film of polylactic acid (PLA Ingeo 4032D, Mn = 88 500 g.mol-1, Mw/Mn = 1,8), and one film product of a blend of the two compounds with a ratio of 72:28 (TPS-PLA) following the procedure described by Salazar-Sánchez et al. (2019).

Fourier transform spectrophotometry (ATR-FTIR) analysis

The tests were conducted in accordance with ASTM E1252-98 (ASTM International, 2013) via Fourier transform infrared spectroscopy (FT-IR) (IRAffinity-1S, Shimadzu, Inc., Shelton CT, Japan). A horizontal attenuated total reflectance (ATR) sampling accessory (ATR-8200HA) equipped with a ZnSe cell was employed for the measurement (Salazar-Sánchez et al., 2019).

Thermal properties

A thermogravimetric analysis (TGA) and a differential sweep analysis (DSC) were performed using a TGA (TGA 2050TA Instruments, USA) and a DSC (Q20 TA Instruments, New Castle, USA), respectively, according to ASTM E1131-20 and ASTM D3418-15 (ASTM International, 2015, 2020; Daza et al., 2018; Carmona et al., 2015; Frone et al., 2013).

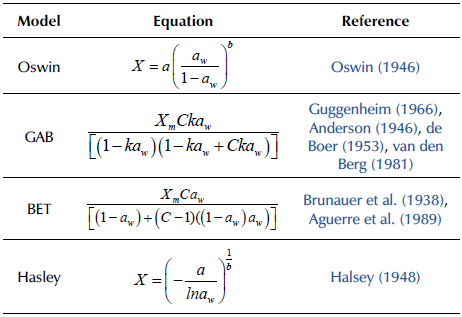

Isotherm analysis

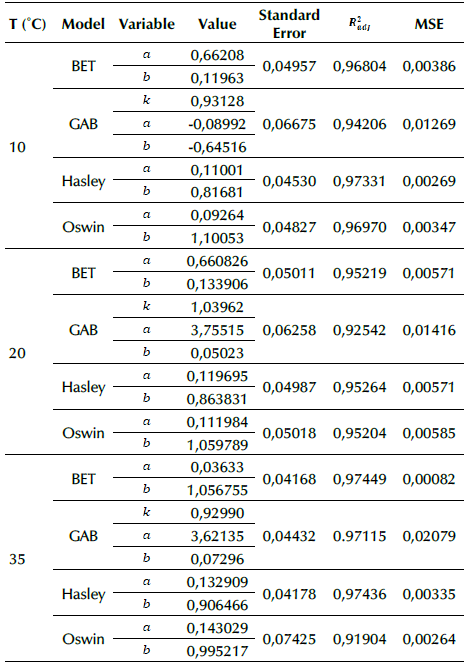

The sorption isotherms were determined at 10, 25, and 35 °C using a vapor sorption analyzer (Aqua Lab VSA, USA) with an a w range of 0,5-0,95. The equilibrium moisture content on a dry basis was plotted against the a w in order to obtain the equilibrium moisture curves (Dutcher et al., 2011). The performance of the models (Table 1) was evaluated via the adjusted coefficient of determination (R 2 adj ) and mean square error (MSE). The models were selected on the basis of a high R 2 adj - and a low MSE (Andrade et al., 2011; Arslan-Tontul, 2020; Homez et al., 2018; Iglesias and Chirife, 1995; Torres et al., 2012).

Biodegradation analysis

The biodegradability test was conducted in triplicate according to ASTM D5988 (ASTM International, 2018). A mixture of coffee soils and compost (derived from agricultural residues) was used as inoculum at a ratio of 25:1, and 4% sand was added as a structuring material to improve aeration. A physicochemical analysis of the soil was performed (organic carbon, water retention capacity, cation exchange capacity, capillary electrophoresis, pulse differential polarography, and carbon/nitrogen ratio) using the Colombian Technical Standard SSLMM-42-2-92 and the 3111B standard method (APHA, 1999) to determine metals and minerals. Microbiological properties were determined by counting the colony-forming units (CFC/g) of mesophylls, thermophiles, mold, yeast, Nematodes and/or Protozoa, Enterobacteria, and Salmonella (supplementary material).

The moisture content was adjusted to approximately 63%. The test material was the mixture described above (TPS/ PLA), and, as a reference microcrystalline, cellulose was used for thin-layer chromatography (Merck KgaA, Germany), as well as 4032D PLA (Ingeo). The cellulose and PLA were conditioned according to ISO 10210 (ISO, 2012), and the crushed fraction with a particle diameter between 250 and 125 urn was chosen. Each reactor was loaded with 200 g of inoculum and 0,74245 ± 0,0009 g of TPS/PLA, 0,6467 ± 0,0016 g cellulose, and 1,0028 ± 0,0005 g PLA -all samples on a wet basis. The carbon mineralization in the mixtures was quantified using a respirometry assembly in a closed chamber, where Ba(OH)2*8H2O 0,025 N (Merck KgaA, Germany) was used as CO2 adsorbent, and HCL 0,05 N as titrator (Merck, Germany). The titration was performed at the endpoint of a 5 ml sample of adsorbent, aided by a TITRINO PLUS (Metrohm) automatic titrator. For the statistical evaluation of the results obtained from the biodegradation process of the samples studied for 4 weeks (W), a univariate analysis of variance was performed (ANOVA and Tukey tests with a 95% reliability and minimum significant difference) and the SMD (standardized mean difference) was estimated. The differences were considered to be significant when p<0,05.

Scanning electron microscopy (SEM) analysis

The samples were characterized via scanning electron microscopy (SEM) using a QUANTA 200F (FEI, The Netherlands). Each SEM sample was coated with Gold-Palladium (0,8 nm thick coating) in an EmiTech K575X Peltier Cooled (QuorumTech, United Kingdom). The samples were observed and analyzed at an accelerating voltage of 10,0 kV at different magnifications (from 50X to 2000X).

Results and discussions

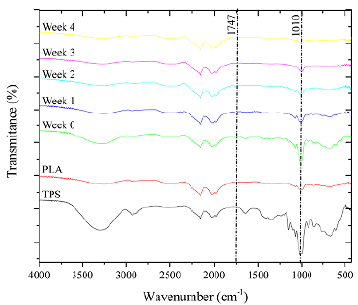

ATR-FTIR analysis

The FTIR spectra were analyzed in the range of 400-4 000 cm-1 and are shown in Figure 1. Bands between 900 and 1 010 cm-1 indicate C-O-C bonds (Liu et al., 2011; Salazar-Sánchez et al., 2019). The characteristic peaks at 2 918 and 2 848 cm-1 correspond to CH3, and those between 1 747 and 1 180 cm-1 are characteristic of 4032D PLA with C=O and C-O carbonyl group stretching, respectively (Riba et al., 2020). The peaks at 730 cm-1 are associated with the bending of the C=C group of the PLA's main chain. Flexure of the carbonyl group CH3 was observed in the 1 458 and 1358 cm-1 peaks, and there was also a CH3 shift in the 1 072 cm-1 peak. Stretching of the -C-COO (1 276 cm-1) and C-O-C (872 cm-1) groups was observed in the PLA spectrum. Similarly, vibrations corresponding to the stretching of the hydroxyl (O-H) group between the 3 400-2 400 cm-1 bands were seen.

Additionally, the spectra of TPS were compared because, when it blends with PLA, the mechanical, thermal, and other properties related to these mixtures (PILATPS) are modified. Therefore, the peaks to be analyzed were established between 750 and 1 250 cm-1 in order to understand the behavior of the TPS structure regarding its amylose/ amylopectin composition before blending, as it is important to understand the crystalline and amorphous behavior of these molecules in the mixture. The stretching attributed to bands 1 040 cm-1 (C-O), 1 024 cm-1 (C-C), and 680 cm-1 (C-O-C) indicates a sensitivity to crystalline change. In other words, decreasing the crystallinity increases the 1 024 cm-1 band, whereas the intensity of the peak at 1 040 cm-1 increases with crystallinity, considering the crystalline structures of starch in this area (Cao et al., 2020). The intensity ratio between these two bands (1 046/1 024 cm-1) is 1,72, thus indicating an increase in crystallinity in starch, which has a high degree of organization and is composed mainly of amylopectin (Özeren et al., 2020; Mierzwa-Hersztek et al., 2019; Homez et al., 2018; Nevoralová et al., 2019). The PILATPS film spectra show a stretch in the OH group in the region from 3 260 to 3 350 cm-1. Likewise, the characteristic -CH peak of starch shows stretching in the 2 914 cm-1 band. The 1 024 cm-1 peak exhibited a shrinkage that could be due to starch retrogradation. When exposing the film to the biodegradation process, structural changes were evidenced; the TPS present in the film degraded from W0 to W4. These changes could be observed in the spectra and are attributed to changes in the crystallinity of starch, which is reflected by the glycosidic bonds of the TPS Neat and could be due to the fact that starch degradation occurs first in the amorphous region (amylose) as well as in the PLA, where the hydrogen bonds are very weak and more accessible to microorganisms, which degrades substantially faster compared to the crystalline part (Sedničková et al., 2018). The bands located at 1 040 cm-1 indicate a C-O functional group. The band located at 1 024 cm-1 indicates the amorphous region of starch given the presence of the C-C group. Similar observations were reported by Palai et al. (2019) and Wang et al. (2020), as well as at 680 cm-1 with vibrations for the C-O-C group (Gopi et al., 2019). The decrease in peak intensity at 1 178 cm-1 for PLA/TPS may be due to the weak chemical interaction between PLA and TPS (Muller et al., 2017).

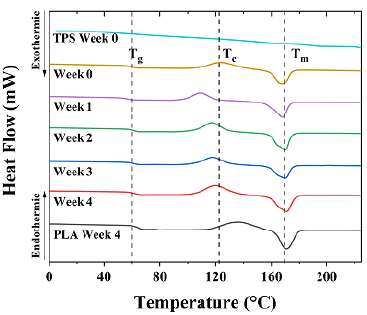

Thermal properties

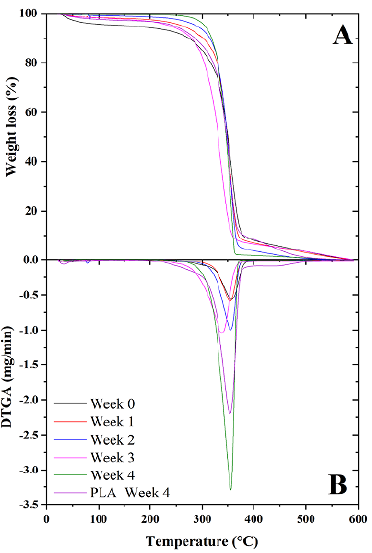

A loss of mass could be observed which reflected the condensation of hydroxyl groups (300-400 °C) (Figures 2a and b). The magnitude and location of this mass loss changed according to the degradation time (W0 to W4). In W1 and W2, the film showed a significant mass loss in the temperature range of 350-365 °C, which indicates the condensation of the hydroxyl groups of cassava starch. In W3 and W4, there was a mass loss in the range of 340-350 °C, which corresponds to the degradation of the PLA present in the blend. Similar results were reported by Nasseri et al. (2020) for mixtures of acetylated rice starch and PLA. The degradation temperatures decreased due to the consumption of the starch content by the microorganisms (de Oliveira, Barbosa, et al., 2019; de Oliveira, de Oliveira Mota et al., 2019; Gralde, et al., 2019).

Source: Authors

Figure 2 TGA (a) and DTG (b) curves for the biodegradation process of the TPS/ PLA film

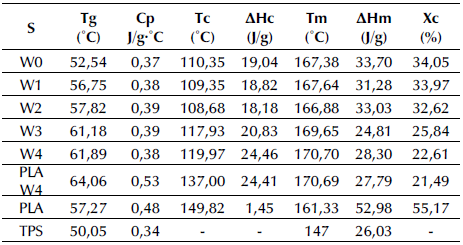

The DSC curves show the glass transition (Tg), crystallization (Tc), and melting I (Tm) temperatures (Figure 3). The Tg is around 60 °C in the analyzed samples. It increases in W3 and W4 and has a lower value in W1 and W2, which could be due to the difference in the nature of the incidence of starch. The addition of TPS within the PLA matrix resulted in a decrease in the Tg of the PLA/TPS blends. A decrease in Tg increased the starch concentration (Li et al., 2020). This decrease in the Tg of the films can be attributed to the plastification of starch with glycerol, given the mobility of the chains caused by the migration of glycerol in the dispersed phase of TPS (Özeren et al., 2020). This effect is also attributed to the nucleation of the dispersed phase of TPS (Cai et al., 2014). The Tc of the samples (Table 2) shows a temperature decrease from 135 to 100 °C in W1, which was reflected on the weeks of biodegradation. This temperature, in comparison with that of PLA, is correlated with the TGA and FTIR results, where structural changes in the film were observed during the biodegradation process. A single endothermic peak for melting at 170 °C was observed in all weeks. Additionally, all PLA/TPS blends showed an increase in the intensity of the endothermal peak attributed to the laminar arrangement and polymorphism of the PLA's crystalline structure (Anakabe et al., 2017).

Table 2 Thermal data for PLA in their corresponding blends: samples (S), week (W), glass transition temperature (Tg), heat capacity (Cp), crystallization temperature (Tc), enthalpy of crystallization (ΔHc) melting temperature I (Tm), enthalpy of fusion (ΔHm), and crystallinity indices (Xc)

Source: Authors

The diffusion coefficient of water in an amorphous or semi-crystalline polymer is related to the molecular dynamics of its amorphous regions (Shogren et al., 2003). If the temperature of an amorphous system (polymer-water) is above the glass transition temperature, the movement will be rapid, the free volume will increase, and the water vapor permeability will be high. Moisture penetration through the film may be due to cavities within the film that produce increased water vapor permeability, which has been linked to the two-phase morphology of PLA/TPS blends.

The isotherms show the behavior of the type I or S sigmoid form, which is indicative of physical adsorption in the multilayers of the material (Valsaraj, 2009). Table 3 shows the fit of the BET, GAB, Oswin, and Hasley models evaluated at different temperatures; it is evident that the model that best fits the data (MSE < 0,01) is BET, with R 3dj2 of 0,96804 at 10 °C, 0,95219 at 25 °C, and 0,97449 at" 35 °C. From the prediction of the BET and GAB models, the amount of water that is strongly absorbed in the active sites of the film can be highlighted and is considered as the value at which the TPS/PLA mixture is most stable during storage (Chen et al., 2008; F. Wang et al., 2020). The addition of PLA in the blend provides a water vapor barrier, and TPS provides favorable water adsorption properties for the biodegradation process. This is because starch is hydrophilic, unlike PLA, which tends to be completely hydrophobic (Sedničková et al., 2018). Therefore, it is possible that, in the film (TPS/PLA), the PLA prevents the starch from swelling, limiting the movement of the molecules and thus providing a part of the resistance to water permeability (Gürler et al., 2020). The variation in the water adsorption of TPS/PLA blends can be attributed to the behavior caused by the transition from the less ordered structure of starch to a higher-order structure that contains less water molecules (Lendvai et al., 2019). Consequently, the 3 300 cm-1 band is attributed to the stretching of the free inter- and intramolecular hydroxyl (-OH) groups of the starch chains, while the TPS exhibits a decrease in its intensity due to the interaction that occurs between starch and plasticizer by thermoplasticization (Altayan et al., 2017), which is due, in turn, to a greater interaction of the plasticizer with the polymeric chains of starch (Zdanowicz et al., 2019). On the other hand, in the region between 1 200 and 900 cm-1, a band at 1 016 cm-1 attributed to the C-O stretching of the C-O-C group of the starch anhydroglucose ring is observed (Esmaeili et al., 2017) which is a function of the PLA concentration. The 995 cm-1 band, sensitive to water, is related to the intramolecular hydrogen bonding of the hydroxyl at C6, which can significantly decrease with increasing PLA.

Table 3 Water activity (aw) models evaluated at different temperatures for a TPS/ PLA blend

Source: Authors

This behavior has been reported by other authors working with hydrophilic polymers that have been plasticized with polyols, and it is associated with the increase in the amount of hydroxyl groups in the plasticizer. This increase causes an increase in the hygroscopicity of the material, reflected on the increase in the solubility coefficient of the samples with higher plasticizer concentration. Other authors have reported that a lower water vapor permeability is related to a lower value of the diffusion coefficient. They have also reported that the solubility coefficients of TPS/PLA blends are lower than those of TPS. This behavior is associated with a lower amount of hydroxyl groups in the blend that are available for interaction as the PLA concentration increases, which is in turn associated with the fact that each D-glucose repeat unit contains three of these groups, whereas PLA has two in each polymeric chain (Müller et al., 2012; Abdillahi et al., 2013). It is important to highlight, as mentioned by other authors (Hu and Vuillaume, 2020), that the increase in crystallinity increases the water vapor permeability in the film structure formed by PLA/TPS. This statement is validated by the data shown in the FTIR, DSC, and SEM analyses. Therefore, the incorporation of starch in these blends not only lowers the cost of the material but also contributes to its rapid biodegradation.

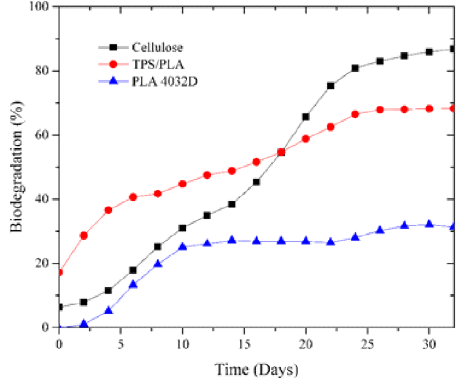

Biodegradation analysis

The results observed can be attributed to the dynamics of material degradation (Figure 4). Cellulose obtained a biodegradation percentage of 84%, the samples of the TPS/ PLA blend 68%, and PLA 32% in 35 days. These results show that the test performed under the ASTM D5988 standard (ASTM International, 2018) is valid because there is a >20% difference between the control sample and the evaluated blend.

The reason for this is that biodegradation generally proceeds faster in the amorphous part of the polymer when compared to the crystalline ones, and the degradation rate of polymers with higher molecular weight (PLA) is expected to be lower in comparison with shorter macromolecules (TPS), which are more easily digested by microorganisms. Consequently, the portion of PLA present in the TPS/ PLA blended film containing a 72/28 ratio became more biodegradable than pure PLA (Sednicková, et al., 2018). These results are similar to those of Šerá et al., (2020), who found that cellulose obtained 91,4% of biodegradation of (25 °C) after 270 days, and a PBT/PLA mixture showed a percentage of 64,4%. These results are consistent with the biodegradation test performed under aerobic composting conditions, in which a 72% biodegradation percentage was found for a TPS/PLA film mixture (Bher, Auras, et al., 2018; Bher et al., 2019; Salazar-Sánchez et al., 2019). According to the results, the semi-crystalline PLA present in the mixture (TPS/PLA) reduces the amorphous regions in such a way that the molecular weight increases significantly and the crystalline regions start to decrease (Karamanlioglu and Robson, 2013; Middleton and Tipton, 2000; Weir et al., 2004), thus causing the fragmentation and disintegration of the material, as observed in the FTIR spectra and SEM micrographs, by means of the modifications to the film surface that could be noticed during the experiment. These results are similar to those reported by Olewnik-Kruszkowska et al. (2020), and they stem from the mineralization effect of the possible hydrolytic processes of microbial origin in the soil.

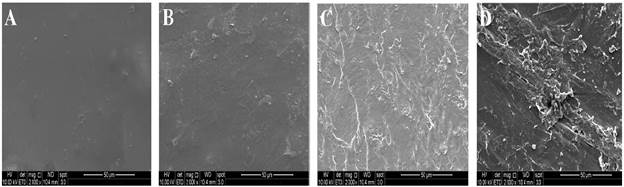

Scanning electron microscopy (SEM) analysis

The surface changes of the TPS/PLA blends during soil degradation (Figure 5) show that the film surfaces were smooth before degradation, and, after degrading under soil conditions during the evaluation time, they became rough; depressions and scratches appeared on the surface of these blends, similar to that reported by Lv et al. (2018) and Lv, Gu et al. (2017) for samples of 306D PLA and corn starch. After 30 days, there were fractures on the surface of each sample, cracks that would lead to the loss of mechanical strength. There were morphological changes regarding the color and shape of the film surface, which resulted from the attack of microorganisms to the PLA/TPS films (60:40) (Phetwarotai et al., 2013).

Conclusions

The addition of PLA and TPS is synergistic and significantly contributes to preservation and biodegradation processes by means of increasing or decreasing the crystallinity due to the number of amorphous phases present in the polymer. The biodegradability of the blends was confirmed by weight loss measurements with exposure time in the soil process. TPS accelerates the biodegradability of the blends in this medium due to its accessibility to microorganisms, its hydrophilic properties, and its amylose composition, which can be degraded more rapidly. The materials obtained from mixtures of TPS and PLA provide an additional advantage derived from the use of renewable sources for their manufacturing, as they provide the mixture with hydrophilic and biodegradable properties. This is an advantage over conventional plastics that must be exploited in order to obtain resistant materials which can be used in a similar way to conventional polymers.