1. INTRODUCTION

Problematic soils refer to soils that expand (swell) or contract or settle to such an extent that the strength of the soil is not uniform. As soil provides the base for foun dations and withstands the load, it must have proper bear ing capacity. There can be a large risk involved if proper analysis is not done and this affects the behavior of the soil characteristics.

Black cotton soil, which is an example of expansive soil, generally refers to any soil or rock material that has high activity and potential for shrinking or swelling under changing moisture conditions. Black cotton soil deposits are generally present in the semi-arid regions of tropical and temperate climatic zones and are abundant where the annual evaporation exceeds the average precipitation[1]. Due to the presence of montmorillonite, severe damages in structures are bound to occur. Soil stabilization refers to the process of improving the overall bearing capacity, soil strength, and durability characteristics under adverse mois ture and stress conditions.

There is a huge scope in the field of environmental geo technics particularly in soil stabilization and ground impro vement. Through the use of certain chemical compounds and wastes which are normally unsafe for disposal, the twin benefits concerning sustainability and satisfying demands for the land is ascertained. Generally, solid wastes like fly ash, blast furnace slag, rice husk etc. are tried on such problema tic soils as part of ground improvement techniques. When Sabat and Pradhan[2], Cokca [3], Oyekan et al.,[4], Muntohar and Hantoro[5] studied and tested the influence of various materials like rice husk ash, fly ash, polypropylene ash, ce ment kiln dust etc. in problematic expansive soils, several specific properties of the improved soil were respectively tested and studied. The importance of such properties and the choice of tests conducted to deduce an optimum pro portion of the waste material depend mainly on the applica tion intended and the material's adhesion with the soil. For example, Moses and Saminu [1] focused their work on the effect of cement kiln dust by conducting UCC, durability and CBR tests, bearing in mind how the modified soil deposits can be better ideated towards sub-base and base material applications in pavement [6]. Patel and Singh [7] carried out an study to investigate the suitability of randomly-distributed-glass, fiber-reinforced, cohesive soil as subgrade ma terial. The effects of fiber content variation on compaction parameters of soil, soaking time variation (4-40 days) on CBR strength were investigated. It has been determined that CBR strength of soil has improved significantly with fiber content up to an optimum fiber content value of 0.75% and decrea ses with an increase in soaking time at any fiber content. It has been found out that glass fibre-reinforced soil can be ex tensively used as subgrade material.

Similarly, the study by Ramya and Jeyapriya [8] focused on the comparison of geopolymer soil column and untreat ed sand in the load-carrying capacity and settlement be havior of footings that were resting on loose sand. A load test was carried in a model footing resting on loose sand, with a geopolymer soil column and untreated sand at vary ing curing periods. It was then observed that a geopoly mer soil column has a high bearing capacity compared to untreated sand, proving it to be an efficient technique for improving soil strength. The settlement was also reduced when using a geopolymer soil column.

The use of crumb rubber from tire waste, generated from automobile industry attracted researchers. The re-use of rubber has gained large importance to the geotechni cal field, where the rubber waste (crumb rubber) has been fused with clayey soils and yielded desired results through the improvement of soil's strength parameters, namely the unconfined compressive strength and CBR values [9]. Crumb rubber works well in inorganic soils [10] compared to high organic clay soil. An optimum percentage of 15% crumb rubber, when mixed with inorganic clay, improves the shear strength of the soil and also reduces the thickness of the pavement [11], [12].

Small concentrations of polymer added to soil has re sulted in improved properties like increased water reten tion, shear strength, ability to support the structure and resistance against erosion. In a study on polymeric sta bilization of soft clay soils, 2 polymers-polyvinyl alcohol and 1,2,3,4 butane tetracarboxylic acid were added to ex pansive clay in different proportions. On testing and com paring with pure clay, polymer-stabilized soils showed better compressive strengths and the strength increased with curing time. Also, the polymer-stabilized clay soils showed better durability when soaked in water [13].

The domain of 3D printing affords a lot of scopes to utilize this technology more effectively. Many of the pre sent manufacturing industries have begun to embrace this field for their overall development and easier wor kflow. The applications of this technology include auto mobile, biotechnology, airplanes and product manufac turing. By performing rapid prototyping across various engineering and biology fields, 3D printing has become a pioneering technology to accomplish design and re search conclusions [14].

The trends in the material used for printing show that around 65% of the printing is done using plastic mate rials. Technology like Fused Deposition Modelling, Multi Jet Fusion Technique (MJF) and Selective Laser Sintering (SLS) are cheap and common practices adopted in mode lling [15]. The most common waste material generated after MJF is Polyamide 12 (PA 12) or Nylon 12. Nylon 12 is a polymer and an engineering thermoplastic, strong but flexible material. Despite the rapid advancement of 3D printing technology, the question of how plastic waste shall be re-used is a domain to explore. To mini mize carbon footprints and progress towards zero waste economy, the waste management issues on MJF and SLS techniques can help spread this study across various dis ciplines. Liu et.al. [16] observes that waste materials can be recycled back. Though there is the scope of recycling waste for printing use, there is additional second ener gy and resource consumption involved in the process. In the research and development industry of 3D Prin ting, there have been numerous research projects going around the world to utilize the plastic waste generated to usable 3D filaments.

In the field of geo-technical engineering, soil stabili zation is the process of improving the engineering pro perties of natural soils which are regarded unsuitable for housing or other construction purposes. The major reason for resorting to soil stabilization is to improve the shear strength properties of the soil, either through cohesion or friction. This study involves the reuse of plastic waste ge nerated in the MJF technique for the applications of soil stabilization of problematic soils.

2. MATERIAL USED

2.1 Properties of PA-12

Both MJF and SLS techniques involve the poly mer-based composite raw material called Polyamide-12 (PA-12) with polymeric formula of [-(CH2)11C(O)NH-]n for functional prototyping and volume applications. PA-12 is characterized as a strong thermoplastic fine powder exhib iting a dense and nearly-isotropic mechanical performance. The polymer properties include resistance to impact and abrasion, low water absorbency and generally ideal for safety and durability applications. Owing to its appealing potential of plastic waste management across various sec tors, the investigation of this PA-12 material can be related to soil improvement through its striking low-water absor bency and wear resistance feature [17].

The literature on the use of PA-12 waste for geotechnical applications is very sparse since the technology is currently new-found. The tests conducted to analyze the PA-12 pro perties, and the basic soil stabilization technique procedures for any virgin material in the soil sample and the preliminary lab tests conducted initially to gather the properties of the polyamide wastes serve as the impediment for the research.

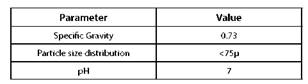

The specific gravity of the PA-12 waste material was con ducted using the density bottle and the value was found to be 0.73. To check the reactivity of the PA-12 material in soil condi tions, a pH test was conducted and indicated a value around 7. The summary of the properties of PA-12 is shown in Table I.

2.2 Properties of Virgin Soil

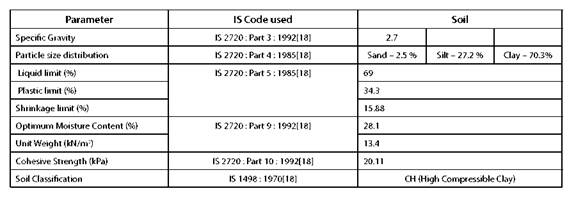

To reuse and utilize PA-12 waste material for the stabili zation of problematic soil, laboratory tests were conducted to check the individual behavior of expansive soil, extract ed from Thaiyur Lake, Chennai, India. The index properties of the soil have been summarized in Table II.

3. METHODOLOGY

After ascertaining the basic properties of PA-12 and the virgin expansive soil, tests are conducted to obtain the index properties of the polymer-induced expansive soil in various proportions. By doing this, the behavior of the soil is preliminarily understood for varying proportions of the waste material. PA-12 was added to this problematic soil without incorporating lime, a common activating agent to analyze its potency independently. Using Unconfined Compression Strength, the shear strength of the soil sam ple was estimated (as shown in Fig. 1 and 2). The test was conducted according to IS 2720 :1991 (Part 10) [18]. From the obtained stress-strain graph, unconfined compressive strength and cohesion of the sample were estimated. The composition of PA-12 where the cohesion of the soil is max imum was found to be the optimum PA-12 content. Also, the results of the initial modulus and secant modulus was ascertained based on the UCS tests conducted for various percentages of PA-12.

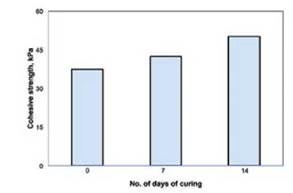

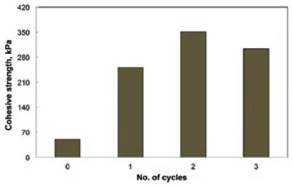

Further in this study, durability tests were conducted for the sample with the optimum PA-12 percentage by weight. The test conducted was done to understand the influence of wet-dry cycles on the strength of this modified compos ite soil. To do so, the curing period for these soil samples were initially derived by studying how the strength of the sample tends to vary with time. It was seen that for trials prepared for a different curing period of 0, 7 and 14 days, the cohesive strength of the soil tends to go on a rising trend, Fig.3. Hence, 14 days was fixed as the curing period for the durability test to be conducted.

A set of 15 samples of soil with the optimum polymer content were prepared in UCS molds and were cured for 14 days (as shown in Fig. 4 and 5). Once the curing period had been completed, one of the cured samples were tak en for testing without undergoing any wet-dry cycle. This is the strength of the modified sample after zero wet-dry cycles. The remaining samples were immersed in water for one day followed by drying them for another day. This is one complete cycle of wetting and drying. Thus, one wet dry cycle lasted 48 hours. Similarly, samples were tested for their strength characteristics till 3 cycles of wetting-drying. Therefore, the strength of the sample for the corresponding wet-dry cycles led to a comparative study between the ini tial clay and the polymer-modified problematic soil

4. Results and Discussion

4.1 Index Properties of the Polymer-Induced Soil

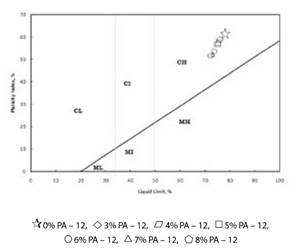

The index properties and behavior of polymer-induced soil (for varying proportions of PA-12) were understood by plotting the Atterberg line. In the figure 6, a decreasing pattern of liquid limit and plasticity index can be observed in the highly compressible clay region, with an increase in the percentage of PA-12 replacing the problematic soil. The reduction in the plasticity index implies that there was no change in the soil classification, which can be attributed to the non-reactive nature of PA-12.

4.2 Strength Properties of the Polymer-Induced soil

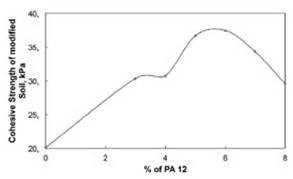

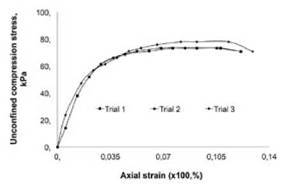

The shear strength of the problematic soil is mainly attributed to its cohesion as the clay was of clayey nature. For improved shear strength properties for better applica tions, PA-12 waste material was added in varied propor tions to the virgin soil. It can be seen that the addition of PA-12 yielded desirable results, with a steady increase in cohesion with increasing concentration of PA-12. Initially, samples were prepared with varying percentage, and it was observed that there was an increase in strength from 3% to 5% and subsequent decline when 10% was tested. Therefore, 3 samples from each of the percentages starting from 3 to 8 were prepared and a UCS test was conducted to understand how the shear strength varied. Figure 7, shows the comparative trend of how the strength properties var ied with the percentage of PA-12 replaced in it.

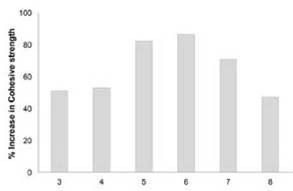

It was observed that the value of unconfined com pressive stress obtained based on load-deflection in the UCS test seems to be increasing from 3 to 6% of PA-12 replacing the problematic soil. However, the value seems to after addition of 7% and 8% PA-12. Based on the results shown in the graph, the optimum percentage of PA-12 in the problematic soil was found to be 6%, Fig. 8. The relation between the unconfined compressive strengths with var ied percentages of PA-12 is given in Fig. 9. While comparing the percentage increase in shear strength of the soil with the replacement of PA -12, the maximum increase was ob served as 86.26 % of the optimum PA-12 percentage con tent when compared with the virgin soil, Fig. 9.

Source: the authors.

Fig. 8 STRESS-STRAIN GRAPH OF THE COMPOSITE SOIL WITH OPTIMUM PERCENTAGE OF PA-12

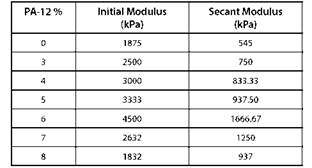

Initial Modulus is defined as the slope of the tangent to any point in an inelastic region. It is used to study the behavior and pattern of initial settlement, which is derived from UCS tests. A tangent is drawn from the origin to touch a point on the curve, and the slope of this tangent is called the tangential modulus of the soil. The resistance to settle ment is directly proportional to the tangential modulus of the soil, i.e. the steeper the tangent, the more stable that soil is. The results of the initial modulus of the soil for a var ied percentage of PA-12 is shown in Table III. From figure 10, the hardness of the material increases by 2.4 times the initial value. This clearly shows the better bond develop ment between the polymer and the soil particles. With the further replacement of PA-12 in the soil, the modulus value reduced and went beyond the initial value; making 8% of PA-12 a less suitable proportion.

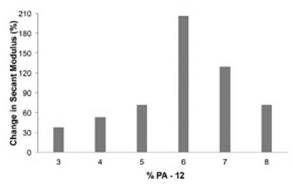

Secant Modulus is defined as the slope of the line join ing any point in the inelastic region to the origin. It is used to analyze the stability of the soil concerning resistance to its settlement, by drawing a secant from the origin of the graph to the peak point of the curve. The greater the slope of the secant, the more stable the soil is. The secant mod uli for various concentrations of PA-12 in the composite soil are listed in Table III. The secant modulus is generally represented as 0.7 - 0.8 times the initial tangent modulus. However, with the addition of polymer, it has reduced to 0.3 - 0.5 times the initial modulus of PA-12 added soil due to reduction in the inelastic region. It was also observed in Fig.11, that the reduction in the modulus after the peak val ue at 6% - 1666.67 kPa did not go beyond the initial value for the proportions considered in the tests.

4.3 Durability test results

Keeping the optimum polymer concentration as the 6% ideal percentage of PA-12 replacing the soil, a durability test was conducted to analyze the strength performance of the polymer-stabilized soil under the influence of mois ture conditions. The zeroth cycle (samples without wetting/ drying) were initially tested and found to have a higher value than the natural clay sample. Further, up to all the 3 cycles of wetting and drying, the UCS value progressively increased with each wet-dry cycle. By plotting the load-de flection coordinates for each of the samples in the respec tive percentages, we have positive trends in the strength and durability performance of the polymer-stabilized soil, as shown in Fig. 12. A considerably manifold increase in the strength can be observed after curing is done, indicating that PA-12 can be a potential stabilizer and can promise better results with curing.

From Figure 12, it can be observed that PA-12 has the capability of improving strength about 7 to 8 times the original cohesive strength of a problematic soil through physical stabilization. Even under the 3rd cycle, the strength shows a marginal declination compared to 2nd cycle, indi cating it is a viable stabilizer. Potentially, ground improve ment through physical stabilization highly dependent on the particulate interaction which binds the soil particles by occupying the voids or by increasing the frictional strength through physical activity. PA-12, as its fine powder that can occupy the interstitial pore spaces, can have the good bind ing capability and result in high unconfined compressive strength of the soil. A varying percentage of PA-12, UCS tests were carried out repeatedly and we found 6% as an ideal percentage to produce better strength results. Addi tionally, the durability tests conducted also indicated the potential benefit of PA-12 for field practice.

5. CONCLUSION

The behavior of the soil under varying percentage of PA-12 replacing the soil was laboratory-tested and stud ied. Different tests to derive its Atterberg limits, cohesive strength, initial and secant moduli and durability were conducted to arrive at an optimum percentage of PA-12 replacement in the soil and also understand the degree at which the stabilizing material is capable of modifying the problematic soil. The following conclusion were obtained:

The Plasticity Index (IP) decreased with an increment in the percentage of PA-12 leading to an increase the workability of the soil.

Wiith the addition of concentration of PA-12 in the proble matic soil, there is a steady increase in cohesion.

The shear strength of the virgin soil is 20.11 kPa; with an increase of polyamide to 6%, the shear strength in creases to 86.28 kPa. The optimum percentage of PA-12 is thus found to be 6%.

To understand the influence of durability of this composi te soil, tests were conducted with a chosen curing period of 14 days. The samples were able to withstand 2 cycles of wetting and drying after the curing period. The durability of the sample showed a significant increase in shear stren gth after 2 cycles by showcasing an increase by 7 times when compared to 0 cycles for the optimum percentage of PA-12.